Solar Mobile Dryer (SMD) [United Arab Emirates]

- Creation:

- Update:

- Compiler: Joren Verbist

- Editor: –

- Reviewers: William Critchley, Rima Mekdaschi Studer

technologies_7197 - United Arab Emirates

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

Principal Natural Resources Economist:

Dhebibi Boubaker

International Center of Agriculture Research in the Dry Areas (ICARDA)

Tunisia

Food and Feed Processing Scientist:

Hilali Muhi El-Dine

International Center of Agriculture Research in the Dry Areas (ICARDA)

Jordan

Activities Coordinator Officer:

Nejatian Arash

International Center of Agriculture Research in the Dry Areas (ICARDA)

United Arab Emirates

Regional Coordinator APRP:

Niane Abdoul Aziz

International Center of Agriculture Research in the Dry Areas (ICARDA)

United Arab Emirates

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

ICARDA Institutional Knowledge Management InitiativeName of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

International Center for Agricultural Research in the Dry Areas (ICARDA) - Lebanon1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

The innovative Solar Mobile Dryer (SMD) developed by ICARDA addresses climate change challenges for date palm growers in the Gulf Cooperation Council (GCC) countries by improving fruit quality, reducing waste, saving energy, and enhancing profitability, thereby supporting sustainable and efficient agricultural practices.

2.2 Detailed description of the Technology

Description:

In the Middle East, the date palm is an essential crop with significant cultural and economic value, thriving in dry, arid, and hot climates. However, climate change is exacerbating production challenges, with higher temperatures, heatwaves, water scarcity, harsh winds, leading to poor pollination, and increased pests amongst other issues. Small-scale date palm producers in the Gulf Cooperation Council (GCC) countries face additional problems of managing unsold or excess produce. Short harvesting periods and high deterioration rates of some date varieties make the situation worse. A common solution to extend shelf life is freezing. However, this has several drawbacks including storage and handling difficulties, nutrient and flavour degradation, and high energy costs.

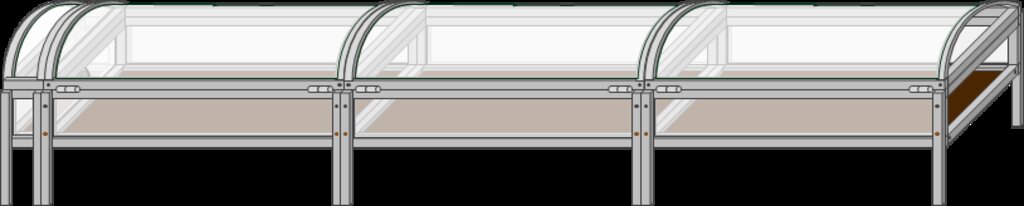

To tackle these post-harvest challenges, the International Center of Agricultural Research in Dry Areas (ICARDA) developed an innovative Solar Mobile Dryer (SMB) for drying dates, achieving the desired colour for marketing while shielding the produce from dust and rain. The mobile solar dryer includes tables with polycarbonate covers forming a tunnel. Each table is 3 meters long, 1 meter wide, with walls 15-30 cm high, and raised 40 cm off the ground on metal legs. Dates are placed on a mesh for enhanced air flow and drying. Temperatures are kept at 70 degrees Celsius, the same as industrial date drying, to avoid textural changes, hardness, and colour alteration. Two versions of the tables have been produced.

The Jordan version, uses an iron frame and includes four tables that can form a 12-meter tunnel. This dryer has a 12V 40W DC fan, with a control unit and solar panel system, providing 6 hours of operation during the day and 2 hours at night, controlled by a temperature sensor.

The second version was developed in United Arab Emirates (UAE) and features a lighter aluminium frame and a 12V 80W fan fixed on one table. It includes temperature and humidity sensors, two solar panels, and a 20A charging controller.

The advantage and disadvantages of the SMB are as follows:

Advantages:

+ Improves fruit quality, especially in humid areas. Produce dried in greenhouses are often higher quality than those sun-dried.

+ Prevents contamination by insects, birds, dust, and rain.

+ Saves energy and drying time, improves product quality, and increases process efficiency.

+ Solar drying systems have low operation and maintenance costs.

+ Reduces waste and loss rates.

+ Reduces air pollution and greenhouse gases from fossil fuels.

+ Can be used for other products (e.g., fruits, vegetables, medicinal, and aromatic plants).

Disadvantages:

- Drying is limited to sunny days unless integrated with conventional energy systems. Drying without sunshine depends on the humidity difference between inside and outside the chamber.

- Solar drying is slower than conventional fuel or electricity-based dryers.

- Requires large land areas and long drying times, subject to solar radiation and temperature fluctuations.

- Farmers may lack maintenance knowledge for the system.

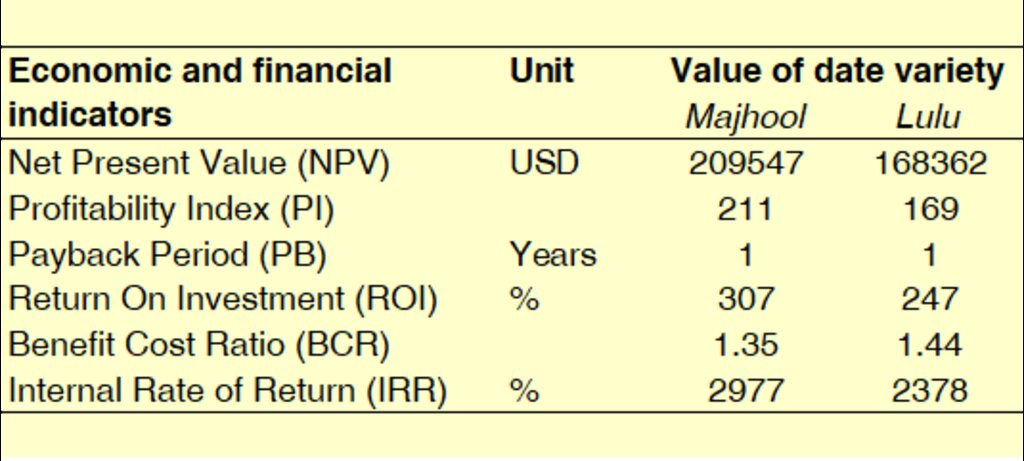

Economic evaluations of the SMD for two date varieties, Majhool and Lulu, demonstrate high profitability. The initial investment in the SMD is approximately 1,000 USD, with an estimated lifetime of about 10 years. The drying process takes between 1 and 3 days. The SMD has a capacity to dry between 6 and 12 kilograms of dates per square meter of drying surface in the SMD, resulting in production of around 5-10 kilograms of dried dates. Maintenance costs are estimated at 25% of the initial investment, while variable costs such as labour, packaging, and transportation are around 500 USD per month. Based on these figures, the net income per kilogram of dried dates is approximately 2.7 USD. Depending on the date variety, the return-on-investment ranges between 240% and 310%, with a payback period of about 4 months. These numbers indicate that the innovation is highly profitable for farmers.

The SMD is a crucial ICARDA initiative for smallholder date palm growers in the GCC countries, offering energy savings, waste reduction, and post-harvest loss prevention, enhancing the competitiveness of modern agriculture in high date production areas.

We express our sincere gratitude to the Gulf Cooperation Council (GCC) Secretariat for funding this research under the "Development of sustainable date palm production systems in the GCC countries of the Arabian Peninsula" project. We are grateful to the Ministries of Agriculture, Agricultural Authorities, and Agricultural Research Institutions and Universities in the GCC countries for their continuous support and collaboration in implementing project activities.

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

United Arab Emirates

Specify the spread of the Technology:

- applied at specific points/ concentrated on a small area

Is/are the technology site(s) located in a permanently protected area?

No

Map

×2.6 Date of implementation

Indicate year of implementation:

2020

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- during experiments/ research

- through projects/ external interventions

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- adapt to climate change/ extremes and its impacts

- mitigate climate change and its impacts

- create beneficial economic impact

- create beneficial social impact

3.2 Current land use type(s) where the Technology is applied

Land use mixed within the same land unit:

No

Cropland

- Tree and shrub cropping

Tree and shrub cropping - Specify crops:

- dates

Number of growing seasons per year:

- 1

3.3 Has land use changed due to the implementation of the Technology?

Has land use changed due to the implementation of the Technology?

- No (Continue with question 3.4)

3.4 Water supply

Water supply for the land on which the Technology is applied:

- mixed rainfed-irrigated

3.5 SLM group to which the Technology belongs

- post-harvest measures

3.6 SLM measures comprising the Technology

other measures

Specify:

This is a post-harvest and technological innovation.

3.7 Main types of land degradation addressed by the Technology

biological degradation

- Bq: quantity/ biomass decline

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

- reduce land degradation

Comments:

This innovation increases the income of the farmers per unit area i.e., increased economic land productivity. This allows farmers to reduce pressure on the land and/or to manage their land more sustainable.

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

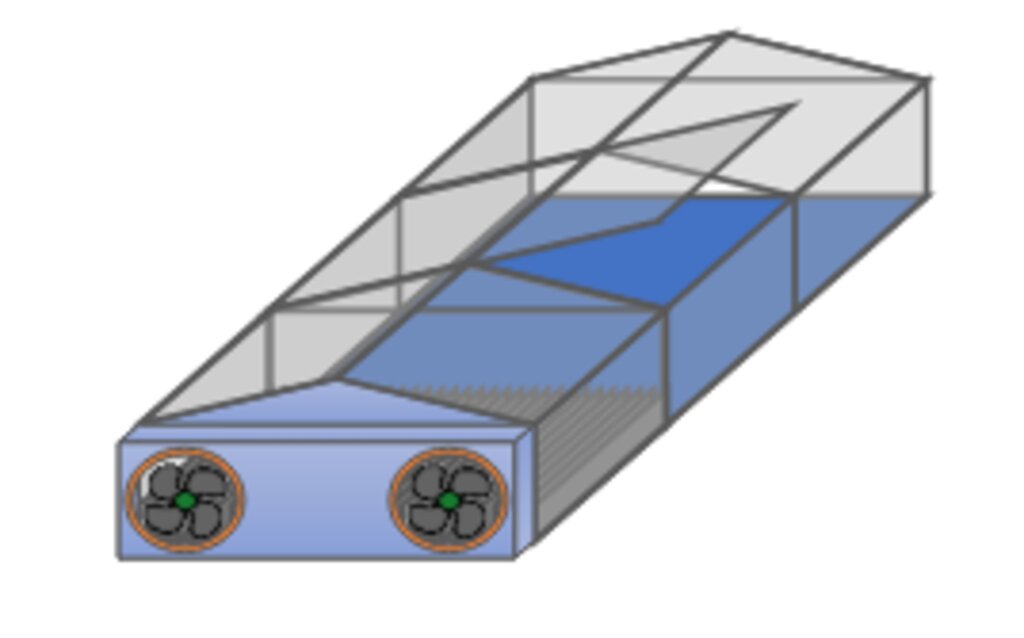

Schematic view of the SMD

Fans blow air to control humidly and temperature. Top windows can be open to store and collect dates, but also for manual control of temperature etc.

Author:

ICARDA

Date:

2022

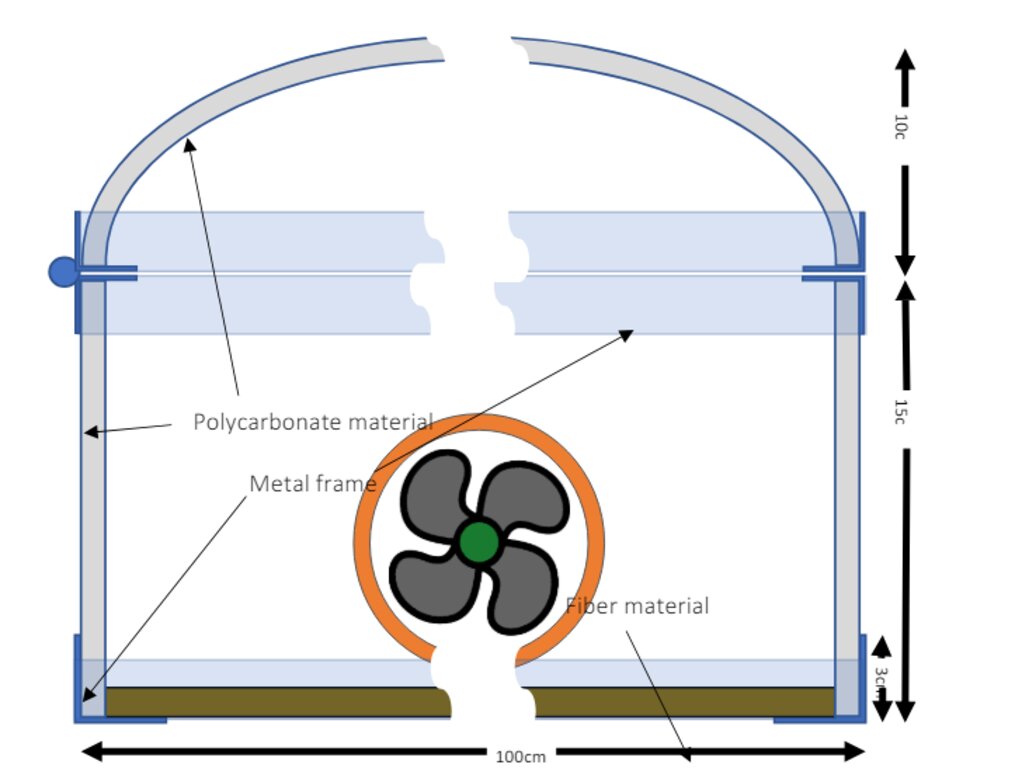

Technical specifications (related to technical drawing):

Side view dimensions of the SMD.

Plastic (poly-carbonate) sheets are held up by an iron frame. The product lay on a plastic net to also support vertical airflow.

Author:

ICARDA

Date:

2022

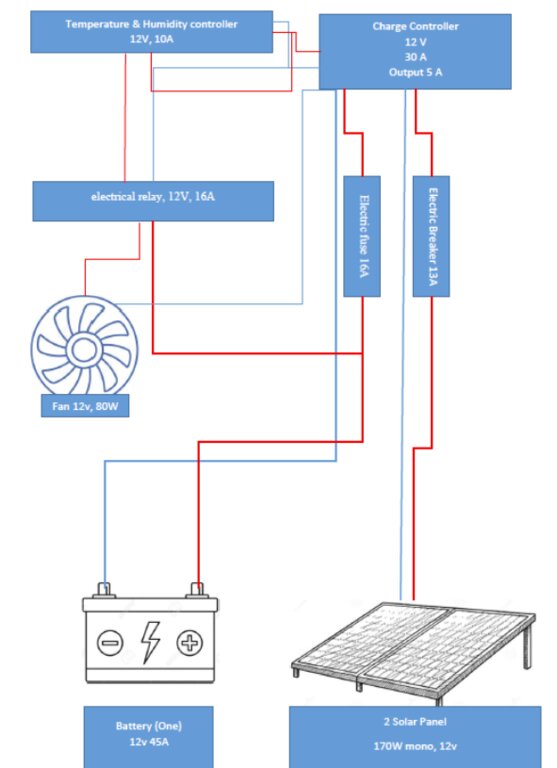

Technical specifications (related to technical drawing):

Technical schematic overview of the SMD

Author:

ICARDA

Date:

2022

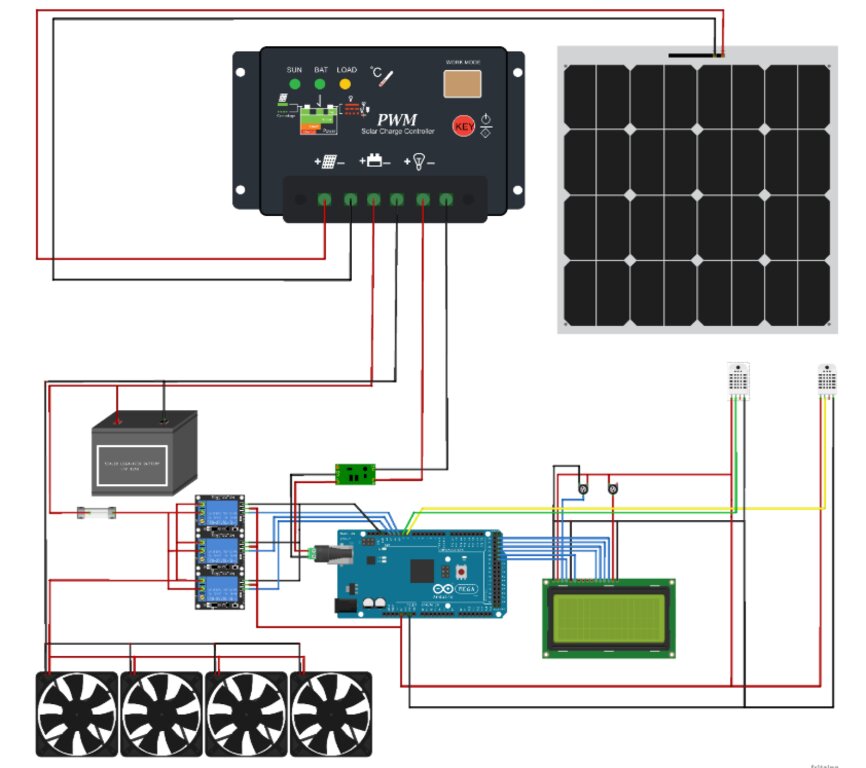

Technical specifications (related to technical drawing):

Electronic parts and connections overview of the SMD

Drawn using Fritzing software, www.fritzing .org

Author:

ICARDA

Date:

2022

Technical specifications (related to technical drawing):

Net Present Value (NPV)

NPV evaluates an investment's profitability by calculating the difference between the present value of cash inflows and outflows. A positive NPV indicates a profitable investment, while a negative NPV signals a potential loss.

Profitability Index (PI)

PI measures the relative profitability of an investment by comparing the present value of future cash inflows to the initial investment. A PI greater than 1 indicates a good investment, whereas a PI less than 1 suggests it may not be viable.

Payback Period (PB)

PB is the time it takes for an investment to recover its initial cost through cash inflows. A shorter PB is preferred as it indicates quicker recovery, though it doesn't account for the time value of money or cash flows after the payback period but provides implication for risk.

Return on Investment (ROI)

ROI assesses the efficiency or profitability of an investment by comparing the net gain to the cost. A higher ROI indicates a more profitable investment.

Benefit-Cost Ratio (BCR)

BCR evaluates the value for money of a project by comparing the present value of benefits to costs. A BCR greater than 1 suggests benefits exceed costs, making the project worthwhile, while a BCR less than 1 indicates the opposite.

Internal Rate of Return (IRR)

IRR is the discount rate at which the NPV of all cash flows from an investment equals zero. If IRR exceeds the required rate of return, the investment is considered good. It's useful for comparing projects.

Author:

ICARDA

Date:

2022

Technical specifications (related to technical drawing):

Schematic drwing of the SMD as used in Jordan

Author:

ICARDA

Date:

2024

4.2 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology unit

Specify currency used for cost calculations:

- USD

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Equipment | Charger control 1 (off grid, 12v 20A) | 1.0 | ||||

| Equipment | Fuse (10A) | 2.0 | ||||

| Equipment | Switch (10A) | 2.0 | ||||

| Equipment | DC relay (16A) | 1.0 | ||||

| Equipment | Sensors (temperature and humidity) | 1.0 | ||||

| Equipment | Arduino micro processor | |||||

| Equipment | LCD screen (2x20) | 1.0 | ||||

| Equipment | DC relay (4 relay module) | 1.0 | ||||

| Construction material | Polycarbonate board (8-10mm) | 2.0 | ||||

| Construction material | Dark fiber board (6mm) | 2.0 | ||||

| Construction material | Metal bars (3cm x 3cm x 10mm) | 20.0 | ||||

| Construction material | Metal bars (2m x 2m) | 10.0 | ||||

| Construction material | Metal hinges (small, <10mm) | 8.0 | ||||

| Construction material | Fan (12v 40-80W) | 1.0 | ||||

| Construction material | Battery (12v 55A) | 1.0 | ||||

| Construction material | Solar panel (170W 12v) | 2.0 | ||||

| Other | Voltage regulator (1-40v) | 1.0 | ||||

| Other | Plastic terminal box (30cm x 40cm) | 1.0 | ||||

| Other | Clock module (5v) | 1.0 | ||||

| Other | SD card module (5v) | 1.0 | ||||

| Other | BCP board | 2.0 | ||||

| Other | Total costs | 1.0 | 1000.0 | 1000.0 | ||

| Total costs for establishment of the Technology | 1000.0 | |||||

| Total costs for establishment of the Technology in USD | 1000.0 | |||||

If you are unable to break down the costs in the table above, give an estimation of the total costs of establishing the Technology:

1000.0

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Other | Maintenance | 1.0 | 250.0 | 250.0 | ||

| Other | Variable (use) cost | 1.0 | 500.0 | 500.0 | ||

| Total costs for maintenance of the Technology | 750.0 | |||||

| Total costs for maintenance of the Technology in USD | 750.0 | |||||

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Material costs for drying such as packaging appeared to be a major cost.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Agro-climatic zone

- semi-arid

- arid

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- not relevant

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Soil texture (> 20 cm below surface):

- medium (loamy, silty)

Topsoil organic matter:

- low (<1%)

5.4 Water availability and quality

Ground water table:

5-50 m

Availability of surface water:

poor/ none

Water quality (untreated):

poor drinking water (treatment required)

Water quality refers to:

both ground and surface water

Is water salinity a problem?

Yes

Is flooding of the area occurring?

No

Comments and further specifications on water quality and quantity:

Because the SMD is mobile and processes the harvest, the natural situation is not that essential. However, ideally, it should be placed in warm and sunny areas.

5.5 Biodiversity

Species diversity:

- low

Habitat diversity:

- low

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

- Semi-nomadic

Market orientation of production system:

- mixed (subsistence/ commercial)

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- poor

Individuals or groups:

- individual/ household

- groups/ community

Level of mechanization:

- manual work

- mechanized/ motorized

Gender:

- men

Age of land users:

- youth

- middle-aged

- elderly

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, not titled

- individual, titled

Land use rights:

- individual

Water use rights:

- individual

Are land use rights based on a traditional legal system?

Yes

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

Comments/ specify:

(Economic) Productivity increases because post-harvest losses decrease and selling prices increase

crop quality

Comments/ specify:

Because of the drying, products are considered higher quality

Income and costs

expenses on agricultural inputs

Comments/ specify:

To reach the higher selling prices additional expenses on the SMD and packaging is required.

farm income

workload

Socio-cultural impacts

food security/ self-sufficiency

Comments/ specify:

Dried products have longer shelf life and less vulnerable to mold and pests.

situation of socially and economically disadvantaged groups

Comments/ specify:

SMD is so designed that it can be easily shared, so that costs for individual smallholder farmers are relatively low.

6.2 Off-site impacts the Technology has shown

impact of greenhouse gases

Comments/ specify:

The SMD only uses solar, so overall less greenhouse gasses are emitted, within the chain, compared to the current situation.

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | very well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

slightly positive

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

very positive

Long-term returns:

very positive

6.5 Adoption of the Technology

- single cases/ experimental

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 0-10%

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

Yes

other (specify):

other inputs

Specify adaptation of the Technology (design, material/ species, etc.):

Experiments are done with other products such as vegetables, fruits, and spices.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| Increased farm income |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Improvement of the fruits’ quality |

| No contamination of dates by insects, birds, dust and rain |

| Energy and drying time saving |

| Waste and loss rate reduction |

| Air pollution and greenhouse gases reduction |

| Multiuse purposes (vegetables, medicinal and aromatic plants-MAPs, etc.) |

| Production of the SMD can result in (local) employment opportunities |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| Drying can be performed only during sunny days unless the system is integrated with a conventional energy-based system | |

| Solar drying process is slow in comparison with dryers that use conventional fuels | The avoidance of costs to fuel may compensate this. |

| Solar drying requires larger land areas and longer drying times | |

| Fluctuations in solar radiation and ambient temperature | |

| Farmers lack of knowledge for the maintenance of the system | Capacity building programme or training when buying the SMD |

7. References and links

7.1 Methods/ sources of information

- interviews with SLM specialists/ experts

- compilation from reports and other existing documentation

7.3 Links to relevant online information

Title/ description:

Boubaker Dhehibi, Muhi El-Dine Hilali, Arash Nejatian. (15/9/2023). Economic and Financial Evaluation of a Low-Cost Portable Solar Dryer for Maturing and Drying of Dates: Business for Development (B4D) Report.

URL:

https://hdl.handle.net/20.500.11766/68749

Title/ description:

Muhi El-Dine Hilali, Arash Nejatian, Abdoul Aziz Niane, Mohamed Ali Bob. (30/11/2023). دليل تصنيع و تشغيل المجفف الشمسي المتنقل. Beirut, Lebanon: International Center for Agricultural Research in the Dry Areas (ICARDA).

URL:

https://hdl.handle.net/20.500.11766/69302

Title/ description:

Muhi El-Dine Hilali, Arash Nejatian. (28/3/2021). Developing solar drier for maturing and drying of dates in the Arabian Peninsula. Lebanon: International Center for Agricultural Research in the Dry Areas (ICARDA).

URL:

https://hdl.handle.net/20.500.11766/12826

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules