Wooden water reservoir for rain water harvesting. [Uganda]

- Creation:

- Update:

- Compiler: Aine Amon

- Editor: Kamugisha Rick Nelson

- Reviewers: Nicole Harari, Udo Höggel

Okutagila amizi aha ibati

technologies_3301 - Uganda

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

land user:

Kabanda Deo

Mubende, Mubende Municipality

Uganda

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Scaling-up SLM practices by smallholder farmers (IFAD)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

National Agricultural Research Organisation (NARO) - Uganda1.3 Conditions regarding the use of data documented through WOCAT

When were the data compiled (in the field)?

13/11/2017

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Ja

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

Nee

Comments:

The reservoir is established out of natural and local materials available to community members and stores relatively clean/safe water for future use.

1.5 Reference to Questionnaire(s) on SLM Approaches

water harvesting [Kenya]

Water harvesting for agricultural production in ASALS.

- Compiler: Philippe Zahner

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

A gutter system constructed on the farmer’s house-roof collects rainwater and directs it into a constructed reservoir raised off the ground with interior walls lined with water-proof tarpaulin. The reservoir has a maximum capacity of 8,000 liters of water; clean enough for irrigation, livestock and domestic use during seasons of scarcity. The reservoir is raised off of ground to minimize contamination and any possible accidents.

2.2 Detailed description of the Technology

Description:

The wooden water reservoir system was introduced to the farmer by staff of the area's local government as a demonstration site to educate others on how to cheaply harvest and store rainwater in a relatively clean form for domestic, livestock and irrigation use. The farmer’s house was fitted with gutters to tap rainwater and direct it into the water reservoir. The water collected is used to buffer the water scarcity during the dry season, which normally stresses livestock and crops in the area. The water can be stored for as long as three months, depending on the size of the water reservoir and the use of the water.

The establishment of the technology requires a clean roof for collecting rainwater, gutters, poles, iron sheets, tarpaulin, hose pipe, jerry can and nails. Further equipment required include; a hammer, hoe and panga (large knife for weeding and forest works). At the farm in Kyegegwa, the reservoir is constructed 3 meters away from the farmer’s main house located at the top of a gently sloping hill. The establishment process involves: leveling of the site on which the technology is planned and constructing a water reservoir supported by a wooden structure. The support structure is constructed using four poles made in such a way that the two front poles are taller (5m) while the two poles behind are shorter (3m). This will give the roof a slight slope to prevent rainwater from stagnating on the roof. A raised rectangular floor supported by the poles is then established at a height of 0.5m above ground. The rectangular reservoir base dimensions are 1m×4m×2m (h×l×w) and is divided into 4 compartment. Each of these, lined with water-tight tarpaulin, can hold 2000 litres of water. The water so collected in the reservoir can be extracted under gravity through a 1.5cm diameter hose pipe into a jerry can placed below the reservoir.

The cost of establishment and durability of this rainwater harvesting system is mainly dependent on the type of materials and gutters used. In Kyegegwa District, wood for construction of the system is locally available valued at US$ 67.99 for the construction of the reservoir system. The iron sheets, gutters and nails are acquired from Kyegegwa Town where they are valued at US$ 127.28. The labor required is also locally available where it takes four men to establish the structure at a total cost of US$ 17.95 in three days.

The water reservoir is semi-permanent and can last for about 1.5 years depending on the quality of materials used. The maintenance activities include cleaning of the reservoir every month and repairing of the worn out parts at the end of the wet season. The farmer strongly recommends the technology since most of the materials and labour used are relatively cheap and locally available. The reservoir is raised off the ground to reduce contamination and minimize possible accidents with children and livestock. Despite the open space above the water level and the roof, the farmer has observed that the reservoir does not breed obnoxious vectors like mosquitoes. The water collected is relatively clean and the farmer uses it for irrigation of home gardens and for watering of livestock. When properly filtered it is as well used for domestic purposes. The technology can be improved by using treated poles, stronger wood material and tarpaulin of improved quality.

2.3 Photos of the Technology

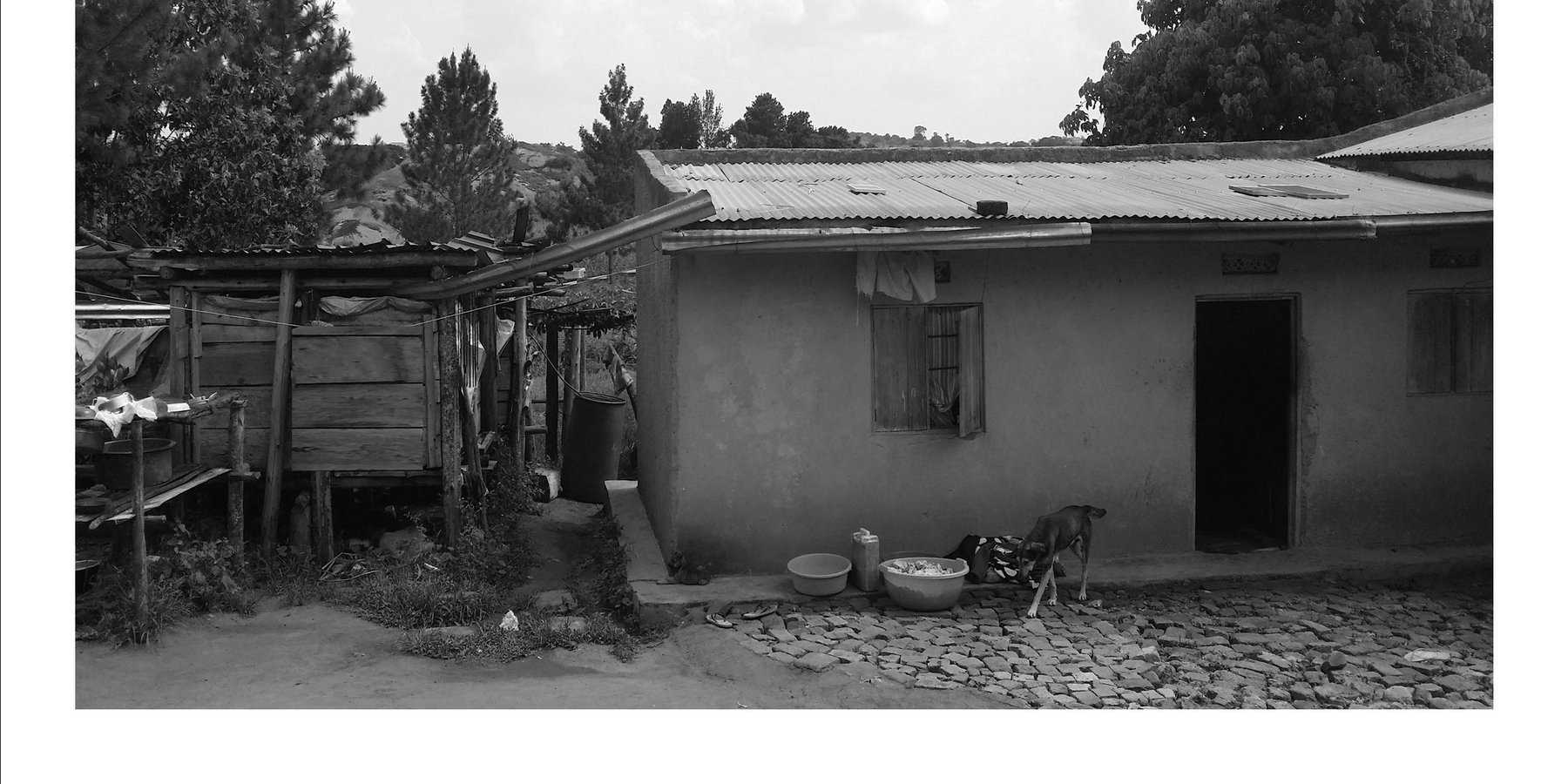

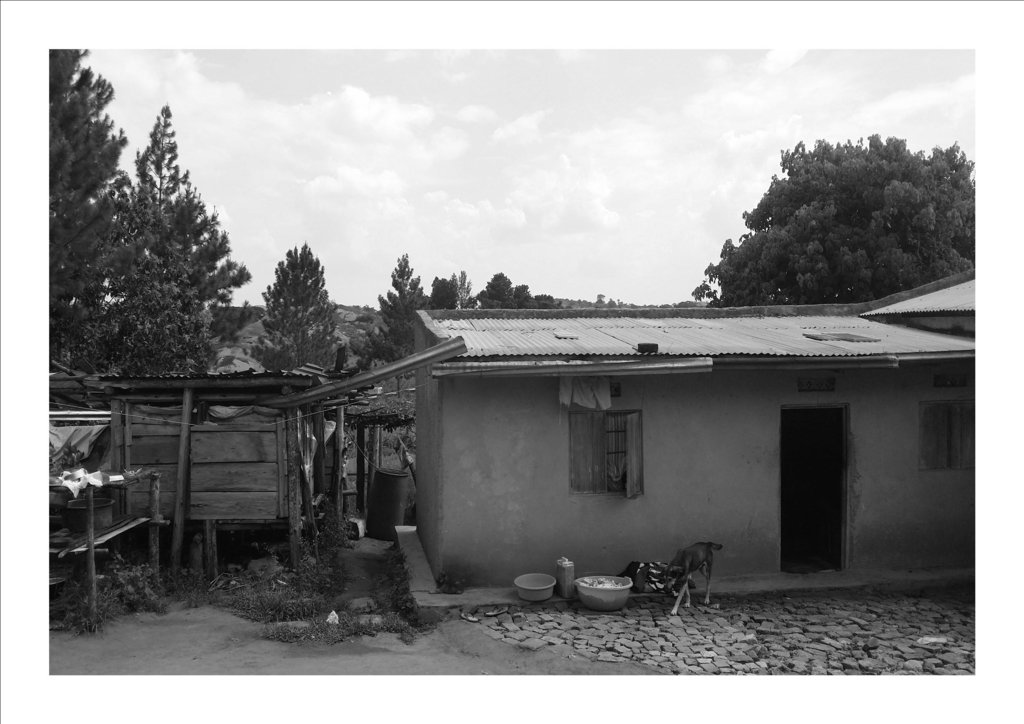

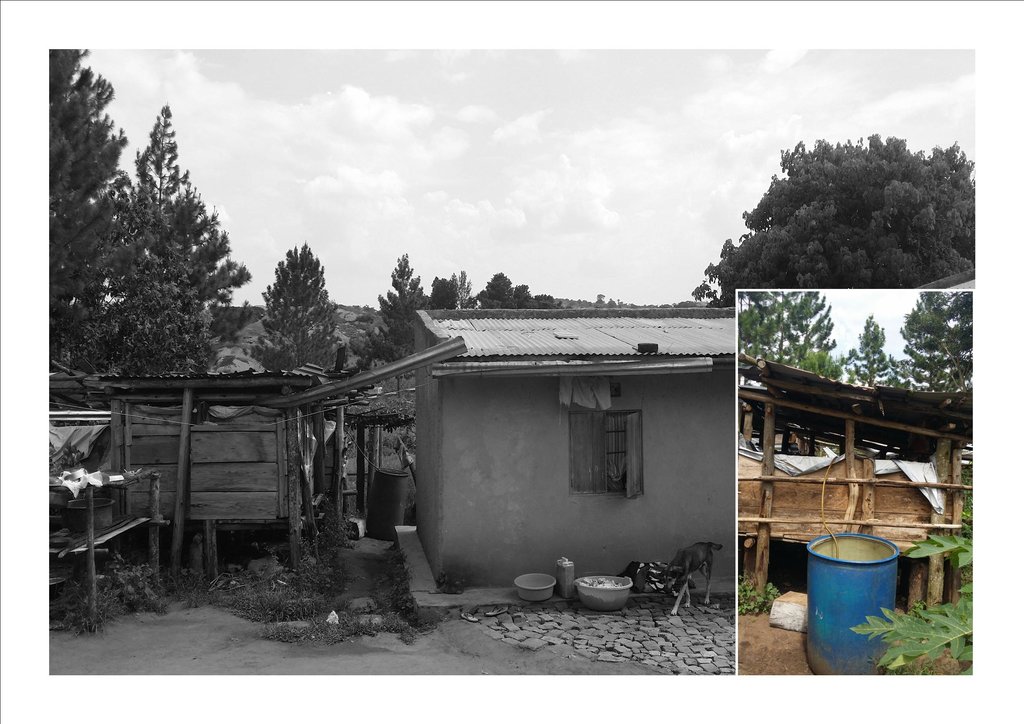

General remarks regarding photos:

The black and white view shows the water system including the house roof, improvised iron sheet gutters and water reservoir structure. The colored picture shows a hose pipe connected into the reservoir to deliver water into the plastic tank by forces of gravity

2.4 Videos of the Technology

Date:

13/11/2017

Location:

Kyeggegwa Town Council

Name of videographer:

Amon Aine

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Uganda

Region/ State/ Province:

Western

Further specification of location:

Kyeggegwa

Comments:

The project is located at the top of a gently sloping hill

Map

×2.6 Date of implementation

Indicate year of implementation:

2015

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

Comments (type of project, etc.):

Local Government project to help local farmers adopting water storage systems for use during drought.

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- reduce risk of disasters

- adapt to climate change/ extremes and its impacts

- create beneficial economic impact

3.2 Current land use type(s) where the Technology is applied

Settlements, infrastructure

- Settlements, buildings

Remarks:

The farmer's house roof top is used as the rain water catchment area.

3.3 Further information about land use

Water supply for the land on which the Technology is applied:

- mixed rainfed-irrigated

Number of growing seasons per year:

- 2

Specify:

March-May and Sept-Nov. However, due to climate change, the seasons vary significantly in length and amount of rain recieved.

3.4 SLM group to which the Technology belongs

- water harvesting

3.5 Spread of the Technology

Specify the spread of the Technology:

- applied at specific points/ concentrated on a small area

3.6 SLM measures comprising the Technology

structural measures

- S6: Walls, barriers, palisades, fences

- S7: Water harvesting/ supply/ irrigation equipment

3.7 Main types of land degradation addressed by the Technology

water degradation

- Ha: aridification

Comments:

To provide safe water for domestic, livestock and irrigation use especially during the drought period.

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

- adapt to land degradation

Comments:

Harvesting rain water reduces the need for constructing dams.

4. Technical specifications, implementation activities, inputs, and costs

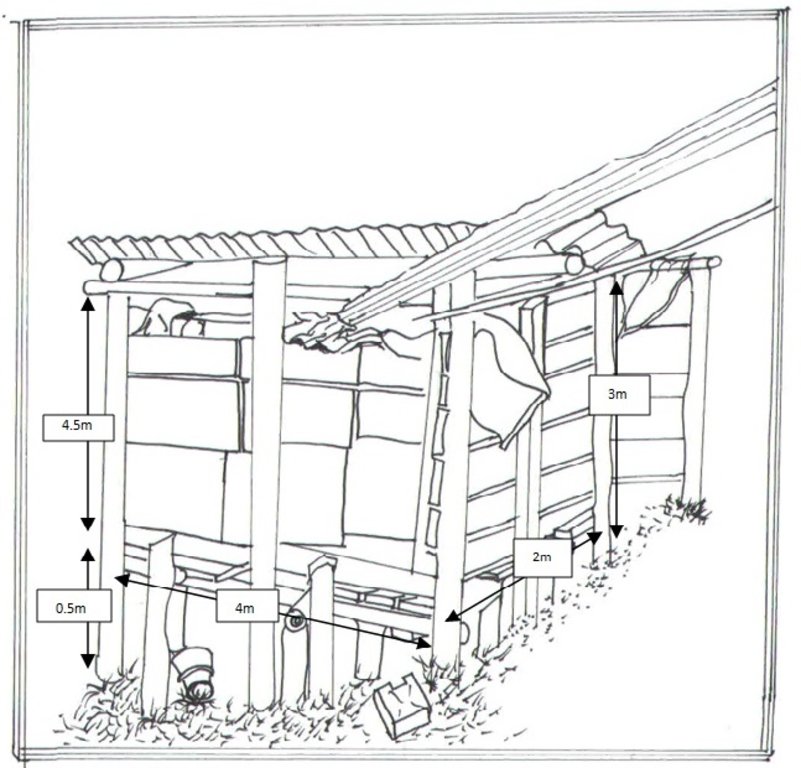

4.1 Technical drawing of the Technology

4.2 Technical specifications/ explanations of technical drawing

The support structure is constructed using four poles made in such a way that the two front poles are taller (5 m) while the two poles behind are shorter (3 m), giving the roof a slight slope to prevent rainwater from stagnating on the roof. A raised rectangular floor supported by the poles is then established at a height of 0.5 m above ground. A cuboid reservoir of dimensions 1 m×4 m×2 m (h×l×w) is constructed with wooden panels; divided into four compartments and placed on the rectangular floor. Each compartment, to hold 2,000 liter of water, is lined with water-tight tarpaulin. Water from the reservoir can be extracted under gravity through a 1.5 cm diameter hose pipe into a jerry can placed below the reservoir.

4.3 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology unit

Specify unit:

Water Reservior

Specify volume, length, etc. (if relevant):

Capacity 8000 liters, segregated into 4 compartments

other/ national currency (specify):

Uganda shillings

Indicate exchange rate from USD to local currency (if relevant): 1 USD =:

3638.35

Indicate average wage cost of hired labour per day:

20000

4.4 Establishment activities

| Activity | Type of measure | Timing | |

|---|---|---|---|

| 1. | Site selection | Structural | Before onset of rain |

| 2. | Clearing and leveling | Structural | Before onset of rain |

| 3. | Erection of poles | Structural | Before onset of rain |

| 4. | Establishment of floor, walls and roofing | Structural | Before onset of rain |

| 5. | Establishment of taupline and gutters | Structural | Before onset of rain |

4.5 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Builders | Man day | 8.0 | 22500.0 | 180000.0 | 100.0 |

| Equipment | Hammer | pieces | 30000.0 | 1.0 | 30000.0 | 100.0 |

| Equipment | Panga | pieces | 9000.0 | 1.0 | 9000.0 | 100.0 |

| Equipment | Dibber | pieces | 15000.0 | 1.0 | 15000.0 | 100.0 |

| Equipment | Hoe | pieces | 10000.0 | 1.0 | 10000.0 | 100.0 |

| Plant material | Spade | pieces | 15000.0 | |||

| Plant material | Poles | pieces | 12.0 | 3000.0 | 36000.0 | 100.0 |

| Plant material | Timber | pieces | 12.0 | 10000.0 | 120000.0 | 100.0 |

| Plant material | Wood | pieces | 8.0 | 1500.0 | 12000.0 | 100.0 |

| Construction material | Tarpaulin | peices | 1.0 | 45000.0 | 45000.0 | |

| Construction material | Iron sheet | peices | 6.0 | 25000.0 | 150000.0 | |

| Construction material | Nails | Kg | 4.0 | 6000.0 | 24000.0 | |

| Construction material | Hose pipe | Meters | 3.0 | 3000.0 | 9000.0 | |

| Construction material | Wood and poles | Pieces | 50.0 | 4900.0 | 245000.0 | |

| Total costs for establishment of the Technology | 885000.0 | |||||

If land user bore less than 100% of costs, indicate who covered the remaining costs:

Kyegegwa District Local Government Community Development Fund.

Comments:

The poles and wood are from the farmer's forest. The labor used was also family labor.

4.6 Maintenance/ recurrent activities

| Activity | Type of measure | Timing/ frequency | |

|---|---|---|---|

| 1. | Cleaning the reservoir/ tarpaulin and unblocking gutters | Management | Twice in the wet season |

| 2. | Renovation of the structure | Structural | Once a year |

| 3. | Replacement of the taupline | Structural | Once a year |

4.7 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Men | 2.0 | 20000.0 | 40000.0 | 100.0 | |

| Equipment | Hose pipe | meters | 3.0 | 2000.0 | 6000.0 | 100.0 |

| Equipment | Jerrycans | 20litres | 2.0 | 9000.0 | 18000.0 | 100.0 |

| Construction material | Poles | pieces | 6.0 | 3000.0 | 18000.0 | 100.0 |

| Construction material | Timber | pieces | 6.0 | 10000.0 | 60000.0 | 100.0 |

| Construction material | Wood | pieces | 5.0 | 1500.0 | 7500.0 | 100.0 |

| Total costs for maintenance of the Technology | 149500.0 | |||||

If land user bore less than 100% of costs, indicate who covered the remaining costs:

Kyegegwa District Local Government

4.8 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

The nature of material used for example wood or metal and the labor hired to construct the system.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specifications/ comments on rainfall:

The rain seasons run from March-May and Sept-Nov.

Agro-climatic zone

- humid

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- not relevant

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Soil texture (> 20 cm below surface):

- medium (loamy, silty)

Topsoil organic matter:

- medium (1-3%)

5.4 Water availability and quality

Ground water table:

> 50 m

Availability of surface water:

medium

Water quality (untreated):

poor drinking water (treatment required)

Is water salinity a problem?

Nee

Is flooding of the area occurring?

Nee

5.5 Biodiversity

Species diversity:

- medium

Habitat diversity:

- medium

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- subsistence (self-supply)

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- average

Individuals or groups:

- individual/ household

Level of mechanization:

- manual work

Gender:

- men

Age of land users:

- elderly

5.7 Average area of land owned or leased by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- medium-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, titled

Land use rights:

- individual

Water use rights:

- communal (organized)

- individual

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

crop quality

fodder production

fodder quality

animal production

wood production

forest/ woodland quality

non-wood forest production

risk of production failure

product diversity

production area

land management

Water availability and quality

drinking water availability

Quantity after SLM:

80000 litres in storage by end of the wet season

drinking water quality

Comments/ specify:

The water stored in the tank is relatively clean compared to that harvested previously using the run off harvest system.

water availability for livestock

water quality for livestock

irrigation water availability

irrigation water quality

Income and costs

expenses on agricultural inputs

Comments/ specify:

Costs on irrigation and income from extended growing seasons

farm income

diversity of income sources

economic disparities

workload

Socio-cultural impacts

food security/ self-sufficiency

health situation

Comments/ specify:

Improved nutrition since the irrigation water supports growth of vegetables

cultural opportunities

recreational opportunities

community institutions

Ecological impacts

Water cycle/ runoff

harvesting/ collection of water

surface runoff

excess water drainage

Soil

soil moisture

Comments/ specify:

Through irrigation in the dry season

nutrient cycling/ recharge

Comments/ specify:

The water facilitates dissolution of nutrients

soil organic matter/ below ground C

acidity

Biodiversity: vegetation, animals

Vegetation cover

biomass/ above ground C

plant diversity

invasive alien species

animal diversity

Climate and disaster risk reduction

drought impacts

6.2 Off-site impacts the Technology has shown

water availability

buffering/ filtering capacity

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Climate-related extremes (disasters)

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | well |

Other climate-related consequences

Other climate-related consequences

| How does the Technology cope with it? | |

|---|---|

| extended growing period | well |

| Livestock and domestic water | well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

positive

Long-term returns:

positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

very positive

Long-term returns:

very positive

6.5 Adoption of the Technology

- 1-10%

Of all those who have adopted the Technology, how many have did so spontaneously, i.e. without receiving any material incentives/ payments?

- 50-90%

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

Ja

other (specify):

Limited finances

Specify adaptation of the Technology (design, material/ species, etc.):

The farmer improvised iron sheets as gutters to collect water from the roof into the reservoir.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| Most of the materials are cheap and locally available. |

| The establishment process is not so complex and can easily be learnt by the local workers. |

| The tarpaulin used is relatively cheap and long lasting. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| The farmer easily benefits from 2 annual rainy seasons. |

| The system is raised off ground which minimizes contamination and accidents. |

| The water is kept in a relatively clean status for livestock, irrigation and domestic use. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| The water system is open to contamination. | Need to construct a wall net to protect the water from contamination |

| The materials (wood) used are prone to destruction by insects which increases maintenance costs. | Use of metallic or concrete poles |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| The taupline is a temporally reservoir that needs routine replacement. | Use of plastic materials or construction of concrete walls. |

| In case of infestation with insects like termites, the poles will suffer damage. | Use treated wood poles or metal poles. |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

1

- interviews with land users

1

7.2 References to available publications

Title, author, year, ISBN:

Rain Water Harvesting Handbook, Ministry of Water and Environment

Available from where? Costs?

https://www.mwe.go.ug/sites/default/files/library/Rain%20Water%20Harvesting%20Handbook.pdf

7.3 Links to relevant information which is available online

Title/ description:

Rainwater Reservoirs above Ground Structures for Roof Catchment

URL:

http://www.itacanet.org/doc-archive-eng/water/Rainwater_reservoirs_GTZ.pdf

Links and modules

Expand all Collapse allLinks

water harvesting [Kenya]

Water harvesting for agricultural production in ASALS.

- Compiler: Philippe Zahner

Modules

No modules