Green cane trash blanket [أستراليا]

- تاريخ الإنشاء:

- تحديث:

- جامع المعلومات: Anthony J. Webster

- المحرر: –

- المُراجع: Alexandra Gavilano

Trash blanket

technologies_951 - أستراليا

عرض الأقسام

توسيع الكل طي الكل1. معلومات عامة

1.3 الشروط المتعلقة باستخدام البيانات الموثقة من خلال WOCAT

متى تم تجميع البيانات (ميدانيا)؟:

01/09/2005

يوافق جامع المعلومات والشخص (لاشخاص) الرئيسي لمصدر المعلومات على الشروط المتعلقة باستخدام البيانات الموثقة من خلال WOCAT:

نعم

2. وصف تقنيةالإدارة المستدامي للأراضي

2.1 وصف مختصر للتقنية

تعريف التقنية:

Elimination of burning as a pre-harvest treatment of sugar cane, and managing the resultant trash as a protective blanket to give multiple on and off-site benefits.

2.2 وصف تفصيلي للتقنية

الوصف:

Under conventional production systems, sugar cane is burnt before being harvested. This reduces the volume of trash - comprising green leaves, dead leaves and top growth - making harvesting of the cane simpler, and subsequent cultivation of the soil easier. In the humid tropics of North Queensland, harvesting of cane used to be carried out by hand - as it still is in many parts of the developing tropics. Burning was necessary to make harvesting possible in a dense stand (and to reduce the danger of snakes). However, with the advent of mechanical harvesters in the 1960s, burning continued to be practiced through habit.

A new system then brought fundamental changes in soil management: The ‘green cane trash blanket’ (GCTB) technology refers to the practice of harvesting non-burnt cane, and trash blown out behind in rows by the sugar cane harvester. This trash forms a more or less complete blanket over the field. The harvested lines of cane re-grow (‘ratoon’) through this surface cover, and the next year the cycle is repeated: the cane is once again harvested and more trash accumulates in the inter-rows. Generally the basic cropping cycle is the same, whether cane is burnt or not. This involves planting of new cane stock (cuttings or ‘billets’) in the first year, harvesting this ‘plant crop’ in the second year, and then in years three, four, five and six taking successive ‘ratoon’ harvests. In year six, after harvest, it is still common, even under the GCTB system, to burn the residual trash so that the old cane stools can be more easily ploughed out, and the ground ‘worked up’ (cultivated) ready for replanting. A minority of planters, however, are doing away with burning altogether, and ploughing in the residual trash before replanting. A further variation is not to plough out and replant after the harvest in year six, but to spray the old cane stock with glysophate (a broad spectrum non-selective systemic herbicide) to kill it, then to plant a legume (typically soy bean) as a green manure crop, and only replant the subsequent year after ploughing-in the legume. Under this latter system, one year of harvest is lost, but there are added benefits to the structure and nutrient content of the soil.

Whatever variation of GCTB is used, there are advantages in terms of increased organic matter, improved soil structure, more biodiversity (especially below ground) and a marked reduction in surface erosion - from over 50 t/ha to around 5 t/ha on average. Less erosion is good for the growers - but is also of crucial importance off-site, as sediment lost from the coastal sugar cane strip is washed out to sea, and damages the growing coral of the Great Barrier Reef.

2.3 صور التقنية

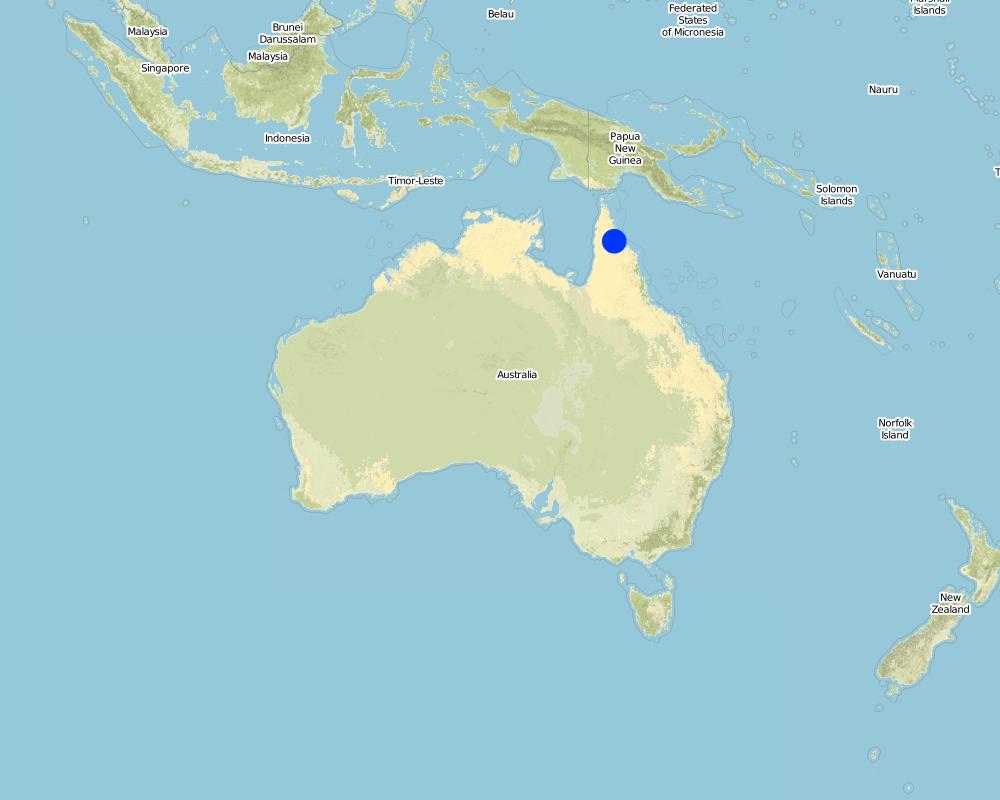

2.5 البلد/المنطقة/المواقع التي تم تنفيذ التقنية فيها والتي يغطيها هذا التقييم

البلد:

أستراليا

المنطقة/الولاية/المحافظة:

North Queensland, Australia

مزيد من التفاصيل حول الموقع:

Ingham

Map

×3. تصنيف تقنية الإدارة المستدامي للأراضي

3.2 نوع (أنواع) استخدام الأراضي الحالية حيث يتم تطبيق التقنية

الأراضي الزراعية

- زراعة معمرة (غير خشبية)

التعليقات:

Major land use problems (compiler’s opinion): Conventional burning of sugar cane before harvest can lead to compaction of top soil and reduced organic matter. There is also, despite the low slopes, a serious problem of sheet/rill erosion that has a negative impact both on the fields, and also off-site on the coral reef.

Major land use problems (land users’ perception): soil erosion, weeds, flooding

3.3 مزيد من المعلومات حول استخدام الأراضي

إمدادات المياه للأرض التي يتم تنفيذ التقنية عليها:

- بعلية

عدد مواسم الزراعة في السنة:

- 1

حدد:

Longest growing period in days: 300

Longest growing period from month to month: Aug - May

3.5 انتشار التقنية

التعليقات:

Total area covered by the SLM Technology is 800 m2.

Wet tropics region of far north Queensland

3.6 التدابير التقنية في مجال إلادارة المستدامة للأراضي

3.7 الأنواع الرئيسية من تدهور الأراضي التي تناولتها التقنية

تآكل التربة بالمياه

- الوزن(Wt): فقدان التربة السطحية/تآكل السطح

- (Wo:) تأثيرات التدهور من مواقع أخرى

التدهور الكيميائي للتربة

- (Cn): تراجع الخصوبة وانخفاض محتوى المادة العضوية (غير ناتج عن الانجراف)

التعليقات:

Main type of degradation addressed: Wt: loss of topsoil / surface erosion, Wo: offsite degradation effects, Cn: fertility decline and reduced organic matter content

3.8 منع أو حد أو عكس تدهور الأراضي

تحديد هدف التقنية فيما يتعلق بتدهور الأراضي:

- الحد من تدهور الأراضي

التعليقات:

Main goals: mitigation / reduction of land degradation

4. المواصفات الفنية، وأنشطة التنفيذ، والمدخلات، والتكاليف

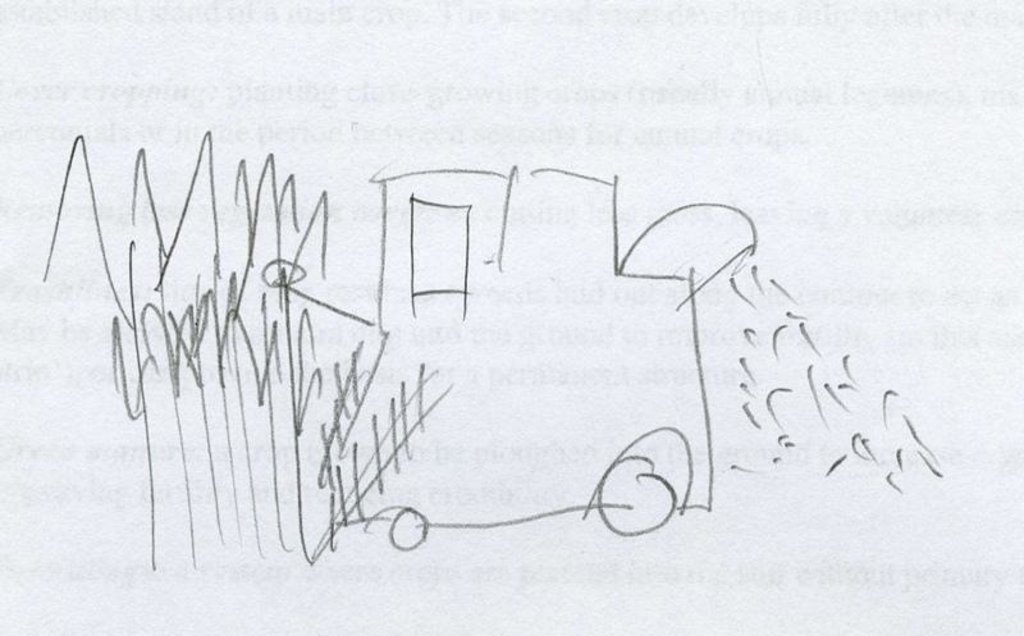

4.1 الرسم الفني للتقنية

4.2 المواصفات الفنية/شروحات الرسم الفني

Harvester harvesting cane and depositing trash on surface

Location: Queensland

Technical knowledge required for field staff / advisors: low

Technical knowledge required for land users: low

Main technical functions: control of raindrop splash, improvement of ground cover, improvement of soil structure, control of dispersed runoff

Secondary technical functions: increase in organic matter, increase of infiltration, increase in soil fertility, increase in surface roughness

Mulching

Remarks: "trash blanketing"

4.3 معلومات عامة بخصوص حساب المدخلات والتكاليف

اذكر متوسط تكلفة أجر العمالة المستأجرة في اليوم الواحد:

100.00

4.6 الصيانة/الأنشطة المتكررة

| النشاط | نوع التدبير | التوقيت/الوتيرة | |

|---|---|---|---|

| 1. | mulching of inter-rows with trash [previously: burn cane with associated trash and then harvest] | زراعية | August |

| 2. | fertilize cane | زراعية | October |

| 3. | spray with Amicide (very efficient herbicide, systemic and non-selective) | زراعية | November |

| 4. | spray with Amicide | زراعية | January |

4.7 التكاليف والمدخلات اللازمة للصيانة/للأنشطة المتكررة (سنويًا)

التعليقات:

Machinery/ tools: sugar-cane harvester

The year budgeted above is a non-planting year, the costs therefore refer to an established crop which grows

throughout the year and is harvested in August. The assumption is a cane yield of 80 t/ha. Each of the three categories of costing groups machinery, labour (at US$12 per hour) and inputs together. The comparative costs for a burnt cane crop system with the same yield are (a) contract harvesting = US$ 378 (b) fertilizer = US$ 120 (c) herbicide = US$ 56, plus (d) cultivation = US$ 30. Note that under the burnt cane system, soil cultivation/tillage is required, but the cost of harvesting is a little cheaper. The total for the burnt crop system is US$ 584 compared with US$ 543 for the GCTB crop, representing a saving of approx. US$ 40 (around 7%) per hectare per year.

5. البيئة الطبيعية والبشرية

5.1 المناخ

هطول الأمطار السنوي

- < 250 مم

- 251- 500 ملم

- 501 - 750ملم

- 1,000-751 ملم

- 1,500-1,100 ملم

- 2,000-1,500 ملم

- 3,000-2,001 ملم

- 4,000-3,100 ملم

- > 4000 ملم

المواصفات/التعليقات على هطول الأمطار:

Annual rainfall: 2000-3000 mm, 3000-4000 mm

المنطقة المناخية الزراعية

- رطبة

Thermal climate class: tropics

5.2 طوبوغرافيا

متوسط الانحدارات:

- مسطح (0-2%)

- بسيط (3-5%)

- معتدل (6-10%)

- متدحرج (11-15%)

- تلال (16-30%)

- شديدة الانحدار(31-60%)

- فائقة الانحدار (>60%)

التضاريس:

- هضاب/سهول

- أثلام مرتفعة

- المنحدرات الجبلية

- منحدرات التلال

- منحدرات في السفوح

- قاع الوادي

المنطقة الارتفاعية:

- 100-0 متر فوق سطح البحر

- 500-101 متر فوق سطح البحر

- 1,000-501 متر فوق سطح البحر

- 1,500-1,001 متر فوق سطح البحر

- 2,000-1,501 متر فوق سطح البحر

- 2,500-2,100 متر فوق سطح البحر

- 3,000-2,501 متر فوق سطح البحر

- 4,000-3,001 متر فوق سطح البحر

- > 4000 متر فوق سطح البحر

5.3 التربة

متوسط عمق التربة:

- ضحل جدًا (0-20 سم)

- ضحلة (21-50 سم)

- متوسطة العمق (51-80 سم)

- عميقة (81-120 سم)

- عميقة جدًا (> 120 سم)

قوام التربة (التربة السطحية):

- ناعم/ثقيل (طيني)

- متوسط ( طميي، سلتي)

المواد العضوية في التربة السطحية:

- منخفضة (<1%)

5.6 خصائص مستخدمي الأراضي الذين يطبقون التقنية

التوجه السوقي لنظام الإنتاج:

- تجاري/سوق

الدخل من خارج المزرعة:

- 10-50% من جميع الإيرادات

المستوى النسبي للثروة:

- متوسط

اذكر الخصائص الأخرى ذات الصلة لمستخدمي الأراضي:

Off-farm income specification: various off-farm enterprises undertaken to supplement income during years of poor sugar prices

5.7 متوسط مساحة الأرض المملوكة أو المستأجرة من قبل مستخدمي الأراضي الذين يطبقون التقنية

- < 0.5 هكتارا

- 0.5 - 1 هكتار

- 1 -2 هكتار

- 2 - 5 هكتار

- 5 - 15 هكتار

- 15 - 50 هكتار

- 50 - 100هكتار

- 500-100 هكتار

- 1,000-500 هكتار

- 10,000-1,000 هكتار

- > 10,000 هكتار

التعليقات:

Average area of land owned or leased by land users applying the Technology: 15-50 ha, 50-100 ha, 100-500 ha

5.8 ملكية الأراضي، وحقوق استخدام الأراضي، وحقوق استخدام المياه

ملكية الارض:

- فردية، يوجد سند ملكية

حقوق استخدام الأراضي:

- فردي

6. الآثار والتصريحات الختامية

6.1 الآثار التي أظهرتها التقنية في الموقع

الآثار الاجتماعية والاقتصادية

الدخل والتكاليف

دخل المزرعة

الآثار الاجتماعية والثقافية

التخفيف من حدة الصراع

الآثار الايكولوجية

دورة المياه / الجريان السطحي

الجريان السطحي

تصريف المياه الزائدة

التربة

رطوبة التربة

غطاء التربة

فقدان التربة

المادة العضوية في التربة/تحت الطبقة c

6.2 الآثار التي أظهرتها التقنية خارج الموقع

الفيضان في اتجاه مجرى النهر

تراكم الطمي باتجاه مصب النهر

تلوث المياه الجوفية/الأنهار

الرواسب المنقولة بواسطة الرياح

6.4 تحليل التكلفة والعائد

كيف تتم مقارنة العوائدمع كلفة الصيانة/التكاليف المتكررة (من وجهة نظر مستخدمي الأراضي)؟

عوائد قصيرة الأجل:

إيجابي قليلا

عوائد طويلة الأجل:

إيجابي

6.5 اعتماد التقنية

التعليقات:

95% of land user families have adopted the Technology without any external material support

1000 land user families have adopted the Technology without any external material support

There is a little trend towards spontaneous adoption of the Technology

Comments on adoption trend: It is possible that the few growers who persist in burning will eventually adopt the GCTB system through social and environmental pressure.

6.7 نقاط القوة / المزايا / الفرص التي توفرها التقنية

| نقاط القوة/ المزايا/ الفرص من وجهة نظر جامع المعلومات أو غيره من الاشخاص الرئيسيين لمصدر المعلومات |

|---|

|

GCTB systems offer multiple on-farm environmental benefits How can they be sustained / enhanced? Continue to refine the system, by encouraging (a) non burning of trash in the |

|

Increases overall farm income by maintaining yields of sugar cane while How can they be sustained / enhanced? Continue to refine the system. |

|

GCTB systems provide protection to the coral reef, through substantially reducing the sediment yield that reaches the lagoon and thence the Great Barrier Reef How can they be sustained / enhanced? Give recognition to the growers for their overall environmental contribution. |

6.8 نقاط ضعف / مساوىء / مخاطر التقنية وسبل التغلب عليها

| نقاط الضعف/ المساوىء/ المخاطر من وجهة نظر جامع المعلومات أو غيره من الاشخاص الرئيسيين لمصدر المعلومات | كيف يمكن التغلب عليها؟ |

|---|---|

| Some burning still continues through (a) the few farmers who have not yet adopted GCTB and (b) the common practice of burning trash before replanting | Continue to encourage non-burning for multiple reasons. |

7. المراجع والروابط

7.2 المراجع للمنشورات المتاحة

العنوان، المؤلف، السنة، النظام القياسي الدولي لترقيم الكتب ISBN:

Mullins JA, Truong PN and Prove BG (1984) Options for controlling soil loss in canelands – some interim values. Proc. Aust. Soc. Sugar Cane Technol., 6: 95–100

العنوان، المؤلف، السنة، النظام القياسي الدولي لترقيم الكتب ISBN:

Vallis I, Parton WJ, Keating BA and Wood AW (1996) Simulation of the effects of trash and N fertilizer management on soil organic matter levels and yields of sugarcane. Soil and Tillage Research. 38: 115–132

العنوان، المؤلف، السنة، النظام القياسي الدولي لترقيم الكتب ISBN:

Wood AW (1991) Management of crop residues

following green harvesting of sugarcane in north Queensland. Soil Till. Res. 20: 69–85

الروابط والوحدات المواضيعية

توسيع الكل طي الكلالروابط

لا يوجد روابط

الوحدات المواضيعية

لا يوجد وحدات مواضيعية