Vermiculture [Nicaragua]

- Creation:

- Update:

- Compiler: Ramén Ernesto Caceres Ordonez

- Editor: –

- Reviewers: Deborah Niggli, Alexandra Gavilano

Lombricultura

technologies_1022 - Nicaragua

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

SLM specialist:

Gómez Martínez Julio César

De ENITEL

Nicaragua

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Book project: where the land is greener - Case Studies and Analysis of Soil and Water Conservation Initiatives Worldwide (where the land is greener)1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

1.5 Reference to Questionnaire(s) on SLM Approaches (documented using WOCAT)

Productive development and food security programme [Nicaragua]

An integrated programme-based approach promoting participatory testing and extension of various SWC technologies, as well as providing institutional support.

- Compiler: Philippe Zahner

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Continuous breeding of earthworms in boxes for production of high quality organic compost.

2.2 Detailed description of the Technology

Description:

Vermiculture is a simple and cheap way to produce a continuous supply of organic compost of high quality. Eisenia foetida, the Red Californian earthworm (also called ‘the red wiggler’) is ideal for vermiculture since it is adapted to a wide range of environmental conditions. Under culture, the worms are kept under shade, in long wooden boxes filled with earth, cattle manure and an absorbent material (eg straw). The box is covered by sheet metal (or wood, thick plastic sheeting, or banana leaves) to protect the worms against UV radiation and birds/chickens, and also to maintain a favourably humid microclimate. Fresh cattle manure is a perfect food for the worms, but rotten coffee pulp can also be fed. Chopped crop residues (eg cowpeas, leucaena leaves or other legumes) may be added.

The compost produced by the earthworms has a dark colour, no smell and a loose and spongy structure. It is a high value, high quality product which is very rich in nutrients, and in a form that makes them readily available to vegetation. The content of a full box can be harvested every 3-4 months, and is used for crops -mainly coffee and vegetables, but also maize and beans. It is very effective in increasing soil fertility and thus crop production. It also improves soil structure, infiltration and water storage capacity.

The compost can either be applied directly to coffee, mixing it with an equal amount of earth and applying 1 kg to each plant. Alternatively it can be sprayed: for preparation of liquid fertilizer 50 kg compost are mixed with 50 litres of water and left to soak for 5 days. The concentrated solution produced is mixed with water at a ratio of 1 to10 and applied to the crop using a knapsack sprayer. The earthworms reach their reproductive age after three months and live for many years. In perfect conditions an earthworm produces up to 1,500 offspring per year. Thanks to their rapid reproduction, new cultures can easily be established, or earthworm stocks can be sold according to the farmer’s needs. A certain amount

of earthworm compost is kept back and being used instead of fresh earth to reinitiate the whole process, or to start new cultures.

The area is characterised by humid climate, steep slopes and low soil fertility. Farmers are mainly smallholders with individual properties. Earthworm culture does not depend closely on the external environment, but it is essential to maintain favourable conditions inside the box - namely continuous feeding and wetting. That’s why it is usually recommended to keep cultures near the house and the home-garden. Ants, the main enemy of earthworms, can be controlled standing the boxes on poles in cans filled with water.

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Nicaragua

Region/ State/ Province:

Matagalpa

Further specification of location:

Matiguas, Pancasán

Comments:

Total area covered by the SLM Technology is 5 m2.

Map

×2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- preserve/ improve biodiversity

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

- Perennial (non-woody) cropping

Number of growing seasons per year:

- 1

Specify:

Longest growing period in days: 300, Longest growing period from month to month: May untill February

Comments:

Major land use problems (compiler’s opinion):

- low crop yields due to soil fertility decline

- water and wind erosion

- small landholdings

3.4 Water supply

Water supply for the land on which the Technology is applied:

- rainfed

3.5 SLM group to which the Technology belongs

- integrated soil fertility management

- beekeeping, aquaculture, poultry, rabbit farming, silkworm farming, etc.

3.6 SLM measures comprising the Technology

agronomic measures

- A4: Subsurface treatment

Comments:

Type of agronomic measures: manure / compost / residues

3.7 Main types of land degradation addressed by the Technology

chemical soil deterioration

- Cn: fertility decline and reduced organic matter content (not caused by erosion)

Comments:

Main causes of degradation: soil management, deforestation / removal of natural vegetation (incl. forest fires), overgrazing (on a single cattle farm), poverty / wealth (lack of capital)

Secondary causes of degradation: over-exploitation of vegetation for domestic use, other natural causes (avalanches, volcanic eruptions, mud flows, highly susceptible natural resources, extreme topography, etc.) specify (impacts of hurricane Mitch), governance / institutional (lack of strenght of law and authorities), inter-generational subdivision of land

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- reduce land degradation

4. Technical specifications, implementation activities, inputs, and costs

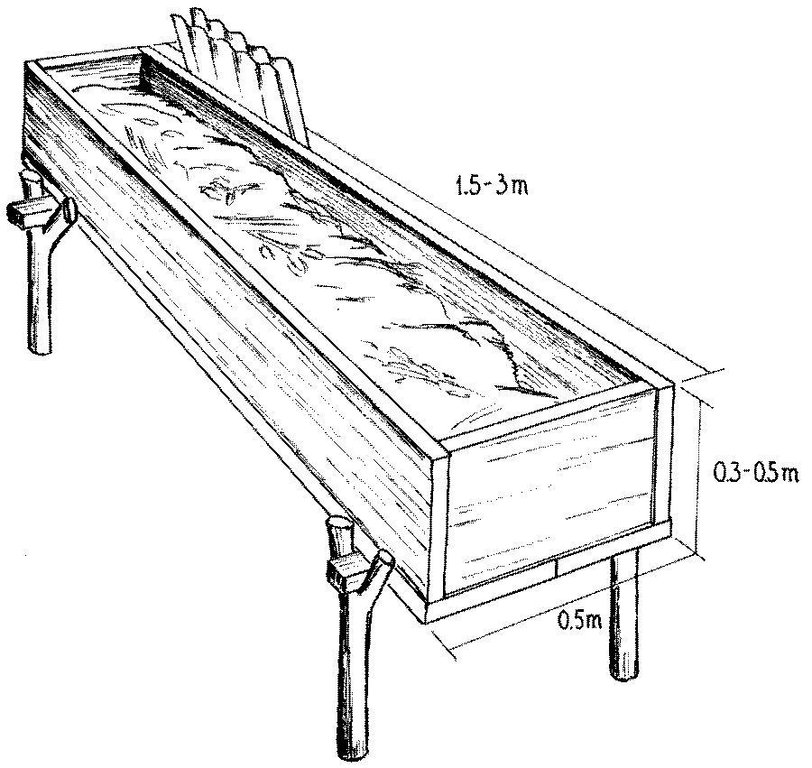

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

Detailed view of wooden box for compost production by earthworms. Cover (corrugated iron or alternative) is important to protect worms from light, from birds and other natural enemies, and to maintain moisture in the box.

Technical knowledge required for field staff / advisors: moderate

Technical knowledge required for land users: moderate

Main technical functions: increase of surface roughness, improvement of topsoil structure (compaction), increase in organic matter, increase in nutrient availability (supply, recycling,…)

Secondary technical functions: increase of infiltration

Manure / compost / residues

Material/ species: compost

Author:

Mats Gurtner

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | labour | ha | 1.0 | 6.0 | 6.0 | 100.0 |

| Construction material | wood | ha | 1.0 | 50.0 | 50.0 | 100.0 |

| Construction material | Sheet metal, plastic | ha | 1.0 | 6.0 | 6.0 | 100.0 |

| Other | earthworms (kg) | ha | 1.0 | 60.0 | 60.0 | |

| Total costs for establishment of the Technology | 122.0 | |||||

| Total costs for establishment of the Technology in USD | 122.0 | |||||

Comments:

Duration of establishment phase: 0.07 month(s)

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | 1. Feeding: add another layer of cattle manure(1 kg earthworms eat 1 kg manure per day). | no specific timing for maintenance / every 3–5 days |

| 2. | 2. Maintain humidity at 80%, water frequently in dry season, maintaintemperature between 15–30°C: do not exceed 42°C. | no specific timing for maintenance / frequently in dry season |

| 3. | 3.The worms migrate into the fresh manure. After 2–3 days take out thesieve and gather the ready, worm free compost. | no specific timing for maintenance / every 3–4 months |

| 4. | 4. Apply compost to the crops (1 kg/coffee plant, see description). | no specific timing for maintenance / every 3–4 months |

| 5. | 6. Possible improvement: add lime to raise pH to a optimum level of 7.0. | no specific timing for maintenance / |

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | labour | ha | 1.0 | 60.0 | 60.0 | 100.0 |

| Total costs for maintenance of the Technology | 60.0 | |||||

| Total costs for maintenance of the Technology in USD | 60.0 | |||||

Comments:

Machinery/ tools: hammer, nails, buckets/wheelbarrow, shovel, possibly water hose, hammer, nails, buckets/wheelbarrow, shovel, possibly water hose

60% of the land users have their own cattle, others get manure free from their neighbours. The cattle manure has no commercial price in the region - there is no market for it. The inputs and costs are estimated for the production of approx. 4,000 kg of worm compost, which is enough for one hectare of coffee per year (note figures from India for vermiculture suggest higher input-output ratios: in other words less output for the same amount of input).

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Agro-climatic zone

- humid

- sub-humid

Thermal climate class: tropics

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- fine/ heavy (clay)

Topsoil organic matter:

- low (<1%)

5.6 Characteristics of land users applying the Technology

Market orientation of production system:

- subsistence (self-supply)

- mixed (subsistence/ commercial)

Off-farm income:

- less than 10% of all income

Indicate other relevant characteristics of the land users:

Off-farm income specification: nearly all land users are fully occupied with agricultural activities, very few are involved in commerce or are employed

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, not titled

- individual, titled

Land use rights:

- leased

- individual

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

fodder production

fodder quality

Income and costs

farm income

Socio-cultural impacts

conflict mitigation

Ecological impacts

Soil

soil moisture

Comments/ specify:

through improvement of soil water storage capacity

Biodiversity: vegetation, animals

pest/ disease control

Comments/ specify:

the compost attracts pests like ants, chickens, moles

6.2 Off-site impacts the Technology has shown

groundwater/ river pollution

Comments/ specify:

lower inputs of chemical fertilizers

6.5 Adoption of the Technology

Comments:

88 land user families have adopted the Technology with external material support

6 land user families have adopted the Technology without any external material support

There is a little trend towards spontaneous adoption of the Technology. As ADDAC (the Association for Agricultural Community Development and Diversification) has a permanent and longterm presence in the approach area, most interested farmers are directly involved in the programme activities: this explains the fact that only 5% of the technology users (6 people) took up earthworm culture without incentives (see approach).

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| Additional economic income through commercialization of earthworm stocks |

| Health: clean products without chemical treatment. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Continuous and increasing production of organic and very effective compost with high nutrient content (replacing chemical fertilizers) |

|

Appropriate for different crops (though in different forms – direct application or spraying). |

| Simple and cheap technology; low labour input |

| Increased crop yields |

| Earthworm culture is becoming an integrated part of the production system, especially for land users who have cows. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| Requires permanent access to water | A close fitting and secure box cover, as well as placement of the box in the shade reduces loss of humidity. Roof-top rainwater collection helps to get over dry periods. |

| Requires continuous availability of manure to feed worms. | Improve the construction of the boxes (close holes and cover the box tightly). |

| Attracts natural enemies like ants, chickens, moles, flies; needs protection |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

- interviews with land users

When were the data compiled (in the field)?

01/02/2004

7.2 References to available publications

Title, author, year, ISBN:

PASOLAC. Guía Técnica de Conservación de Suelos y Agua.. 2000.

Available from where? Costs?

PASOLAC, Managua

Title, author, year, ISBN:

Ferruzzi C. Manual de Lombricultura. Ediciones Mundi-Prensa. Madrid, Spain. 1986.

Title, author, year, ISBN:

Castillo H . La lombricultura. in Altertec. Alternativas de Mejoramiento de Suelos.Proceso de Capacitación para Profesionales. Modulo II. Altertec, Ciudad de Guatemala. 1994.

Links and modules

Expand all Collapse allLinks

Productive development and food security programme [Nicaragua]

An integrated programme-based approach promoting participatory testing and extension of various SWC technologies, as well as providing institutional support.

- Compiler: Philippe Zahner

Modules

No modules