Low-Pressure Irrigation System ‘Californian’ [Senegal]

- Creation:

- Update:

- Compiler: Julie Zähringer

- Editor: –

- Reviewers: Alexandra Gavilano, Fabian Ottiger

technologies_946 - Senegal

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Book project: SLM in Practice - Guidelines and Best Practices for Sub-Saharan Africa (SLM in Practice)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Food and Agriculture Organization of the United Nations (FAO) - Italy1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

The low pressure pipe distribution system called ‘Californian’ has proven to be a very efficient irrigation system for small-holder farmers group in Africa.

2.2 Detailed description of the Technology

Description:

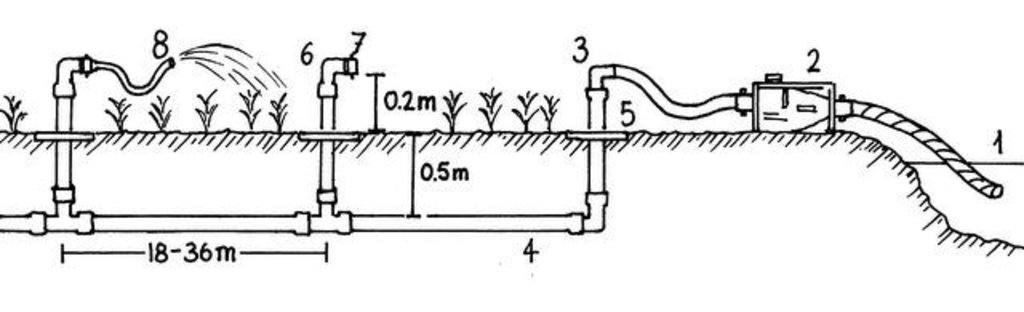

The principle of the Californian system is to convey water to the crops through fixed underground rigid PVC pipes (40–75 mm diameter). The pipe network is buried at 0.50 m depth to avoid deterioration by UV radiation and agricultural practices. Risers with hydrants are fixed to those rigid pipes at regular distance (18-36 m). To each riser a 14 m long flexible hose is attached which can be dragged around to irrigate the individual plots and crops. The installation of the pipe network can be made locally by plumbers. Water is supplied through a pump (manual, pedal or small motor) from a well, a reservoir or a river. From the intake water is conveyed to the highest point of the plot which allows the conveyance to the field’s most distant point (irrespective of topographical conditions - upslope or downslope).

The system is remarkably efficient in sandy or salty soils. It is adapted to small–scale farming especially for vegetable crops, rice and tree crops and is suitable for areas ranging between 0.25 - 1 ha; one riser irrigates an area of 500-1000 m2. The system as such does not require maintenance. In case of deterioration of pipes or fittings, the farmer can easily fix the problem himself or with the assistance of a local plumber. The estimated life expectancy for the Californian system is 6-10 years in West African conditions. Ideal conditions for transfer / adoption of the technology include: (1) Availability of shallow aquifers, and other water sources; (2) Occurrence of sandy soils and sandy clay soils; (3) Clearly defined land legislation and tenure; (4) Access to markets and to microfinance institutions.

Establishment / maintenance activities and inputs: Establishment activities for this technology are the following: 1. Layout of pipe network by putting stakes along the line to indicate the orientation of the canal to be dug. 2. Excavate network of canals (0.2 m wide, 0.5 m deep; straight and regular). In sandy soil the interval between risers is 30m x 18m or 36m x 18m (intervals are multiples of 6 m = PVC pipe unit length). Density of risers is 10 -15 risers / ha.

3. Install the pipes into the open canals, fittings are assembled by sticking. 4.Install hydrants composed by a 0.2 m high riser, a PVC elbow and a locally made flow control device (plug); the risers are anchored in the soil through a small concrete slab.

5. Put the pipe under flow condition to verify the water tightness of the system. 6. Bury the canals. 7. Protect risers from sun. Regarding maintenance of the system the following is important: 1.Before starting to pump it is recommended to let open one of the hydrants in order to avoid excessive pressure and blasting of pipes. 2. In case of deterioration of the pipes or fittings, land users can easily fx the problem themselves or request the intervention of a local plumber.

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Senegal

Region/ State/ Province:

Diourbel

Further specification of location:

Diourbel, Baba garage village

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- reduce, prevent, restore land degradation

- create beneficial economic impact

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

3.4 Water supply

Water supply for the land on which the Technology is applied:

- rainfed

3.5 SLM group to which the Technology belongs

- irrigation management (incl. water supply, drainage)

- water diversion and drainage

3.6 SLM measures comprising the Technology

agronomic measures

- A7: Others

3.7 Main types of land degradation addressed by the Technology

water degradation

- Hg: change in groundwater/aquifer level

Comments:

Main type of degradation addressed: Hg: change in groundwater / aquifer level

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

Dimensions and main components of the low-pressure irrigation system: (1) water source; (2) manual or motor pump; (3) input hydrant; (4) rigid PVC pipes; (5) small concrete slab; (6) elbow; (7) plug; (8) flexible hose for irrigation

Technical knowledge required for field staff / advisors: high (Technical assistance needed for design, installation and operation of the system; installation of pipes is quick and easy; no need for topographical survey)

Technical knowledge required for land users: high

Main technical functions: water harvesting / increase water supply, water spreading

Agronomic measure: low pressure irrigation

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Layout of pipe network by putting stakes along the line to indicate the orientation of the canal | |

| 2. | Excavate network of canals (0.2 m wide, 0.5 m deep; straight and regular). In sandy soil the inte | |

| 3. | Install the pipes into the open canals, fittings are assembled by sticking | |

| 4. | Install hydrants composed by a 0.2 m high riser, a PVC elbow and a locally made flow control devi | |

| 5. | Put the pipe under flow condition to verify the water tightness of the system | |

| 6. | Bury the canals | |

| 7. | Protect risers from sun |

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour | ha | 1.0 | 50.0 | 50.0 | |

| Construction material | None | None | ||||

| Construction material | PVC | ha | 1.0 | 1333.0 | 1333.0 | |

| Total costs for establishment of the Technology | 1383.0 | |||||

| Total costs for establishment of the Technology in USD | 1383.0 | |||||

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Before starting to pump it is recommended to let open one of the hydrants in order to avoid excessive pressure and blasting of pipes | |

| 2. | In case of deterioration of the pipes or fittings, land users can easily fix the problem themselves or request the intervention of a local plumber |

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

If soil is not sandy labour input for establishment increases. Hand or treadle pumps are provided by the project. Motor pumps (with pump capacity 2 HP) increase costs for establishment and maintenance (fuel) but reduce labour inputs for operation.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specify average annual rainfall (if known), in mm:

450.00

Specifications/ comments on rainfall:

9 months dry period

Agro-climatic zone

- semi-arid

Thermal climate class: tropics

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- coarse/ light (sandy)

Topsoil organic matter:

- low (<1%)

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

Soil fertility: Low

Soil drainage/infiltration: Good

Soil water storage capacity: Low

5.4 Water availability and quality

Availability of surface water:

good

5.6 Characteristics of land users applying the Technology

Market orientation of production system:

- mixed (subsistence/ commercial)

Individuals or groups:

- individual/ household

Level of mechanization:

- manual work

- animal traction

Indicate other relevant characteristics of the land users:

Land users applying the Technology are mainly disadvantaged land users

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

Comments:

Average is 0.5 ha

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, titled

Land use rights:

- individual

Comments:

Strong local leadership, long term land use rights and external funding or access to microfinance institutions are preconditions

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

risk of production failure

product diversity

production area

Quantity before SLM:

0.1

Quantity after SLM:

2

Comments/ specify:

ha per farmer group

Water availability and quality

drinking water availability

Quantity before SLM:

< 10

Quantity after SLM:

20

Comments/ specify:

l / person-days

Income and costs

farm income

Socio-cultural impacts

food security/ self-sufficiency

health situation

cultural opportunities

Comments/ specify:

pilgrimage to Mecca, marriages et.

community institutions

SLM/ land degradation knowledge

Comments/ specify:

group management of irrigation facilities

situation of socially and economically disadvantaged groups

Ecological impacts

Water cycle/ runoff

water quantity

water quality

surface runoff

Soil

soil moisture

soil cover

salinity

Biodiversity: vegetation, animals

biomass/ above ground C

plant diversity

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | well |

Climate-related extremes (disasters)

Meteorological disasters

| How does the Technology cope with it? | |

|---|---|

| local rainstorm | well |

| local windstorm | well |

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | well |

Hydrological disasters

| How does the Technology cope with it? | |

|---|---|

| general (river) flood | well |

Other climate-related consequences

Other climate-related consequences

| How does the Technology cope with it? | |

|---|---|

| reduced growing period | well |

Comments:

High tolerance as long as water source is not depleted

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

positive

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

positive

Long-term returns:

positive

Comments:

The estimated life expectancy for the Californian system is 6-10 years in the West African conditions

6.5 Adoption of the Technology

Comments:

468 land user families have adopted the Technology with external material support

There is a strong trend towards spontaneous adoption of the Technology

Comments on adoption trend: There is high demand for the technology. Full participation of stakeholders in the whole project process and the involvement of local leaders, local NGOs and private companies are pre¬requisites for successful implementation

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| Initial investment cost of construction material and equipments | |

| Breakage of riser pipes | |

| Scarcity of surface water resources, poor water quality due to salinity, low water discharge from the shallow wells and boreholes limit the applicability of the technology | |

| Lack of farmers knowledge on irrigation techniques and lack of qualified personnel for training and supervision hinder successful implementation |

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules