Low-cost irrigation with a treadle pump [Uganda]

- Creation:

- Update:

- Compiler: Bernard Fungo

- Editors: JOY TUKAHIRWA, Kamugisha Rick Nelson, betty adoch, Sunday Balla Amale

- Reviewers: Donia Mühlematter, John Stephen Tenywa, Nicole Harari, Renate Fleiner, Stephanie Jaquet, Alexandra Gavilano

Money Maker

technologies_2788 - Uganda

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Scaling-up SLM practices by smallholder farmers (IFAD)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

CDE Centre for Development and Environment (CDE Centre for Development and Environment) - Switzerland1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

Comments:

Irrigation of annual and perennial cropland is a buffer against crop failure caused by prolonged drought, ensuring adaptation to change in weather patterns.

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Use of the manual Treadle pump is a relatively cheap and effective way to ensure adequate soil moisture to ensure crop production throughout the year.

2.2 Detailed description of the Technology

Description:

Northern Uganda receives low rainfall (600 – 1100 mm annually) and experiences longer dry spells (4 – 5 months) compared to other areas of the country. This makes the region vulnerable to drought, thereby increasing the risk of crop failure in most cases. Therefore, irrigation has the potential to improve land productivity. However, moving water from its source into cropland is labor-demanding for farmers, thereby making irrigation farming less profitable compared to rain-fed agriculture, even with the erratic nature of rainfall.

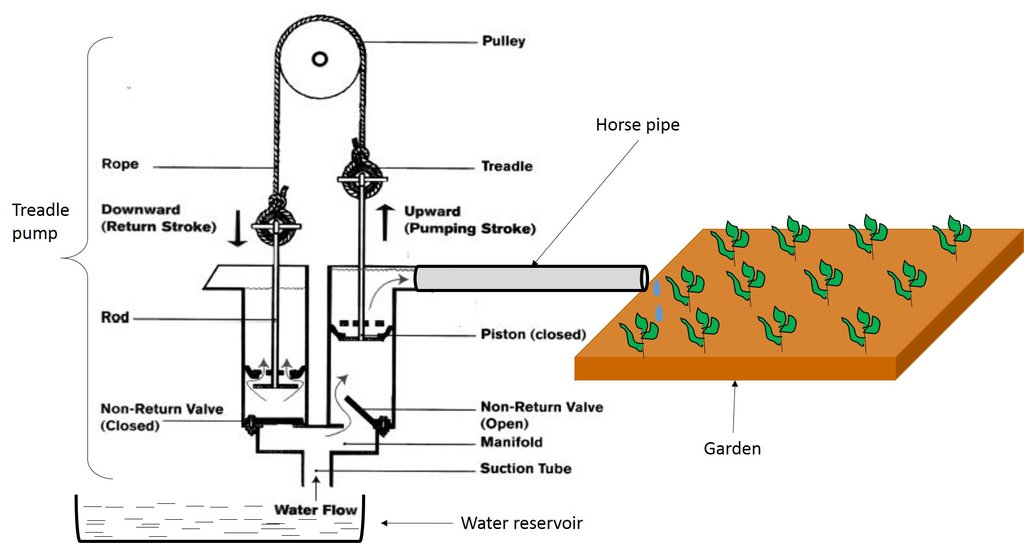

To engage in profitable irrigation farming, farmers have resorted to use simple contraptions such as the treadle pump. The treadle pump is used to move water from its source (which maybe a well, underground tank, valley dam or reserve tank) into the cropland with significantly lower labour requirements. This reduces the cost of irrigation and improves profitability. Treadle pumps are powered by human effort, with the legs and feet peddling up and down on treadles/ peddles that are connected to two small piston pumps. The pump is connected to a hosepipe, which dispenses the water, running from the water source into the cropland. This machine is gender-responsive because its energy requirements are very low and can thus be operated by any gender (men, women and teenagers).

Mechanically, a treadle pump is a suction pump that is placed on top of a well. It is designed to lift water from a depth of seven meters or less. It can lift five to seven cubic meters of water per hour (5-7 m3 hr-1) from wells and boreholes and can also be used to draw water from lakes and rivers. The pumping is activated by stepping up and down on a treadle/ peddles, which drive the pistons, creating cylinder suction that draws groundwater to the surface. The treadle pump can do most of the work done by a motorized pump, but costs considerably less. Its cost, including installation ranges between US$100 and 300. Since it is not motorized, it can also cost less (e.g. by 50%) to operate than a motorized pump. Many treadle pumps are manufactured locally, but they can be challenging to produce up to the right standards without highly skilled welders and production hardware. Use of manual rather than fossil fuel means that the technology is carbon neutral, another important climate smart dimension of the pump.

Despite its benefits, the adoption rate has been low due to the initial cost, which although is relatively lower compared to the motorized pumps, is still unaffordable by most smallholder farmers. To overcome this high cost, some farmers form groups, purchase one piece and share the cost among the group members. The second problem with this technology is the lack of nearby water sources, which may be a serious challenge or where the water table is very low and/or where porous soils do not allow significant harvestable water during rainy seasons. To ensure the technology is sustainable, farmers are building concrete tanks to harvest water from the roofs of their houses when it rains and use it for irrigation when the drought sets-in.

2.3 Photos of the Technology

2.4 Videos of the Technology

Date:

12/5/2017

Location:

Lamwo

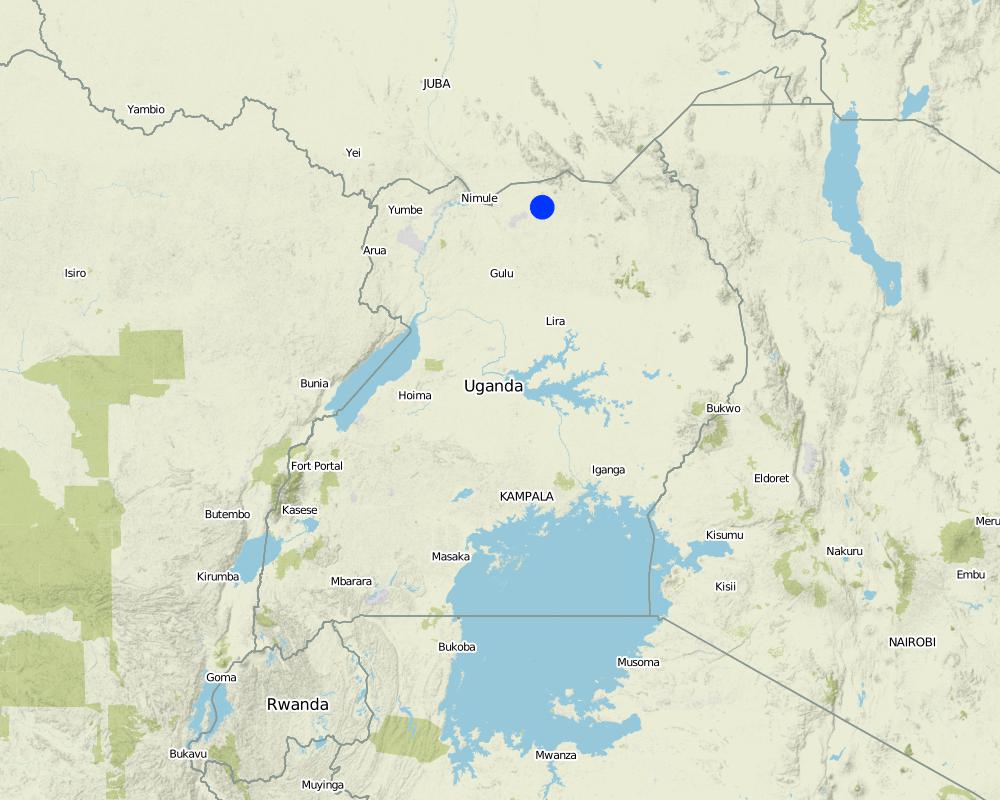

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Uganda

Region/ State/ Province:

Northern

Further specification of location:

Padibe s/county Lamwo District

Specify the spread of the Technology:

- evenly spread over an area

If precise area is not known, indicate approximate area covered:

- < 0.1 km2 (10 ha)

Map

×2.6 Date of implementation

Indicate year of implementation:

2012

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

Comments (type of project, etc.):

The project was called Action Against Hunger.

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- reduce risk of disasters

- adapt to climate change/ extremes and its impacts

- create beneficial economic impact

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

Annual cropping - Specify crops:

- cereals - maize

- legumes and pulses - beans

- vegetables

Number of growing seasons per year:

- 3

Specify:

The growing take place out the year.

Grazing land

Forest/ woodlands

3.4 Water supply

Water supply for the land on which the Technology is applied:

- mixed rainfed-irrigated

Comments:

Irrigation is only done during the dry spells or when the rains don't come as expected.

3.5 SLM group to which the Technology belongs

- irrigation management (incl. water supply, drainage)

3.6 SLM measures comprising the Technology

structural measures

- S7: Water harvesting/ supply/ irrigation equipment

3.7 Main types of land degradation addressed by the Technology

biological degradation

- Bl: loss of soil life

water degradation

- Ha: aridification

- Hs: change in quantity of surface water

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- reduce land degradation

- adapt to land degradation

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

1. Water head should be within 7 meters from the ground.

2. The garden where watering will be done should be within 25 meters from the treadle pump if the area is flat.

3. The pump should fixed firmly in the ground to avoid falling while the peddling is going-on.

Author:

Bernard Fungo

Date:

12/5/2017

4.2 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology unit

Specify unit:

Piece

Specify dimensions of unit (if relevant):

One piece of treadle pump with its tubing to where the garden is

other/ national currency (specify):

Uganda Shilings

If relevant, indicate exchange rate from USD to local currency (e.g. 1 USD = 79.9 Brazilian Real): 1 USD =:

3500.0

Indicate average wage cost of hired labour per day:

5000

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Buying treadle pump | Once |

| 2. | Connection | Once |

| 3. | Pumping | Once a day |

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Pumping | Man/days | 30.0 | 5000.0 | 150000.0 | 100.0 |

| Equipment | Treadle Pump | Piece | 1.0 | 1000000.0 | 1000000.0 | 100.0 |

| Equipment | Horse pipes | Meters | 50.0 | 3000.0 | 150000.0 | 100.0 |

| Total costs for establishment of the Technology | 1300000.0 | |||||

| Total costs for establishment of the Technology in USD | 371.43 | |||||

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | pumping | when needed |

| 2. | Replacement of pipe | When needed |

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour for pumping water | Mandays | 30.0 | 5000.0 | 150000.0 | 100.0 |

| Equipment | Treddle pump | Piece | 1.0 | 1050000.0 | 1050000.0 | |

| Equipment | pipe | Meters | 30.0 | 70000.0 | 2100000.0 | |

| Total costs for maintenance of the Technology | 3300000.0 | |||||

| Total costs for maintenance of the Technology in USD | 942.86 | |||||

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Cost for acquiring the pump and the cost of labor for running the pump.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Indicate the name of the reference meteorological station considered:

Gulu, Uganda

Agro-climatic zone

- sub-humid

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- not relevant

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Soil texture (> 20 cm below surface):

- medium (loamy, silty)

Topsoil organic matter:

- medium (1-3%)

5.4 Water availability and quality

Ground water table:

> 50 m

Availability of surface water:

medium

Water quality (untreated):

for agricultural use only (irrigation)

Is water salinity a problem?

No

Is flooding of the area occurring?

No

5.5 Biodiversity

Species diversity:

- medium

Habitat diversity:

- medium

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- mixed (subsistence/ commercial)

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- average

Individuals or groups:

- individual/ household

Level of mechanization:

- manual work

- animal traction

Gender:

- men

Age of land users:

- middle-aged

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- medium-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, not titled

Land use rights:

- individual

Water use rights:

- individual

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

crop quality

risk of production failure

land management

Water availability and quality

irrigation water availability

Comments/ specify:

Increased construction of underground reservoirs and roof water harvesting have increased availability of water for irrigation.

Socio-cultural impacts

food security/ self-sufficiency

SLM/ land degradation knowledge

Comments/ specify:

As the project was promoting the pump, sensitization about land degradation and options for improving management were also intruded to farmers, hence improving their knowledge on land degradation.

Ecological impacts

Climate and disaster risk reduction

drought impacts

6.2 Off-site impacts the Technology has shown

groundwater/ river pollution

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | moderately | |

| seasonal temperature | wet/ rainy season | increase | moderately |

| annual rainfall | decrease | moderately | |

| seasonal rainfall | dry season | decrease | moderately |

Climate-related extremes (disasters)

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

negative

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

positive

Long-term returns:

very positive

6.5 Adoption of the Technology

- 1-10%

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 0-10%

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

No

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| Increase productivity. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| No risk of pump being stolen since it is portable, and can be shared by several farmers thus amenable to cost sharing. |

| It can be used by many genders (Youth, male and female). |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| Cost for acquiring. | Farmers can share the cost of purchase and they utilize in tern. |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| The low water table in the area makes it difficult to have sufficient water when it is needed. | Construction of under ground tanks to harvest water during rainy seasons |

| Only suitable for small gardens (one acre). | Grow high value crops that take small spaces such as vegetable and fruits. |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

2

- interviews with land users

2

When were the data compiled (in the field)?

12/05/2017

7.2 References to available publications

Title, author, year, ISBN:

N/a

7.3 Links to relevant online information

Title/ description:

N/a

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules