Dyker System [Switzerland]

- Creation:

- Update:

- Compiler: Deborah Niggli

- Editor: –

- Reviewers: Tatenda Lemann, Alexandra Gavilano

Dyker-System (oder Lochstern) im Kartoffelanbau

technologies_1304 - Switzerland

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Preventing and Remediating degradation of soils in Europe through Land Care (EU-RECARE )Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

CDE Centre for Development and Environment (CDE Centre for Development and Environment) - Switzerland1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

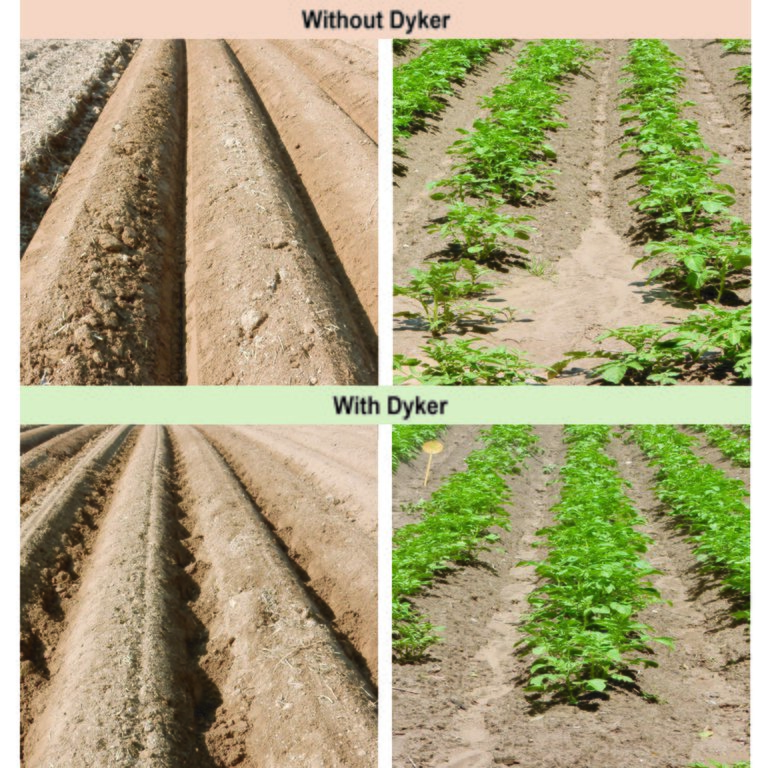

The Dyker consists of a set of wheels with three to four inclined shovels each. Attached to the rear end of the planting machine, it digs holes into the bottom of the furrows between the potato hills.

2.2 Detailed description of the Technology

Description:

The Dyker system consists of a new tractor trailer for cultivating potatoes. It was established by Grimme from Germany. With this new technology small holes and micro-dams are built in the furrows between the potato hills. They are intended to improve water infiltration and to help retain water near the plants, while preventing waterlogging and stagnant water in depressions and minimizing surface runoff and soil erosion.

On conventionally farmed potato fields (where an all-in-one potato planter can be used) no additional working steps are necessary and the Dyker can be used simultaneously with the potato planting machine. This saves time and money. For other crops or if no all-in-one potato planter is used, the Dyker can also be attached to a tractor as an individual trailer (without potato planter). Then one ore more additional working steps are needed after plantation.

The system is intended to prevent soil erosion and waterlogging during the cultivation process of potatoes. Furrows running parallel to the gradient are mostly endangered by soil erosion during the first 4-8 weeks until soil cover reaches a certain percentage. Small holes and micro-dams in the furrows increase infiltration and reduce surface runoff and thereby prevent soil erosion and water logging.

2.3 Photos of the Technology

2.4 Videos of the Technology

Comments, short description:

The Dyker in use with a Grimme GL 420 potato planter

Date:

07/05/2016

Location:

Frienisberg

Name of videographer:

Tatenda Lemann

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Switzerland

Region/ State/ Province:

Wiler bei Seedorf

Further specification of location:

Bern

Specify the spread of the Technology:

- evenly spread over an area

If precise area is not known, indicate approximate area covered:

- < 0.1 km2 (10 ha)

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

- through contructors' innovation

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- reduce, prevent, restore land degradation

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

Annual cropping - Specify crops:

- root/tuber crops - potatoes

Number of growing seasons per year:

- 1

Comments:

Major land use problems (land users’ perception): The major land use problem is soil erosion by water occuring mainly at hillside situations. Land use problems related to the use of the plow are only minor because most of the land users have shifted to direct seeding, mulching or strip tillage.

3.4 Water supply

Water supply for the land on which the Technology is applied:

- rainfed

3.5 SLM group to which the Technology belongs

- cross-slope measure

- water diversion and drainage

3.6 SLM measures comprising the Technology

agronomic measures

- A3: Soil surface treatment

- A4: Subsurface treatment

3.7 Main types of land degradation addressed by the Technology

soil erosion by water

- Wt: loss of topsoil/ surface erosion

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

Technical knowledge required for field staff / advisors: moderate

Technical knowledge required for land users: high

Main technical functions:

-control of concentrated runoff: retain / trap,

-control of concentrated runoff: impede / retard,

-control of concentrated runoff: drain / divert

Secondary technical functions:

-reduction of slope length,

-increase of infiltrationgth, increase of infiltration

4.2 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology unit

Specify unit:

Dyker (attachment for tractor or potato planter)

other/ national currency (specify):

CHF

If relevant, indicate exchange rate from USD to local currency (e.g. 1 USD = 79.9 Brazilian Real): 1 USD =:

1.0

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Dyker system usage during cultivation of potatoes | During or after potato plantation |

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour | days/year | 2.0 | 250.0 | 500.0 | |

| Equipment | Dyker | piece | 1.0 | 8500.0 | 8500.0 | |

| Total costs for establishment of the Technology | 9000.0 | |||||

| Total costs for establishment of the Technology in USD | 9000.0 | |||||

If land user bore less than 100% of costs, indicate who covered the remaining costs:

Depending if the Dyker belongs to the farmer or a contractor

Comments:

Standard costs for potato plantation like seeds and fertilizer, herbicide and pesticide are not included in the calculations for the costs. It is assumed that the Dyker is used with an "all-in-one" potato planter where no additional working steps are required.

In many cases the Dyker belongs to a contractor, who is planting potatoes for the farmers. In this case no additional costs can be expected for the farmers. The farmers only have to pay for the labour (contractor), seeds and fertilizer, herbicide and pesticide but not for the usage of the Dyker.

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

- If the Dyker belongs to a contractor with a all-in-one potato planter, no additional costs are expected for the farmer (but for the contractor)

- If the Dyker is not attached to a all-in-one potato planter but e.g. to a tractor, additional working steps are necessary.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Agro-climatic zone

- sub-humid

Thermal climate class: temperate

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- not relevant

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Soil texture (> 20 cm below surface):

- medium (loamy, silty)

Topsoil organic matter:

- medium (1-3%)

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

Soil texture is medium

Soil fertility is high

Soil drainage infiltration is medium

Soil water storage capacity is medium

5.4 Water availability and quality

Ground water table:

5-50 m

Availability of surface water:

good

Water quality (untreated):

good drinking water

Is water salinity a problem?

No

Is flooding of the area occurring?

No

5.5 Biodiversity

Species diversity:

- high

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- commercial/ market

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- rich

Individuals or groups:

- individual/ household

Level of mechanization:

- mechanized/ motorized

Gender:

- men

Age of land users:

- children

Indicate other relevant characteristics of the land users:

Land users applying the Technology are mainly leaders / privileged

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- medium-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, titled

Land use rights:

- individual

Water use rights:

- individual

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

risk of production failure

Income and costs

workload

Comments/ specify:

When used with potato planter not additional work step needed. Workload is slightly increasing due to preparation of the Dyker.

Socio-cultural impacts

SLM/ land degradation knowledge

conflict mitigation

Ecological impacts

Water cycle/ runoff

surface runoff

Soil

soil loss

Other ecological impacts

Hazard towards adverse events

6.2 Off-site impacts the Technology has shown

downstream flooding

damage on neighbours' fields

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | well |

Climate-related extremes (disasters)

Meteorological disasters

| How does the Technology cope with it? | |

|---|---|

| local rainstorm | not known |

Hydrological disasters

| How does the Technology cope with it? | |

|---|---|

| general (river) flood | not well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

neutral/ balanced

Long-term returns:

positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

neutral/ balanced

Long-term returns:

slightly positive

6.5 Adoption of the Technology

- 11-50%

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 51-90%

Comments:

There is a moderate trend towards spontaneous adoption of the Technology. Many farmer use a contractor: if the contractor has a Dyker, then the farmers will use it.

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

No

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| The small holes and micro dams in the furrows enhance infiltration, reduce surface runoff and prevent soil erosion and waterlogging. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| The problematic crop of potatoes can be prevented from soil erosion thanks to the Dyker system. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| The weight of the Dyker which is added behind the axe --> more difficult to maneuver the machine | Good technical skills and experience with big, heavy machines are necessary to use the Dyker system correctly. In terms of risk of soil compaction this is negligible, as the dyker does not add much to the total weight of the machinery. |

| price of Dyker: US$ 8000 – 8500 for a contractor these costs are not a problem. However, for a single farmer the price is high | Shared use of the Dyker can reduce costs for individual farmer |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

- interviews with land users

When were the data compiled (in the field)?

27/08/2015

7.3 Links to relevant online information

Title/ description:

RECARE Project Dissemination Hub

URL:

http://www.recare-hub.eu/stakeholder-platforms/frienisberg-switzerland

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules