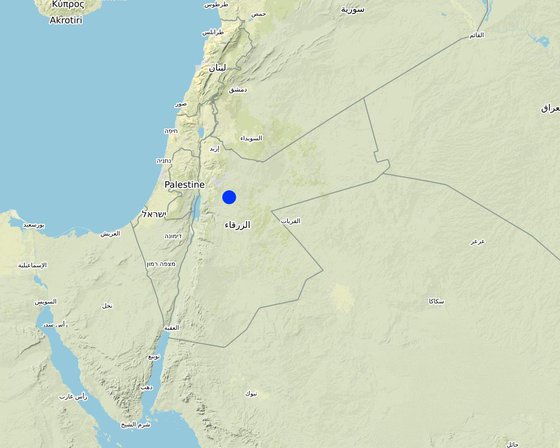

Arid drylands of Jordan receive less than 200mm average annual rainfall. The specific site is located close by Al Majeddyeh village, around 30km south-east of Amman. The average annual rainfall at the site is around 130mm. The average temperature is above 18 degrees Celsius. The human environment is characterized by agro-pastoralists. These are farmers that live in permanent houses but transport their livestock to graze. As consequence of the natural environment and mis-management (e.g. overgrazing) desertification has been an increasingly problem, not only from an environmental perspective (e.g. carbon stocking; lack of water), but also from an socio-economic perspective, because desertification leads to reduced productive lands, consequently resulting in less income for the rural population.

Therefore, the aim of the technology is to achieve high-yield agriculture through flood/macro-catchment water harvesting in arid environments commonly unsuitable for field crop agriculture, creating beneficial impact for local land users. The high yield barley is fed to the livestock (goats and sheeps) of the local agro-pastoralists. Applied in an integrated watershed approach, it meets agricultural demands and motivates sustainable dryland ecosystem management in the uplands. The Marab-technology has a buffering effect on extreme runoff through water retention, for further use in downstream areas, including the trapping of relative fertile sediments from upstream. As the Marab increases yields, it also improves the livelihood of the local population.

The Marab-technology is a macro-catchment water harvesting technology. The Marab is located in the natural depression of the watershed (10 square kilometres), therefore most of the water from the watershed is captured here, instead of being spilled away. Combining this natural depression with the construction of bunds and specific soil leveling, leads to decreased run-off, thus highly increased water infiltration and soil moisture. Thereby, the biomass-production increased as well.

The watershed is characterized by degraded lands upstream (720 ha), where low yield and subsidized barley cultivation is practiced, and by gullies. In a limited part (12 ha) of the upstream area, Vallerani micro-catchments are implemented as a pilot-plot. This might seem contradicting since upstream micro-catchment water harvesting decreases the water in the Marab downstream. However, the Vallerani micro-catchments also have beneficial impacts on the watershed and the Marab, such as flattening peak water flows, reducing erosion and providing fodder. The reduction in water run-off for the Marab as consequence of the Vallerani structures is not significant, due to the small size of the pilot area. But the relations between upstream and downstream should be taken into account.

Upstream watershed measures to buffer and/or avoid extreme runoff events (extreme downstream flooding) in the Marab such as micro-catchment water harvesting structures (Vallerani tractor plow system) and the out-planting of native shrub seedlings, as well as the stabilization of erosive gully systems through gully plugging and revegetation of side banks are advised to be taken before implementing the Marab technology downstream, as they safeguard and protect the Marab. But they are not further into account in this documentation.

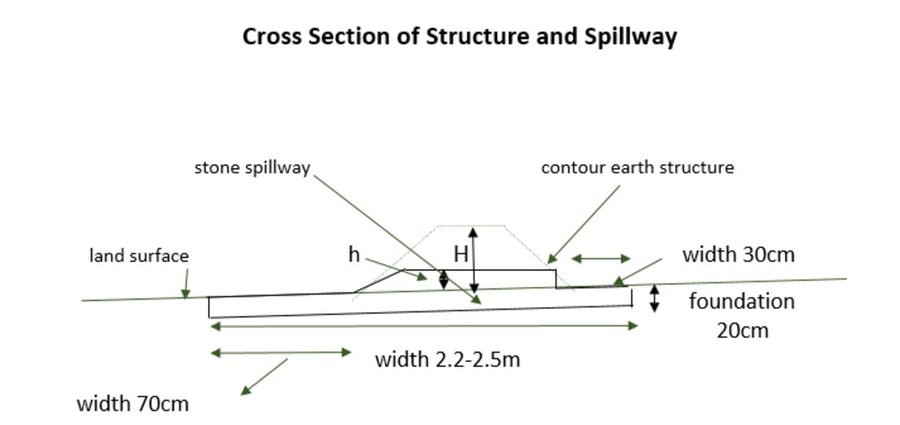

Establishment of the downstream Marab system includes:

•Local filling of downstream gull(system) with deep soil

•Leveling/grading of flood plains

•Construction of earth bunds

•Construction of the spillways (stone made)

• Seedbed preparation for planting annual crop such as barley

Marab agricultural production is high and stable. It can reach around 5-6 t ha-1 of barley, compared with the low and strongly varying yields of around 0.05-0.30 t ha-1 in traditionally, without macro water harvesting, cultivated barley. Marab barley produces grains (for fodder and reseeding purposes) and requires local inputs, such as fertilizer. The Marab mitigates downstream flooding and loss of sediments from the watershed. Local farmers applying the Marab technology are very satisfied, because of the extremely increased yield as consequence of the technology. However, as water is captured in the watershed, tensions may arise between the downstream (Marab) users and the upstream users.

Lieu: Al Majeddyeh Village, Al Jiza District, Jordanie

Nbr de sites de la Technologie analysés: site unique

Diffusion de la Technologie: appliquée en des points spécifiques ou concentrée sur une petite surface

Dans des zones protégées en permanence ?: Non

Date de mise en oeuvre: 2017

Type d'introduction

| Spécifiez les intrants | Unité | Quantité | Coûts par unité (dollars américains) | Coût total par intrant (dollars américains) | % des coût supporté par les exploitants des terres |

| Main d'œuvre | |||||

| Local Workers | person-days | 50,0 | 35,0 | 1750,0 | |

| Land Survey | person-days | 6,0 | 35,0 | 210,0 | |

| Engineer (+assistance) | person-days | 15,0 | 50,0 | 750,0 | |

| Drivers of heavy machinery | person-days | 12,0 | 35,0 | 420,0 | |

| Equipements | |||||

| Grader | machine-days | 3,0 | 250,0 | 750,0 | |

| Loader | machine-days | 10,0 | 250,0 | 2500,0 | |

| Deep Plow | machine-days | 3,0 | 200,0 | 600,0 | |

| Tractor (to pull the shallow and deep plow) | machine-days | 5,0 | 200,0 | 1000,0 | |

| Shallow Plow | machine-days | 2,0 | 200,0 | 400,0 | |

| Water Tank Truck | Tank | 1,0 | 50,0 | 50,0 | |

| Small Equipment (Shovel, pickaxe, buckets) | Equipment | 1,0 | 200,0 | 200,0 | |

| Matériaux de construction | |||||

| Stones | Kubic Metre | 200,0 | 10,0 | 2000,0 | |

| Autre | |||||

| Transportation of heavy machinery | 1,0 | 2000,0 | 2000,0 | ||

| Security | 1,0 | 300,0 | 300,0 | ||

| Coût total de mise en place de la Technologie | 12'930.0 | ||||

| Coût total de mise en place de la Technologie en dollars américains (USD) | 12'930.0 | ||||

| Spécifiez les intrants | Unité | Quantité | Coûts par unité (dollars américains) | Coût total par intrant (dollars américains) | % des coût supporté par les exploitants des terres |

| Main d'œuvre | |||||

| Engineer | person days per year | 2,0 | 50,0 | 100,0 | 100,0 |

| Worker | person days per year | 6,0 | 35,0 | 210,0 | 100,0 |

| Equipements | |||||

| Loader | machine days per year | 1,0 | 250,0 | 250,0 | 100,0 |

| Matériaux de construction | |||||

| Stones | Kubic Metre | 10,0 | 10,0 | 100,0 | 100,0 |

| Coût total d'entretien de la Technologie | 660.0 | ||||

| Coût total d'entretien de la Technologie en dollars américains (USD) | 660.0 | ||||

The crops produced are used as fodder

Quantité avant la GDT: 0.05ton/ha

Quantité après la GDT: 5ton/ha

The production of the fodder is increased as the barley yield is mostly used to feed animals and also the stubble is grazed.

The barley is fed to the livestock

Due to the bunds (but very limited and inevitable)

Expenses are slightly increased due to possible maintenance of the Marab. However, the increased yield justifies this.

Due to possible maintenance

During the construction, local community were hired as workers, this has significantly boosted their knowlegde about SLM.

Reduced downstream flooding is desired

Reduced downstream siltation is desired