Passive solar greenhouses for winter commercial vegetable production [Tajikistan]

- Creation:

- Update:

- Compiler: Julie Zähringer

- Editor: –

- Reviewers: Alexandra Gavilano, David Streiff, Joana Eichenberger

technologies_1041 - Tajikistan

- Full summary as PDF

- Full summary as PDF for print

- Full summary in the browser

- Full summary (unformatted)

- Passive solar greenhouses for winter commercial vegetable production: March 21, 2017 (inactive)

- Passive solar greenhouses for winter commercial vegetable production: July 28, 2017 (inactive)

- Passive solar greenhouses for winter commercial vegetable production: Aug. 19, 2019 (inactive)

- Passive solar greenhouses for winter commercial vegetable production: Nov. 2, 2021 (public)

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

SLM specialist:

Khudonazarov Artur

Manager of the "Centre for Sustainable and Innovative Technology", a project of MSDSP

Tajikistan

SLM specialist:

Shariff Jamil

MSDSP

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Pilot Program for Climate Resilience, Tajikistan (WB / PPCR)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Kyrgyzstan Mountain Societies Development Support Programme, Aga Khan Development Network (MSDSP KG) - Kyrgyzstan1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Passive solar greenhouses heated entirely by sunlight were established with the aim to produce vegetables for commercial use during the harsh winter conditions.

2.2 Detailed description of the Technology

Description:

A passive solar greenhouse is a greenhouse heated entirely by sunlight, with no additional fuel-based heating. In the Pamirs, the temperature inside these greenhouses can be kept high enough to grow vegetables throughout the year, even in winter if the greenhouse is built efficiently. Thus greenhouses can be of great use, particularly in those areas where there are continuing concerns about food security and economic development. These greenhouses were developed by GERES (Renewable Energy and Environment Group) and ICIMOD (International Centre for Integrated Mountain Development) and first tested with farmers in Ladakh, India. MSDSP adopted the idea and introduced it to the GBAO region in Tajikistan establishing 3 demonstration greenhouses in collaboration with farmers in the Shugnan district in 2010.

Purpose of the Technology: A solar greenhouse aims to trap and intensify the heating effect of solar radiation and thus enables plants to be grown that cannot be grown under the normal (outside) ambient conditions. Solar greenhouses are particularly useful in areas where there is a lot of sunshine in winter, but where the air is too cold for growing crops. The main benefits of solar greenhouses are that vegetables can be grown during the winter, helping to fulfill basic subsistence needs of people in remote areas and income generation through selling the produce.

Establishment / maintenance activities and inputs: A greenhouse is only efficient if it is constructed in the right place, in the right way, and is used properly. An efficient solar greenhouse should be designed along an east-west axis, with the length of the south face increased and angled to present the largest possible surface area to the sun, the size of the east and west facing walls reduced to minimise heat loss and provide shade inside the greenhouse, and the north wall should be heavily insulated.

The following steps are required in constructing an efficient greenhouse: (1) selecting an appropriate place: there needs to be a source of running water close to the greenhouse, solar radiation needs to be sufficient (sunrise should be before 9.30 and sunset after 3.00 pm even on the shortest days of the year), the land has to be flat and dry; (2) selecting the most appropriate design: (see manual); (3) constructing the foundation: digging a trench and filling the foundation with mud mortar; (4) preparing the floor; (5) building the double walls separated by one insulation layer; (6) making and installing an access door; (7) making and installing the wall ventilator; (8) constructing the roof; (9) making and installing the roof ventilator (shutter); (10) installing the polyethylene shutter; (11) installing night insulation.

Natural / human environment: The greenhouses were established in three villages of Shugnan district: Buni, Sokhcharv and Darmoracht. Two of these villages are located at about 2,500 metres a.s.l. and receive less than 300 mm of annual precipitation. The farmers who constructed these greenhouses are small-scale farmers with less than 0.5 ha of land available.

2.3 Photos of the Technology

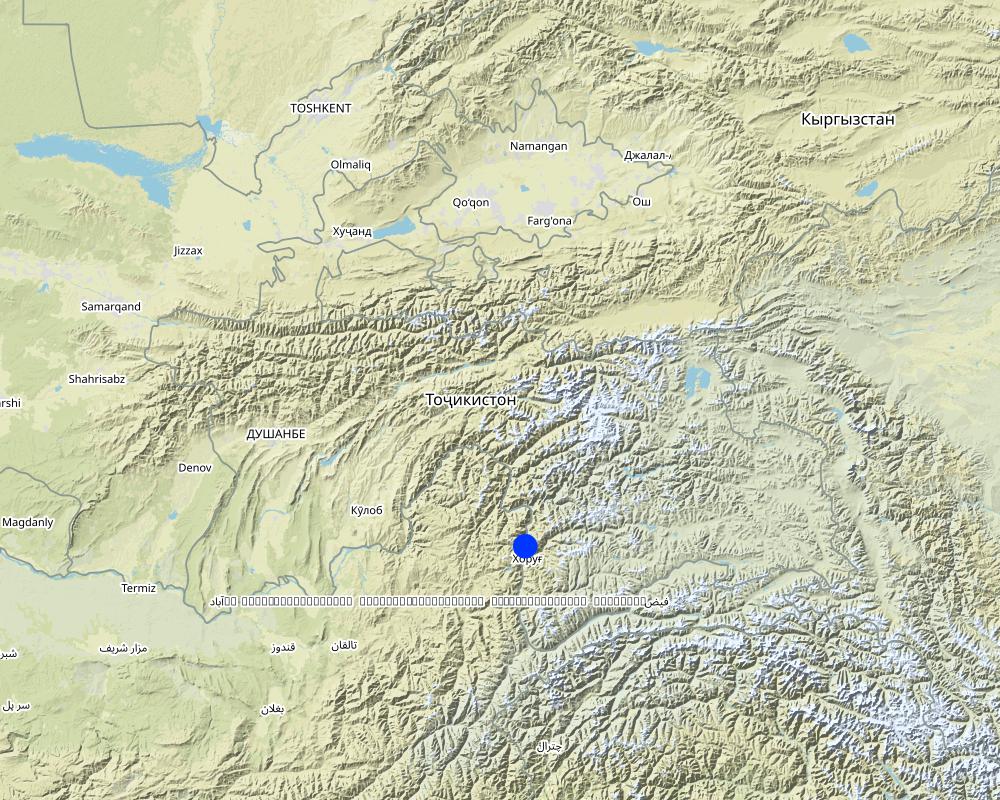

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Tajikistan

Region/ State/ Province:

Tajikistan

Further specification of location:

GBAO/Shugnan

Comments:

At least 3 greenhouses built in Shugnan district, each one is 50 m2 in size.

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

Comments (type of project, etc.):

2010

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

- Cucumbers, tomatoes, radishes, salad greens, onions

Number of growing seasons per year:

- 1

Specify:

Longest growing period in days: 170Longest growing period from month to month: late April-early October

Settlements, infrastructure

- Settlements, buildings

Comments:

Major land use problems (compiler’s opinion): A lack of precipitation and therefore irrigation water, soil erosion, low soil fertility (no fertilisers used or rotations), harsh climatic conditions (high altitude).

Future (final) land use (after implementation of SLM Technology): Cropland: Ca: Annual cropping

3.3 Has land use changed due to the implementation of the Technology?

Cropland

- Annual cropping

Settlements, infrastructure

3.4 Water supply

Water supply for the land on which the Technology is applied:

- full irrigation

3.5 SLM group to which the Technology belongs

- home gardens

- greenhouse

3.6 SLM measures comprising the Technology

agronomic measures

- A2: Organic matter/ soil fertility

structural measures

- S11: Others

Comments:

Main measures: agronomic measures, structural measures

Type of agronomic measures: manure / compost / residues

3.7 Main types of land degradation addressed by the Technology

chemical soil deterioration

- Cn: fertility decline and reduced organic matter content (not caused by erosion)

biological degradation

- Bq: quantity/ biomass decline

- Bs: quality and species composition/ diversity decline

Comments:

Main type of degradation addressed: Cn: fertility decline and reduced organic matter content, Bq: quantity / biomass decline, Bs: quality and species composition /diversity decline

Main causes of degradation: soil management (no application of fertilisers), deforestation / removal of natural vegetation (incl. forest fires), overgrazing, change of seasonal rainfall (decreased), droughts

Secondary causes of degradation: war and conflicts (during the civil war a lot of vegetation was cut to provide energy)

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

4. Technical specifications, implementation activities, inputs, and costs

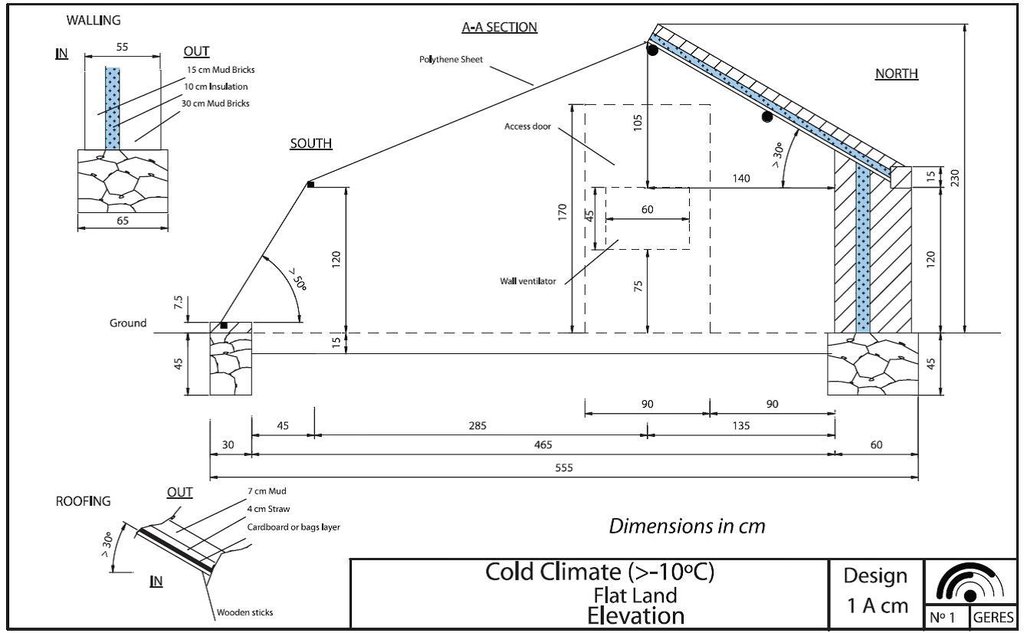

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

The diagram shows a greenhouse adapted to a cold climate, for greenhouses adapted to different climates please see the manual (annex 1)

GBAO

Date: 2004

Technical knowledge required for field staff / advisors: high

Technical knowledge required for land users: moderate (brochures available in Tajik)

Main technical functions: increase in organic matter, reduction in wind speed, increase of biomass (quantity), spatial arrangement and diversification of land use, production of microclimate suitable for crop growth in winter

Manure / compost / residues

Material/ species: manure is mixed with the soil to cover the floor of the greenhouse

Structural measure: greenhouse

Construction material (earth): mud

Construction material (stone): stone

Construction material (wood): wood (poplar, willow)

Construction material (other): straw, wool

Author:

GERES / ICIMOD

4.2 General information regarding the calculation of inputs and costs

other/ national currency (specify):

Somoni

If relevant, indicate exchange rate from USD to local currency (e.g. 1 USD = 79.9 Brazilian Real): 1 USD =:

4.5

Indicate average wage cost of hired labour per day:

9.00

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Digging trench for fundament, 60 cm deep | spring |

| 2. | Put fundament using stones mixed with mud | |

| 3. | Build walls: outer layer stones (40 cm width), then insulation layer with straw or wool (10 cm), inner layer out of mudbricks (15-20 cm). Total height of wall is 1.20 m. | |

| 4. | Build doors | |

| 5. | Build wall ventilators | |

| 6. | Build roof: southfacing side put 2 layers of each 40m2 cellophane, northfacing side put woodlogs | |

| 7. | Build roof ventilators | |

| 8. | Install night insulation |

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Digging trench for fundament, | Persons/day | 3.0 | 40.0 | 120.0 | 100.0 |

| Labour | Put fundament | Persons/day | 10.5 | 40.0 | 420.0 | 100.0 |

| Labour | Build walls | Persons/day | 30.0 | 40.0 | 1200.0 | 100.0 |

| Labour | Build doors | Persons/day | 2.0 | 20.0 | 40.0 | 100.0 |

| Equipment | Shovels | Pieces | 2.0 | 20.0 | 40.0 | 100.0 |

| Equipment | Nails | kg | 3.0 | 10.0 | 30.0 | |

| Construction material | Cellophane foil | sq m | 80.0 | 4.0 | 320.0 | |

| Other | Labour: Build wall ventilators | Persons/day | 12.0 | 40.0 | 480.0 | 100.0 |

| Other | Labour: Build roof ventilators | Persons/day | 4.0 | 40.0 | 160.0 | 100.0 |

| Other | Labour: Install night insulation | Persons/day | 5.0 | 40.0 | 200.0 | 100.0 |

| Total costs for establishment of the Technology | 3010.0 | |||||

| Total costs for establishment of the Technology in USD | 668.89 | |||||

If land user bore less than 100% of costs, indicate who covered the remaining costs:

MSDSP

Comments:

Duration of establishment phase: 1.5 month(s)

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Replace cellophane | when needed, every 1-2 years for bad material, 5 years for good material |

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Replace cellophane | Persons/day | 2.0 | 40.0 | 80.0 | 100.0 |

| Construction material | Cellophane | sq m | 80.0 | 4.0 | 320.0 | 100.0 |

| Total costs for maintenance of the Technology | 400.0 | |||||

| Total costs for maintenance of the Technology in USD | 88.89 | |||||

Comments:

The costs were calculated for the establishment of one 5x10m greenhouse.

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Apart from the cellophane cover, mainly local materials were used which did not require investments. If labour has to be paid, this is the most determinate factor, also wooden poles if they have to be bought.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specifications/ comments on rainfall:

200-300 mm

Agro-climatic zone

- arid

Thermal climate class: temperate

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Comments and further specifications on topography:

Landforms: plateau / plains, hill slopes, footslopes, valley floors

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- coarse/ light (sandy)

Topsoil organic matter:

- low (<1%)

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

Soil fertility is low

Soil drainage / infiltration is medium

Soil water storage capacity is medium

5.4 Water availability and quality

Ground water table:

< 5 m

Availability of surface water:

good

Water quality (untreated):

poor drinking water (treatment required)

Comments and further specifications on water quality and quantity:

Water availability is good because area is close to river.

5.5 Biodiversity

Species diversity:

- low

5.6 Characteristics of land users applying the Technology

Market orientation of production system:

- mixed (subsistence/ commercial)

- commercial/ market

Off-farm income:

- less than 10% of all income

Relative level of wealth:

- average

Individuals or groups:

- individual/ household

Level of mechanization:

- animal traction

- mechanized/ motorized

Gender:

- women

- men

Indicate other relevant characteristics of the land users:

Land users applying the Technology are mainly common / average land users

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- state

- individual, titled

Land use rights:

- individual

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

risk of production failure

production area

Income and costs

farm income

diversity of income sources

workload

Comments/ specify:

During construction of the greenhouse, 6 weeks

Other socio-economic impacts

Establishment costs

Comments/ specify:

high investment (400 $ for 1 greenhouse)

Socio-cultural impacts

food security/ self-sufficiency

health situation

Livelihood and human well-being

Comments/ specify:

Higher income and better health through availability of vegetables in the winter

Ecological impacts

Other ecological impacts

Creation of microclimate for growing vegetables during wintertime

6.2 Off-site impacts the Technology has shown

Availability of vegetables on the market during wintertime

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | well |

Climate-related extremes (disasters)

Meteorological disasters

| How does the Technology cope with it? | |

|---|---|

| local windstorm | not well |

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | not well |

Other climate-related consequences

Other climate-related consequences

| How does the Technology cope with it? | |

|---|---|

| reduced growing period | well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

slightly positive

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

slightly positive

Long-term returns:

very positive

Comments:

Income revenues from vegetables are high, during one winter season two yields of vegetables can be planted.

6.5 Adoption of the Technology

- single cases/ experimental

If available, quantify (no. of households and/ or area covered):

3 households

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 0-10%

Comments:

100% of land user families have adopted the Technology with external material support

3 land user families have adopted the Technology with external material support

There is a strong trend towards spontaneous adoption of the Technology

Comments on adoption trend: many land users who have seen the demonstration greenhouses want to start constructing their own.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

|

The materials are locally available (mud, wood, straw, stone), except for the transparent cover sheet How can they be sustained / enhanced? Some traders should start providing transparent foil |

|

Using the available construction manual it can be constructed by local builders How can they be sustained / enhanced? The local builders still need to be advised by specialists |

|

The cost can be recouped in less than three years if the production is well-managed and the products sold |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

|

Vegetable production during wintertime and diversified food production all year round How can they be sustained / enhanced? Farmers should have access to microloan organisations in order to be able to invest in building greenhouses (initial investments are relatively high) |

|

Availability of vegetables during wintertime, otherwise they have to be brought in from the capital (600 km by road) which makes them very expensive How can they be sustained / enhanced? Greenhouses should be distributed over the whole of GBAO in order to ensure local availability of crops, because during wintertime transport might be a big problem |

|

Income opportunity How can they be sustained / enhanced? Better access to markets would improve profitability |

|

Minimal heat loss, heat is stored during the day time and released at night How can they be sustained / enhanced? The greenhouse and should be constructed in a very careful and exact manner in order to make sure that the inside temperature can be well regulated |

|

Adequate air circulation and prevention of crop damage by overheating, through installation of manually operated ventilators in walls and roof How can they be sustained / enhanced? Farmers need access to specialists who will help them in designing greenhouses appropriate to the prevailing ecological conditions |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| Comparatively expensive, about 400 USD have to be invested for the construction of one greenhouse | The increased revenues from selling the produced vegetables can help cover the initial investment |

| Comparatively time consuming to build compared to conventional greenhouses in the area, one greenhouse needs about 6 weeks to be constructed | Plastic poles could be used instead of wooden ones |

| No good quality cellophane foil is available in this area, therefore it has to be replaced every 1-2 years | Instead of cellophane plexiglas could be used which is stronger. |

7. References and links

7.1 Methods/ sources of information

7.2 References to available publications

Title, author, year, ISBN:

Stauffer, Vincent. Solar Greenhouses for the Trans-Himalayas. Kathmandu, ICIMOD / Aubagne, GERES 2004.

Available from where? Costs?

http://books.icimod.org/index.php/search/publication/93

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules