Gravity Irrigation for enhancing Community-Based Restoration efforts in the degraded forests of Paktya [Afghanistan]

- Creation:

- Update:

- Compiler: Mohammad Wazir Ahmadzai

- Editors: Mir Wali Khan Lakanwal, Mohammad Mustafa Sahebzada, Mohammad Ajmal Rahimy

- Reviewers: Rima Mekdaschi Studer, Illias Animon, Muhammad Ishaq Safi, Megha bajaj

Obu Zakhira

technologies_7481 - Afghanistan

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Community-based sustainable land and forest management in AfghanistanName of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

FAO Afghanistan (FAO Afghanistan) - Afghanistan1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

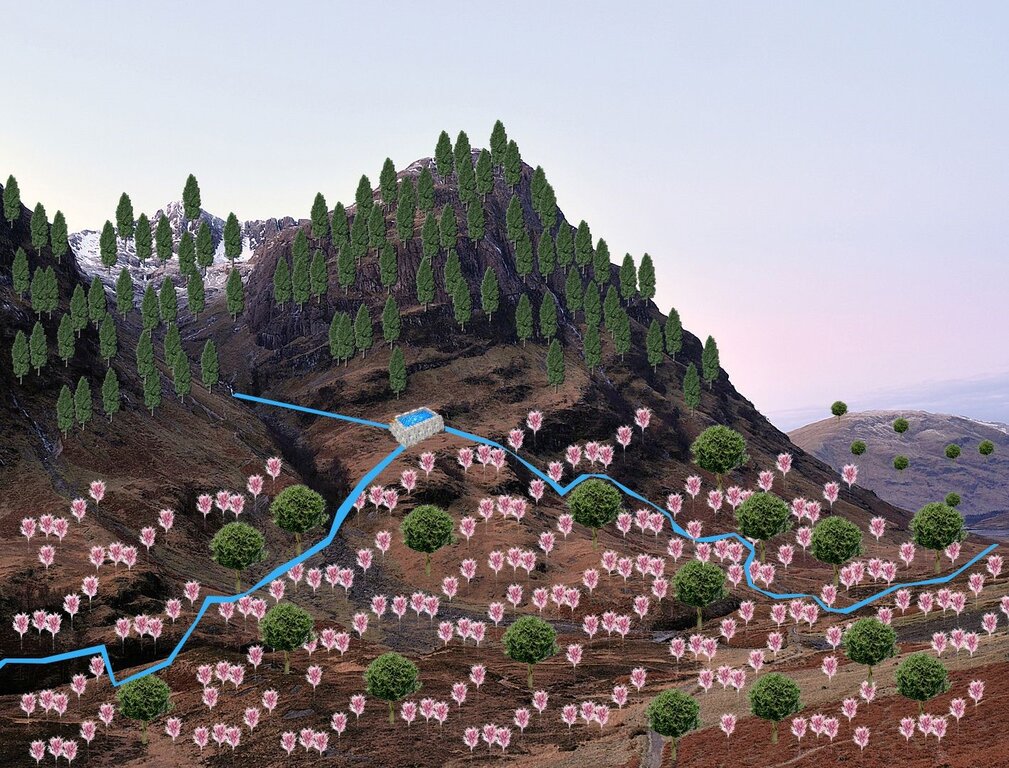

Using a gravity-irrigation system, spring water is diverted to fill reservoirs and then distributed to fields for the restoration of degraded forest areas, with the active involvement of local communities and a focus on the sustainable use of water resources (spring water).

2.2 Detailed description of the Technology

Description:

The Paktya province in Afghanistan, known for its mountainous terrain and rich forests of pine nuts deodar, cedar, and conifers, faces severe challenges. Most water in the province comes from rivers, springs, and tube wells, with high mountains acting as natural reservoirs. Unfortunately, many traditional water sources have been destroyed over decades of conflict and natural drought, forcing farmers to rely on costly tube wells for irrigation.

To support sustainable water management in the mountainous areas of Ahmad Aba and Sayed Karam districts, 60 water reservoirs with a total storage capacity of 6,000 m³ were constructed. The volume of individual reservoirs varies depending on the availability and flow of upstream spring water ranging from 36 m³ to 192 m³.

Water is diverted from a small intake near the source and delivered to the reservoir inlet through a 2-inch Polyvinyl Chloride (PVC) pipe. For irrigation of the restored areas, the outlets from the reservoirs are connected to 1-inch PVC pipes for distributing water to various plantation sites.

This technology is applied in a natural environment and is designed to support environmental sustainability by recharging the groundwater table, as water is harvested into reservoirs, it can infiltrate through the side walls and bottom. This percolation process contributes to the natural hydrological cycle, harvesting surplus water (water evaporate or percolating into atmosphere or soil) into reservoirs for irrigation of planted saplings, and extending existing forest boundaries.

The system enables the local community to sustainably manage and utilize spring water for gravity-based irrigation of restored areas, while also supporting the expansion of forested land through sapling plantation.

Before constructing the reservoirs, a feasibility survey of the water source (the spring) was conducted to verify the perennial availability of water and to determine the optimal distance between the spring and the designated reforestation sites. The preliminary selection of reservoir locations was based on key criteria including the year-round reliability of the water source, the size of the target reforestation area, and the discharge capacity of the spring. Excavation of the rocky mountain earth was carried out using a hand excavator as per the specified requirements as per technical drawing and approved design. The stone masonry work was completed using random rubble coursed stone with a cement-sand mortar mix (1:2, Type A). As per the design, Plain Cement Concrete (PCC M20) was applied to the top of the stone masonry and on all floors of the reservoirs. A 20 mm thick plastering was carried out on the internal walls using cement-sand mix (1:2). The external walls were backfilled to a height of 1.5 meters.

The benefits of this gravity-fed irrigation technique include increased reforestation rates, reduced water loss due to evaporation and runoff, achieved by using closed piping systems instead of open channels, and improved water use efficiency. These improvements have led to higher sapling survival rates and better growth. Overall, the socio-economic and environmental conditions of rural populations have been improved. Additionally, the implementation of the gravity irrigation system has reduced the cost of restoring degraded forests.

As a low-cost, environmentally friendly technology, it allows for the efficient harvesting of spring water for irrigation, supports sapling planting for carbon sequestration, and helps mitigate the severe impacts of climate change.

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Afghanistan

Region/ State/ Province:

Paktya

Further specification of location:

Ahamd Aba and Sayed Karam district

Specify the spread of the Technology:

- evenly spread over an area

Is/are the technology site(s) located in a permanently protected area?

Yes

Comments:

The technology being applied in various location of forest areas, while in the map only two points highlighted in Ahmad Aba and Sayed Karam district of Paktya

However, 46 water reservoirs constructed in Sayed Karam, while 14 water reservoirs constructed in Ahmad Ab

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- reduce, prevent, restore land degradation

- conserve ecosystem

- protect a watershed/ downstream areas – in combination with other Technologies

- preserve/ improve biodiversity

- mitigate climate change and its impacts

- create beneficial economic impact

- create beneficial social impact

3.2 Current land use type(s) where the Technology is applied

Land use mixed within the same land unit:

No

Forest/ woodlands

- Tree plantation, afforestation

Tree plantation, afforestation: Specify origin and composition of species:

- Monoculture local variety

Type of tree plantation, afforestation:

- subtropical dry forest plantation - Pinus spp.

Type of tree:

- Pinus species

Are the trees specified above deciduous or evergreen?

- mixed deciduous/ evergreen

Products and services:

- Timber

- Fuelwood

- Fruits and nuts

3.3 Has land use changed due to the implementation of the Technology?

Has land use changed due to the implementation of the Technology?

- No (Continue with question 3.4)

Land use mixed within the same land unit:

No

Waterways, waterbodies, wetlands

Comments:

With the implementation of the technology, degraded land has been restored to forested areas through reforestation.

3.4 Water supply

Water supply for the land on which the Technology is applied:

- full irrigation

3.5 SLM group to which the Technology belongs

- forest plantation management

- irrigation management (incl. water supply, drainage)

- surface water management (spring, river, lakes, sea)

3.6 SLM measures comprising the Technology

structural measures

- S5: Dams, pans, ponds

3.7 Main types of land degradation addressed by the Technology

soil erosion by water

- Wt: loss of topsoil/ surface erosion

- Wg: gully erosion/ gullying

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- reduce land degradation

4. Technical specifications, implementation activities, inputs, and costs

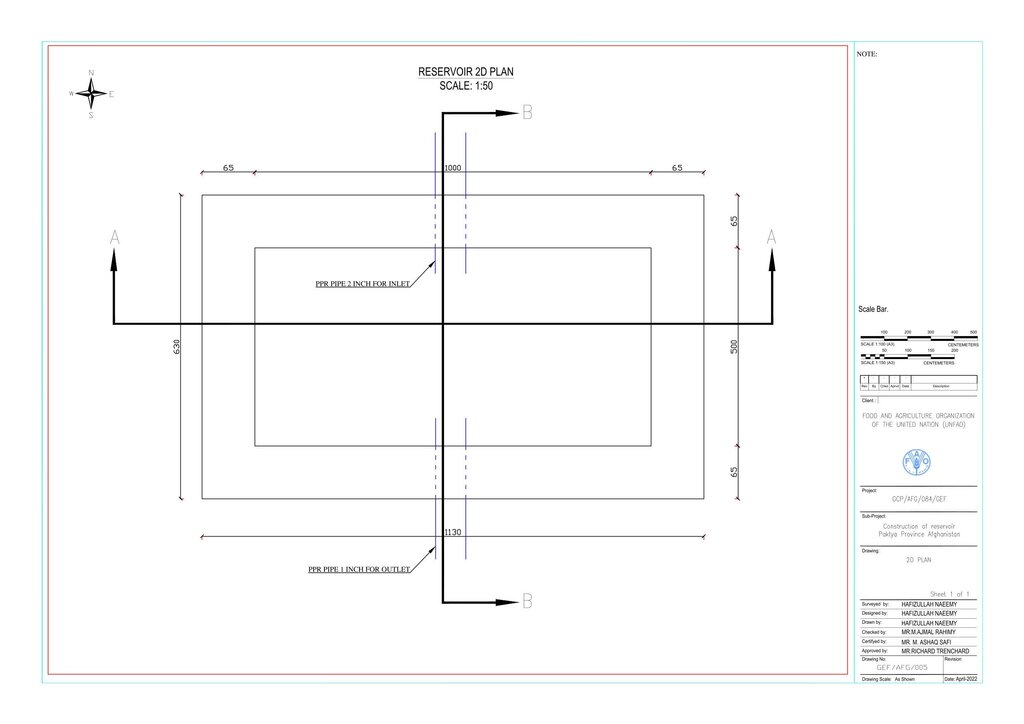

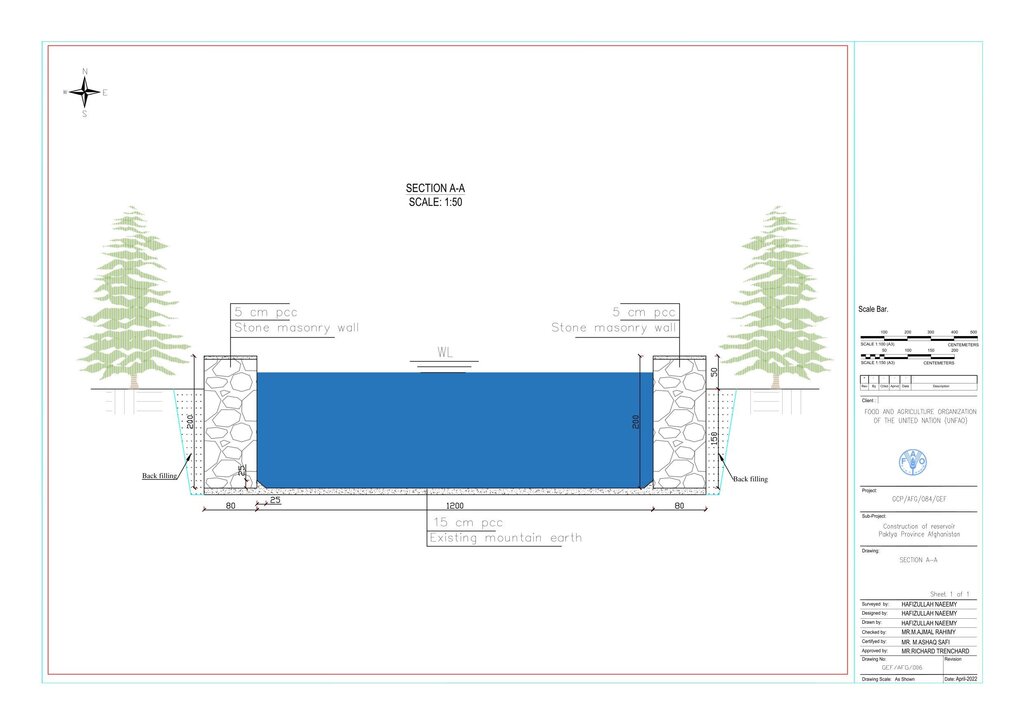

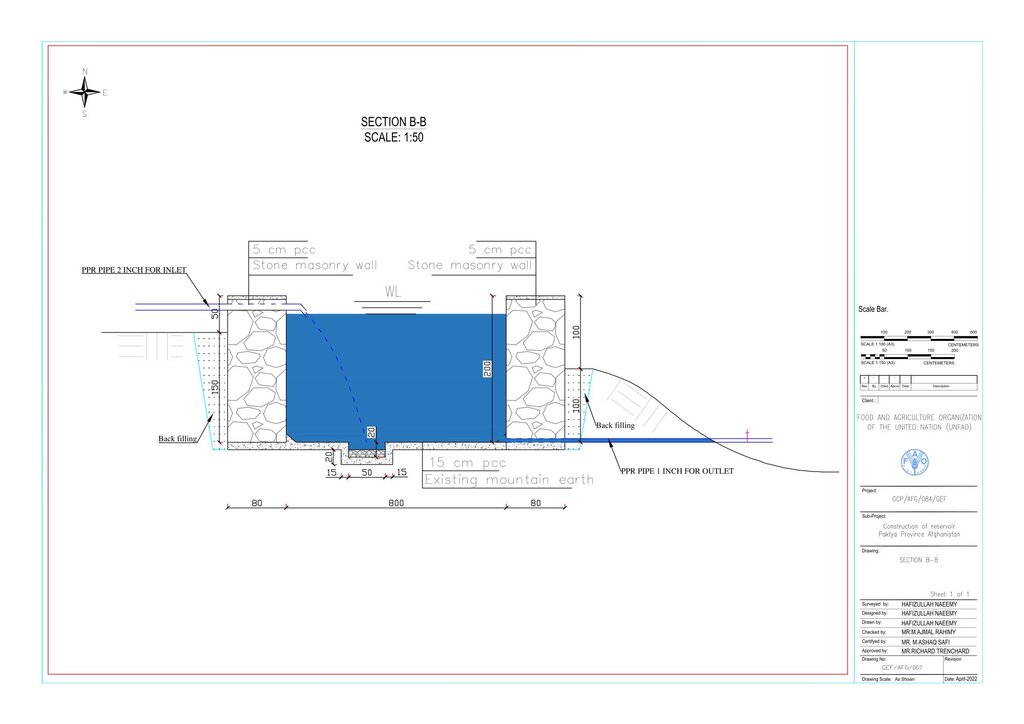

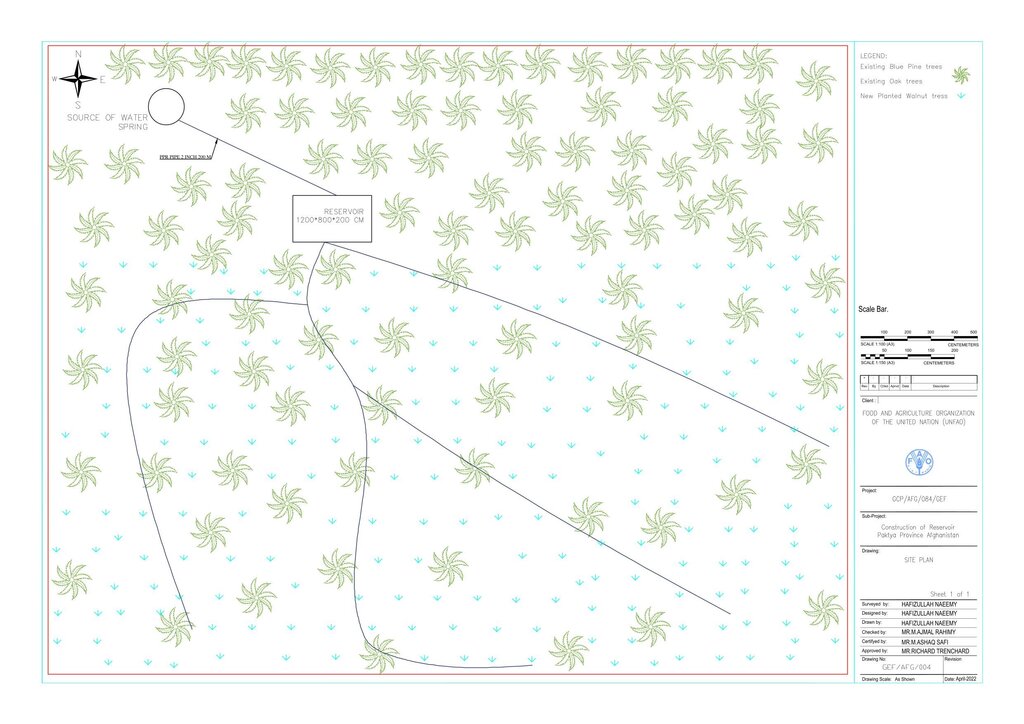

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

Technical drawing: indicated the details of the dimension of water reservoirs

Author:

Hafizullah Neemy

Date:

30/03/2022

Technical specifications (related to technical drawing):

Technical drawing

Author:

Hafizullah Neemy

Date:

23/03/2022

Technical specifications (related to technical drawing):

Technical drawing

Author:

Hafizullah Neemy

Date:

30/03/2022

Technical specifications (related to technical drawing):

Drawing

Author:

Hafizullah Neemy

Date:

30/03/2022

4.2 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology area

Specify currency used for cost calculations:

- USD

Indicate average wage cost of hired labour per day:

5

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Excavation to build reservoirs | When construction work is possible |

| 2. | Back filling of all outside of reservoir through soil | After construction the reservoir |

| 3. | Stone masonry using random rubble coursed stone, laid with a cement-sand mortar mix of 1:2 (Type A) | When construction work is possible |

| 4. | Plain Cement Concrete (PCC) M20 with formwork and waterproof compound applied under and on top of the stone masonry, as well as on the reservoir floor | When construction work is possible |

| 5. | Plastering of internal reservoir wall with cement sand (mix 1:2), 20 mm thick | When construction work is possible |

| 6. | Installation of pipes; 1 and 2 inch with elbow, joints , and connectors and valves for fitting in outlet and inlet area of reservoir | After construction work |

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Excavation to build the reservoris | M3 | 62.0 | 10.0 | 620.0 | |

| Labour | Stone masonry using random rubble coursed stone, laid with a cement-sand mortar mix of 1:2 (Type A) | M3 | 23.0 | 14.0 | 322.0 | |

| Labour | Plain Cement Concrete (PCC) M20 with formwork and waterproof compound applied under and on top of the stone masonry, as well as on the reservoir floor | M3 | 6.0 | 14.0 | 84.0 | |

| Labour | Plastering of internal reservoir wall with cement sand (mix 1:2), 20 mm thick | M3 | 42.0 | 14.0 | 588.0 | |

| Labour | Back filling of all outside of reservoir through soil | Man-days | 5.0 | 5.0 | 25.0 | |

| Labour | Installation of pipes; 1 and 2 inch with elbow, joints , and connectors and valves for fitting in outlet and inlet area of reservoir | Man-days | 8.0 | 5.0 | 40.0 | |

| Equipment | Shovel | PC | 5.0 | 5.0 | 25.0 | |

| Equipment | Hammer | PC | 2.0 | 10.0 | 20.0 | |

| Equipment | Excavator (taking by rent for excavation) | Cubic meter cost | 192.0 | 10.0 | 1920.0 | |

| Construction material | Cement | Package | 75.0 | 6.0 | 450.0 | |

| Construction material | Stone | Cubic meters | 23.0 | 14.0 | 322.0 | |

| Construction material | Polyethelen pipe 1 inch | Meter | 500.0 | 0.8 | 400.0 | |

| Construction material | Polyethelen pipe 2 inch | Meter | 200.0 | 1.0 | 200.0 | |

| Construction material | Elbow joint | Piece | 3.0 | 1.0 | 3.0 | |

| Construction material | Valves | Piece | 4.0 | 4.0 | 16.0 | |

| Construction material | Sand | Cumbic meter | 20.0 | 5.0 | 100.0 | |

| Other | Transportation | LS | 1.0 | 700.0 | 700.0 | |

| Total costs for establishment of the Technology | 5835.0 | |||||

| Total costs for establishment of the Technology in USD | 5835.0 | |||||

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Installation of pipes to outlet and inlet area of water reservoir | Spring season |

| 2. | Maintenance of reservoir for clearing and unclogging the inlet area | As per requirement |

| 3. | Replacement and installation of valves and elbow joints to prevent water clogging in the pipes | During non-function |

| 4. | The embankment constructed to accumulate the water and put the pipes inside to water for diverting to the reservoir | Spring season |

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour for repairing of pipes at outlet and valves | Person | 1.0 | 100.0 | 100.0 | 100.0 |

| Labour | Labour for clearing and unclogging | Person | 1.0 | 50.0 | 50.0 | 100.0 |

| Construction material | Valves | PC | 5.0 | 3.0 | 15.0 | 100.0 |

| Construction material | Elbow joint | Pc | 5.0 | 1.0 | 5.0 | 100.0 |

| Total costs for maintenance of the Technology | 170.0 | |||||

| Total costs for maintenance of the Technology in USD | 170.0 | |||||

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

The distance between the spring and reservoir can affect the total cost of technology

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specify average annual rainfall (if known), in mm:

553.00

Agro-climatic zone

- semi-arid

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- convex situations

Comments and further specifications on topography:

The construction site is situated at an elevation of 2500-3000 meters above sea level, with a terrain slope ranging from 15% to 20%. Photo related to field skitch, indicated that the area of reforestation is around the reservoir.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- coarse/ light (sandy)

- medium (loamy, silty)

Soil texture (> 20 cm below surface):

- medium (loamy, silty)

Topsoil organic matter:

- medium (1-3%)

5.4 Water availability and quality

Ground water table:

< 5 m

Availability of surface water:

excess

Water quality (untreated):

good drinking water

Water quality refers to:

both ground and surface water

Comments and further specifications on water quality and quantity:

As the water from spring harvesting through pipes and accumulated in reservoirs can reduced the evaporation and stored for 2 or 3 days in reservoirs that can excess the water quantity for irrigation purposes.

5.5 Biodiversity

Species diversity:

- medium

Habitat diversity:

- low

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- poor

- average

Individuals or groups:

- individual/ household

Level of mechanization:

- manual work

- animal traction

Gender:

- women

- men

Age of land users:

- youth

- middle-aged

- elderly

Indicate other relevant characteristics of the land users:

All age group excluding children

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

- medium-scale

Comments:

The small-scale covered the reforestation areas about 10 ha for irrigation, while the medium scale covered about 20 ha for irrigation purposes.

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- communal/ village

Land use rights:

- communal (organized)

Water use rights:

- communal (organized)

Comments:

The water reservoirs were constructed on communal land for use by the local community, allowing shared access for irrigating reforested areas. Access and use are managed through a community-agreed contribution system.

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

wood production

Comments/ specify:

The establishment of woodlots and other forest can increase the fuel wood for heating the house and cooking, fodder for livestock and fruit for home consumption. The established woodlots consist of a mix of fruit and non-fruit tree species.

non-wood forest production

Comments/ specify:

The non-wood forest productions increased with increasing the area of production through gravity irrigation systems enhanced the community-based efforts in degraded forest.

production area

Comments/ specify:

The production areas of NTFPs have expanded due to the annual planting of saplings in degraded forest areas, supported by water reservoirs that provide irrigation and enable the extension of existing forest boundaries.

Water availability and quality

irrigation water availability

Comments/ specify:

The irrigation water availability has improved due to efficient management of the spring water. As the spring water gradually decreases from June to December months which considered as dry period, while January to March months is the wettest period that water is excessive and can be harvested for the following dry period.

demand for irrigation water

Comments/ specify:

As the construction of water reservoirs can significantly improve the water availability during the year both in the wettest period and followed by dry period, by storing the water can balance the demand for the irrigation water.

Income and costs

diversity of income sources

Comments/ specify:

Households living in rural areas rely on income from non-timber forest products (NTFPs) and agricultural production, resulting in a diversification of their income sources.

workload

Comments/ specify:

the workload for the irrigation of reforestation areas reduced with application of technology because the number of days for irrigation done manually reduced and also the cost of irrigation.

Socio-cultural impacts

food security/ self-sufficiency

Vegetation Cover

Comments/ specify:

Vegetation cover has improved each year due to ongoing tree planting and the protection of designated areas through quarantine measures.

Ecological impacts

Water cycle/ runoff

water quantity

harvesting/ collection of water

Soil

soil moisture

soil cover

soil accumulation

soil crusting/ sealing

soil compaction

nutrient cycling/ recharge

soil organic matter/ below ground C

Biodiversity: vegetation, animals

Vegetation cover

Climate and disaster risk reduction

flood impacts

drought impacts

emission of carbon and greenhouse gases

micro-climate

6.2 Off-site impacts the Technology has shown

water availability

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| seasonal temperature | summer | decrease | very well |

| annual rainfall | increase | moderately | |

| seasonal rainfall | spring | increase | very well |

Comments:

The forest function for the regulating of climate, rainfall and snowfall. By increasing the forest cover that can help in regulating the annual rainfall.

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

positive

Long-term returns:

slightly positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

slightly positive

Long-term returns:

positive

6.5 Adoption of the Technology

- 1-10%

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 0-10%

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

Yes

If yes, indicate to which changing conditions it was adapted:

- climatic change/ extremes

Specify adaptation of the Technology (design, material/ species, etc.):

The technology adapted well to reduce the severe impacts of the water on the plant growth and development during water scarity situation in summer.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| The technology is cost-effective for irrigating afforested areas and is easy to use and conducive to implementation. |

| The workload for irrigating the afforested area has been reduced, resulting in fewer man-days required for irrigation. |

| The harvesting of water from ground spring allows to expand the forest area through plantation of saplings, otherwise it not possible. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| The sustainable management of ground water spring contributed to the expansion of restoration efforts in the community level. |

| By implementation of technology at specific point, the soil vegetation cover improved from 10 to 15 percent. |

| The biodiversity enhanced with restoration of degraded forest area, through plantation of native species, regeneration of native bushes, grasses. |

| The unproductive soil converted into productive soil through plantation of bio energy plants to produce fuel wood, fodder and fruit. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| Initial capital for construction of water reservoir. | Government should provide subsidy for construction of reservoir. |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| Communities' willingness and technical knowledge for the resource management depends on the component of the project . | Providing supporting from the government side for establishment and technical knowledge. |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

Sixty field visits were conducted to assess the constructed water systems.

- interviews with land users

Four land users interviewed using SLM technology questionnaire.

- interviews with SLM specialists/ experts

Two SLM specialists were interviewed to gather their insights on aspects of the project.

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules