Smallstock Manure Production [Togo]

- Creation:

- Update:

- Compiler: Julie Zähringer

- Editor: –

- Reviewers: Alexandra Gavilano, Laura Ebneter

Houré bow

technologies_955 - Togo

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

SLM specialist:

Gbenonchi Mawussi

gmawussi@gmail.com

Ecole Supérieure d'Agronomie, Université de Lomé (ESA UL), Lomé, Togo

Togo

1.3 Conditions regarding the use of data documented through WOCAT

When were the data compiled (in the field)?

20/08/2007

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

Yes

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Smallstock manure production technology is an easy and efficient method to produce organic fertilizer for the conservation and improvement of soil fertility.

2.2 Detailed description of the Technology

Description:

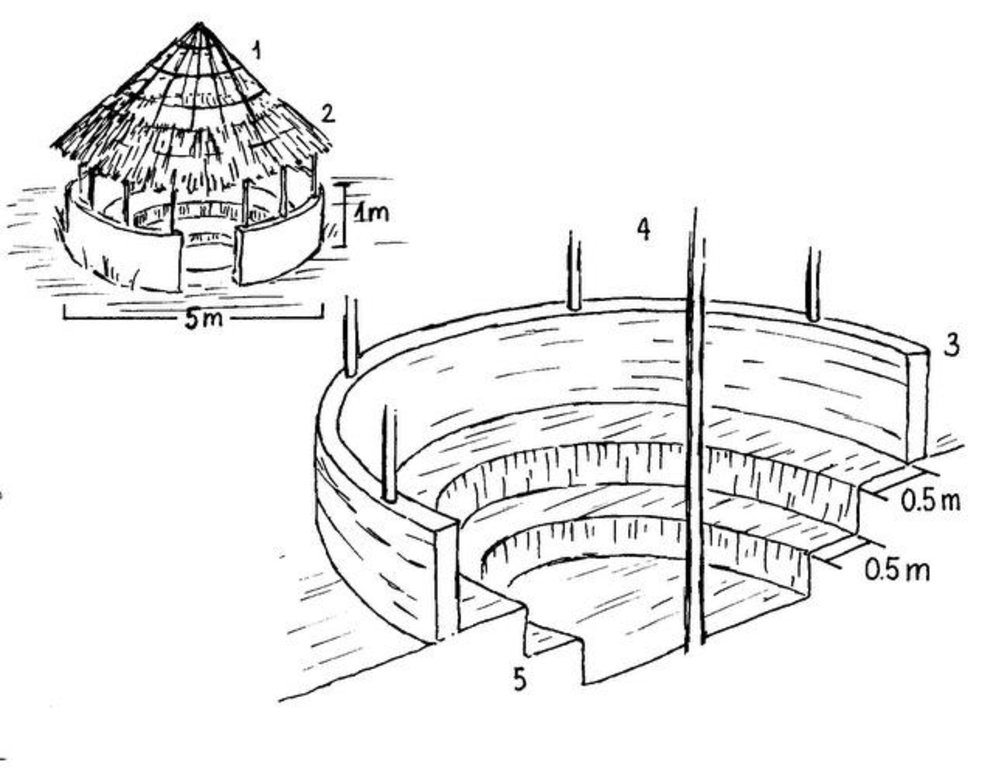

The main item within this practice is the so-called fosse fumière - a 1-2 m deep and 3-4 m diameter circular pit, enclosed by a stone wall. The pit has a double function: it is the place where manure is produced and it serves as shed for small ruminants (goats, sheep), particularly to avoid uncontrolled grazing /browsing during the cropping season (from April until November). Animals are fed in the fosse, and they drop their faeces, which together with chopped organic material accruing from the kitchen and field activities, piles up in the pit for decomposition. The fosse is partly roofed to provide optimal micro-climatic conditions: partial shading, partial exposure to sunlight and appropriate moistening through rainfall. Inside the pit, one or more circular terraces (0.5 m high, 0.5 m wide) serve as resting area for the animals. The terrace riser need to be plastered or reinforced with stones, particularly in case of loose soil, to avoid damage caused by animal trampling. After decomposition the manure is removed from the pit and distributed on the fields beginning of each cropping season (March). Then straw bedding is renewed and the process starts from scratch. During the dry season from December to March smallstock is left to graze freely on the fields and pastures.

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Togo

Region/ State/ Province:

Kara

Further specification of location:

Lassa

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- more than 50 years ago (traditional)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- as part of a traditional system (> 50 years)

Comments (type of project, etc.):

The technology was early traditional and passed from father to son. It was improved in 1987.

3. Classification of the SLM Technology

3.2 Current land use type(s) where the Technology is applied

Mixed (crops/ grazing/ trees), incl. agroforestry

- Agro-pastoralism

Comments:

Major land use problems (compiler’s opinion): soil fertility decline

3.3 Further information about land use

Number of growing seasons per year:

- 1

Specify:

Longest growing period in days: 180, Longest growing period from month to month: May-October

3.4 SLM group to which the Technology belongs

- integrated crop-livestock management

3.5 Spread of the Technology

Comments:

Total area covered by the SLM Technology is 0.15.

3.6 SLM measures comprising the Technology

agronomic measures

- A2: Organic matter/ soil fertility

management measures

- M2: Change of management/ intensity level

Comments:

Type of agronomic measures: manure / compost / residues

3.7 Main types of land degradation addressed by the Technology

chemical soil deterioration

- Cn: fertility decline and reduced organic matter content (not caused by erosion)

Comments:

Main type of degradation addressed: Cn: fertility decline and reduced organic matter content

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- reduce land degradation

- restore/ rehabilitate severely degraded land

Comments:

Main goals: mitigation / reduction of land degradation

Secondary goals: rehabilitation / reclamation of denuded land

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

4.2 Technical specifications/ explanations of technical drawing

Dimensions and main components of a manure production pit: (1) open part of the roof; (2) covered part of the roof; (3) stone wall; (4) poles (holding the roof); (5) terraces (where animals can rest)

Technical knowledge required for field staff / advisors: moderate

Technical knowledge required for land users: low

Main technical functions: increase in organic matter, increase in nutrient availability (supply, recycling,…)

Material/ species: compost (mixture of animal faeces and vegetative scraps

4.3 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology unit

Specify unit:

1

Specify volume, length, etc. (if relevant):

1-2 m deep and 3-4 m diameter circular pit

Specify currency used for cost calculations:

- US Dollars

4.4 Establishment activities

| Activity | Type of measure | Timing | |

|---|---|---|---|

| 1. | Delimitation of the perimeter of the pit and the position of the steps | Agronomic | |

| 2. | Excavation of the pit, shaping a terraced structure 1-3 circular, 0.5 m high and 0.5 wide terrace | Agronomic | |

| 3. | Build up a stone wall around the pit, spaced at minimum 0.5 m from the pit, with an integrated ga | Agronomic | |

| 4. | Build a roof, which partly covers the pit | Agronomic | |

| 5. | Put straw on the ground and corral the animals | Agronomic | |

| 6. | After one year (April to March) the compost is ready for application on the field | Agronomic |

4.5 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour | ha | 1.0 | 200.0 | 200.0 | 100.0 |

| Equipment | machine use | |||||

| Equipment | animal traction | |||||

| Equipment | tools: shovel, cutlass, rope, mattock | |||||

| Construction material | poles, crossbars, stones/bric | ha | 1.0 | 182.0 | 182.0 | 100.0 |

| Total costs for establishment of the Technology | 382.0 | |||||

Comments:

Material such as stones and straw are available on the farm (no monetary costs)

4.6 Maintenance/ recurrent activities

| Activity | Type of measure | Timing/ frequency | |

|---|---|---|---|

| 1. | Continuous depositing and piling up of vegetative material (dung, kitchen waste, crop residues) | Agronomic | |

| 2. | Let decompose the organic material inside the pit. Twice a year (between April and November) the material is actively mixed for aeration | Agronomic | Twice a year (between April and November |

| 3. | Distribute the manure on the fields (during rainy season) | Agronomic | during rainy season |

4.7 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour | ha | 1.0 | 150.0 | 150.0 | 100.0 |

| Total costs for maintenance of the Technology | 150.0 | |||||

4.8 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Main cost-relevant factor is labour.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Agro-climatic zone

- sub-humid

Thermal climate class: tropics

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Topsoil organic matter:

- low (<1%)

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

good soil drainage to avoid flooding of the ditch

5.6 Characteristics of land users applying the Technology

Market orientation of production system:

- subsistence (self-supply)

- mixed (subsistence/ commercial

Individuals or groups:

- individual/ household

Level of mechanization:

- manual work

Indicate other relevant characteristics of the land users:

Population density: 200-500 persons/km2

5.7 Average area of land owned or leased by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, titled

Land use rights:

- leased

- individual

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

fodder production

Comments/ specify:

search for fodder necessary

production area

Income and costs

farm income

Comments/ specify:

the production surplus is sold

workload

Socio-cultural impacts

food security/ self-sufficiency

conflict mitigation

Ecological impacts

Soil

soil moisture

nutrient cycling/ recharge

soil organic matter/ below ground C

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Comments:

Technology not much affected by climatic extremes or changes.

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

slightly positive

Long-term returns:

positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

slightly positive

Long-term returns:

positive

6.5 Adoption of the Technology

Of all those who have adopted the Technology, how many have did so spontaneously, i.e. without receiving any material incentives/ payments?

- 90-100%

Comments:

60 land user families have adopted the Technology without any external material support

There is a moderate trend towards spontaneous adoption of the Technology

Comments on adoption trend: depending mainly on the availability of livestock

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

|

Production of green manure How can they be sustained / enhanced? maintenance of the pit |

|

Increase of crop yield through fertilization How can they be sustained / enhanced? renewal of litter |

| Rehabilitation of degraded soils |

|

Limited animal roaming and destroying of crops How can they be sustained / enhanced? corrall livestock in the pit |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| Manual construction is very labour-intensive | mechanized excavation |

| Air pollution through smelly animal dung | add products which attenuate the smell; establish the manure pit outside the residential area |

| Accident risk for children | establish the manure pit outside the residential area |

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules