Better quality farmyard manure through improved decomposition [Nepal]

- Creation:

- Update:

- Compiler: Richard Allen

- Editor: –

- Reviewers: David Streiff, Alexandra Gavilano

Upayukta bighatan prakriya dwara ramro gunastar ko gothemal (Nepali)

technologies_1759 - Nepal

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

SLM specialist:

Director

Soil Management Directorate, Department of Agriculture

Nepal

SLM specialist:

Team Leader

Sustainable Soil Management Programme

Nepal

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Sustainable Soil Management Programme, Nepal (SSMP)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Department of Agriculture, Soil Management Directorate, Hariharbhawan Lalitpur (doasoil) - NepalName of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

HELVETAS (Swiss Intercooperation)1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.5 Reference to Questionnaire(s) on SLM Approaches (documented using WOCAT)

Farmer field schools on integrated plant nutrient systems [Nepal]

Participatory and collaborative learning through the farmer field school approach

- Compiler: Richard Allen

Farmer-to-farmer diffusion [Nepal]

Wider diffusion of sustainable soil management technologies through a demand responsive farmer-to-farmer diffusion approach

- Compiler: Richard Allen

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Collection and proper storage of farmyard manure in heaps or pits

2.2 Detailed description of the Technology

Description:

Farmyard manure - a varying mixture of animal manure, urine, bedding material, fodder residues, and other components - is the most common form of organic manure applied in the midhills of Nepal. Farmyard manure has a high proportion of organic material which nurtures soil organisms and is essential in maintaining an active soil life. Only about half of the nutrient content of farmyard manure becomes available for crop growth during the first year after it has been applied to the soil - the rest is channeled through soil biotic processes and the nutrients are released in the following years. The high organic matter content and the active soil life improve or maintain friable soil structures, increase the cation exchange capacity, water holding capacity, and infiltration rate, and reducing the risk of soil pests building up.

Indigenous methods of preparing and using farmyard manure vary widely depending on the ecological zone, access to bedding material from crop or forest land, access to crop residues and fodder, labour availability, and other factors. A prerequisite for the manure having a positive impact on soil fertility is that it is properly decomposed. The application of partially decomposed manure can increase the number of white grubs, red ants and other soil pests.

Decomposition is enhanced and the time it takes to happen is reduced if the manure is kept warm and moist (but not wet) at all times. Heaping the manure up or storing it in a pit helps. Whether it is best to heap up the manure or put it in a pit depends on the local climate. Heaping has the advantage of being less costly, while the pit method reduces runoff and the loss of nutrient rich fluids. Adding nitrogen in the form of urine (N) improves the carbon to nitrogen ratio.

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Nepal

Further specification of location:

Midhills districts of Nepal

Specify the spread of the Technology:

- applied at specific points/ concentrated on a small area

Map

×3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- Access to manure

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

Comments:

Major land use problems (compiler’s opinion): Intensifying cultivation practices with either 1) inadequate application of fertilisers leading to a decline in soil fertility and the mining of soil nutrients or 2) application of too much fertiliser causing environmental problems through excessive leaching, and losses of fertiliser in surface runoff and consequent eutrophication or nitrification of streams, ponds or groundwater.

3.5 SLM group to which the Technology belongs

- integrated soil fertility management

3.6 SLM measures comprising the Technology

management measures

- M2: Change of management/ intensity level

3.7 Main types of land degradation addressed by the Technology

chemical soil deterioration

- Cn: fertility decline and reduced organic matter content (not caused by erosion)

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- reduce land degradation

4. Technical specifications, implementation activities, inputs, and costs

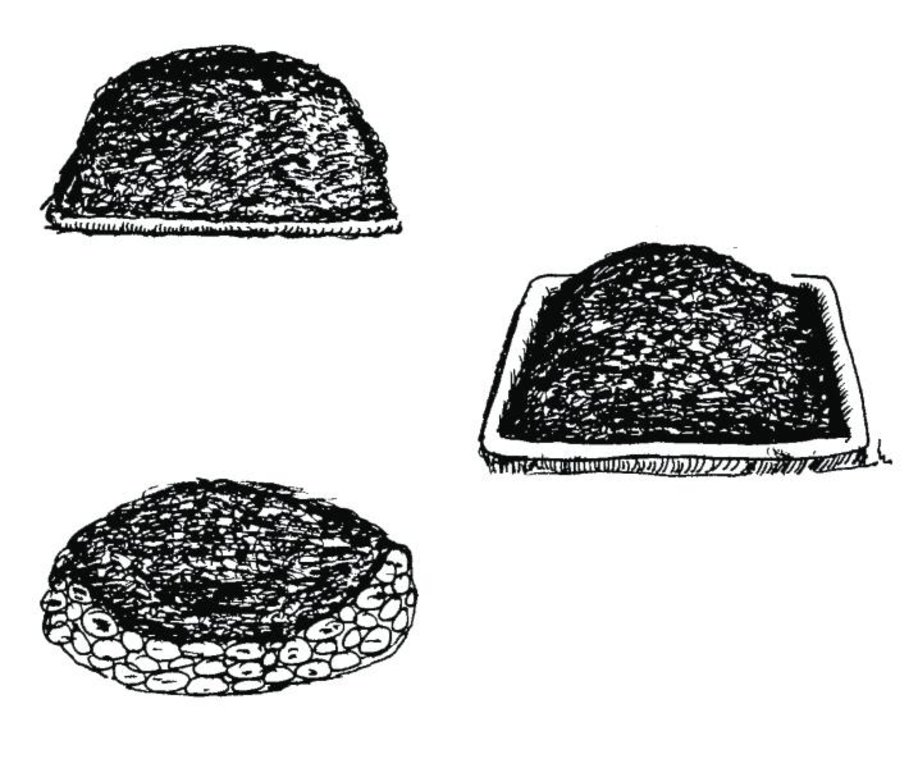

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

a) Heap method

b) Pit method

c) Semi-pit method

The method should be chosen that

is most convenient and provides the

most favourable environment for

decomposition of the manure.

Generally heaps and pits are about 1 to 2m in diameter

depending on the amount of

manure produced and required.

Technical knowledge required for field staff / advisors: low

Technical knowledge required for land users: low

Main technical functions: increase in organic matter, increase in soil fertility, increase in soil productivity

Secondary technical functions: increased infiltration rate and water holding capacity, improved soil physical properties

Layout change according to natural and human environment: heaping or storage in pits

4.2 General information regarding the calculation of inputs and costs

Specify currency used for cost calculations:

- USD

Indicate average wage cost of hired labour per day:

2.00

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Dig a 1m deep and 2m diameter pit using a shovel or spade. | |

| 2. | Pit method: Put dung mixed with leaf litter, bedding material and fodder residues in the pit until it is full. | |

| 3. | Apply urine directly over the manure heap using a plastic pipe or jug. | |

| 4. | Cover the heap with a fine layer of straw, mud, soil or plastic sheet or any other suitable local materials to protect it from direct sunlight and excessive water. |

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Preapring manure pit | Persons/day | 1.0 | 2.0 | 2.0 | 100.0 |

| Total costs for establishment of the Technology | 2.0 | |||||

| Total costs for establishment of the Technology in USD | 2.0 | |||||

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | About one month after beginning to collect and pile up the material, turn | |

| 2. | Depending on the location, it takes about 3-4 months to prepare fully decomposed farmyard manure. |

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Decompose manure | Persons/day | 1.0 | 2.0 | 2.0 | 100.0 |

| Total costs for maintenance of the Technology | 2.0 | |||||

| Total costs for maintenance of the Technology in USD | 2.0 | |||||

Comments:

Cost as in January 2007

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

The heap method is cheaper, as no digging is involved

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specifications/ comments on rainfall:

Annual rainfall: Also 2000-3000 mm

Agro-climatic zone

- humid

Thermal climate class: subtropics

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Comments and further specifications on topography:

Slopes on average: Also moderate (6-10%), rolling (11-15%) and hilly (16-30%)

Landforms: Also footslopes

Altitudinal zone: Also 1000-1500 m a.s.l., 1500-2000 m a.s.l. and 2000-2500 m a.s.l.

5.6 Characteristics of land users applying the Technology

Market orientation of production system:

- subsistence (self-supply)

- mixed (subsistence/ commercial)

Individuals or groups:

- individual/ household

Indicate other relevant characteristics of the land users:

Off-farm income specification: In most farm households, off-farm income plays at least a minor and increasingly a major role. Occasional opportunities for off-farm income present themselves in the form of daily labour wages. Some households’ members receive regular salaries, whilst an increasing number of Nepalis are working in India, the Middle East, Malaysia, and elsewhere and sending remittance incomes home.

Market orientation of production system: Also commercial/ market

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, not titled

- individual, titled

Land use rights:

- leased

- individual

Comments:

sharecropping between owner and tenant

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

Income and costs

expenses on agricultural inputs

Comments/ specify:

Reduced cash expenses on agrochemicals (fertilisers, pesticides; substituted by labour)

Other socio-economic impacts

Cleaner environment around houses if manure heap or pit is well maintained

Ecological impacts

Other ecological impacts

Incidence ofsoil pests (white grub, red ant)

Application of mineral fertilisers

6.2 Off-site impacts the Technology has shown

groundwater/ river pollution

Comments/ specify:

Reduced influx of nutrients into water bodies

Dependence on outside inputs

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

positive

Long-term returns:

positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

positive

Long-term returns:

positive

Comments:

The high costs of mineral fertiliser mean that the establishment costs are recovered quarterly. Over the long-term, the major reduction in costs leads to large benefits.

6.5 Adoption of the Technology

Comments:

Comments on acceptance with external material support: Heap and pit methods have been very well accepted and adopted widely ( 60-70% ) of among participants in SSMP.The semi-pit method is not as accepted as the other methods due to its high initial establishment costs.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

|

The use of improved and well-decomposed farmyard manure reduced the need for mineral fertiliser and pesticides thereby reducing production costs, cash expenditure, and outside dependency How can they be sustained / enhanced? Further promote the technology to increase this impact. |

| The use of fully decomposed farmyard manure reduces pest incidence, especially attacks of red ants and white grubs |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| The initial establishment costs for building a semi-pit may hamper adoption |

Promote alternative methods of building a semi-pit without using cement and using local resources |

7. References and links

7.1 Methods/ sources of information

7.2 References to available publications

Title, author, year, ISBN:

STSS; SSMP (2001) Farmyard Manure and Compost Management (in Nepali) Kathmandu: Soil Testing Services Section, Department of Agriculture and Sustainable Soil Management Programme

Available from where? Costs?

SSMP

Links and modules

Expand all Collapse allLinks

Farmer field schools on integrated plant nutrient systems [Nepal]

Participatory and collaborative learning through the farmer field school approach

- Compiler: Richard Allen

Farmer-to-farmer diffusion [Nepal]

Wider diffusion of sustainable soil management technologies through a demand responsive farmer-to-farmer diffusion approach

- Compiler: Richard Allen

Modules

No modules