Contour trenches and contour strips [Uzbekistan]

- Creation:

- Update:

- Compiler: Joren Verbist

- Editor: Hayot Ibrakhimov

- Reviewers: William Critchley, Rima Mekdaschi Studer

technologies_7557 - Uzbekistan

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Senior Scientist Sustainable Land Management:

Akramkhanov Akmal

International Center of Agriculture Research in the Dry Areas (ICARDA)

Uzbekistan

Crop Specialist:

Fayzullayev Abdulla

International Center of Agriculture Research in the Dry Areas (ICARDA)

Uzbekistan

Water Harvesting Expert:

Muddaber Mohammad Ali

International Center of Agriculture Research in the Dry Areas (ICARDA)

Jordan

Water Harvesting Expert:

Jafar Alwidyan

International Center of Agriculture Research in the Dry Areas (ICARDA)

Jordan

Project Manager:

Nurbekov Aziz

Food and Agriculture Organization (FAO) of the United Nations

Uzbekistan

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

ICARDA Institutional Knowledge Management InitiativeName of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Food Systems, Land Use, and Restoration Impact Program in Uzbekistan (GCP/UZB/010/GFF) (FOLUR)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

International Center for Agricultural Research in the Dry Areas (ICARDA) - Lebanon1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Contour trenches for the cultivation of almond trees, and contour strips for cereals are types of rainwater harvesting structures. They are designed to capture runoff, reduce erosion, and enhance soil moisture—thereby improving land productivity and supporting climate-resilient agriculture in lowland dry areas.

2.2 Detailed description of the Technology

Description:

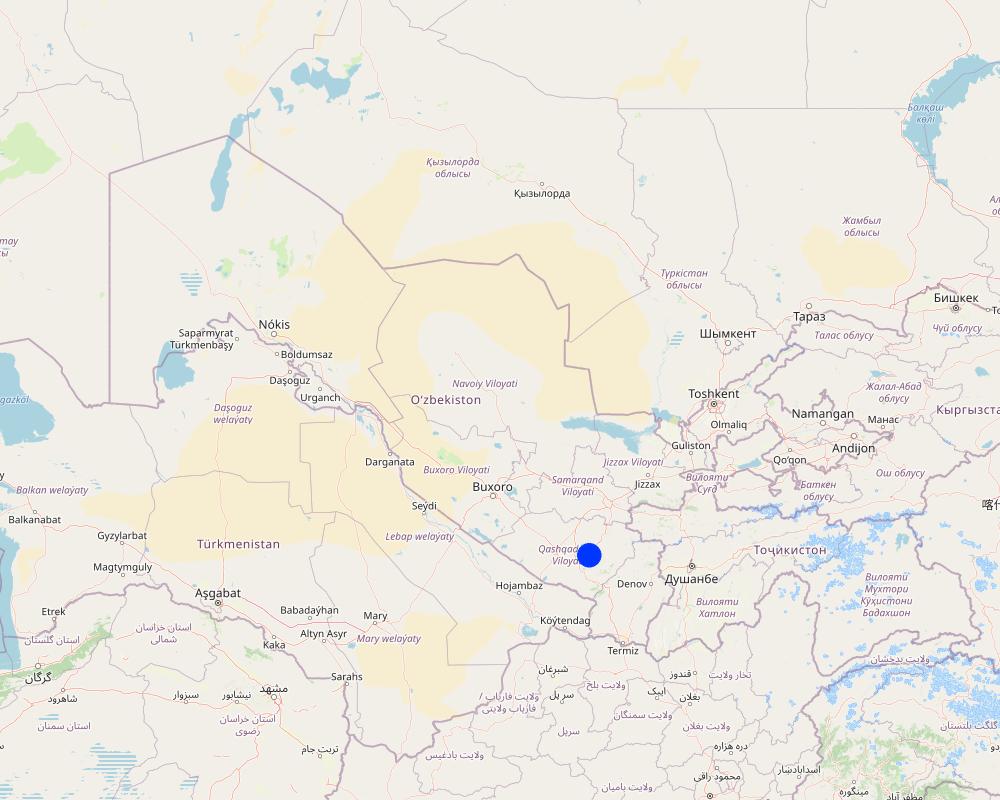

Qashqadaryo Province in southern Uzbekistan experiences a hot, dry summer and a mild winter. Combined with unsustainable land management practices, climatic stresses have exacerbated land degradation and made local livelihoods increasingly vulnerable.

As part of the Food Systems, Land Use and Restoration (FOLUR) project, the International Center for Agricultural Research in the Dry Areas (ICARDA) designed and tested rainwater harvesting (RWH) structures to combat land degradation and enhance rural livelihoods. These RWH structures support vegetation growth, reduce surface runoff, prevent erosion, and restore soil health—thereby reversing degradation and improving agricultural productivity.

Based on slope gradients and hydrological characteristics, two RWH techniques were selected: modified contour trenches for the slightly sloping upper areas, and modified contour strips for the flatter zones.

In the upper portion of the site, which spans 1.54 hectares, modified contour trenches were implemented for perennial tree crops. Design calculations suggested a spacing of 8 metres between trenches, and 7 metres between almond trees along each trench.

Implementation began with the marking of contour lines using a laser level: two labourers worked for two days. Then a tractor fitted with a three-mouldboard plough dug the trenches. While the tractor generally performed well, work had to be completed manually at sharp bends and gully crossings. Eight labourers then spent two days shaping and stabilizing the trenches. In total, approximately 1,300 metres of trench lines were created.

Costs were relatively modest. The tractor, hired from a farmer, cost $150 per day. Manual labour amounted to 24 person-days at $10 per day. 100 almond trees were planted, and 85 tamarix trees were added as a protective windbreak.

In the lower, flatter part of the site—about 1.68 hectares—standard contour strips were unsuitable due to the very low slope, which would not generate enough runoff. Instead, a modified version was implemented. Low ridges along contour at a vertical interval of 30 cm, allowed rainwater to pool and infiltrate. The same tractor was used with a single mouldboard plough to form nine contour ridges, shaped by two passes.

Afterwards, ten local women labourers finalized the ridges manually. The total length of the contour strips reached 500 metres, and the ratio of catchment to cultivated area varied from 5:1 in the upper sections to 1:1 in the lower zones, based on expected runoff.

The cost of this phase included one day of tractor use and 15 person-days of labour, totalling approximately $300. This site is intended for rainfed cultivation, and will follow a crop rotation system including barley, legumes and fallow periods. Over time, farmers are encouraged to adopt no-till practices to improve soil health.

Following implementation, light rainfall provided a test of the structures. Both the contour trenches and strips performed as intended, with no damage observed.

The interventions demonstrate how a tailored combination of RWH structures and cropping systems can rehabilitate degraded land. Local involvement helped to build community ownership. The result is a more productive and climate-resilient landscape that offers long-term benefits for soil conservation and rural livelihoods.

Acknowledgement: This SLM was introduced by ICARDA in the framework of Food Systems, Land Use and Restoration Impact Program (FOLUR) in Uzbekistan (GCP/UZB/010/GFF), implemented by FAO with funding from the Global Environment Facility (GEF)

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Uzbekistan

Region/ State/ Province:

Qashqadaryo Province in southern Uzbekistan

Further specification of location:

8°43'14.26"N, 66°41'51.87"E

Specify the spread of the Technology:

- evenly spread over an area

If precise area is not known, indicate approximate area covered:

- < 0.1 km2 (10 ha)

Is/are the technology site(s) located in a permanently protected area?

No

Map

×2.6 Date of implementation

Indicate year of implementation:

2024

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- reduce, prevent, restore land degradation

- adapt to climate change/ extremes and its impacts

- create beneficial economic impact

- create beneficial social impact

3.2 Current land use type(s) where the Technology is applied

Land use mixed within the same land unit:

No

Cropland

- Annual cropping

- Perennial (non-woody) cropping

Annual cropping - Specify crops:

- cereals - barley

- Nuts/ fruits including almonds

Number of growing seasons per year:

- 1

Is intercropping practiced?

No

Is crop rotation practiced?

Yes

If yes, specify:

Barley, legumes etc

Comments:

Note fruits/ nuts on one part of the land and cereals/ legumes/ fodder on another section (see 2.2)

3.3 Has land use changed due to the implementation of the Technology?

Has land use changed due to the implementation of the Technology?

- Yes (Please fill out the questions below with regard to the land use before implementation of the Technology)

Land use mixed within the same land unit:

No

Grazing land

Extensive grazing:

- Semi-nomadic pastoralism

- Mixed

3.4 Water supply

Water supply for the land on which the Technology is applied:

- rainfed

3.5 SLM group to which the Technology belongs

- improved ground/ vegetation cover

- cross-slope measure

- water harvesting

3.6 SLM measures comprising the Technology

agronomic measures

- A1: Vegetation/ soil cover

- A3: Soil surface treatment

- A4: Subsurface treatment

vegetative measures

- V1: Tree and shrub cover

structural measures

- S1: Terraces

- S2: Bunds, banks

- S3: Graded ditches, channels, waterways

- S7: Water harvesting/ supply/ irrigation equipment

management measures

- M1: Change of land use type

3.7 Main types of land degradation addressed by the Technology

soil erosion by water

- Wt: loss of topsoil/ surface erosion

- Wg: gully erosion/ gullying

- Wo: offsite degradation effects

soil erosion by wind

- Et: loss of topsoil

- Ed: deflation and deposition

- Eo: offsite degradation effects

physical soil deterioration

- Pc: compaction

- Pk: slaking and crusting

biological degradation

- Bc: reduction of vegetation cover

- Bq: quantity/ biomass decline

- Bl: loss of soil life

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- reduce land degradation

- restore/ rehabilitate severely degraded land

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

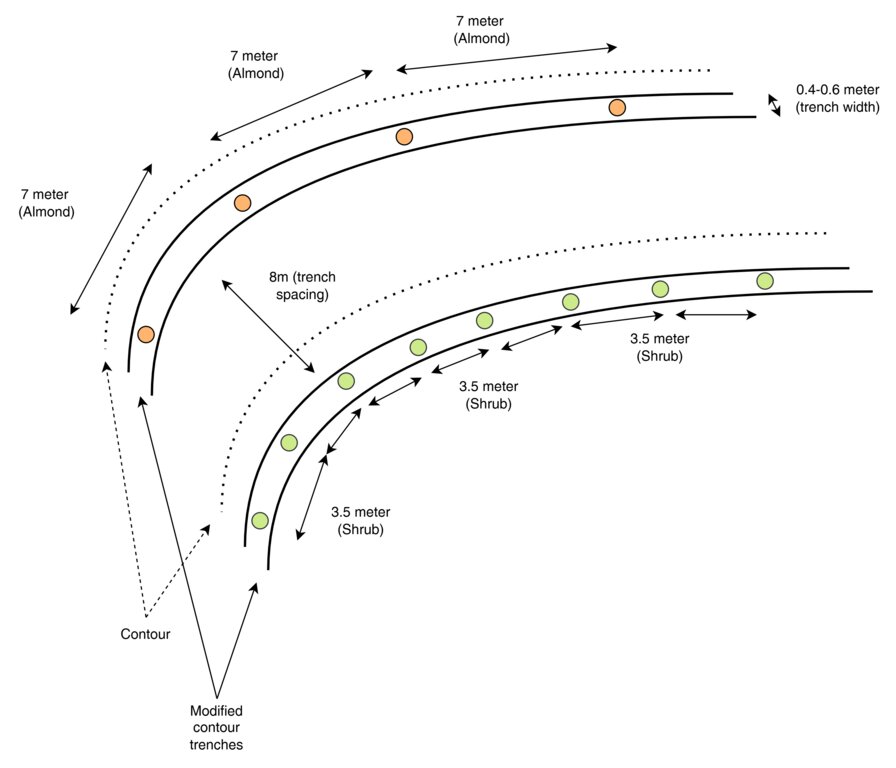

This top-view diagram shows the layout of modified contour trenches along contour lines, spaced 8 meters apart vertically. Each trench supports either:

Almond trees, spaced 7 meters apart, or

Shrubs, spaced 3.5 meters apart.

Each trench is aligned to follow the natural contour of the land to intercept runoff and enhance infiltration. Shrubs and trees are planted separately in designated trenches, not mixed.

Author:

ICARDA

Date:

2025

Technical specifications (related to technical drawing):

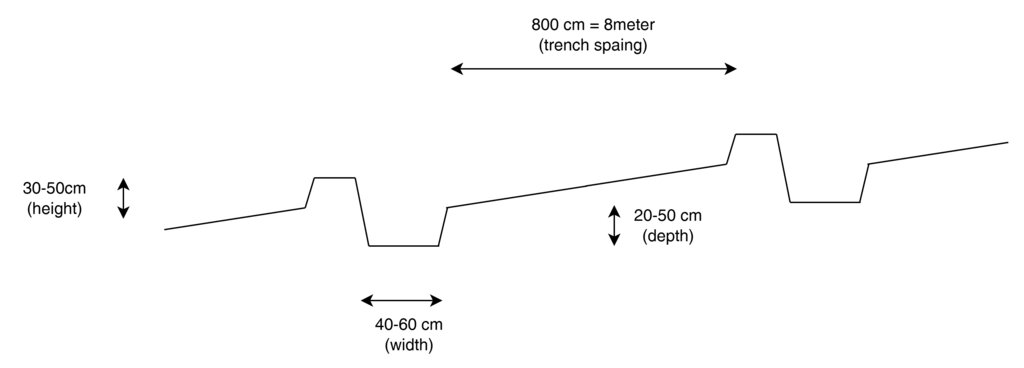

This cross-sectional profile illustrates the physical dimensions of a modified contour trench:

Width: 40–60 cm

Depth: 20–50 cm

Bund height (upslope side): 30–50 cm

Trench spacing: 8 meters

These dimensions are designed to retain and slow down surface runoff on slopes of 10–20%, enhancing water infiltration for tree or shrub growth.

Author:

ICARDA

Date:

2025

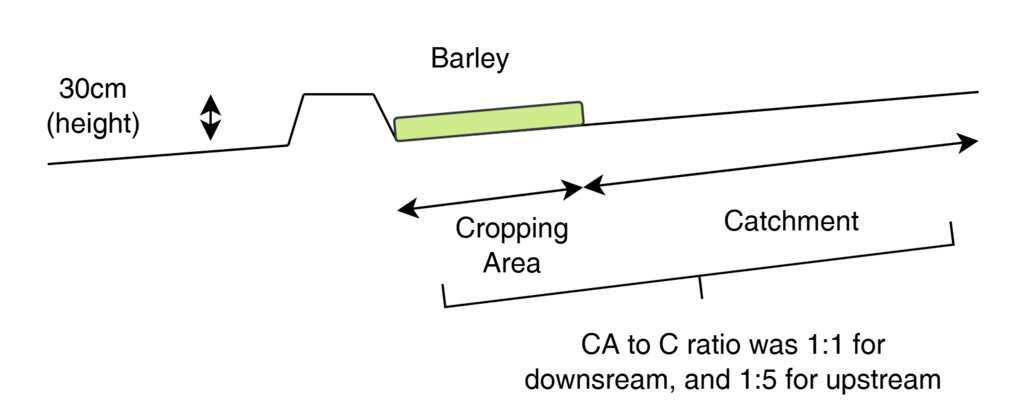

Technical specifications (related to technical drawing):

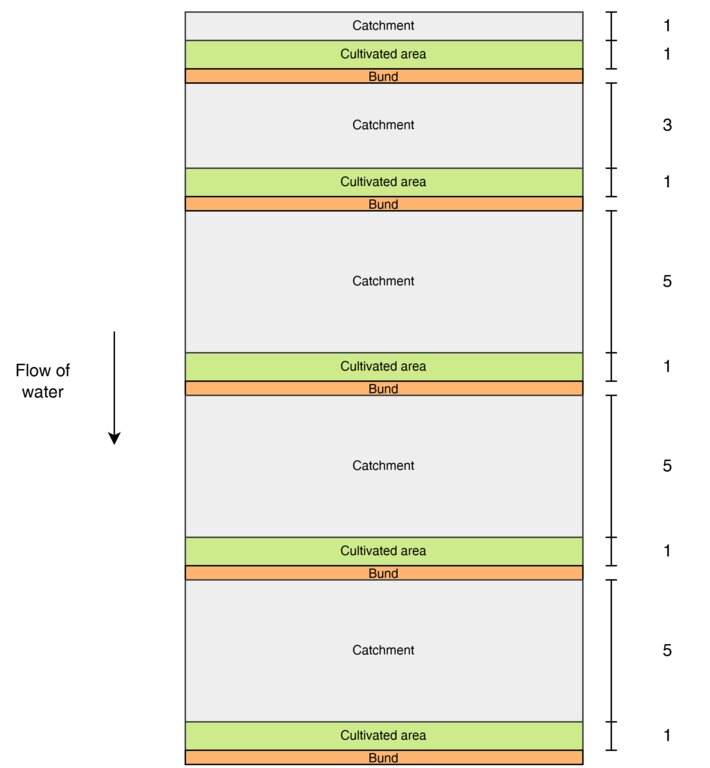

This diagram shows the layout of modified contour strips designed to enhance rainwater harvesting and crop productivity on sloped land. Each unit consists of a cultivated strip supported by a bund, located just downslope of a catchment area that concentrates surface runoff toward the crops.

Water flows downslope through the system.

The catchment-to-cultivated area ratio increases downslope to account for the growing volume and force of accumulated runoff, as well as differences in slope and infiltration capacity:

1:1 in the upper strips, where the steeper slope generates stronger runoff, and only limited water is desired to avoid erosion or damage.

3:1 in the middle strips, where moderate runoff accumulates.

5:1 in the lower strips, where the gentler slope allows more infiltration and where the lower kinetic energy of the runoff poses less risk to the structures.

Author:

ICARDA

Date:

2025

Technical specifications (related to technical drawing):

This cross-sectional view illustrates a modified contour strip:

A 30 cm high earth bund holds runoff upslope.

The cropping area (e.g., barley) is placed directly upstream (behind) the bund.

A catchment area lies upslope, sloped to direct water into the cultivated zone.

The catchment-to-cultivated ratio ranges from 5:1 (upper strips) to 1:1 (lower strips) depending on expected runoff volume, ensuring efficient water use and soil conservation.

Author:

ICARDA

Date:

2025

4.2 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology area

Indicate size and area unit:

3 ha (with half: half of each RWH technology)

Specify currency used for cost calculations:

- USD

Indicate average wage cost of hired labour per day:

10

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Contour marking | 22–23 September |

| 2. | Tractor ploughing | 24–25 September |

| 3. | Manual shaping/finishing | 25–26 September |

| 4. | Tree/shrub planting | 26–27 September |

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Contour trench construction | Person-days | 24.0 | |||

| Labour | Bunds for contour strips | Person-days | 15.0 | |||

| Labour | Marking contours | Person-days | 4.0 | |||

| Equipment | Ploughing (contour trenches) | Machine-days | 3.0 | |||

| Equipment | Ploughing (contour strips) | Machine-days | 2.0 | |||

| Plant material | Almond seedlings | 100.0 | ||||

| Plant material | Shrubs | 85.0 | ||||

| Fertilizers and biocides | Manure | kg | 600.0 | |||

| Other | Lumpsum contour strips | 1.0 | 1000.0 | 1000.0 | ||

| Other | Lumpsum contour trenches | 1.0 | 1000.0 | 1000.0 | ||

| Total costs for establishment of the Technology | 2000.0 | |||||

| Total costs for establishment of the Technology in USD | 2000.0 | |||||

If you are unable to break down the costs in the table above, give an estimation of the total costs of establishing the Technology:

2000.0

Comments:

Total implementation costs are around 2k USD. 50/50 between the two designs.

We have spent around 310 for tractor

300 for loader for levelling

270 labour for shaping the pits (after tractor)

400 for ploughing prior of planting the barley

340 for no till planter services for planting the barley

250 labour for applying fertilizer

100 for fertilizer (inc transport)

Estimation 20-50 for labour for plating the seedlings

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Inspection and incidental repairs | |

| 2. | Potentially sediment cleaning |

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

Comments:

No numbers have been recorded yet as the structures are new. An estimate of the maintenance costs would be 10-25% of the establishment costs.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specify average annual rainfall (if known), in mm:

325.00

Agro-climatic zone

- semi-arid

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- not relevant

Comments and further specifications on topography:

The strips are better suited for the flatter areas and the trenches on the higher sloping areas.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Soil texture (> 20 cm below surface):

- medium (loamy, silty)

Topsoil organic matter:

- medium (1-3%)

5.4 Water availability and quality

Ground water table:

5-50 m

Availability of surface water:

poor/ none

Water quality (untreated):

for agricultural use only (irrigation)

Water quality refers to:

both ground and surface water

Is water salinity a problem?

No

Is flooding of the area occurring?

Yes

Regularity:

episodically

5.5 Biodiversity

Species diversity:

- low

Habitat diversity:

- low

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- mixed (subsistence/ commercial)

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- very poor

- poor

Individuals or groups:

- individual/ household

- employee (company, government)

Level of mechanization:

- manual work

- mechanized/ motorized

Gender:

- men

Age of land users:

- children

- middle-aged

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- state

- individual, titled

Land use rights:

- individual

- Water not available

Are land use rights based on a traditional legal system?

Yes

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

Comments/ specify:

At first relatively unproductive land, with rwh techniques, production is increase is expected

risk of production failure

Comments/ specify:

More water is retained in the land and in the soil hence less drought vulnerable

product diversity

Comments/ specify:

Trees, shrubs, and crops

land management

Comments/ specify:

Structures require some maintenance

Income and costs

farm income

Comments/ specify:

Increase in more stable yield is positive for farm income

Socio-cultural impacts

food security/ self-sufficiency

Comments/ specify:

Less dependent on external food during dry periods

SLM/ land degradation knowledge

Comments/ specify:

Implementation was together with local land users, enhancing their knowledge in SLM

Ecological impacts

Water cycle/ runoff

harvesting/ collection of water

Comments/ specify:

Water is much better retained as consequence of the rwh structures.

surface runoff

Comments/ specify:

Run-off (damage) poses less because the ability to accumale is limited because water is now trapped by trenches and bunds

Soil

soil moisture

soil cover

soil loss

soil accumulation

Biodiversity: vegetation, animals

Vegetation cover

biomass/ above ground C

Specify assessment of on-site impacts (measurements):

Expert estimates

6.2 Off-site impacts the Technology has shown

downstream flooding

Comments/ specify:

More water is retained in the catchment, hence less flood risk downstream

downstream siltation

Comments/ specify:

The RWH structures can trap sediments

wind transported sediments

Comments/ specify:

Because of improved vegetation cover, soil is better held together, becoming less susceptible for being lifted up the wind

damage on neighbours' fields

damage on public/ private infrastructure

Specify assessment of off-site impacts (measurements):

Expert estimates

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| annual rainfall | decrease | moderately |

Climate-related extremes (disasters)

Hydrological disasters

| How does the Technology cope with it? | |

|---|---|

| flash flood | well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

slightly negative

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

positive

Long-term returns:

very positive

Comments:

Expectations

6.5 Adoption of the Technology

- single cases/ experimental

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 0-10%

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

No

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| Income diversification through forest nut and fodder production: Modified contour trenches enable the planting of both almond trees and fodder shrubs, supporting a mix of high-value cash crops and livestock-based livelihoods while restoring degraded sloped land. |

| Higher and more stable yields in flat rainfed systems: Modified contour strips improve water use efficiency and infiltration in cereal fields (e.g., barley), leading to better germination, stronger crop stands, and increased yields—especially valuable in low-rainfall zones where productivity is otherwise constrained. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Improved erosion control and landscape stability: Both techniques reduce surface runoff, limit gully formation, and prevent soil loss—thereby rehabilitating degraded land and protecting long-term soil productivity. |

| Enhanced soil moisture and drought resilience: By capturing and infiltrating rainwater along the contour, both methods improve water availability in the root zone, boosting the performance of crops and vegetation under arid and increasingly variable climate conditions. |

| Cost-effective and locally scalable: Constructed with accessible tools like mouldboard ploughs and finished by manual labour, both structures are affordable, require minimal inputs, and are suitable for community-based, participatory land restoration efforts. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| One challenge with modified contour trenches is that their effectiveness can be reduced over time due to sediment accumulation inside the trenches, which may reduce their water storage capacity and redirect runoff flow, especially during intense rainfall events. In addition, the bunds can weaken or collapse if the soil is loosely compacted or livestock walk over them. | Periodic maintenance is required every 4–5 years to remove sediment, re-shape trenches, and recompact or reinforce bunds, especially in sensitive segments. Involving local land users in routine inspection and light seasonal upkeep helps sustain long-term functionality. Introducing controlled grazing or fencing can prevent trampling by animals. |

| Modified contour strips are relatively low structures and therefore vulnerable to damage or overtopping if catchment-to-cultivated ratios are misjudged, or if bunds are not compacted well—especially during unexpected intense rainfall. Another limitation is that the strips rely on proper elevation spacing and contour accuracy, which requires some technical skill. | Ensuring accurate layout using a laser level and proper training of local staff during implementation is key. Adjusting catchment ratios downslope (e.g., from 5:1 to 1:1) helps avoid overloading. Annual visual checks and minor repairs after each rainy season are usually sufficient to maintain bund height and integrity. |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

- interviews with land users

- interviews with SLM specialists/ experts

- compilation from reports and other existing documentation

7.3 Links to relevant online information

Title/ description:

Oweis, T. and Haddad, M. 2023. Rainwater Harvesting Design Manual: Micro-catchment Systems for Drylands Agriculture. Lebanon, Beirut: International Center for Agricultural Research in the Dry Areas (ICARDA).

URL:

https://hdl.handle.net/10568/169777

Title/ description:

Mekdaschi Studer, R. & Liniger H. (2013). Water Harvesting: Guidelines to Good Practice. WOCAT, Bern, Switzerland

URL:

wocat.net/documents/85/WaterHarvesting_lowresolution.pdf

Title/ description:

Critchley, W. & Siegert, K., (1991). Water Harvesting: A Manual for the Design and Construction of Water Harvesting Schemes for Plant Production. Rome: Food and Agriculture Organisation, Rome

URL:

https://www.fao.org/3/U3160E/U3160E00.htm

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules