Subsoiling is carried out on arable land. Subsolier is pulled by a tractor and chisels (tines) break up a compacted layer below the surface. Subsoiling disturbs this dense layer and loosens the soil. This treatment improves air-water relations in the soil. The depth of subsoiling can be adjusted. On heavier soils, deeper subsoiling may be necessary. The farmer surveyed (who has a medium sized enterprise of about 400 ha) subsoils at a depth of 40-45 cm. Subsoiling is used especially for root crops such as sugar beet - and for other crops to a lesser extent, depending on the needs and condition of the soil. It is possible to adjust the spacing of the chisels (tines) and the power of the tractor. An average spacing between the chisels is 50 cm. A 200 horsepower tractor is able to pull a five-tine subsoiler. If time permits, the whole field should be subsoiled. Subsoiling takes quite a long time (about 10 ha per day). This technology is required every year when sugar beet is planted. In other fields, only machinery tracks and headlands (where the machine turns) should be subsoiled every year. Subsoiling is often used after harvest and before other field operations such as ploughing etc. On average, due to crop rotation, the whole field is only subsoiled once every four years. Subsoiling is a form of tillage which can be used instead of traditional ploughing to loosen soil without inverting it: thus it can form part of a reduced tillage system.

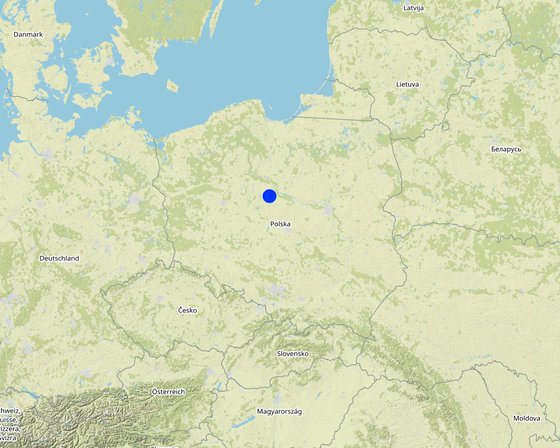

Lugar: Southern part of the region called Kujawy, Kuyavian-Pomeranian Voivodeship, Polonia

No. de sitios de Tecnología analizados: 2-10 sitios

Difusión de la Tecnología: distribuida parejamente sobre un área (approx. 1-10 km2)

¿En un área de protección permanente?: No

Fecha de la implementación: 10-50 años atrás

Tipo de introducción

| Especifique insumo | Unidad | Cantidad | Costos por unidad (n.d.) | Costos totales por insumo (n.d.) | % de los costos cubiertos por los usuarios de las tierras |

| Mano de obra | |||||

| - | |||||

| Equipo | |||||

| - | |||||

| Material para plantas | |||||

| - | |||||

| Fertilizantes y biocidas | |||||

| - | |||||

| Material de construcción | |||||

| - | |||||

| Otros | |||||

| - | |||||

| Especifique insumo | Unidad | Cantidad | Costos por unidad (n.d.) | Costos totales por insumo (n.d.) | % de los costos cubiertos por los usuarios de las tierras |

| Mano de obra | |||||

| skill labour | person-hour | 1,0 | 30,0 | 30,0 | 100,0 |

| Equipo | |||||

| tractor and subsoiler (depreciation) | machine-hour | 1,0 | 10,0 | 10,0 | 100,0 |

| chisels | machine-hour | 1,0 | 25,0 | 25,0 | 100,0 |

| tractor fuel | liter per hour | 20,0 | 7,0 | 140,0 | 100,0 |

| Indique los costos totales para mantenecer la Tecnología | 205.0 | ||||

| Costos totales para mantener la Tecnología en USD | 46.07 | ||||

The yield-forming effect of this treatment is visible throughout the entire crop rotation.

These notes especially concern sugar beet and root crops.

-

Relatively expensive measure.

Guarantee of high and stable crop yield (e.g. sugar beet).

-

-

Increased rate of infiltration.

Especially when subsoiling is performed instead of ploughing.

Increased soil water capacity and soil aeration.

-

The main purpose of the measure is to remove soil excessive compaction.

Subsoiling as a part of reduced tillage technology (as a tillage performed instead traditional ploughing) causes lower rate of organic matter decomposition comparing to the ploughing.

Subsoilng as a part of reduced tillage technology (as a tillage performed instead traditional ploughing) reduces CO2 emission from soil comparing to traditional ploughing.

Using subsoiling instead of conventional ploughing reduces emission of CO2 from soil.