Stall-Feeding of Dairy Cows [Bhutan]

- Creation:

- Update:

- Compiler: Karma Wangdi

- Editor: Tashi Wangdi

- Reviewers: William Critchley, Rima Mekdaschi Studer, Joana Eichenberger

Tsa Chhag Jin Tey Nor So Chong (རྩ་ཆག་བྱིན་སྟེ་ནོར་གསོ་སྐྱོང་།)

technologies_6869 - Bhutan

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

land user:

Chettri Hemlal

Arekha, Darla Gewog (Block), Chhukha Dzongkag (District)

Bhutan

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Strengthening national-level institutional and professional capacities of country Parties towards enhanced UNCCD monitoring and reporting – GEF 7 EA Umbrella II (GEF 7 UNCCD Enabling Activities_Umbrella II)1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

Comments:

This technology does not have any problem with regard to land degradation

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Stall-feeding is an improved cattle production system, which is increasingly being adopted with a growing population of high yielding exotic dairy breeds. Thus, most improved dairy cattle in Nepal are being reared under confinement with limited access to grazing, as it allows for easy and optimal supplementation of fodder.

2.2 Detailed description of the Technology

Description:

Stall-feeding, or “zero-grazing”, is a livestock management approach that confines animals within stalls or pens for feeding. It offers various advantages, such as improved waste management, precise nutrition control, and reduced risk of overgrazing. It allows farmers to carefully regulate their animals' diets to ensure they receive the necessary nutrition for optimal growth and productivity (Hadush, 2002). To effectively implement stall-feeding, several key components are required. Firstly, animals must be housed in separate stalls of appropriate size to facilitate cleaning and waste collection. Secondly, a well-planned feeding system is essential, which may involve the use of automatic feeding equipment, or alternatively manual distribution of hay, grains, and supplements tailored to each breed’s unique nutritional needs. Thirdly, a comprehensive waste management system is crucial to handle the manure produced by confined animals, which involves thorough stall cleaning and composting, transforming waste into organic fertilizer. Proper water supply and ventilation are also imperative for the animals' health and well-being. Adhering to these technical requirements (Garber, 2010) ensures optimal productivity and animal welfare in the stall-feeding system.

Stall-feeding is employed in various agricultural contexts worldwide, particularly where traditional open grazing is impractical or unsustainable. It is applied in areas with limited grazing land and high population density, such as urban and peri-urban settings. Moreover, it may be used in arid or semi-arid regions with scarce natural pastures, as well as during dry seasons when grazing resources are scarce. Smallholder farms and intensive livestock production systems aim to maximize output while optimizing resource usage, making stall feeding a prevalent practice. Dairy farming employs stall-feeding to boost milk production and enhance the quality of dairy products (Oosting et al., 2021).

According to Sahoo et al. (2015), the primary objective of stall-feeding is to provide controlled and ideal conditions for managing and feeding cattle. This approach ensures that animals are housed indoors according to their age, sex, breed, and weight, preventing them from grazing outdoors. To establish a well-functioning system, several crucial steps must be taken. First and foremost is the construction of individual stalls or pens, with careful consideration of size and design to accommodate different animals comfortably. The implementation of a reliable and well-planned feeding strategy is equally crucial. Adequate water supply and optimal ventilation within the stalls are also vital considerations (Van Eerdenburg & Ruud, 2021).

One of the primary advantages of stall feeding is its ability to provide animals with controlled and balanced nutrition, resulting in improved growth rates and higher-quality products like milk or meat. It also aids in disease prevention and mitigates the environmental impact of overgrazing. However, the main drawback lies in the additional effort and expense associated with feeding, cleaning, and waste management. Improperly managed confinement can limit animals' freedom of movement, potentially affecting their behavioral and psychological well-being. Proper ventilation and hygiene within the stalls are essential to address these concerns (Sahoo et al., 2015).

The type of fodder grown for dairy cattle primarily includes a variety of grasses and legumes suitable for the region's climate and terrain. Common fodder crops grown for dairy farming include Napier grass (Pennisetum purpureum), Rhodes grass (Chloris gayana), Alfalfa (Medicago sativa), Clover (Trifolium spp.), Ryegrass (Lolium spp.) sorghum (Sorghum bicolor). Additionally, Bhutan's traditional agroecological practices may also involve grazing on natural pastures and feeding on crop residues such as maize stalks and rice straw.

In Bhutan, traditional cattle breeds such as the Jersey, Brown Swiss, and local breeds are commonly raised for milk production. The milk yield per cow varies significantly based on factors such as breed genetics, nutrition, health, and management practices. On average, dairy cows in Bhutan may produce anywhere from 5 to 10 liters of milk per day, although some high-yielding breeds or well-managed farms may achieve higher yields. However, it's essential to note that these figures are approximate and can vary widely.

2.3 Photos of the Technology

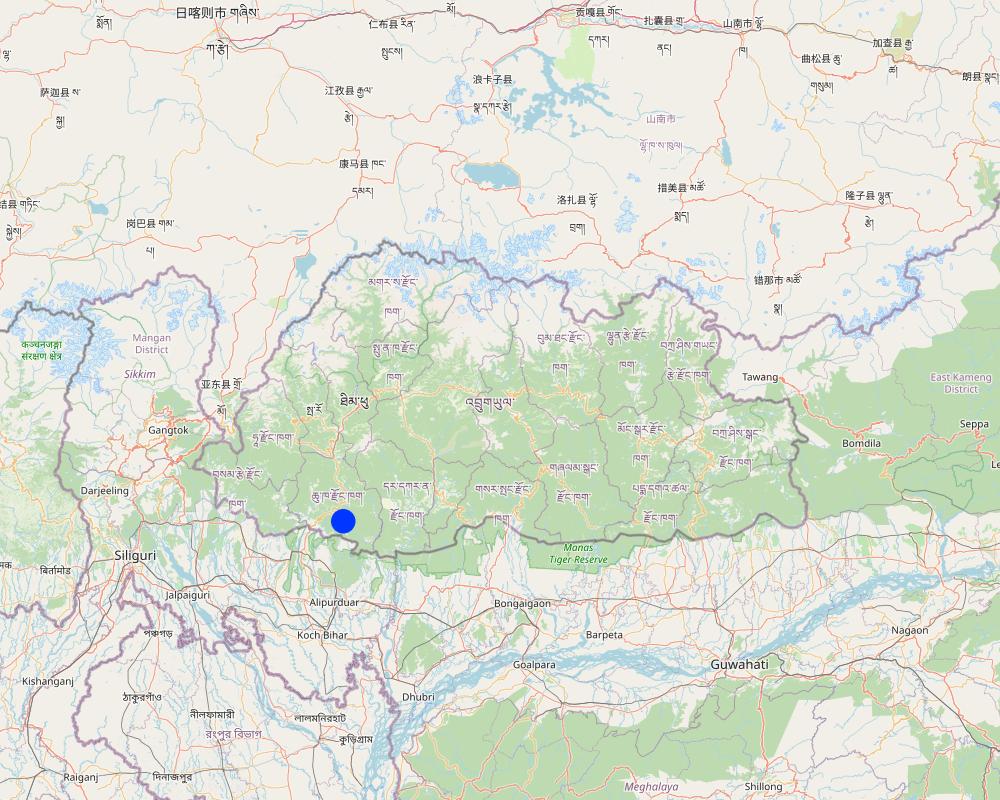

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Bhutan

Region/ State/ Province:

Chukha

Further specification of location:

Arekha, Darla,

Specify the spread of the Technology:

- applied at specific points/ concentrated on a small area

Is/are the technology site(s) located in a permanently protected area?

No

Comments:

n/a

Map

×2.6 Date of implementation

Indicate year of implementation:

2016

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through land users' innovation

- through projects/ external interventions

Comments (type of project, etc.):

Stall-feeding technology was adopted for rearing Holstein Fresian cattle, with fund (low interest loan) supports from Rural Enterprise Development Corporation Limited/Cottage and Small Industry

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- reduce, prevent, restore land degradation

- reduce risk of disasters

- create beneficial economic impact

3.2 Current land use type(s) where the Technology is applied

Grazing land

Intensive grazing/ fodder production:

- Cut-and-carry/ zero grazing

Animal type:

- cattle - dairy

Is integrated crop-livestock management practiced?

No

Products and services:

- manure as fertilizer/ energy production

Species:

cattle - dairy

Count:

18

3.3 Has land use changed due to the implementation of the Technology?

Has land use changed due to the implementation of the Technology?

- Yes (Please fill out the questions below with regard to the land use before implementation of the Technology)

Land use mixed within the same land unit:

No

Grazing land

Extensive grazing:

- Semi-nomadic pastoralism

- Ranching

Animal type:

- cattle - dairy

Is integrated crop-livestock management practiced?

Yes

If yes, specify:

Grows fodder

Products and services:

- manure as fertilizer/ energy production

Species:

cattle - dairy

Count:

18

Comments:

16 Holstein Friesian and 2 Jersey cattle

3.4 Water supply

Water supply for the land on which the Technology is applied:

- mixed rainfed-irrigated

Comments:

The farm has independent water source.

3.5 SLM group to which the Technology belongs

- integrated crop-livestock management

- improved plant varieties/ animal breeds

- energy efficiency technologies

3.6 SLM measures comprising the Technology

structural measures

- S9: Shelters for plants and animals

management measures

- M1: Change of land use type

- M2: Change of management/ intensity level

- M3: Layout according to natural and human environment

3.7 Main types of land degradation addressed by the Technology

soil erosion by water

- Wm: mass movements/ landslides

biological degradation

- Bc: reduction of vegetation cover

Comments:

He grows fodder nearby his dairy farm increasing the vegetation.

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

4. Technical specifications, implementation activities, inputs, and costs

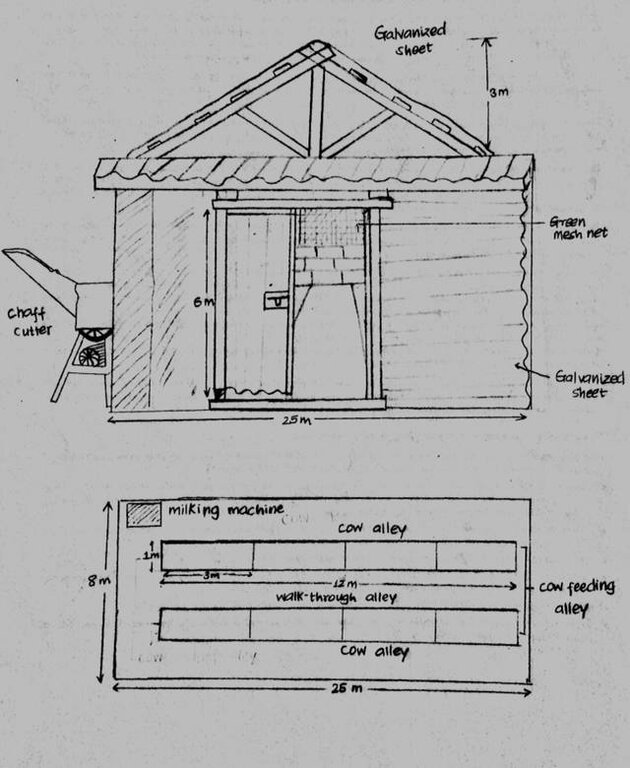

4.1 Technical drawing of the Technology

4.2 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology unit

Specify unit:

Stall-feed unit

Specify dimensions of unit (if relevant):

approx 3500 metres squared (Stall-Feeding unit)

other/ national currency (specify):

Ngultrum

If relevant, indicate exchange rate from USD to local currency (e.g. 1 USD = 79.9 Brazilian Real): 1 USD =:

80.0

Indicate average wage cost of hired labour per day:

500

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Site selection (Near the road) | Winter |

| 2. | Gathered raw materials | winter |

| 3. | Construction of shelter | winter |

| 4. | Construction of individual stalls with proper size and design to comfortably accommodate the cattles | winter |

| 5. | Set up a dependable and well thought feeding strategy | winter |

| 6. | Roofing of the stalls with CGI sheets | winter |

| 7. | Installation of proper ventilation for cattles | winter |

| 8. | Installing of water pumps to clean the areas | winter |

| 9. | Installing of miliking machine and chaff cutter | winter |

Comments:

The dairy shed was constructed in April, 2016

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | labor | per head | 150.0 | 500.0 | 75000.0 | 100.0 |

| Equipment | Spade | numbers | 10.0 | 300.0 | 3000.0 | |

| Equipment | Crowbar | numbers | 10.0 | 500.0 | 5000.0 | |

| Construction material | Cement | bags | 50.0 | 390.0 | 19500.0 | 100.0 |

| Construction material | CGI sheet | number | 117.0 | 750.0 | 87750.0 | 100.0 |

| Construction material | iron rod | piece | 14.0 | 600.0 | 8400.0 | 100.0 |

| Construction material | Bricks | piece | 1000.0 | 7.0 | 7000.0 | 100.0 |

| Construction material | Stones | trucks | 16.0 | 6700.0 | 107200.0 | 100.0 |

| Construction material | Wood | CFT | 250.0 | 450.0 | 112500.0 | 100.0 |

| Other | Cattle | numbers | 8.0 | 75000.0 | 600000.0 | 100.0 |

| Other | Chaff cutter | number | 1.0 | 50000.0 | 50000.0 | 100.0 |

| Other | milking machine | number | 1.0 | 35350.0 | 35350.0 | 100.0 |

| Other | water pump | number | 1.0 | 8000.0 | 8000.0 | 100.0 |

| Total costs for establishment of the Technology | 1118700.0 | |||||

| Total costs for establishment of the Technology in USD | 13983.75 | |||||

Comments:

The owner bore all the cost by himself except for the 2 Jersey and 3 Holstein Friesen which was supported by department of livestock, Ministry of Agriculture and LIvestock

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Floor cracking repair | December, 2020 |

Comments:

Maintenance cost was bored by the owner

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Helper | per head | 30.0 | 500.0 | 15000.0 | 100.0 |

| Construction material | cement | bags | 8.0 | 390.0 | 3120.0 | 100.0 |

| Total costs for maintenance of the Technology | 18120.0 | |||||

| Total costs for maintenance of the Technology in USD | 226.5 | |||||

Comments:

Maintenance cost was borne by the owner

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Lack of materials and procurement of materials is expensive

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specify average annual rainfall (if known), in mm:

1800.00

Specifications/ comments on rainfall:

rainy in monsoon season. (may- August)

Indicate the name of the reference meteorological station considered:

National center for hydrology and metrology

Agro-climatic zone

- humid

humid subtropical agro climatic zone.

Elevation range from 500 to 1000 m

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- not relevant

Comments and further specifications on topography:

ACZ- Humid subtropical zone

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Soil texture (> 20 cm below surface):

- medium (loamy, silty)

Topsoil organic matter:

- medium (1-3%)

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

Soil Type: Sandy loam

MC (%):4.83

OM (%): 9.22

OC (%):5.36

pH (H20): 6.51

EC (µs/cm): 235.03

N (%):0.27

P (ppm):0.82

K (mg/100ml:99.07

5.4 Water availability and quality

Availability of surface water:

good

Water quality (untreated):

good drinking water

Is water salinity a problem?

No

Is flooding of the area occurring?

No

5.5 Biodiversity

Species diversity:

- high

Habitat diversity:

- high

Comments and further specifications on biodiversity:

Thick vegetation with high diversity of plants and animals

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- mixed (subsistence/ commercial)

Off-farm income:

- less than 10% of all income

Relative level of wealth:

- rich

Individuals or groups:

- individual/ household

Level of mechanization:

- mechanized/ motorized

Gender:

- women

- men

Age of land users:

- children

- youth

- middle-aged

- elderly

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- medium-scale

5.8 Land ownership, land use rights, and water use rights

- Family

Land use rights:

- individual

Water use rights:

- individual

Are land use rights based on a traditional legal system?

Yes

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

fodder production

animal production

Socio-cultural impacts

food security/ self-sufficiency

Specify assessment of on-site impacts (measurements):

Growing of fodders protect soil degradation

6.2 Off-site impacts the Technology has shown

Specify assessment of off-site impacts (measurements):

na

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| seasonal temperature | wet/ rainy season | increase | moderately |

| seasonal rainfall | summer | decrease | moderately |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

positive

Long-term returns:

positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

positive

Long-term returns:

positive

Comments:

If he can expand the farm he seeslong term benefits to access to market

6.5 Adoption of the Technology

- 1-10%

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 0-10%

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

Yes

If yes, indicate to which changing conditions it was adapted:

- climatic change/ extremes

Specify adaptation of the Technology (design, material/ species, etc.):

Stalls designed: to ensure proper ventilation and drainage to maintain optimal living conditions for the animals. Cemented the flooring of the shed. Feed Management: The availability and affordability of feed ingredients in Bhutan which influence the composition of the diet provided to dairy cattle. Local feed resources such as grasses, legumes, crop residues, and agro-industrial by-products utilized efficiently.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| Employment opportunities (Farm attendant) |

| Income generation |

| Community service |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Ease management - ensures that the animals to be kept inside the shed or house as per their age, sex, weight and breed. |

| ensures to keep away the animals from grazing outside. |

| Proper care, appropriate feeds for better growth of the cattle and production |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| Diseases of animals | Proper management |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| High investment |

Land support from government and other projects Subsidy support |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

1

- interviews with land users

1

When were the data compiled (in the field)?

18/07/2023

7.2 References to available publications

Title, author, year, ISBN:

Does it pay to switch from free grazing to stall feeding,Hadush, M, 2021.

Available from where? Costs?

Website

Title, author, year, ISBN:

Farmed animal production in tropical circular food systems,Oosting, S., van der Lee, J., Verdegem, M., de Vries, M., Vernooij, A., Bonilla-Cedrez, C., & Kabir, K ,2021

Available from where? Costs?

website

Title, author, year, ISBN:

Stall Feeding in Small Ruminants,Sahoo, A., Bhatt, R. S., & Tripathi, M. K, 2015

Available from where? Costs?

website

Title, author, year, ISBN:

Design of Free Stalls for Dairy Herds,Van Eerdenburg, F. J. C. M., & Ruud, L. E., 2021

Available from where? Costs?

website

7.3 Links to relevant online information

Title/ description:

Guide for the Care and Use of Laboratory Animals,Garber Janet C, 2010

URL:

https://grants.nih.gov/grants/olaw/guide-for-the-care-and-use-of-laboratory-animals.pdf

7.4 General comments

na

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules