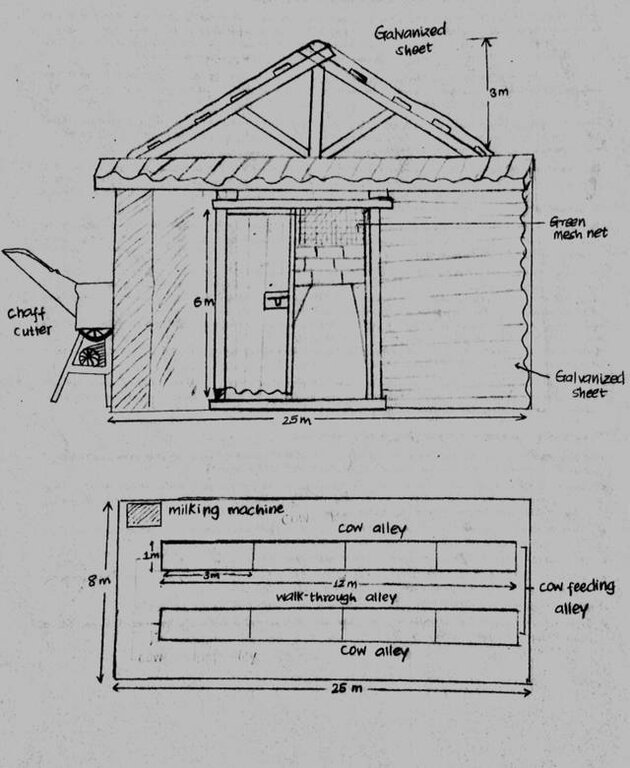

Stall-feeding, or “zero-grazing”, is a livestock management approach that confines animals within stalls or pens for feeding. It offers various advantages, such as improved waste management, precise nutrition control, and reduced risk of overgrazing. It allows farmers to carefully regulate their animals' diets to ensure they receive the necessary nutrition for optimal growth and productivity (Hadush, 2002). To effectively implement stall-feeding, several key components are required. Firstly, animals must be housed in separate stalls of appropriate size to facilitate cleaning and waste collection. Secondly, a well-planned feeding system is essential, which may involve the use of automatic feeding equipment, or alternatively manual distribution of hay, grains, and supplements tailored to each breed’s unique nutritional needs. Thirdly, a comprehensive waste management system is crucial to handle the manure produced by confined animals, which involves thorough stall cleaning and composting, transforming waste into organic fertilizer. Proper water supply and ventilation are also imperative for the animals' health and well-being. Adhering to these technical requirements (Garber, 2010) ensures optimal productivity and animal welfare in the stall-feeding system.

Stall-feeding is employed in various agricultural contexts worldwide, particularly where traditional open grazing is impractical or unsustainable. It is applied in areas with limited grazing land and high population density, such as urban and peri-urban settings. Moreover, it may be used in arid or semi-arid regions with scarce natural pastures, as well as during dry seasons when grazing resources are scarce. Smallholder farms and intensive livestock production systems aim to maximize output while optimizing resource usage, making stall feeding a prevalent practice. Dairy farming employs stall-feeding to boost milk production and enhance the quality of dairy products (Oosting et al., 2021).

According to Sahoo et al. (2015), the primary objective of stall-feeding is to provide controlled and ideal conditions for managing and feeding cattle. This approach ensures that animals are housed indoors according to their age, sex, breed, and weight, preventing them from grazing outdoors. To establish a well-functioning system, several crucial steps must be taken. First and foremost is the construction of individual stalls or pens, with careful consideration of size and design to accommodate different animals comfortably. The implementation of a reliable and well-planned feeding strategy is equally crucial. Adequate water supply and optimal ventilation within the stalls are also vital considerations (Van Eerdenburg & Ruud, 2021).

One of the primary advantages of stall feeding is its ability to provide animals with controlled and balanced nutrition, resulting in improved growth rates and higher-quality products like milk or meat. It also aids in disease prevention and mitigates the environmental impact of overgrazing. However, the main drawback lies in the additional effort and expense associated with feeding, cleaning, and waste management. Improperly managed confinement can limit animals' freedom of movement, potentially affecting their behavioral and psychological well-being. Proper ventilation and hygiene within the stalls are essential to address these concerns (Sahoo et al., 2015).

The type of fodder grown for dairy cattle primarily includes a variety of grasses and legumes suitable for the region's climate and terrain. Common fodder crops grown for dairy farming include Napier grass (Pennisetum purpureum), Rhodes grass (Chloris gayana), Alfalfa (Medicago sativa), Clover (Trifolium spp.), Ryegrass (Lolium spp.) sorghum (Sorghum bicolor). Additionally, Bhutan's traditional agroecological practices may also involve grazing on natural pastures and feeding on crop residues such as maize stalks and rice straw.

In Bhutan, traditional cattle breeds such as the Jersey, Brown Swiss, and local breeds are commonly raised for milk production. The milk yield per cow varies significantly based on factors such as breed genetics, nutrition, health, and management practices. On average, dairy cows in Bhutan may produce anywhere from 5 to 10 liters of milk per day, although some high-yielding breeds or well-managed farms may achieve higher yields. However, it's essential to note that these figures are approximate and can vary widely.

Lieu: Arekha, Darla,, Chukha, Bhoutan

Nbr de sites de la Technologie analysés: site unique

Diffusion de la Technologie: appliquée en des points spécifiques ou concentrée sur une petite surface

Dans des zones protégées en permanence ?: Non

Date de mise en oeuvre: 2016; il y a moins de 10 ans (récemment)

Type d'introduction

| Espèces | Nombre |

| bétail - laitier | 18 |

| Spécifiez les intrants | Unité | Quantité | Coûts par unité (Ngultrum) | Coût total par intrant (Ngultrum) | % des coût supporté par les exploitants des terres |

| Main d'œuvre | |||||

| labor | per head | 150,0 | 500,0 | 75000,0 | 100,0 |

| Equipements | |||||

| Spade | numbers | 10,0 | 300,0 | 3000,0 | |

| Crowbar | numbers | 10,0 | 500,0 | 5000,0 | |

| Matériaux de construction | |||||

| Cement | bags | 50,0 | 390,0 | 19500,0 | 100,0 |

| CGI sheet | number | 117,0 | 750,0 | 87750,0 | 100,0 |

| iron rod | piece | 14,0 | 600,0 | 8400,0 | 100,0 |

| Bricks | piece | 1000,0 | 7,0 | 7000,0 | 100,0 |

| Stones | trucks | 16,0 | 6700,0 | 107200,0 | 100,0 |

| Wood | CFT | 250,0 | 450,0 | 112500,0 | 100,0 |

| Autre | |||||

| Cattle | numbers | 8,0 | 75000,0 | 600000,0 | 100,0 |

| Chaff cutter | number | 1,0 | 50000,0 | 50000,0 | 100,0 |

| milking machine | number | 1,0 | 35350,0 | 35350,0 | 100,0 |

| water pump | number | 1,0 | 8000,0 | 8000,0 | 100,0 |

| Coût total de mise en place de la Technologie | 1'118'700.0 | ||||

| Coût total de mise en place de la Technologie en dollars américains (USD) | 13'983.75 | ||||

| Spécifiez les intrants | Unité | Quantité | Coûts par unité (Ngultrum) | Coût total par intrant (Ngultrum) | % des coût supporté par les exploitants des terres |

| Main d'œuvre | |||||

| Helper | per head | 30,0 | 500,0 | 15000,0 | 100,0 |

| Matériaux de construction | |||||

| cement | bags | 8,0 | 390,0 | 3120,0 | 100,0 |

| Coût total d'entretien de la Technologie | 18'120.0 | ||||

| Coût total d'entretien de la Technologie en dollars américains (USD) | 226.5 | ||||