Stall feeding of Friesian cow by cut and carry for livestock management [Uganda]

- Creation:

- Update:

- Compiler: Kamugisha Rick Nelson

- Editors: Bernard Fungo, Richard Otto Kawawa, Sunday Balla Amale, JOY TUKAHIRWA

- Reviewers: Rima Mekdaschi Studer, Stephanie Jaquet, Renate Fleiner, Nicole Harari, John Stephen Tenywa, Donia Mühlematter

Gokwo dyang

technologies_2816 - Uganda

- Full summary as PDF

- Full summary as PDF for print

- Full summary in the browser

- Full summary (unformatted)

- Stall feeding of Friesian cow by cut and carry for livestock management: July 16, 2018 (inactive)

- Stall feeding of Friesian cow by cut and carry for livestock management: March 22, 2019 (inactive)

- Stall feeding of Friesian cow by cut and carry for livestock management: Aug. 22, 2019 (public)

- Stall feeding of Friesian cow by cut and carry for livestock management: June 14, 2018 (inactive)

- Stall feeding of Friesian cow for manure: May 22, 2018 (inactive)

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

land user:

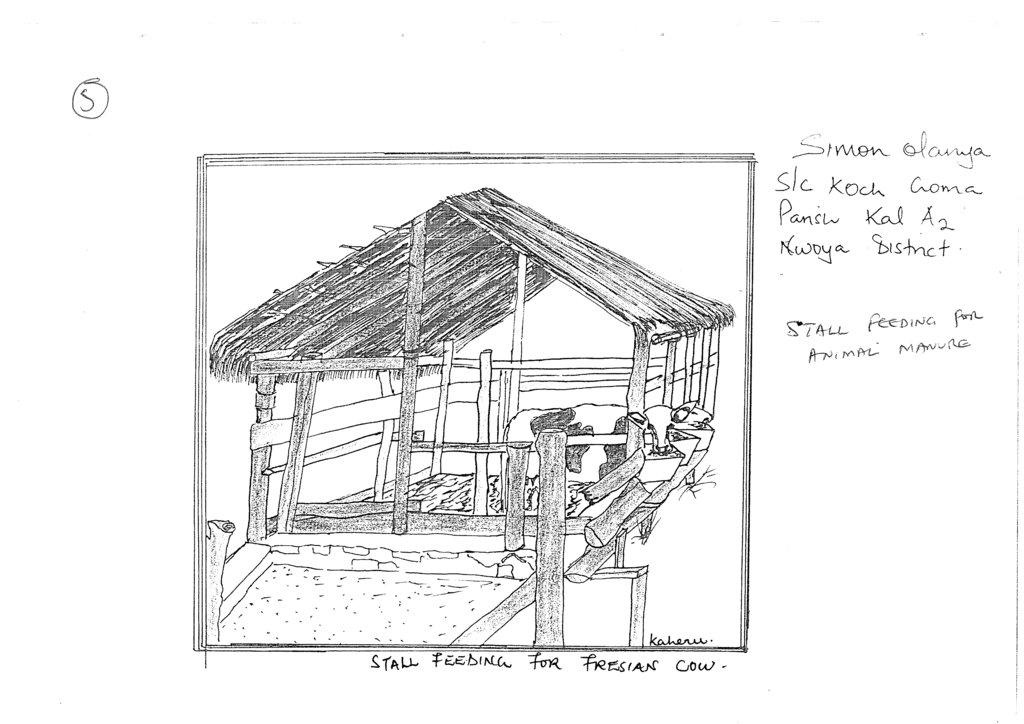

Olanya Simon

0705255647

Farmer

Kosh village , Goma parish Unyona sub-county , Nwoya District

Uganda

Kosh village , Goma parish Unyona sub-county , Nwoya district

Uganda

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Scaling-up SLM practices by smallholder farmers (IFAD)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

CDE Centre for Development and Environment (CDE Centre for Development and Environment) - Switzerland1.3 Conditions regarding the use of data documented through WOCAT

When were the data compiled (in the field)?

24/05/2017

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

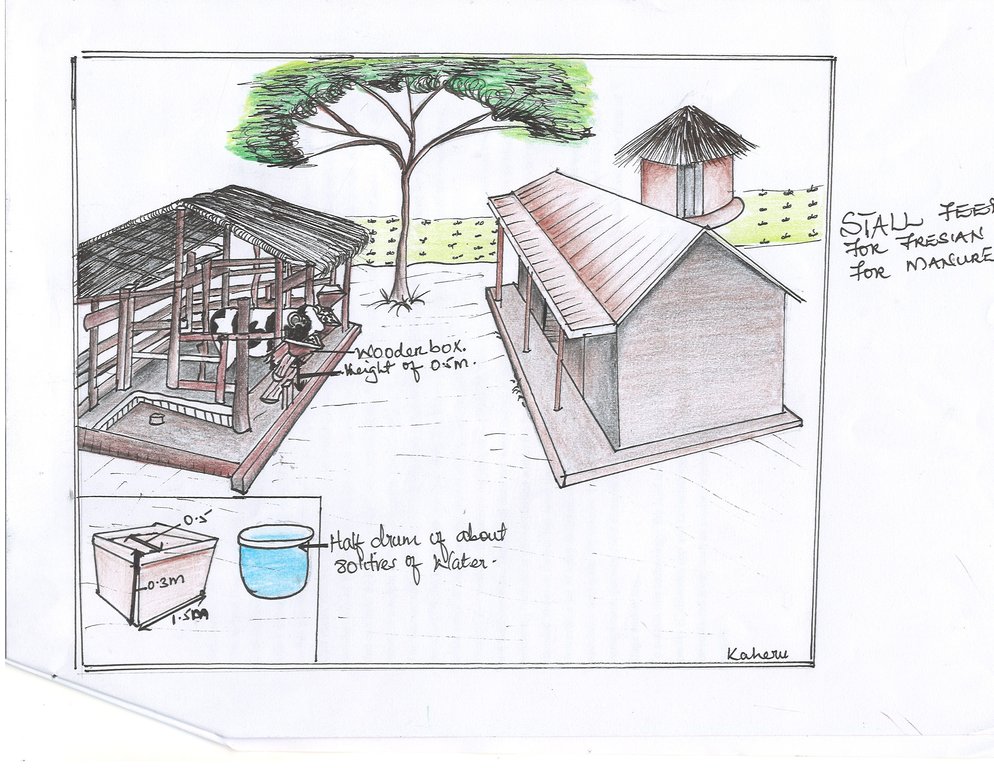

Zero grazing by cut and carry feeding. The cows do not graze but are confined inside the stall, feed and water is provided for the animals.

2.2 Detailed description of the Technology

Description:

Due to land fragmentation and conflicts, traditional grazing systems where animals are reared in open grasslands is no longer feasible and sustainable since grassland is limited and stray animals would destroy neighboring crops. Now small holders with limited land but diversified livelihoods have to utilize the available land in full capacity and sustainable ways. For dairy farmers, stall feeding is an innovative and promising system.

In this practice, a Friesian cow and its calf are confined inside the built stall. The stall has four partitions. A Calf room, milking pallor, feeding and drinking area and sleeping room. Within the feeding area is placed a wooden box of width 0.5m, length 1.5m and height 0.3m; into which feed is put for the animal. A half drum that can hold 80 liters of water is also put inside the feeding area. Both the wooden feeder and half drum are raised to a height of 0.5 m above the ground surface to prevent contamination of the feed with dung and urine; and also ensure efficient feed intake.

The farmer cultivated 1 acre of Napier grass (elephant grass), which provides adequate feed for the demands of the cow (75-100 kg of fresh grass per day). The Napier grass is cut, chopped and put inside the wooden box, while water is fetched from the stream and put into the half drum.

Through this method, the animal movement is restricted. This reduces the exposure to parasites such as ticks, and contagious diseases such as East Coast Fever. This practice also reduces land conflicts that would be caused by stray animals destroying crops of neighbors. The animal does not waste energy to look for pasture and water, hence milk productivity is enhanced. Manure is also deposited within the feeding area and thus easy to collect, decompose and apply in both farmers’ crop and pasture fields. Animals do not need to be attended to, hence farmer has more time to rest and carry out other activities.

However, a lot of labor is required for cutting and chopping the grass, and carrying the feeds and water especially during the dry season. Treatment of animals and maintenance of the stall is costly and if management is poor, parasites and diseases can also build up within the stall. Stall feeding requires feed preservation in the form of fermented pasture (silage) and/or dried pasture (hay); stored and to be used for feeding the animals during dry seasons when pasture is dry and of poor quality.

To sustain this technology, the land users can supplement the feed through cultivating multipurpose tree species (Calliandra spp and Grivellia spp), leguminous forages such as lablab spp and macuna beans. Non-conventional feeds such as kitchen wastes (cassava, sweet potato and banana peelings) can also supplement the cut and carried Napier grass.

2.3 Photos of the Technology

2.4 Videos of the Technology

Comments, short description:

Video showing Stall feeding for fresian cow for animal manure

Date:

26/05/2017

Location:

Kosh village , Goma parish Unyona sub-county , Nwoya District

Name of videographer:

Issa Aiga

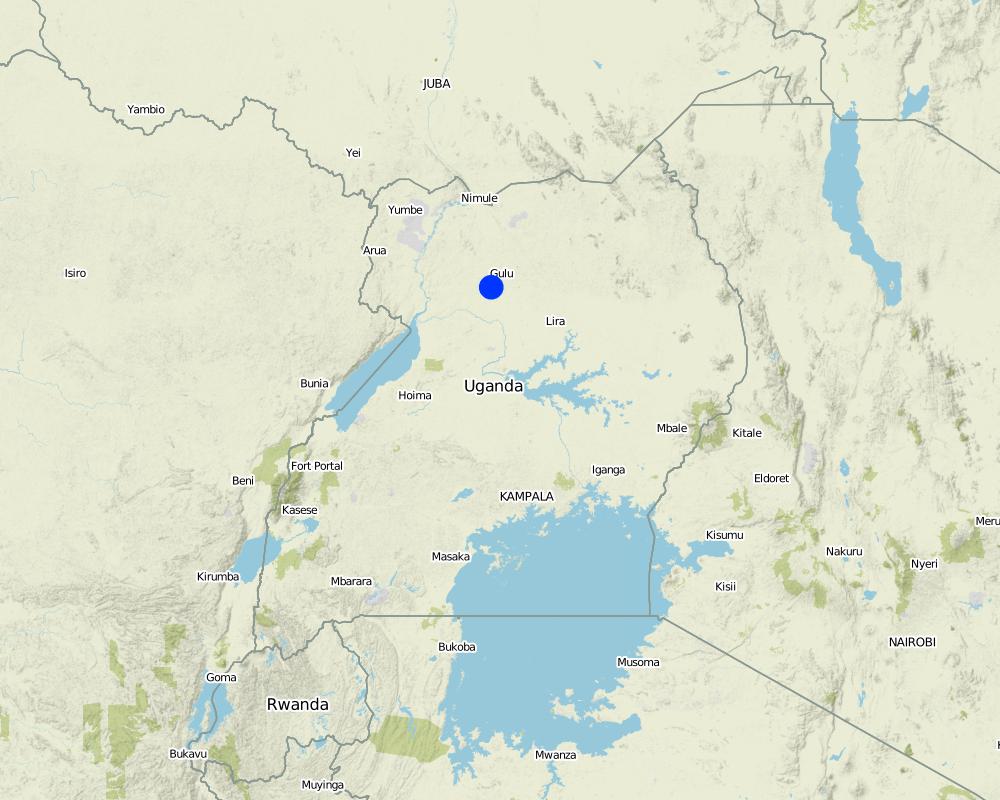

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Uganda

Region/ State/ Province:

Northern Region,Uganda

Comments:

Map showing the technology site in Northern Uganda

Map

×2.6 Date of implementation

Indicate year of implementation:

2014

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- create beneficial economic impact

- create beneficial social impact

3.2 Current land use type(s) where the Technology is applied

Grazing land

Intensive grazing/ fodder production:

- Cut-and-carry/ zero grazing

Main animal species and products:

Fresian cow, milk production, manure and calf.

If land use has changed due to the implementation of the Technology, indicate land use before implementation of the Technology:

Cropland:ca

3.3 Further information about land use

Water supply for the land on which the Technology is applied:

- rainfed

Comments:

Use tap water from neighbour(brother) who pump under ground using generator.

Number of growing seasons per year:

- 2

Livestock density (if relevant):

cow =1 . calf =1

3.4 SLM group to which the Technology belongs

- integrated crop-livestock management

- integrated soil fertility management

- Stall feeding

3.5 Spread of the Technology

Specify the spread of the Technology:

- evenly spread over an area

If the Technology is evenly spread over an area, indicate approximate area covered:

- < 0.1 km2 (10 ha)

Comments:

Barn, area where napier grass is planted, cut and carried.

3.6 SLM measures comprising the Technology

agronomic measures

- A2: Organic matter/ soil fertility

management measures

- M1: Change of land use type

- M2: Change of management/ intensity level

other measures

Comments:

Cut and carry

3.7 Main types of land degradation addressed by the Technology

chemical soil deterioration

- Cn: fertility decline and reduced organic matter content (not caused by erosion)

physical soil deterioration

- Pc: compaction

- Pu: loss of bio-productive function due to other activities

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- reduce land degradation

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

4.2 Technical specifications/ explanations of technical drawing

The stall should be 3 m tall, approximately with 4 rooms 1st floor for calf, second one for milking 3rd for sleeping and the 4th for feeding and drinking water.

The Inputs required for this technology include: concrete wall built with cement, , wood (makonko), grass or iron roof, wooden box of about 1.5x0.5 m, half drum of about 80 litres both raised at 50cm above the floor, rake , tauplin and polythene paper.

Slope: Gentle slope.

4.3 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology area

Indicate size and area unit:

1.5 acres

other/ national currency (specify):

UGX

Indicate exchange rate from USD to local currency (if relevant): 1 USD =:

3803.0

Indicate average wage cost of hired labour per day:

5000

4.4 Establishment activities

| Activity | Type of measure | Timing | |

|---|---|---|---|

| 1. | looking for land where to plant pasture | Agronomic | During the first rainy season |

| 2. | Looking for labour to clear the land, planting | Agronomic | Once in a year(April-June) |

| 3. | Looking for seed | Structural | once before establsihment |

| 4. | Planting the pasture | Structural | Daily after establishment |

| 5. | Initial construction of the stall | Structural | Once before establishment |

| 6. | Initial construction of of feeding and drinking troughs | Structural | Once before establishment |

| 7. | Putting the cow/s in the stall | Other measures | Once after establishment |

| 8. | Feeding and watering | Management | Daily |

4.5 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | labour for transporting wood and cement | Persons | 25.0 | 5000.0 | 125000.0 | 70.0 |

| Labour | Labour for preparing and planting fields | Persons | 45.0 | 5000.0 | 225000.0 | 30.0 |

| Labour | Labour for constructing stall | persons | 12.0 | |||

| Equipment | Hoe | Pieces | 2.0 | 10000.0 | 20000.0 | 100.0 |

| Equipment | Panga | Pieces | 1.0 | 7000.0 | 7000.0 | 100.0 |

| Equipment | Spranger | Pieces | 1.0 | 10000.0 | 10000.0 | 100.0 |

| Plant material | Elephant grass | bundles | 5.0 | 100000.0 | 500000.0 | 100.0 |

| Plant material | lab lab | Pieces | 4.0 | 5000.0 | 20000.0 | 100.0 |

| Plant material | Mucuna | Pieces | 1.0 | 20000.0 | 20000.0 | 100.0 |

| Construction material | Timber | Pieces | 40.0 | 3000.0 | 120000.0 | 100.0 |

| Construction material | Cement | bags | 10.0 | 30000.0 | 300000.0 | 100.0 |

| Construction material | Logs | Pieces | 60.0 | 3000.0 | 180000.0 | 100.0 |

| Construction material | Nails | kgs | 10.0 | 3500.0 | 35000.0 | 100.0 |

| Other | ||||||

| Other | Grass to thatch the stall | bundles | 24.0 | 2000.0 | 48000.0 | 100.0 |

| Total costs for establishment of the Technology | 1610000.0 | |||||

Comments:

Some seed like Macuna and brucheria was provided for free

4.6 Maintenance/ recurrent activities

| Activity | Type of measure | Timing/ frequency | |

|---|---|---|---|

| 1. | Weeding pasture | Agronomic | Three times per year |

| 2. | Repairing of stall | Structural | once after establishment and when need |

| 3. | Treatment of cow | Management | When need arises(sick) |

| 4. | Insemination | Agronomic | Once in two years |

| 5. | Spraying | Management | Twice per week |

| 6. | Reseeding | Agronomic | During the rainy season |

| 7. | Replanting of pasture | Agronomic | During the rainy season |

| 8. | Cutting and carrying the grass to the animal | Other measures | Daily after establishment |

| 9. | Collection of manure | Other measures | Daily |

| 10. | Applying manure to the garden | Agronomic | Daily |

| 11. | Making silage and hay | Agronomic | During the wet season |

4.7 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour on daily basis | Persons | 3.0 | 5000.0 | 15000.0 | 70.0 |

| Labour | Hired labour on monthly basis | Persons | 2.0 | 150000.0 | 300000.0 | 30.0 |

| Equipment | Hoe | Pieces | 10.0 | 10000.0 | 100000.0 | 100.0 |

| Equipment | Rake | Pieces | 2.0 | 7000.0 | 14000.0 | 100.0 |

| Equipment | Tauplin | Pieces | 1.0 | 35000.0 | 35000.0 | 100.0 |

| Equipment | Polythene | Rolls | 1.0 | 25000.0 | 25000.0 | 100.0 |

| Plant material | ||||||

| Plant material | pasture for planting | Bundles | 43.0 | 10000.0 | 430000.0 | 100.0 |

| Other | Pesticides (monthly) | litres | 2.0 | 12000.0 | 24000.0 | 100.0 |

| Total costs for maintenance of the Technology | 943000.0 | |||||

4.8 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Labour costs for establishing and maintaining the technology.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specify average annual rainfall (if known), in mm:

1500.00

Specifications/ comments on rainfall:

Two rainy season separated by about two weeks and dry spell and dry season of 4 weeks.

Agro-climatic zone

- sub-humid

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- not relevant

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Soil texture (> 20 cm below surface):

- fine/ heavy (clay)

Topsoil organic matter:

- medium (1-3%)

5.4 Water availability and quality

Ground water table:

5-50 m

Availability of surface water:

medium

Water quality (untreated):

good drinking water

Is water salinity a problem?

No

Is flooding of the area occurring?

No

5.5 Biodiversity

Species diversity:

- low

Habitat diversity:

- low

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- mixed (subsistence/ commercial

Off-farm income:

- less than 10% of all income

Relative level of wealth:

- average

Individuals or groups:

- individual/ household

Level of mechanization:

- manual work

Gender:

- women

- men

Age of land users:

- youth

- middle-aged

5.7 Average area of land owned or leased by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- medium-scale

Comments:

Inherited land

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, not titled

Land use rights:

- individual

Water use rights:

- communal (organized)

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

Comments/ specify:

The area which is under pasture.

fodder production

Comments/ specify:

0.5 acre improved pasture but lack management.

animal production

Quantity before SLM:

3 litres of milk per day

Quantity after SLM:

10litres of milk per day

Comments/ specify:

Increased milk production.

production area

Comments/ specify:

Additional fodder.

land management

Comments/ specify:

Trees hold soils , are perennial as compared to annuals that need to be planted every year and need less maintenance.

Water availability and quality

water quality for livestock

Comments/ specify:

But it has no much effect.

Income and costs

expenses on agricultural inputs

Comments/ specify:

Planting material.

farm income

Comments/ specify:

Sale of milk.

diversity of income sources

Comments/ specify:

More products for sale (grass, milk, manure).

workload

Comments/ specify:

Feeding animal.

Socio-cultural impacts

food security/ self-sufficiency

Comments/ specify:

Income received from sale of milk is used for buying food.

community institutions

Comments/ specify:

Especially in savings and credit (SACCO).

Ecological impacts

Soil

soil loss

Comments/ specify:

Restricted movements of cattle since the ve is only cut and carried to where the animal is fed.

soil compaction

Comments/ specify:

Less tampering with the soil.

soil organic matter/ below ground C

Comments/ specify:

Due to application of manure.

6.2 Off-site impacts the Technology has shown

damage on neighbours' fields

Comments/ specify:

No zero grazing.

impact of greenhouse gases

Comments/ specify:

No bio gas production.

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | Type of climatic change/ extreme | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | moderately |

Comments:

The land user requires more knowledge and skills for sustainability of this technology.

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

positive

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

positive

Long-term returns:

very positive

Comments:

Once established the farmer needs only to pay for labour to cut and carry grass and make silage and hay only.

6.5 Adoption of the Technology

- 1-10%

Of all those who have adopted the Technology, how many have did so spontaneously, i.e. without receiving any material incentives/ payments?

- 0-10%

Comments:

Motivated by NGO.

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

Yes

If yes, indicate to which changing conditions it was adapted:

- climatic change/ extremes

Specify adaptation of the Technology (design, material/ species, etc.):

During the dry season, the land user seeks fodder from the swamps.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| The technology is good at providing income for household needs. |

| The technology is replicable in other areas and helps diversify income source because of the many products derived from the technology. |

| Does not require labour to attend to it for 12 hours in a day unlike those technologies that concern cultivation. This means the farmer has more time to do other activities in a day. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Appropriate for low maintenance costs. |

| The technology does not promote conflicts among land users. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| High costs of treatment. | Reduce risk of infection and infestation. |

| Veterinary services expensive and not easily available. | Training of local trainers to support extension. |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| The technology is not sustainable if not well manged by the land user. | Improve management of the technology. |

| Requires day to day monitoring of diseases. | Engage household labour to keep alternating. |

| The land user require skills on how to make concentrates. | Train the land user on how to make concentrates. |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

01

- interviews with land users

01

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules