Multigrain Nutrient Ball [India]

- Creation:

- Update:

- Compiler: MARIA ROSELIN

- Editors: Nicole Stolz, Boris Orlowsky

- Reviewers: Boris Orlowsky, Alexandra Gavilano, Deborah Niggli

Horlicks Laddoo

technologies_731 - India

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Book project: where people and their land are safer - A Compendium of Good Practices in Disaster Risk Reduction (DRR) (where people and their land are safer)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

CARITAS (Switzerland) - Switzerland1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

1.5 Reference to Questionnaire(s) on SLM Approaches (documented using WOCAT)

Fighting malnutrition by promoting locally produced horlicks (multigrain … [India]

Multigrain nutritional ball to ght malnutrition and improve the health of rural communities especially during and after disasters like floods (and droughts).

- Compiler: MARIA ROSELIN

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Introducing a multigrain flour to prevent malnutrition of rural communities, enhancing community resilience to natural disasters such as floods.

2.2 Detailed description of the Technology

Description:

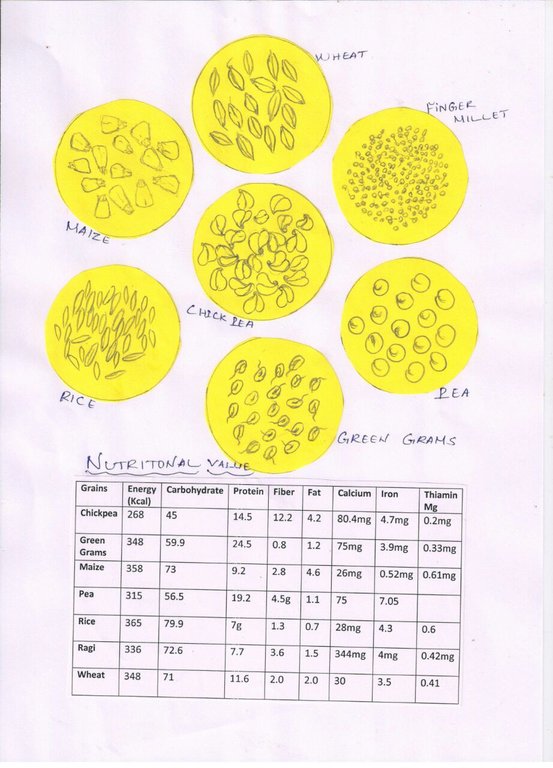

The multigrain flour can be used to produce both "nutritional balls" and "energy drinks". The multi-grain flour is composed of 7 grains, namely raw rice, wheat, finger millet (raggie), green grams, maize, chick pea (channa) and pea. These grains are rich in vitamins and minerals.

Preparation: Equal quantities of the grains of wheat, finger millet (raggie), green grams, maize, channa and pea are soaked seperately in water for 24 hours. After being soaked well, they are tied in a soft wet cotton cloth for 1 or 2 days until sprouts come out of the grain. Once the sprout is out, the grains are dried in the sun and afterwards fried separately one by one. After being fried, the husk is removed from channa, pea and green grams. Finally all grains together are grounded in a grinding mill. Once the flour is ready, as part of the value addition process, ghee and smashed jaggery (unrefined brown sugar made from sugar cane or palm tree) are added and mixed thoroughly. If needed, 100 grams of raisins and cashew nuts can be added to the products for garnishing. After mixing them well, the powder can either be kept as it is or shaped like balls.

The process of dry roasting keeps the nutritional value intact and leads to a longer shelf life. The rich content of vitamins, minerals and carbohydrates makes the nutritional balls particularly valuable for children, adolecent and pregnant women, preventing malnutrition. They are as well suitable for people suffering from diabetics, if consumed without sugar.

The prime objective of the Technology is eliminating anemia among the rural poor, especially among women and children and make them self sufficient. It can also be an additional source of income, once people become aware of the high nutrient level and begin buying the product.

The nutritional ball, locally named "Horlicks laddoo", has a particularly high nutritional value and is promoted to the rural communites in the target villages of the NGO "Nirmal Mahila Kalyan Kendre" (NMKK), especially for women and children. It is also used as an energy drink, especially for children, preventing malnutrition.

2.3 Photos of the Technology

2.4 Videos of the Technology

Comments, short description:

Production of Horlicks Laddoo

Name of videographer:

Ranjan

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

India

Region/ State/ Province:

BIHAR

Further specification of location:

Town - Darbhanga

Specify the spread of the Technology:

- evenly spread over an area

If precise area is not known, indicate approximate area covered:

- 10-100 km2

Comments:

it is spread in villages in different regions of Bihar

Map

×2.6 Date of implementation

Indicate year of implementation:

2003

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

Comments (type of project, etc.):

During the implementation of Community Health Education Development (CHED) project, this Technology was introduced. The CHED project found through village assessment malnutrition as a major problem in the rural community. So in order to reduce malnutrition, workshops and training were organized for the women to introduce this technology.

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- reduce risk of disasters

- mitigate climate change and its impacts

- It helps in prevention of malnutrition among women and children

3.5 SLM group to which the Technology belongs

- post-harvest measures

3.6 SLM measures comprising the Technology

other measures

Comments:

Post harvest conservation technology only indirectly related to land

3.7 Main types of land degradation addressed by the Technology

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- not applicable

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

Ingredients:

Maize - 1Kg

Wheat -1Kg

Green Grams -1Kg

Finger Millet -1Kg

Rice - 1Kg

Chick pea -1Kg

Pea - 1Kg

Glucose powder - 500gm

Jaggery (unrefined brown sugar made out of sugar cane or palm tree) -3 Kg

For preparation instructions, refer to the main description.

Author:

Sr. Roselin

Date:

09/01/2017

4.2 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology unit

Specify unit:

8Kg of nutritious multi-grain flower

other/ national currency (specify):

Rupees

If relevant, indicate exchange rate from USD to local currency (e.g. 1 USD = 79.9 Brazilian Real): 1 USD =:

67.0

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Preparation of the food balls | whenever |

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Grinding Charge | 1Kg | 8.0 | 5.0 | 40.0 | 100.0 |

| Equipment | Vessels | 8 | 8.0 | 120.0 | 960.0 | 100.0 |

| Equipment | Cotton Cloth | 7Pcs | 4.0 | 148.0 | 592.0 | 100.0 |

| Equipment | Tharpolin | 1Pc | 1.0 | 1500.0 | 1500.0 | 100.0 |

| Plant material | Pulses (Chick Pea,Pea,Green grams) | 3Kg | 3.0 | 120.0 | 360.0 | 100.0 |

| Plant material | Grains (Wheat,Maize, Ragi,Rice) | 4Kg | 3.0 | 30.0 | 90.0 | 100.0 |

| Plant material | Packing Polythin | 1Kg | 1.0 | 200.0 | 200.0 | 100.0 |

| Total costs for establishment of the Technology | 3742.0 | |||||

| Total costs for establishment of the Technology in USD | 55.85 | |||||

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Investment costs

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specify average annual rainfall (if known), in mm:

1142.30

Agro-climatic zone

- sub-humid

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- not relevant

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Soil texture (> 20 cm below surface):

- fine/ heavy (clay)

Topsoil organic matter:

- high (>3%)

5.4 Water availability and quality

Ground water table:

5-50 m

Availability of surface water:

excess

Water quality (untreated):

poor drinking water (treatment required)

Is water salinity a problem?

No

Is flooding of the area occurring?

Yes

5.5 Biodiversity

Species diversity:

- low

Habitat diversity:

- high

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- subsistence (self-supply)

Off-farm income:

- less than 10% of all income

Relative level of wealth:

- very poor

Individuals or groups:

- individual/ household

Level of mechanization:

- manual work

Gender:

- women

Age of land users:

- middle-aged

- elderly

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

Comments:

Women were preparing multigrain nutrient flour at small scale for the family use.

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, not titled

- individual, titled

Land use rights:

- leased

- individual

Water use rights:

- leased

- individual

5.9 Access to services and infrastructure

technical assistance:

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Income and costs

diversity of income sources

Socio-cultural impacts

health situation

Ecological impacts

Climate and disaster risk reduction

flood impacts

6.2 Off-site impacts the Technology has shown

Improved health condition of women and children

Specify assessment of off-site impacts (measurements):

Improved health condition of women and children

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Comments:

not applicable

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

positive

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

positive

Long-term returns:

positive

6.5 Adoption of the Technology

- 11-50%

If available, quantify (no. of households and/ or area covered):

100HHs -200HHs

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 91-100%

Comments:

For some years, this technology was adopted by the health network leaders who applied it in their daily diet whenever necessary.

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

No

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

|

1. Multi grain nutrient ball is particularly meant for pregnant women and lactacting mother 2. It helps to fight against malnutrition of children 3. It is rich in vitamins , minerals and energy 4. It keeps the body cool and prevents indigestion, too 5. During disaster situations, especially floods, this will serve as a balanced nutrition 6. It can also be consumed by persons with diabetic as a porridge |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

|

1. This can be included in the regular diet of rural women and children as they are suffering from anemia and undernourishment 2. It can provide alternative income generation, e.g. when improving the product with little investment 3. It can be included in the flood preparedness list of dry foods and utilized during flood |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

|

1. People prefer horlicks from market over homemade horlicks due to ecessive time requirement of the preparation 2. Drastic price increase of grains especially for pulses in recent years in India 3. Ignorance of nutritional value of the product 4. Low appreciation of local products |

1. Awareness raising within the community regarding the technology 2. Grain and pulses that are produced by the health network leaders can be exchanged within the networks or sold at moderate rates 3. Some success stories /case studies have to be made visible to the community regarding the benefits of Horlicks laddoo 4. Training on Entrepreneurship must be given to the women |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

|

1. People do not want to try it / practice it 2. Marketing availability is one of the key issue 3. Lack of Business orientation among the women |

1. Group of interested women has to be motivated to initiate this technology 2. Organization must facilitate market availability till the product gets public attraction 3. Women must be given Entrepreneurial skill |

7. References and links

7.1 Methods/ sources of information

- interviews with land users

15

- interviews with SLM specialists/ experts

4

When were the data compiled (in the field)?

02/11/2016

Links and modules

Expand all Collapse allLinks

Fighting malnutrition by promoting locally produced horlicks (multigrain … [India]

Multigrain nutritional ball to ght malnutrition and improve the health of rural communities especially during and after disasters like floods (and droughts).

- Compiler: MARIA ROSELIN

Modules

No modules