Automatic Pumping System (Ram Pump) Using Natural Stream Flow for Domestic and Agricultural Purposes [Cambodia]

- Creation:

- Update:

- Compiler: Be Gechkim

- Editors: Navin Chea, SOBEN KIM, Sophea Tim

- Reviewers: Nimul CHUN, Ursula Gaemperli

Water pumping engine run by water flow (Ram Pump)

technologies_2136 - Cambodia

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

Acting Chief of District Office of Agriculture, Forestry and Fisheries ,Preaek Prasab:

land user:

Hour Pros

(+855) 97 69 14 569

Facebook: Kraties' chicken farm (In Khmer) / Mixed Green Community (in Khmer)

Farmer

Saob Krom Village, Saob commune, Preaek Prasab district, Kratie province

Cambodia

Commune Extension Worker at Saob commune office:

Sopheak Song

(+855) 97 94 23 388

N/A

Office of Saob commune, Preaek Prasab District, Kratie Province

Saob Leu Village, Saob commune, Preaek Prasab district, Kratie province

Cambodia

Chief of District Office of Agriculture, Forestry and Fisheries, Sambo :

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Scaling-up SLM practices by smallholder farmers (IFAD)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Royal University of Agriculture (RUA) - Cambodia1.3 Conditions regarding the use of data documented through WOCAT

When were the data compiled (in the field)?

12/04/2017

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

Comments:

This equipment use without motor or machine just needs water flow speed and can use for many years without much maintenance.

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

This equipment is able to automatically pump water without the use of fuel, requires little maintenance and can transfer water for domestic and agricultural uses including livestock raising and the cultivation of crops.

2.2 Detailed description of the Technology

Description:

A ram pump which uses a natural stream flow is an equipment that pumps water, which is used for long time ago in Europe and some parts of Asia. However, it has been lost, but then because of the requirement, which its processing depends only on water flow and it will work as long as the water flow is available and no need much care that cause this technology is reintroduced (ACF, 2009). As such, this pumping equipment does not need a machine or fossil fuel and requires less labor. According to the above advantages, Mr. Hour Pros, a farmer in Saob Krom village, Saob commune, Preaek Prasab district, Kratie province, is the first person who did the installation. Even though, the cost of installation is relatively high at USD 1,500 depending on the types of materials from which it is manufactured (he selected the high quality of the iron pipe connections), this pumping equipment is quite durable and can be used for up to 20-30 years, he said. Furthermore, it has no adverse impacts on the environment since there are no greenhouse gas emissions.

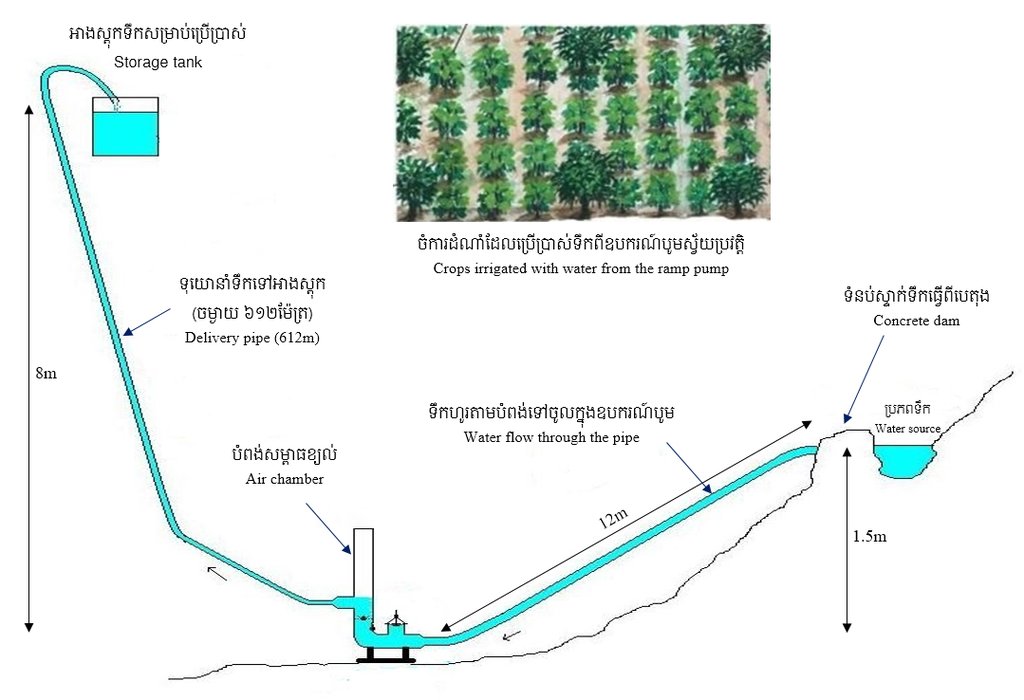

This ram pump was installed at Sre Ngeat dam, where there is a natural stream flowing throughout the whole year. As a part of the installation of the ram pump the farmer constructed a concrete dam across the stream with a water gate that can be opened. Additionally, a concrete base had to be built 1.5 meters lower than the water level in the dam in order to house the ram pump equipment. A 12-meter steel pipe which is 144 mm in diameter runs straight from the dam’s water gate directly to the pumping equipment. From the pumping equipment, there is a 30 mm hose (the size of this outlet must be smaller than that of the inlet) that transfers the pumped water to the location where it is needed. This pump is operated by the air pressure that is created by the water flowing from the dam to the pipe of pump and uses the air pressure to pushes water through the small pipe to bring water to the place where it is utilized, which is around 600 meters away at an elevation of around 8 meters compared to the pumping equipment. This ram pump has a pumping capacity of around 1.5 cubic meters per hour and can operate for 24-hours a day, with the ability to pump up to a height of 20 meters.

The water that is supplied by the ram pump is stored in two big water tanks (each one with a capacity of 4.7 m3), which can then be used for household consumption, the raising of about 100 chickens, and for the open valve irrigation of 5 ha of agricultural land. Another advantage of this pump system is that it does not affect the water quantity or pollute the downstream flow due to the fact that this system only took about 20-30 % of the water from the dam; 70-80% of the water was able to flow downstream, and so this allocation of the water supply did not cause any dispute between upstream and downstream users.

2.3 Photos of the Technology

2.4 Videos of the Technology

Comments, short description:

N/A

Name of videographer:

N/A

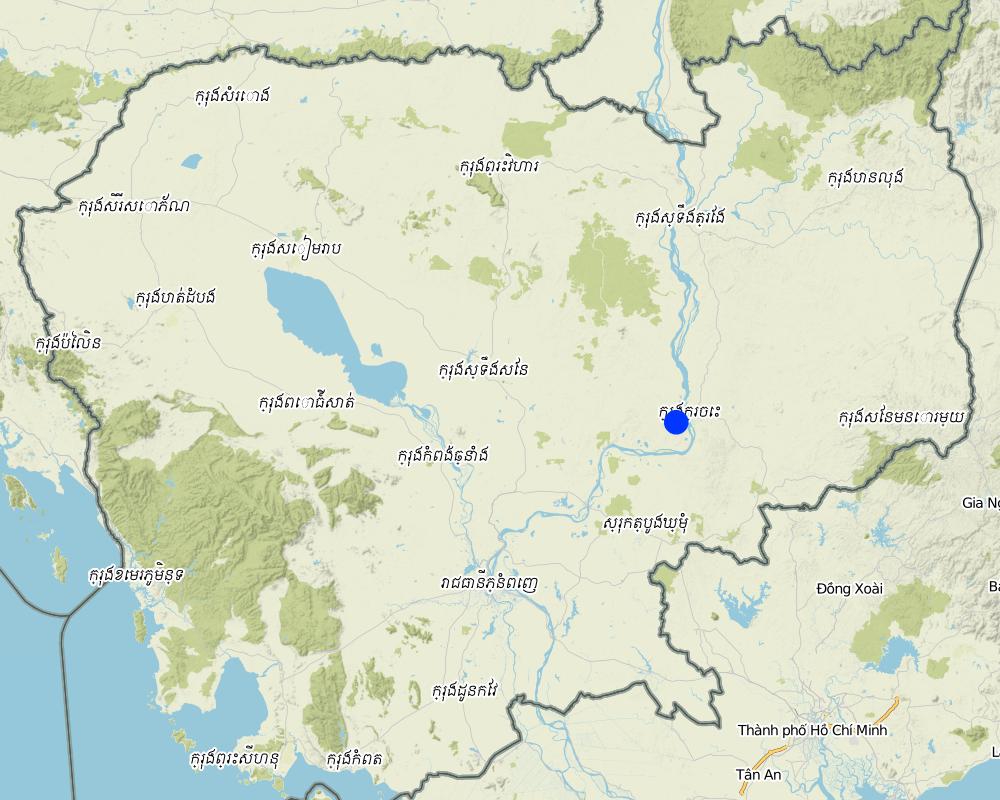

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Cambodia

Region/ State/ Province:

Saob Krom Village, Saob commune, Preaek Prasab district, Kratie province

Map

×2.6 Date of implementation

Indicate year of implementation:

2015

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through land users' innovation

- during experiments/ research

- Research on the Internet

Comments (type of project, etc.):

Farmers created the equipment by their own by learning more through YouTube.

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- reduce, prevent, restore land degradation

- reduce risk of disasters

- adapt to climate change/ extremes and its impacts

- create beneficial economic impact

3.2 Current land use type(s) where the Technology is applied

Waterways, waterbodies, wetlands

- Ponds, dams

Main products/ services:

Sre Ngeat dam can provide water all year round both in dry and rainy seasons.

3.3 Further information about land use

Water supply for the land on which the Technology is applied:

- mixed rainfed-irrigated

Comments:

Needs supported from automatic pump only when having no rain.

Number of growing seasons per year:

- 1

Specify:

Mango trees and vegetable cultivation such as long bean, cucumber, lettuce, water morning glory

3.4 SLM group to which the Technology belongs

- irrigation management (incl. water supply, drainage)

- water diversion and drainage

3.5 Spread of the Technology

Specify the spread of the Technology:

- applied at specific points/ concentrated on a small area

Comments:

This equipment was installed on the Sre Ngeat dam in Saob Krom village, Kratie province.

3.6 SLM measures comprising the Technology

structural measures

- S7: Water harvesting/ supply/ irrigation equipment

3.7 Main types of land degradation addressed by the Technology

water degradation

- Ha: aridification

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- reduce land degradation

Comments:

This equipment can provide enough water for cultivation along sloping areas to reduce soil erosion and a part of soil fertility restoration.

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

4.2 Technical specifications/ explanations of technical drawing

This pumping system is located on a natural stream flow of 1.5 meters height in comparison with the ground of placing the equipment. A 12 meter steel pipe which is 144 mm in diameter runs straight from the dam’s water gate directly to the pumping equipment. The outlet hose is 30 mm in diameter. The distance from the pump to the area where the water is being used is around 600 meters, and it lies at an elevation of 8 meters compared to the pumping point. The water is pumped up at 1.5 cubic meters per hour and can be pushed up to a height of 20 meters.

4.3 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology unit

Specify unit:

Automatic Pumping Device

Specify volume, length, etc. (if relevant):

Setup space: 1 square meter

other/ national currency (specify):

Riel

Indicate exchange rate from USD to local currency (if relevant): 1 USD =:

4000.0

Indicate average wage cost of hired labour per day:

20000 Riel

4.4 Establishment activities

| Activity | Type of measure | Timing | |

|---|---|---|---|

| 1. | Buy materials | Other measures | Dry season |

| 2. | Equipment preparation | Structural | Dry season |

| 3. | Equipment installation | Structural | Dry season |

| 4. | Preparation of irrigation system for vegetable | Structural | Dry season |

4.5 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Total of establishment that done by themselves and materials | Total | 1.0 | 6000000.0 | 6000000.0 | 100.0 |

| Total costs for establishment of the Technology | 6000000.0 | |||||

If land user bore less than 100% of costs, indicate who covered the remaining costs:

N/A

4.6 Maintenance/ recurrent activities

| Activity | Type of measure | Timing/ frequency | |

|---|---|---|---|

| 1. | Access water for using everyday | Other measures | Everyday |

| 2. | Change valve | Structural | Every each years |

4.7 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Change valve | set | 1.0 | 100000.0 | 100000.0 | 100.0 |

| Total costs for maintenance of the Technology | 100000.0 | |||||

If land user bore less than 100% of costs, indicate who covered the remaining costs:

For repairing, it costs around 25 USD a year for changing of the valve.

4.8 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Construction materials and hose that is needed because of far distance between the ram pump and water use places.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specify average annual rainfall (if known), in mm:

1138.20

Specifications/ comments on rainfall:

The average annual rainfall in 2015 is 1138.2 mm, in 2014 is 1696.5 mm, in 2013 is 1661.8 mm.

Indicate the name of the reference meteorological station considered:

Department of Meteorology, Ministry of Water Resources and Meteorology (2015)

Agro-climatic zone

- sub-humid

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- concave situations

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- coarse/ light (sandy)

Soil texture (> 20 cm below surface):

- medium (loamy, silty)

Topsoil organic matter:

- high (>3%)

5.4 Water availability and quality

Ground water table:

5-50 m

Availability of surface water:

good

Water quality (untreated):

for agricultural use only (irrigation)

Is water salinity a problem?

No

Is flooding of the area occurring?

No

5.5 Biodiversity

Species diversity:

- low

Habitat diversity:

- low

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- commercial/ market

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- average

Individuals or groups:

- individual/ household

Level of mechanization:

- mechanized/ motorized

Gender:

- men

Age of land users:

- middle-aged

5.7 Average area of land owned or leased by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- medium-scale

Comments:

Medium-scale because he has only 30 hectares and other have until 50 hectares.

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- communal/ village

Land use rights:

- open access (unorganized)

Water use rights:

- open access (unorganized)

Comments:

Water resource for technology installation is the open access place but the water from technology is for only the own person.

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

Comments/ specify:

Crop production increased because there is enough water for irrigation leading to increased crop production.

risk of production failure

Comments/ specify:

Can be managed because of enough water from the river is easily available now and it does not require a lot of labor.

Water availability and quality

water availability for livestock

Comments/ specify:

Ram pump can provide enough water all the time with less labor.

irrigation water availability

Comments/ specify:

More water can be extracted automatically.

Income and costs

expenses on agricultural inputs

Comments/ specify:

The using of equipment is help to reduce labor, time, cost of reparation, and no needs much maintenance. This technology also reduced fuel consumption for pumping water because ram pump is powered by the water flow.

farm income

Comments/ specify:

Increase in revenue because it does not cost much to pump water. In addition more crops can be grown now.

diversity of income sources

Comments/ specify:

Because enough water for irrigate is available now more different crops are grown now.

economic disparities

Comments/ specify:

With this technology extra income can be generated and furthermore the costs of irrigation were reduced.

workload

Comments/ specify:

The workload decreased due to the automatically working ram pump.

Socio-cultural impacts

SLM/ land degradation knowledge

Comments/ specify:

Regarding the water pump technology the farmer improved his knowledge constantly by doing. And actually he got enough experience to act as facilitator for other farmers. This means he shares his knowledge with neighbors which drives them to use this technology too.

Ecological impacts

Water cycle/ runoff

water quantity

Comments/ specify:

The quantity of water is not reduced or increased as the ram pump accesses only 20 to 30% of water flow and it does not cuts off water flow.

excess water drainage

Comments/ specify:

Ram pump can be used to extract water regularly without labor.

6.2 Off-site impacts the Technology has shown

water availability

Comments/ specify:

Other farmers and neighbors still get water from the dam because the system has accessed to water only 20 to 30%.

impact of greenhouse gases

Comments/ specify:

Without using any machines that it does not emit greenhouse gases.

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | Type of climatic change/ extreme | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | well | |

| annual rainfall | decrease | well |

Climate-related extremes (disasters)

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

positive

Long-term returns:

positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

positive

Long-term returns:

positive

Comments:

The farmer gets many benefits because before had to expense a lot for the labour to pump the water from well and also he had to spend money for fuel which is not anymore necessary now.

6.5 Adoption of the Technology

- 1-10%

Of all those who have adopted the Technology, how many have did so spontaneously, i.e. without receiving any material incentives/ payments?

- 90-100%

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

No

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| Even it costs much at the beginning it still gain a better profit compared to the use of pumping by machine with gasoline for regular water access. |

| Does not involve the use of too much labor because it is able to pump water by itself. |

| Water for irrigation is available at all times and during all seasons. |

| An increase in income through the improved crop cultivation deploying the water supplied by the ram pump. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| A reduction of impacts on the environment because no fuel is being used in the pumping process. |

| A ram pump can operate for many years and does not cost a lot to maintain. |

| A reduction in the amount of labor and time to obtain water for consumption. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| The equipment is expensive to install. | Save money in order to purchase one. |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| - |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

A place

- interviews with land users

A person

- interviews with SLM specialists/ experts

3 people

7.2 References to available publications

Title, author, year, ISBN:

ACF (2009). Hydraulic Ram Pump Systems. From

Available from where? Costs?

https://www.pseau.org/outils/ouvrages/acf_gravity_fed_system_in_rural_areas_6_hydraulic_ram_pump_systems_2009.pdf

7.3 Links to relevant information which is available online

Title/ description:

Judy of the Woods. Homemade Hydraulic Ram Pump. Retrieved on May 20 2017 from

URL:

http://www.judyofthewoods.net/diy/ram_pump.html

Title/ description:

Hydraulic ram pump 8 inches in Cambodia. Retrieved on May 20 2017 from

URL:

https://www.youtube.com/watch?v=5MiLas_FCfQ

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules