Under ground water abstraction for livestock production [Uganda]

- Creation:

- Update:

- Compiler: Kamugisha Rick Nelson

- Editors: JOY TUKAHIRWA, Bernard Fungo

- Reviewers: Drake Mubiru, Nicole Harari, Renate Fleiner, Stephanie Jaquet, Rima Mekdaschi Studer

IET

technologies_2304 - Uganda

- Full summary as PDF

- Full summary as PDF for print

- Full summary in the browser

- Full summary (unformatted)

- Under ground water abstraction for livestock production: May 22, 2018 (inactive)

- Under ground water abstraction for livestock production: July 16, 2018 (inactive)

- Under ground water abstraction for livestock production: March 22, 2019 (inactive)

- Under ground water abstraction for livestock production: Aug. 11, 2019 (public)

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

SLM specialist:

Obita Churchill

Ayom village savings group

Ayom village, Ywaya parish, PADIBE west sub-county, Lamwo District

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Scaling-up SLM practices by smallholder farmers (IFAD)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Centre Ecologique Albert Schweitzer (CEAS) - Switzerland1.3 Conditions regarding the use of data documented through WOCAT

When were the data compiled (in the field)?

12/05/2017

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Under groundwater is abstracted by excavating water abstraction points for livestock production.

Waterhole is excavated for abstracting underground water for watering livestock as well as irrigating crops during the dry season.

2.2 Detailed description of the Technology

Description:

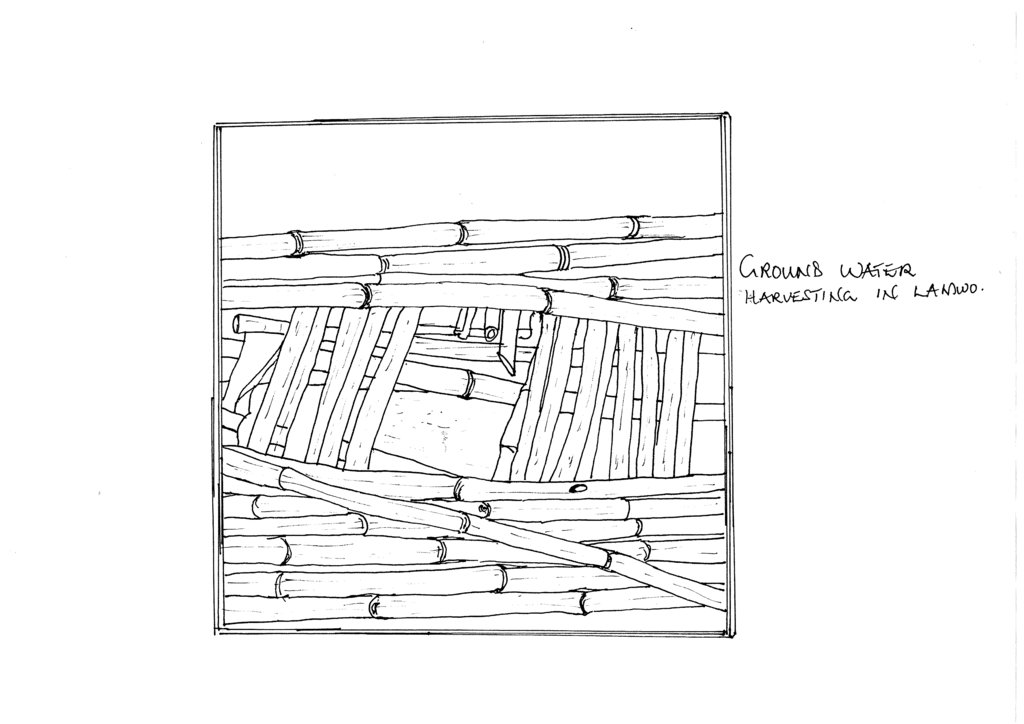

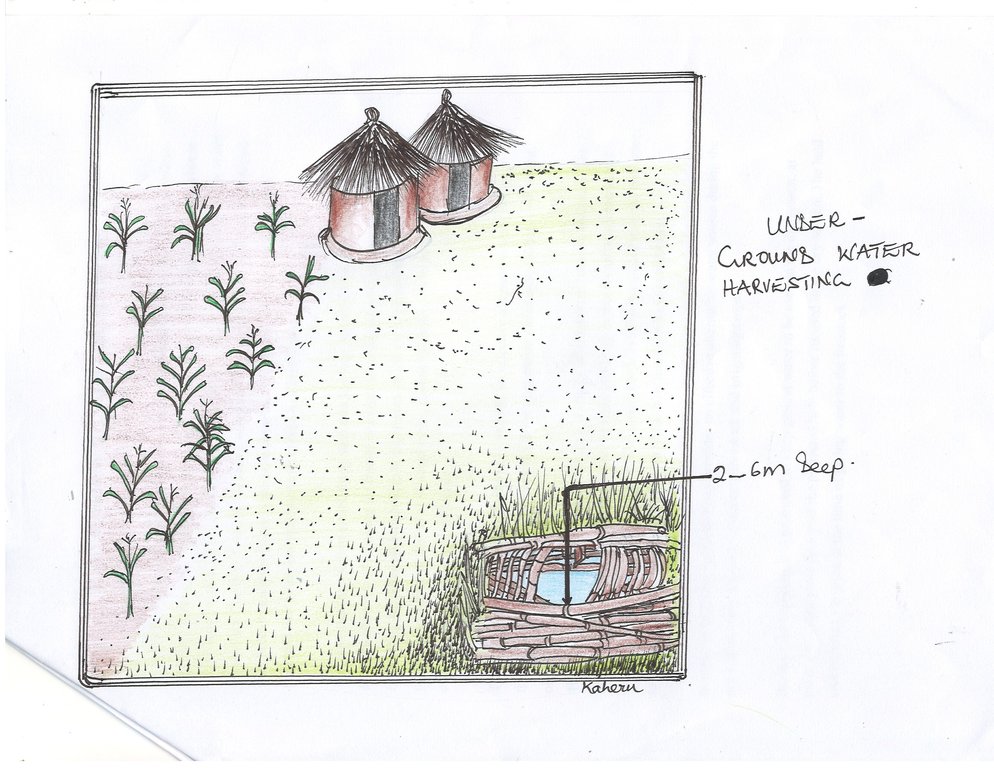

Farming in rural Northern Uganda is vulnerable to climate variability and drought in particular since it overwhelmingly depends on rainfall. Thus, innovative small scale farmers there resort to underground water resources to further their agricultural and water resources are sustained naturally through recharge. The mechanism used is in accessing underground water resources is termed underground water obstruction and involves excavation of structures such as open wells, soak pits, and recharge shaft/ trenches of 2-6 m deep hole, which is manually dug from the ground to allow water to come up (see Figure below).

Underground water abstraction is done by excavating a hole in the ground to reach water underground . A 2-6 m deep hole is manually dug in the ground/ soil to allow water to collect and come up. The hole is shaped in such a way that water does not flow out, and the top is covered to keep the water in the hole protected from contamination. The opening is covered with local materials like poles, bamboo stems (Bamboo aridinarifolia), etc. Water flows into the hole through various methods of groundwater recharge such as open wells, soak pits, and recharge shaft/ trench.

The activities involved in establishing such a underground water hole include (1) identifying suitable site for digging the hole, (2) looking for trainer or expert to advise on how to dig and cover the hole, (3) looking for labor, and tools (e.g. hoes, spades, poles, etc.), (4) digging the hole to a depth of about 2-6 m, depending on the level of water table, (5) protect the hole with bamboo or wood to ensure hygiene and from people falling in.

The returns derived from this technology include: an effective alternative water source during the dry season which is used for crop irrigation (e.g. maize – Zea mays; cabbage - Brassica oleracea) and for livestock production/ watering.

This technology is most preferred because it is cheap, affordable and easy to maintain. The only costs are at the establishment phase. Its main challenge is that it can be contaminated when managed poorly. To ensure this, the farmer needs to keep in contact with the land user to ensure maximum proper management of the hole to minimise contamination.

In terms of impacts, the technology provides an effective alternative water source during the dry season, which is used majorly for livestock and irrigating crops.

Because the technology is promoted as a supplementary water source for the dry season, during the wet season grass may grow on top of the protected hole. Before its use in the dry season the land user removes the grass before abstracting the well water for livestock or crop production.

The resources required for establishing and maintaining this technology include knowledge of suitable sites for the technology, expert advice on construction of the structure, labour, and tools (e.g. hoes, spades, poles, etc.).

This technology is liked by farmers because it is fairly inexpensive and easy to maintain. It may be considered costly are at the establishment level but in the long run, the returns are worth the investment. The other concern is that it can be contaminated when managed poorly.

2.3 Photos of the Technology

General remarks regarding photos:

The grass left to grow does not imply poor management but a protection for a longer period leading to dry season when there is shortage of water.

2.4 Videos of the Technology

Comments, short description:

Video showing underground water abstraction for animal production using : A deep hole is dug and covered with wood and bamboo to provide water for livestock during the dry season.

Date:

12/05/2017

Location:

Ayom Village, Nyaya parish, Padibe West Sub-county, Lamwo District.

Name of videographer:

Issa Aiga

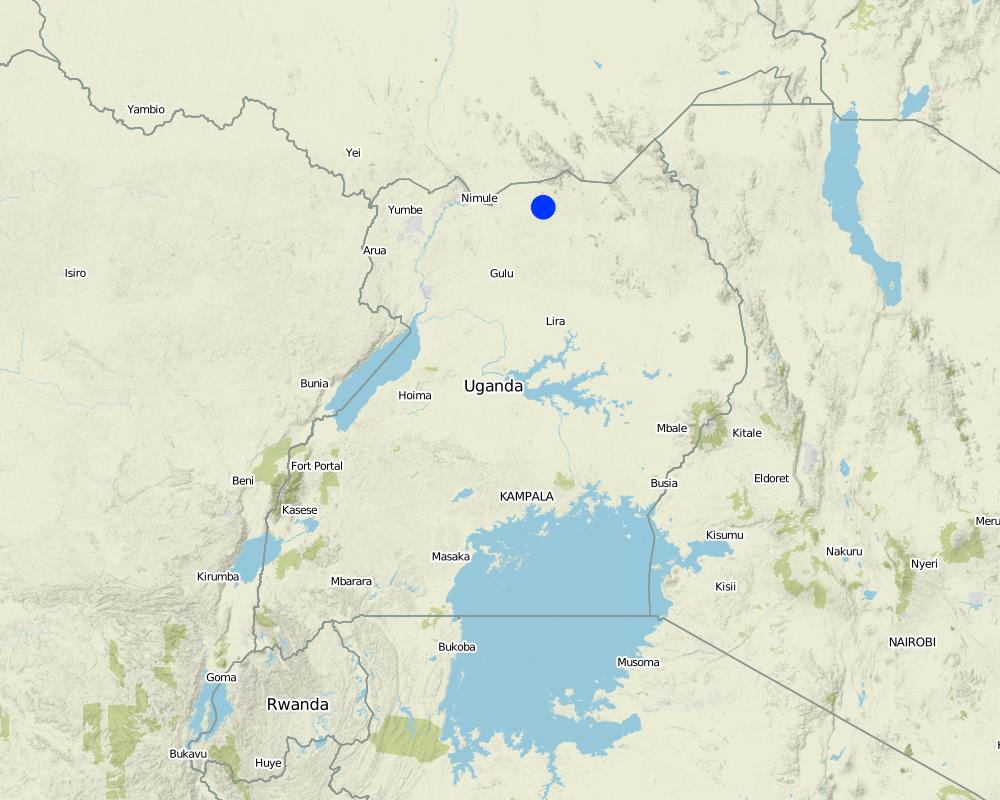

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Uganda

Region/ State/ Province:

Nothern Region

Further specification of location:

Lamwo

Comments:

Map showing technology site in Northern Uganda

Map

×2.6 Date of implementation

Indicate year of implementation:

2016

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through land users' innovation

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- protect a watershed/ downstream areas – in combination with other Technologies

- reduce risk of disasters

- adapt to climate change/ extremes and its impacts

- mitigate climate change and its impacts

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

Main crops (cash and food crops):

Maize

Grazing land

Intensive grazing/ fodder production:

- Cut-and-carry/ zero grazing

If land use has changed due to the implementation of the Technology, indicate land use before implementation of the Technology:

crop land

3.3 Further information about land use

Water supply for the land on which the Technology is applied:

- mixed rainfed-irrigated

Comments:

Irrigated with the harvested water.

Number of growing seasons per year:

- 2

Specify:

During the dry season because this is the appropriate time whe there are no rains.

Livestock density (if relevant):

Not relevant

3.4 SLM group to which the Technology belongs

- integrated crop-livestock management

- water harvesting

- irrigation management (incl. water supply, drainage)

3.5 Spread of the Technology

Specify the spread of the Technology:

- applied at specific points/ concentrated on a small area

Comments:

Established far distant from the homes and near the streams.

3.6 SLM measures comprising the Technology

structural measures

- S3: Graded ditches, channels, waterways

- S6: Walls, barriers, palisades, fences

- S7: Water harvesting/ supply/ irrigation equipment

- S9: Shelters for plants and animals

3.7 Main types of land degradation addressed by the Technology

soil erosion by water

- Wt: loss of topsoil/ surface erosion

- Wg: gully erosion/ gullying

- Wm: mass movements/ landslides

- Wo: offsite degradation effects

water degradation

- Hs: change in quantity of surface water

- Hg: change in groundwater/aquifer level

- Hq: decline of groundwater quality

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

- reduce land degradation

Comments:

Through water erosion

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

4.2 Technical specifications/ explanations of technical drawing

Sinking the hole should be at least between 2-6m deep depending on the level of the water table established on a gentle sloping.

4.4 Establishment activities

| Activity | Type of measure | Timing | |

|---|---|---|---|

| 1. | Identification of suitable site for establishing the hole | Management | Once /before establishment |

| 2. | Look for the expert to train how toLook for the expert to train how to make the hole and cover make | Management | Once before establishment |

| 3. | look for labour to dig the hole | Management | Before establishment |

| 4. | buy inputs required ( hoes, spades, poles / bamboo | Agronomic | During establishment |

| 5. | sinking of the pit hole at least 2-6m deep depending on the level of the water table | Structural | During establishment |

| 6. | protect the hole with Bamboo and poles but ensure you leave some space for water scooping. | Management | After estabiishment |

4.5 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour | Persons | 5.0 | 5000.0 | 25000.0 | |

| Equipment | Hoe | Pieces | 1.0 | 10000.0 | 10000.0 | |

| Equipment | Spade | Pieces | 1.0 | 10000.0 | 10000.0 | |

| Equipment | Poles | Pieces | 100.0 | 200.0 | 20000.0 | |

| Plant material | Bamboo | Pieces | 1.0 | 10000.0 | 10000.0 | |

| Total costs for establishment of the Technology | 75000.0 | |||||

4.6 Maintenance/ recurrent activities

| Activity | Type of measure | Timing/ frequency | |

|---|---|---|---|

| 1. | Fencing | Structural | After establishment |

| 2. | Slashing | Management | After establishment |

| 3. | Hygiene inspection | Management | Routine / Daily - before and after establishment |

4.7 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | labour for fencing | Persons | 2.0 | 5000.0 | 10000.0 | |

| Labour | Labour for slashing | Persons | 2.0 | 5000.0 | 10000.0 | |

| Labour | Labour for Hygiene inspection (monthly) | Persons | 3.0 | 2000.0 | 6000.0 | |

| Total costs for maintenance of the Technology | 26000.0 | |||||

Comments:

The costs of maintenance are higher than establishment due to the daily routine costs.Hygiene inspection does not require alot of labour.It only requires more routine inspection.

4.8 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Hygiene inspection.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specifications/ comments on rainfall:

Fair rainfall in the months of April to October and dry spell from Nov-March

Agro-climatic zone

- sub-humid

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- concave situations

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Soil texture (> 20 cm below surface):

- medium (loamy, silty)

Topsoil organic matter:

- medium (1-3%)

5.4 Water availability and quality

Ground water table:

5-50 m

Availability of surface water:

medium

Water quality (untreated):

good drinking water

Is water salinity a problem?

No

Is flooding of the area occurring?

No

5.5 Biodiversity

Species diversity:

- medium

Habitat diversity:

- medium

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- mixed (subsistence/ commercial

Off-farm income:

- less than 10% of all income

Relative level of wealth:

- poor

Individuals or groups:

- groups/ community

Level of mechanization:

- manual work

Gender:

- women

- men

Age of land users:

- children

- youth

5.7 Average area of land owned or leased by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- medium-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- communal/ village

Land use rights:

- communal (organized)

Water use rights:

- communal (organized)

Comments:

Have community management rules

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

Comments/ specify:

Due to irrigation water

animal production

Water availability and quality

water availability for livestock

Comments/ specify:

water is available for livestock during dry spells

water quality for livestock

Comments/ specify:

underground water clean. not poluted

irrigation water availability

Comments/ specify:

water available for irrigating crops in the dry season

irrigation water quality

Comments/ specify:

underground water is not poluted

Income and costs

farm income

Comments/ specify:

extented crop cultivation and increased production during dry seasons

6.2 Off-site impacts the Technology has shown

water availability

Comments/ specify:

Especially during the dry season

reliable and stable stream flows in dry season

Comments/ specify:

Kept to be used in the dry season

downstream flooding

Comments/ specify:

Water is controlled using the bore hole

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | Type of climatic change/ extreme | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | not well at all | |

| seasonal temperature | winter | increase | not well at all |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

slightly positive

Long-term returns:

positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

slightly positive

Long-term returns:

slightly positive

Comments:

The difference is only with the hygiene inspection costs. low at establishment but high at hygiene inspection which is routine

6.5 Adoption of the Technology

- single cases/ experimental

Of all those who have adopted the Technology, how many have did so spontaneously, i.e. without receiving any material incentives/ payments?

- 0-10%

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

Yes

If yes, indicate to which changing conditions it was adapted:

- climatic change/ extremes

Specify adaptation of the Technology (design, material/ species, etc.):

Adding Bamboo to cover the top in addition to poles.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| The technology provides Constant water supply for livestock production during the dry season. |

| Its cost effective and affordable by the local communities. Once established the costs of maintenance just slightly goes high due to routine inspection. |

| It can be replicated and used by other farmers in other areas. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| The technology is effective in minimising water wastage and enhancing water access during the dry season but is established over along distance 3-5 km from the land user. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| The technology requires routine labour for inspection and technical know how. | Training on hygiene inspection. |

| Dangerous to roaming animals and people when they fall in. | Protection using a berbed wire fence or using local local materials (wood). |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| Not fenced. The fence was removed. | Fencing to protect animals . |

| Need strong bylaw on under groundwater management. | Facilitate formulation and implementation of bylaw on under groundwater management. |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

01 key informant

- interviews with land users

01

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules