Multiple Use Water System ( Gravity-Fed ) [Nepal]

- Creation:

- Update:

- Compiler: Jhuna Kattel

- Editor: –

- Reviewer: Renate Fleiner

Saajh Pani Ghaito

technologies_5200 - Nepal

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

Water User:

B.K. Amrita

Nepal

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Prospects and challenges of water use systems as climate adaptive option for sustainable water management in Himalayan RegionName of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Kathmandu University (KU) - Nepal1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

Comments:

The technology used serves as a source of providing water for drinking and other multiple uses; such that it acts as a means to conserve and manage water resources rather than degrade them.

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

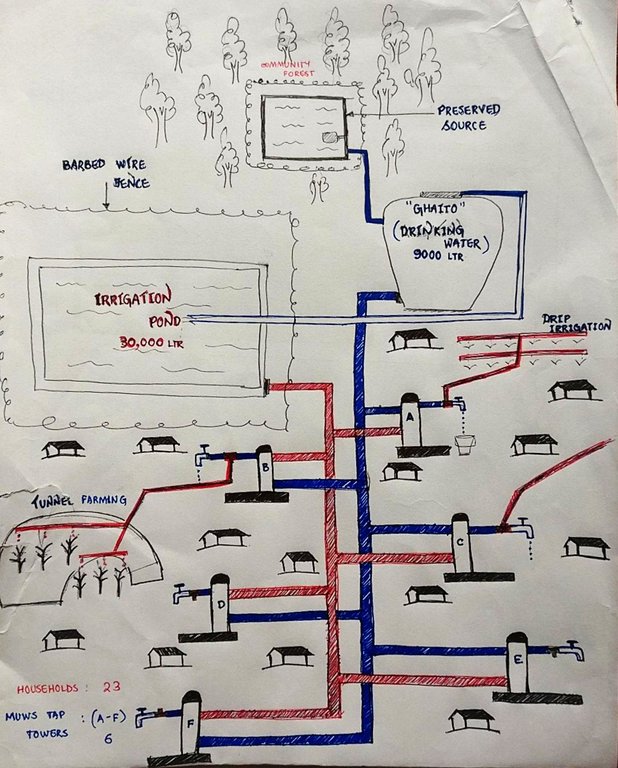

Natural water source in hill top is collected in a small reservoir-chamber ( to preserve natural source), then passes onto a Reservoir Tank (RVT) for drinking water (ferro-cement tank/ Ghaito) with a capacity of 9000L that falls within individual’s plot of land. When the ferro-cement tank gets filled, water overflows, is collected in another reservoir pond (30,000L) for irrigation and other multiple uses. From the Ghaito and reservoir pond, two pipelines are fed and water is supplied into individual Multiple Use Water System (MUWS) tap towers.

2.2 Detailed description of the Technology

Description:

The technology is applied in a natural environment. The place of study falls under the dry belt of Nepal, receiving less than average annual rainfall (in context of Nepal). The source of water is natural that is located within a community forest area (samudayik ban), which is owned by the government and consists of trees like Sal, Supari (areca nuts), etc. From there, water collects onto a Ghaito / ferro-cement tank, which falls on the land owned by Mr. Krishna Bahadur B.K., who voluntarily agreed to donate the land for its construction. The total area covered for the tank is 1 ropani (1 hectare = 19.65 ropanis). From the reservoir, water is collected in a ferrocement tank / Ghaito / Thulo tanki (for drinking water) and a reservoir pond (for irrigation). Poly Vinyl Chloride (PVC) pipes are fed onto the tanks to distribute the water for multiple purposes in 6 Multiple Use Water System (MUWS) tap-towers; which consist of two faucets each - one for drinking and the other for irrigation and other purposes.

The major purposes of this technology are to supply clean water for drinking and other purposes to the community that is comprised of 23 households, through a cheap, effective and simple system. For establishing the system, labour and construction materials were needed for building Ghaito and pipeline systems. For the maintenance, manual labour is necessary. The natural source of water is locally maintained. The quality of the water that is supplied to the 23 households is good and the quantity seems sufficient for the number of households. Operation and maintenance works are done by the locals who collect NPR. 50 from each household. The system is guarded by a watchman (Chaukidar) who is given a monthly stipend of NPR. 800 from the committee. The system was financed through a public-private-partnership (PPP) program; out of which some amount was funded by a Non-Governmental Organization (NGO) - Sundar Nepal, primary survey of the natural source of water was done by another NGO- Anukulan Project with the help from UK-AID (NPR. 1,46,000) , and the remaining funds were contributed by the locals’ group (NPR. 1,39,183), by collecting NPR. 3000 initially then NPR. 1200 from each household. The then Village Development Committee (VDC) donated NPR. 1,00,000 and labour costs borne by the locals amounted to NPR. 85,600. Total amount invested for the project amounted to NPR. 4,70,783. Benefits of the technology are the sustainable use of water resources through a MUWS system, cheap and effective way to conserve water resources and the ensured availability of clean water even through dry seasons. The villagers like the facts that the water is clean, more water is available for irrigation for vegetable farming, and that their day-to-day life is simplified. They dislike the limited availability of water during dry season and that out of 6 systems only 3 are in operation and the other ones are in a non-working condition.

A separate committee is set up for the smooth operation of the system, which consists of 20 members- 10 males and 10 females. The head of the committee is Mrs. Amrita B.K.. The committee conducts a monthly meeting on 10th of each Nepalese month to discuss the problems and need of maintenance. During the initial setup, the connection of pipelines from the tap systems to the reservoir tanks was, however, done with the contribution of the locals. Every month, each family contributes NPR 50, which goes to a fund that is set up for the times of need. The labor contribution by the people of the VDC was dependent upon the number and availability of family members in the household. Similarly, the use of MUWS system and water from it is also dependent upon the availability of family members. Little to no maintenance was done to the system till now from 2073 B.S. ( 3 years) . Equal number of male and female members are in the committee dedicated to the MUWS system.

2.3 Photos of the Technology

General remarks regarding photos:

Ghaito/ Ferrocemetn tank for drinking water, Irrigation pond, the committee, MUWS tower and tunnels with drip irrigation are shown in the images

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Nepal

Region/ State/ Province:

Province-6, Mid-Western Development Region

Further specification of location:

Kunathari VDC-5, Saajh Pani, Barahataal, Badichaur

Specify the spread of the Technology:

- applied at specific points/ concentrated on a small area

Is/are the technology site(s) located in a permanently protected area?

No

Map

×2.6 Date of implementation

Indicate year of implementation:

2015

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

Comments (type of project, etc.):

Sundar Nepal- a non governmental organization helped initiate the project

UKAID ( Anukulan Project) - an inernational non governmental project ( INGO ) helped with the technical aspects of the project

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- reduce, prevent, restore land degradation

- adapt to climate change/ extremes and its impacts

- create beneficial economic impact

- improve water security and increase efficient use at a household level

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

- Perennial (non-woody) cropping

Annual cropping - Specify crops:

- cereals - barley

- cereals - maize

- cereals - rice (wetland)

- cereals - wheat (winter)

Perennial (non-woody) cropping - Specify crops:

- areca

- banana/plantain/abaca

- sugar cane

Number of growing seasons per year:

- 3

Specify:

The water used for irrigation is used in fields for 2-3 cycles of crop growing (annual) like rice, maize and barley and into kitchen-farming/tunnel farming (perennial) where vegetables grown are cucumber, tomatoes, chilli, bitterguard, peas, etc.

Is intercropping practiced?

No

Is crop rotation practiced?

Yes

If yes, specify:

Rice, Maize and Wheat are cycled according to the seasons.

Other

Specify:

Drinking Water

Remarks:

Drinking water used directly from the tap systems. Some boil it but most of them use it straight from the tap systems and consume without filtration.

Comments:

Irrigation and Multiple Uses: The locals use the technology in order to irrigate their cropland so that the plant productivity is increased. As well, the introduction of this technology has opened up doors to new possibilities like construction of tunnels ( green houses) so that the locals can grow seasonal and off-seasonal vegetables in their backyards. Animal husbandry has also been an increasing practice. Human uses like washing, cooking, cleaning, bathing, etc are amply sufficient due to adequacy of water from this technology.

3.3 Has land use changed due to the implementation of the Technology?

Has land use changed due to the implementation of the Technology?

- Yes (Please fill out the questions below with regard to the land use before implementation of the Technology)

Cropland

- Annual cropping

- Perennial (non-woody) cropping

Annual cropping - Specify crops:

- cereals - barley

- cereals - maize

- cereals - rice (wetland)

- cereals - wheat (winter)

Perennial (non-woody) cropping - Specify crops:

- banana/plantain/abaca

Is intercropping practiced?

No

Is crop rotation practiced?

No

Comments:

Before the introduction of the technology, the land productivity was minimal. Water for human uses like bathing, cleaning, washing, cooking, etc. were scarce; especially during the dry seasons. No green houses were constructed. They used to rear very few cattle.

After the technology, vegetables from green houses in their backyards are sold to markets, which has acted as an alternative source of earning perennially.

3.4 Water supply

other (e.g. post-flooding):

- Natural source (Mool) of water in foliage atop a hill that falls under Mr. Krishna Bdr. B.K.'s land

Comments:

The supply of water comes from a natural source ( 'mool' in local language) , where a small enclosure is constructed so that the source is preserved and water is amply supplied to the ferro-cement tank for drinking purposes ( 'Ghaito' in local language) and the reservoir pond for irrigation purposes.

3.5 SLM group to which the Technology belongs

- water harvesting

- irrigation management (incl. water supply, drainage)

- Gravity Fed Multiple Use Water System (MUWS) , New Scheme

3.6 SLM measures comprising the Technology

structural measures

- S5: Dams, pans, ponds

- S6: Walls, barriers, palisades, fences

- S7: Water harvesting/ supply/ irrigation equipment

- S11: Others

Comments:

The technology is comprised of structures like Tanks (ferro-cement), Ponds (Concrete), Pipes, etc which use a myriad of resources like cement, iron rods, PVC pipes, fences for enclosure, etc.

3.7 Main types of land degradation addressed by the Technology

water degradation

- Hs: change in quantity of surface water

- Hp: decline of surface water quality

Comments:

Before setting up the technology, much of the water during dry seasons would evaporate from the natural source ( mool) and there would be scarcity of water during dry seasons. This has been addressed by the technology, where securing the natural source of water prevented evaporation and storing water in enclosed tanks helped supply water during dry seasons.

Similarly, due to no preservation of the source and no storage tanks, the water would be soiled by sediments, wastes and insects' larvae. After setting technology up, the quality of water has vastly improved as well

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

Comments:

The technology prevents water source degradation, improves perennial water availability, reduces effects like drought, floods, etc. Thus, land degradation by means of lands turning barren, dry,etc is tackled by this technology.

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

Source: Natural (mool) atop a small hill, secured by wire fences and preserved with concrete and metal lid ( to prevent evaporation).

Water from source collected in Ferro-Cement Tank / Reservoir Tank (RVT) / "Ghaito" in local language, with capacity 9000Ltrs.

Water overflows from RVT into an Irrigation Pond (Open Top, Concrete) with capacity 30,000Ltrs.

PVC Pipes leave the RVT and Pond into 6 MUWS Tap Towers ("Thaado" in local language) to serve 23 households.

One faucet supplies drinking water from RVT and next faucet supplies water for irrigation and other multiple purposes (drip irrigation, tunnel farming, etc.).

Author:

Jhuna Kattel

Date:

26/05/2019

4.2 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology area

Indicate size and area unit:

5-6 dhurs

If using a local area unit, indicate conversion factor to one hectare (e.g. 1 ha = 2.47 acres): 1 ha =:

1 hectare = 590.70 dhurs

other/ national currency (specify):

NPR

If relevant, indicate exchange rate from USD to local currency (e.g. 1 USD = 79.9 Brazilian Real): 1 USD =:

110.0

Indicate average wage cost of hired labour per day:

N/A ( voluntary labour from each household)

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Enclosement for the groundwater source | Summer Season ( Before Rains) |

| 2. | Construction of Ferro-cement tank for Drinking Water | Summer Season ( Before Rains) |

| 3. | Construction of Concrete tank for Irrigation | Summer Season and During Rainy Season |

| 4. | Securing the perimeter for the tanks | Rainy Season |

| 5. | Laying down the PVC pipework | Rainy Season |

| 6. | Construction of 6 individual MUWS tap towers ( Thaado in Nepalese language) | After Rains |

| 7. | Final touch-ups, Setting up faucets, Preliminary checking | After Rains |

Comments:

A total of roughly 5 months (140 days ) was required for the construction of the technology to be completed.

Construction was initiated before the rains, and could only be completed after the rainy season.

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour Costs by Locals | N/A | 1.0 | 85600.0 | 85600.0 | 100.0 |

| Labour | Primary Survey and Securing of Source | 1 | 1.0 | 146000.0 | 146000.0 | |

| Equipment | Construction of Tank, Pond and MUWS Tap Towers | 1 | 1.0 | 100000.0 | 100000.0 | |

| Equipment | Laying down pipework, Other Construction | 1 | 1.0 | 139183.0 | 139183.0 | 100.0 |

| Total costs for establishment of the Technology | 470783.0 | |||||

| Total costs for establishment of the Technology in USD | 4279.85 | |||||

If you are unable to break down the costs in the table above, give an estimation of the total costs of establishing the Technology:

470783.0

If land user bore less than 100% of costs, indicate who covered the remaining costs:

Village Developmment Committee, Anukulan Project (under UK-AID) NGO, Sundar Nepal (NGO)

Comments:

1.Village Developmment Committee:NPR. 1,00,000

2.Anukulan Project (under UK-AID) NGO: ~ NPR. 1,46,000

3.Water – Users : NPR. 1,39,000 ( collected from households)

4. NPR. 85,600 ( labour costs contributed by the locals)

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Pipeline Maintenance Work | During Dry Seasons (Winter) annually |

Comments:

The maintenance works have been carried out on the pipework for 2-3 times during the winter seasons, wherein the PVC pipes had to be replaced due to the collection of lime inside.

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Voluntary Labour borne by the Locals | 1 | 1.0 | 100.0 | ||

| Equipment | PVC Pipes | 1 metres | 400.0 | 30.0 | 12000.0 | 100.0 |

| Total costs for maintenance of the Technology | 12000.0 | |||||

| Total costs for maintenance of the Technology in USD | 109.09 | |||||

Comments:

The maintenance works were borne by the locals through voluntary contribution, which couldn't be calculated to an exact number. However, estimating the costs of PVC pipes per meter and the number of times they were replaced, the total costs for maintenance came to around 109.09 USD (~ NPR 12,000).

The locals voluntarily agreed for labour required.

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

PVC Pipes costs.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specifications/ comments on rainfall:

Monsoon/ Rainy Season 2-3 months ( June-August)

Indicate the name of the reference meteorological station considered:

Meteorological Forecasting Division, Nepal ( www.mfd.gov.np)

Agro-climatic zone

- sub-humid

The annual total rainfall has been stated as 1609.0mm but, average annual rainfall of the study area couldn't be found in any literature

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

- fine/ heavy (clay)

Soil texture (> 20 cm below surface):

- medium (loamy, silty)

Topsoil organic matter:

- medium (1-3%)

5.4 Water availability and quality

Ground water table:

< 5 m

Availability of surface water:

good

Water quality (untreated):

good drinking water

Water quality refers to:

both ground and surface water

Is water salinity a problem?

No

Is flooding of the area occurring?

No

Comments and further specifications on water quality and quantity:

Before the introduction of MUWS technology, the water used to be a problem during the dry seasons. However, after the technology was applied, the natural ground water source is conserved, people have been monitoring the water levels cautiously and nowadays, the water sustains the locals during the dry seasons as well.

Salinity is not a problem, but the presence of lime in the water is a problem.

5.5 Biodiversity

Species diversity:

- medium

Habitat diversity:

- medium

Comments and further specifications on biodiversity:

Birds are abundant, new fowls are sighted regularly.Lampuchhre ( Long-tailed widowbird),Ravens,Hawks,Peacocks and peafowls,Peasants,Guinea fowls and other fowls; rarely seen before are common after setting up the technology.

Animal sighting is rare. Forests, although consisting of a few varieties of trees, like Saal ( shorea robusta), Sadhana ( Moringa) , Belauti ( Guava), Sallo ( pine tree), Aap ( Mango). very few species are abundant in a given stretch of land.

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Semi-nomadic

Market orientation of production system:

- mixed (subsistence/ commercial)

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- poor

Individuals or groups:

- individual/ household

Level of mechanization:

- manual work

Gender:

- women

- men

Age of land users:

- children

- youth

- middle-aged

- elderly

Indicate other relevant characteristics of the land users:

Members of the community: 1:1 ratio of males to females

Age : mostly middle-aged, a few children and few elderly

Caste/ Ethnicity: Thakuri, Dalit and Janajati

Literacy: few persons completed High – School level (+2), rest are literate ( Class 5)

Total Land Holding: 16 ropanis (1 Hectare = 19.65 ropanis) of land. Human Settlement since last 40+ years in search of better opportunities and access to better services of water, roads, etc.

Total households: 23

Jobs: Males : bread- earners, construction workers, labour, farming

Females: Housewives, Farming. Most of the males in the village have been to foreign country ( India specially) for manual labor and mostly females are present in the village.

Ethnicity: Few families are of Upper- Caste: Thakuris ( as per Nepalese traditions) and most are Dalits and Janajatis; who were considered lower caste previously. But, the caste system has already been abolished from Nepal.

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

Comments:

23 households spread over around 16 ropanis of land

1 hectare = > 19 ropanis

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, not titled

- The source, tanks fall under private land area- owned by the Mr. Krishna Bdr. B.K., who voluntarily donated the land

Land use rights:

- communal (organized)

Water use rights:

- communal (organized)

Are land use rights based on a traditional legal system?

No

Specify:

Previously, the society had a caste system in which the higher and lower caste discrimination was done and the water tainted by the lower caste ( Dalits, Janajatis) were deemed “unfit” by the upper caste ( Thakuris, Brahmins, Chhetris). However, after the abolishment of the caste system, everyone enjoys equal rights to the access to water.

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

Comments:

The access to health, education and markets along with other facilities is only accessible after a 15 minute journey to the ‘bazaar’ or market area from the village.

After implementation of the project, people are able to grow vegetables in green houses, annually, and that has added to their source of income.

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

crop quality

fodder production

fodder quality

animal production

wood production

forest/ woodland quality

non-wood forest production

risk of production failure

product diversity

production area

land management

energy generation

Water availability and quality

drinking water availability

drinking water quality

water availability for livestock

water quality for livestock

irrigation water availability

irrigation water quality

demand for irrigation water

Income and costs

expenses on agricultural inputs

farm income

diversity of income sources

economic disparities

workload

Socio-cultural impacts

food security/ self-sufficiency

health situation

land use/ water rights

cultural opportunities

recreational opportunities

community institutions

national institutions

SLM/ land degradation knowledge

conflict mitigation

situation of socially and economically disadvantaged groups

Ecological impacts

Water cycle/ runoff

water quantity

water quality

harvesting/ collection of water

surface runoff

evaporation

Comments/ specify:

evaporation of water decreased after the construction of enclosures / tanks.

Soil

soil moisture

soil cover

soil loss

soil accumulation

soil crusting/ sealing

soil compaction

nutrient cycling/ recharge

salinity

soil organic matter/ below ground C

acidity

Biodiversity: vegetation, animals

Vegetation cover

biomass/ above ground C

plant diversity

invasive alien species

animal diversity

beneficial species

habitat diversity

pest/ disease control

Climate and disaster risk reduction

flood impacts

landslides/ debris flows

drought impacts

6.2 Off-site impacts the Technology has shown

Specify assessment of off-site impacts (measurements):

Since this technology is adapted in a small area, without any significant construction, there is virtually no off-site impact.

However, this technology is bound to show some beneficial impacts (off-site) in the long run.

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | moderately | |

| seasonal temperature | summer | increase | moderately |

| annual rainfall | decrease | moderately | |

| seasonal rainfall | wet/ rainy season | decrease | moderately |

Climate-related extremes (disasters)

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

positive

Comments:

The system has been in operation since 3 years only. Thus, long term effects are yet to be visible.

The running and maintenance costs were an approximate calculation as per the local water users.

However, it is evident from the running and maintenance costs that the benefits outweigh the costs.

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

No

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| The system has been in operation since 3 years only. Thus, long term effects are yet to be visible |

| Availability of water even during the dry seasons. |

| Increase in the productivity of perennial vegetables in kitchen garden, construction of tunnels for farming vegetables possible. Hence, new source of income generated by selling vegetables annually. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Increase in the productivity of perennial vegetables in kitchen garden, construction of tunnels for farming vegetables possible |

| Need of alternative sources of water during dry seasons not present after construction of MUWS system |

| Overall productivity of land improved through effective irrigation of water |

| Self-sufficiency in the aspect of water and crops, as well as alternative sources of income increased, improving the quality of lives of the water users. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| Water levels not rising in few tap systems out of the six constructed | Technician could oversee the problem of elevation and give a viable solution so that 6 out of 6 tap systems could be functional again |

| Pipes breaking down due to lime, and their diameter and quality could be improved | If the government and/or NGO could add to the savings of the group, good quality of Galvanized Iron (GI) pipes could be installed instead of the PVC pipes used |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| The tank for irrigation is left open at the top, leading to evaporation of water, usually in dry seasons leading to less water in taps during dry seasons | Closing the top of the tank using a lid |

| The pipes used are not sustainable | The use of heavier PVC pipes and/or hybrid GI pipes could result in less chances of system failure due to lime in the water |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

>10

- interviews with land users

>1

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules