Modified stoves to improve household energy efficiency and reduce impact on forests [Tajikistan]

- Creation:

- Update:

- Compiler: Daler Domullodzhanov

- Editor: –

- Reviewers: William Critchley, Rima Mekdaschi Studer

Печҳои таҷдидшуда баҳри самаранокии неруи хоҷагиҳо ва кам намудани буридашавии ҷангалҳо

technologies_6163 - Tajikistan

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

CARITAS (Switzerland) - Switzerland1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

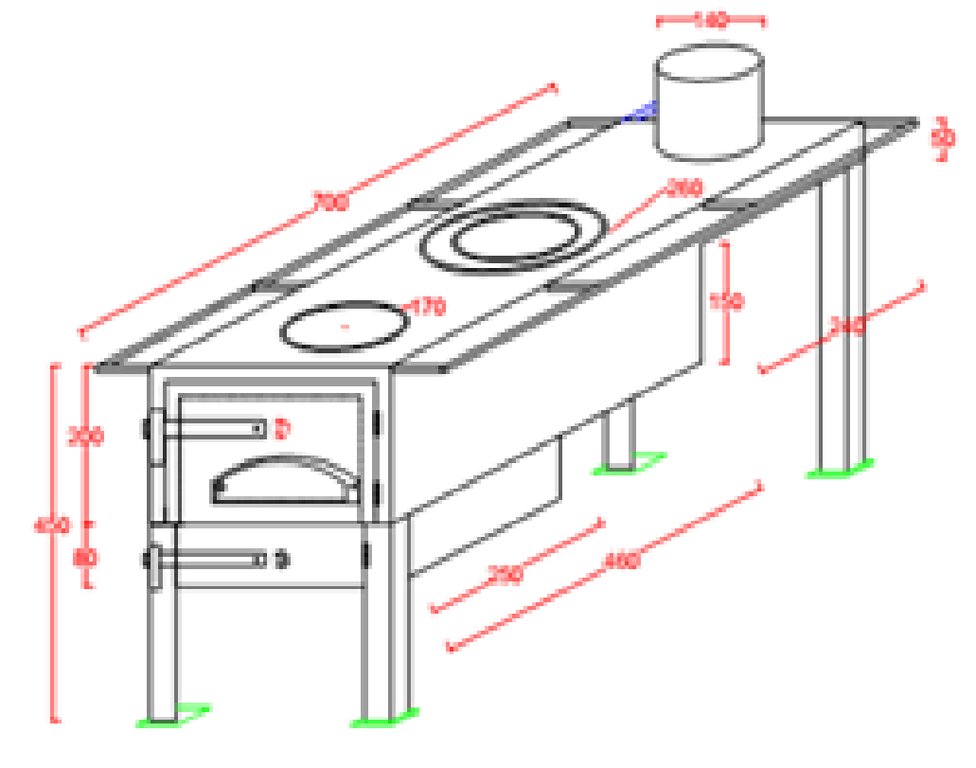

This energy-efficient stove was developed in close cooperation with the local blacksmith and pilot households. Its major features are a shorter burning chamber, lower height, air draft controller, enlarged burners and double circled pipes for heating water. The modified stove consumes much less firewood. It is possible to add heat exchangers and water boiling tank/water radiators which will further increase efficiency.

2.2 Detailed description of the Technology

Description:

In Tajikistan, forest cover has been reduced to 3% of the land area: it must not be allowed to decrease further. Forest destruction contributes to natural disasters that affect the environment and agricultural land, as well as damage houses and endanger lives. Examples are:

- floods: such as in 2012 that caused huge losses for rural households and infrastructure;

- landslides caused by soil erosion;

- fertile soil washed away, and water infiltration and holding capacity of the soil reduced;

- fewer reliable water sources and reduced flows with poorer quality;

- microclimatic changes and reduced rainfall becomes less.

To reduce pressure on the existing forest area of the Muminobod district and also to decrease the use of dried cow dung cakes for fuel that are better used as fertilizer, in the framework of the energy efficiency project of Caritas Switzerland a modified metallic stove has been developed that uses much less firewood than the stoves currently in use. This energy-efficient stove was developed in close cooperation with local blacksmiths and active women field promoters in pilot houses. There are multiple advantages including a 30% saving of energy for cooking, simultaneous heating of water and warming the living space. Furthermore, the stoves are cheaper, the work of women is reduced and there is no smoke inside the room. Further advantages can be obtained by using accessories such as a heat exchanger, and a water boiler/water radiator to make the stove multi-functional.

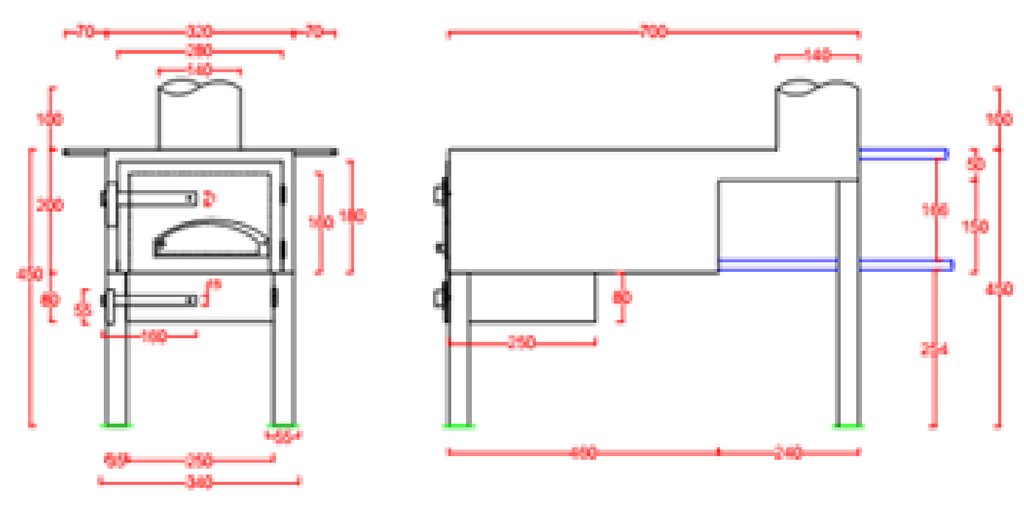

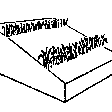

The stoves are 70 cm in length, 32 cm wide, and 20 cm in height with 2 burners of different diameters.

Advice on installation and best use of stoves and accessories include removing ash before lighting; cleaning the chimney; regulating the flame by use of the inlet draft controller; ensuring regular air exchange in the room; installing the heat exchanger at a minimum 40 cm height from the stove and cleaning regularly. To ensure proper circulation of the water in the system water tank should be lifted 15—20 cm from the ground level.

Moreover, other international organisations have provided technical and financial support to farmers to establish agroforestry plots and orchards, to rehabilitate degraded forest areas, and to set up nurseries to produce planting materials to sustain the afforestation process. The fruit orchards have multiple benefits: they yield fruits, produce firewood, anchor topsoils, prevent soil erosion, maintain water balance, protect the environment and absorb greenhouse gasses.

2.3 Photos of the Technology

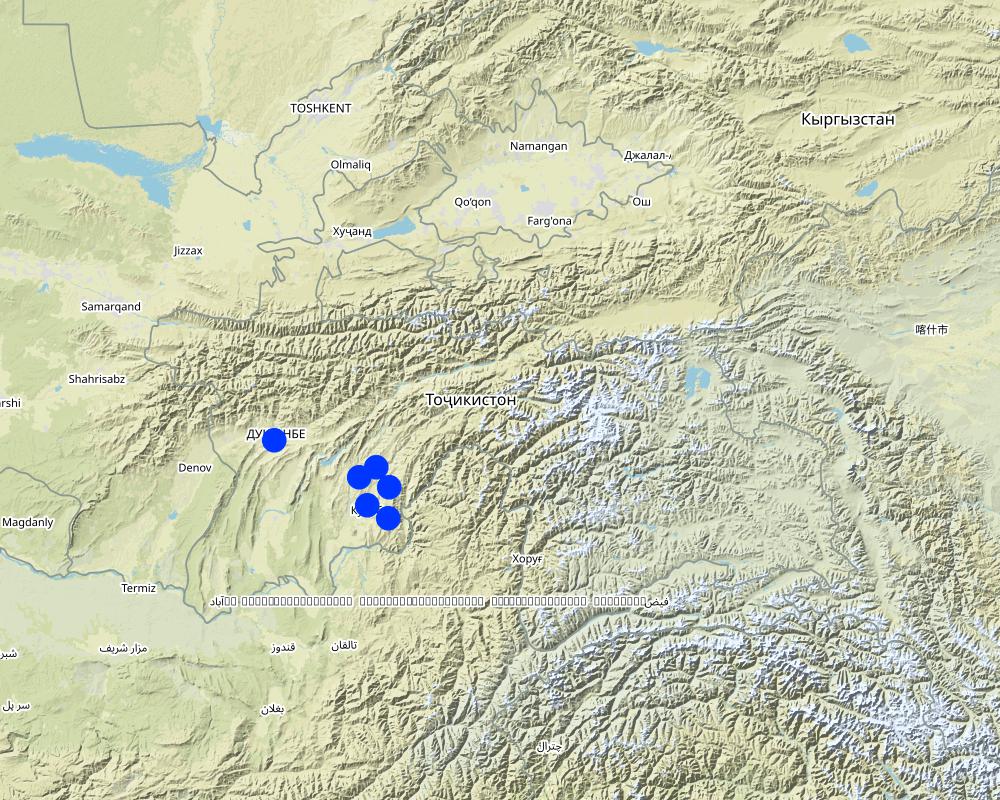

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Tajikistan

Region/ State/ Province:

Muminobod, Shurobod, Khovaling, Kulob districts of Khatlon region

Comments:

More than 2,000 modified stoves with different accessories were produced and disseminated among the rural inhabitants.

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through land users' innovation

- during experiments/ research

- through projects/ external interventions

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- reduce, prevent, restore land degradation

- conserve ecosystem

- reduce risk of disasters

- mitigate climate change and its impacts

3.2 Current land use type(s) where the Technology is applied

Land use mixed within the same land unit:

Yes

Specify mixed land use (crops/ grazing/ trees):

- Agro-pastoralism (incl. integrated crop-livestock)

Forest/ woodlands

- (Semi-)natural forests/ woodlands

- Tree plantation, afforestation

Tree plantation, afforestation: Specify origin and composition of species:

- Monoculture local variety

Are the trees specified above deciduous or evergreen?

- deciduous

Products and services:

- Grazing/ browsing

3.3 Has land use changed due to the implementation of the Technology?

Forest/ woodlands

- (Semi-)natural forests/ woodlands

Type of (semi-)natural forest:

- boreal mountain systems natural vegetation

3.4 Water supply

Water supply for the land on which the Technology is applied:

- mixed rainfed-irrigated

3.5 SLM group to which the Technology belongs

- natural and semi-natural forest management

- forest plantation management

- ecosystem-based disaster risk reduction

3.6 SLM measures comprising the Technology

vegetative measures

- V1: Tree and shrub cover

other measures

Specify:

House energy efficiency structure.

3.7 Main types of land degradation addressed by the Technology

soil erosion by water

- Wt: loss of topsoil/ surface erosion

- Wg: gully erosion/ gullying

- Wm: mass movements/ landslides

- Wr: riverbank erosion

soil erosion by wind

- Et: loss of topsoil

biological degradation

- Bc: reduction of vegetation cover

- Bh: loss of habitats

- Bq: quantity/ biomass decline

- Bs: quality and species composition/ diversity decline

water degradation

- Hg: change in groundwater/aquifer level

- Hp: decline of surface water quality

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

- reduce land degradation

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

Dimensions of the modified stove

Author:

Daler Domullodzhanov

Date:

16/02/2015

4.2 General information regarding the calculation of inputs and costs

Specify currency used for cost calculations:

- USD

If relevant, indicate exchange rate from USD to local currency (e.g. 1 USD = 79.9 Brazilian Real): 1 USD =:

5.62

Indicate average wage cost of hired labour per day:

100 TJS

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Producing of a sets of modified stove, heat-exchange and water tank | per 1/5 working day |

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Production cost of modified stove | set | 1.0 | 18.2 | 18.2 | 100.0 |

| Labour | Production cost of heat exchanger | set | 1.0 | 9.1 | 9.1 | 100.0 |

| Labour | Production cost of water tank | set | 1.0 | 9.1 | 9.1 | 100.0 |

| Construction material | Construction materials for production of stove | set | 1.0 | 221.16 | 221.16 | 100.0 |

| Construction material | Construction materials for production of heat-exchanger | set | 85.23 | 100.0 | ||

| Construction material | Construction materials for production of water tank | set | 1.0 | 40.24 | 40.24 | 100.0 |

| Other | Social tax | lumpsum | 0.2 | 3.2 | 0.64 | 100.0 |

| Other | Income simplified tax 6% | lumpsum | 0.2 | 112.41 | 22.48 | 100.0 |

| Other | Operation and maintenance | lumpsum | 0.5 | 14.0 | 7.0 | 100.0 |

| Total costs for establishment of the Technology | 327.92 | |||||

| Total costs for establishment of the Technology in USD | 58.35 | |||||

If land user bore less than 100% of costs, indicate who covered the remaining costs:

all cost bared by user

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Cleaning of the chimney | once per 2 months |

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Cleaning of the chimney | times | 4.0 | 1.0 | 4.0 | 100.0 |

| Construction material | Procurement of pipes | pcs | 2.0 | 3.0 | 6.0 | 100.0 |

| Total costs for maintenance of the Technology | 10.0 | |||||

| Total costs for maintenance of the Technology in USD | 1.78 | |||||

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

High inflation rate constantly increasing price for row materials.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Agro-climatic zone

- semi-arid

- arid

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- not relevant

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Soil texture (> 20 cm below surface):

- medium (loamy, silty)

Topsoil organic matter:

- low (<1%)

5.4 Water availability and quality

Ground water table:

5-50 m

Availability of surface water:

medium

Water quality (untreated):

good drinking water

Water quality refers to:

ground water

Is water salinity a problem?

No

Is flooding of the area occurring?

No

5.5 Biodiversity

Species diversity:

- medium

Habitat diversity:

- medium

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- subsistence (self-supply)

Off-farm income:

- less than 10% of all income

Relative level of wealth:

- average

Individuals or groups:

- groups/ community

Level of mechanization:

- manual work

Gender:

- women

Age of land users:

- middle-aged

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- state

- communal/ village

Land use rights:

- open access (unorganized)

- leased

Water use rights:

- open access (unorganized)

- communal (organized)

Are land use rights based on a traditional legal system?

Yes

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Income and costs

farm income

Quantity before SLM:

3000

Quantity after SLM:

4500

Ecological impacts

Soil

soil moisture

Comments/ specify:

The forest increases infiltration rate and soil moisture

6.2 Off-site impacts the Technology has shown

impact of greenhouse gases

Comments/ specify:

Protected forests significantly sequestrate GHG.

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

slightly positive

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

very positive

Long-term returns:

very positive

6.5 Adoption of the Technology

If available, quantify (no. of households and/ or area covered):

more than 2,000

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 51-90%

Comments:

After the promotion of modified stoves by the project, the workshops and trained blacksmith continued production and dissemination of modified stoves.

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

No

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| Cooking, boiling water and room heating can be done simultaneously |

| The modified stove is cheaper than the traditional stove |

| The saving of firewood in only 1 winter is enough to buy a modified stove. Stoves can be purchased in different qualities, for example with thicker iron for use of coal |

| Stove rings allow adjusting burner’s size to different pot sizes |

| No smoke inside of the room |

| Has operational stove tools like hook, trowel and hoe |

| The stove becomes more multi-functional. The heat exchanger allows baking, integrated water boiler provides hot water (approximately 35 L), and the possibility to install water radiators in several rooms for heating. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Saving 30% of energy for cooking only |

| The duration of cooking decreases by up to 15% |

| Reduces work of women |

| Reduces carbon dioxide emissions into the atmosphere |

| Draft control of inlet gives opportunity to regulate the flame, save fire material and the oven keeps more heat inside |

| Through the use of a heat exchanger an additional room can be heated to a comfortable temperature; |

| Possibility to install water radiators in several rooms |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| A shorter fire chamber increases the workload for cutting firewood to size | To automate the process of preparing firewood |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| Behaviour change takes time. | More awareness-raising campaigns need to be arranged. |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

Information was gathered during experiments with 13 different prototypes of the stoves and the promotion campaign of modified stoves among the local farmers.

When were the data compiled (in the field)?

06/10/2015

Comments:

The modified stove was patented. The Petty Patent #TJ 707 was obtained in 2015 by Daler Domullodzhanov.

7.2 References to available publications

Title, author, year, ISBN:

The manual on modified stove production for blacksmith, Daler Domullodzhanov, 2016, ISBN: 987-99975-895-0-7

7.3 Links to relevant online information

Title/ description:

Energy efficiency measures to increase the application of organic fertilizers

URL:

http://cdewocat.unibe.ch/wocatQT/qt_summary.php?lang=English&qt_id=354 http://cdewocat.unibe.ch/wocatQT/qt_summary.php?lang=Russian&qt_id=577

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules