Integrated agronomic measure for sustainable cassava production in convex sloppy landform [Tanzania, United Republic of]

- Creation:

- Update:

- Compiler: ALLAN BUBELWA

- Editor: –

- Reviewers: Ursula Gaemperli, Fabian Ottiger, Alexandra Gavilano

Matumizi ya matuta na vikinga maji katika kilimo cha mihogo

technologies_1201 - Tanzania, United Republic of

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

SLM specialist:

Kamene Nyangeta

Karonge Village

Tanzania, United Republic of

District council member:

Baraba Gordfrey

Bukoba District Council

Tanzania, United Republic of

Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Bukoba district council (Bukoba district council) - Tanzania, United Republic of1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Use of contour ridging cultivation, tiles, manure application and improved genetic material for sustainable cassava production in convex sloppy landforms.

2.2 Detailed description of the Technology

Description:

Contour ridges cultivation is a seasonal water conservation and erosion control land tilling practice aiming at improving production of cassava (Manihot esculenta), improving potential of the soil and environmental function of the land. The technology is among a list of basket of choices of SLM practices recently introduced and adapted to the area by land user working in collaboration with extension officers/SLM specialists under the auspicious support of the Tras-boundary Agro-ecosystem Management Project (Kagera TAMP).

Contour ridges are cultivated in rows across a convex slope landform of average slope category lying between 5-8%. The average height of a ridge is 0.45 -0.50m, with width lying between 0.4 -0.5m, and the distance between rows is 1 meter. To be stronger, contour ridges are tied with furrows (Tiles) dug along the slope intercepting the ridges almost perpendicular. Within a cassava block farm of average size 0.5 acres, the average length of a contour ridge is approximately 30 - 35m. Within tiles, pits are dug. The distance from one pit to another is usually 5 meters. Soils from dug pit are piled on the lower side of the slope to form a supportive bund which is stabilized and made productive by planting pineapples on it. The number of pineapples (suckers) planted on each pit bund is 3-4. Tiles provide diagonal strength to the ridges, trap runoff and allow water to infiltrate and be available to the plants. Manure application is done after contour ridging by incorporating or mixing manure with soil. Manure application at a rate of 12 tons per hectare is done before cassava planting.

Purpose of the Technology: The basic tenet of this technology is to turn a poorly managed land resource that is exposed to detrimental grazing, poor agricultural practices and uncontrolled fire burning into a managed, productive agricultural land that contribute to improved agriculture production, livelihood income and ecosystems (put the triple win solution into reality).

The rural food security and income are enhanced through soil erosion control, fertility improvement, beneficial harvesting of rainfall-runoff and use of improved cassava germ-plasm (with high resilience to climatic change and diseases and no use of chemicals).

Establishment / maintenance activities and inputs: The technology is largely agronomic dominated by seasonally repeatedly activities. The dominant recurrent activities are land preparation, contour ridging cultivation, tile digging (furrow digging, pit digging, bund making and pineapple planting), manure application, cassava planting, weeding and harvesting. The inputs needed are: tools (machete, sickles, hand holes), planting materials (cassava and pineapple), manure and labour.

The average costs per hectare of this technology is 1155.48 USD. Manure application is the most cost determinant factor and accounts for 50.89% of the total costs. Average production of cassava per hectare is 7,376.32 USD. In monetary terms the average benefit to cost ratio B/C is 6.38 exemplifying viability of the technology.

Natural / human environment: Naturally the environment encompasses cropland land use type , the technology is largely agronomic, climatic zone is sub humid with 210 length of growing period, slope category is foot slopes, the dominant soil textural class is loam with a medium soil depth. On human environment the defined level of mechanization is largely hand tools, production is mixed. land ownership is largely individual not titled and there is also communally owned land.

2.3 Photos of the Technology

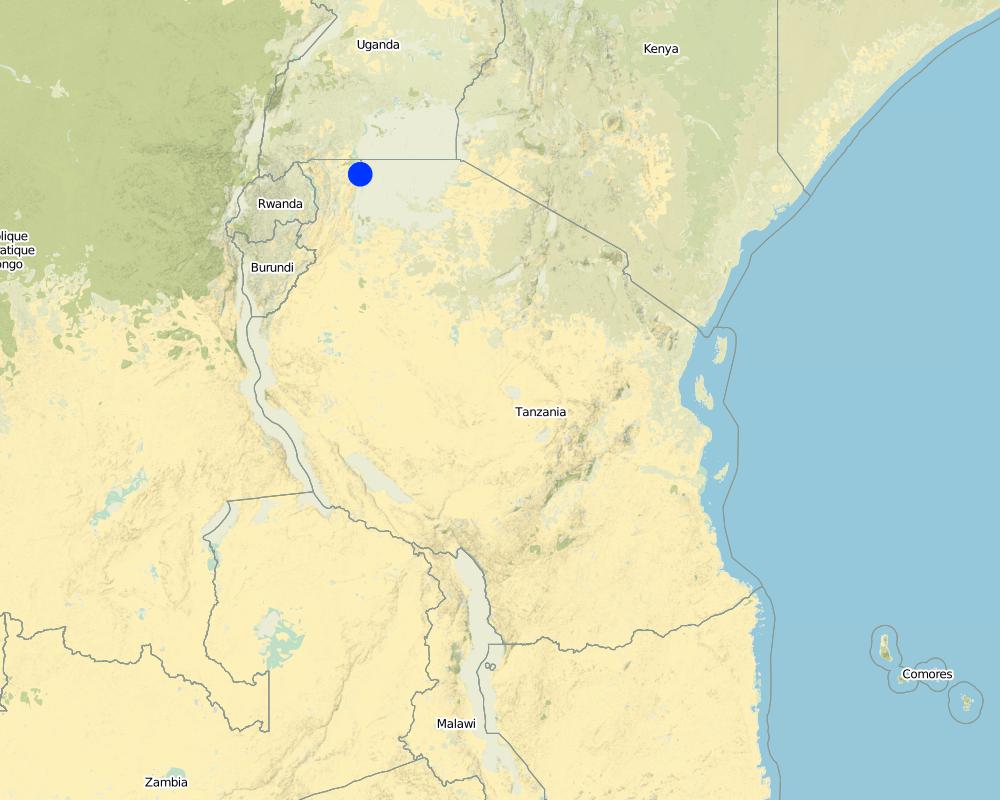

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Tanzania, United Republic of

Region/ State/ Province:

Tanzania/Kagera

Further specification of location:

Bukoba rural district/Karonge

Specify the spread of the Technology:

- evenly spread over an area

If precise area is not known, indicate approximate area covered:

- < 0.1 km2 (10 ha)

Comments:

The area considered is a portion of area exposed to degradation and under SLM Farmer Field School training.

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

Comments (type of project, etc.):

Is one of the technology being promoted in Bukoba Rural District through Community integrated catchment ecosystem approach (SLM FFS approach) supported by the Kagera Trans boundary Argo-ecosystem management project (Kagera TAMP).

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- reduce, prevent, restore land degradation

- create beneficial economic impact

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

- Perennial (non-woody) cropping

Annual cropping - Specify crops:

- root/tuber crops - cassava

Perennial (non-woody) cropping - Specify crops:

- pineapple

Number of growing seasons per year:

- 2

Specify:

Longest growing period in days: 120, Longest growing period from month to month: September to December Second longest growing period in days: 90 Second longest growing period from month to month: March to May

Comments:

Major land use problems (compiler’s opinion): Soil erosion caused by rainfall runoff, soil infertility, poor soil moisture and poor cassava husbandry practices that contribute to low productivity.

Major land use problems (land users’ perception): Poor unproductive soil and cassava diseases.

3.5 SLM group to which the Technology belongs

- integrated soil fertility management

- improved plant varieties/ animal breeds

3.6 SLM measures comprising the Technology

agronomic measures

- A2: Organic matter/ soil fertility

- A3: Soil surface treatment

Comments:

Type of agronomic measures: contour planting / strip cropping, manure / compost / residues, contour ridging, furrows (drainage, irrigation), pits

3.7 Main types of land degradation addressed by the Technology

soil erosion by water

- Wt: loss of topsoil/ surface erosion

chemical soil deterioration

- Cn: fertility decline and reduced organic matter content (not caused by erosion)

Comments:

Main causes of degradation: soil management (Ignorance in fertility, nutrients and moisture improvement methods, contuor ridge ploughing along the slope), crop management (annual, perennial, tree/shrub) (Poor crop husnbandry practices (use of cassava varieties prone cassava mildew, use of incorrect crop stand)), population pressure (Continuous use of the land), poverty / wealth (Incapacity to invest effectively in sustainable land managment), governance / institutional (Poor bylaw and law reinforcement especially in disease control)

Secondary causes of degradation: deforestation / removal of natural vegetation (incl. forest fires) (Uncontrolled fire burning, poor agricultural methods (biasness to land expansion rather than intensification)), change in temperature (Due to climatic change and variability), change of seasonal rainfall (Due to climatic change and variability), Heavy / extreme rainfall (intensity/amounts) (Due to climatic change and variability), droughts (Due to climatic change and variability)

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

- reduce land degradation

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

echnical knowledge required for field staff / advisors: low (Skills and knowledge on contour ridging cultivation, use of tiles and manuring can easily be acquired by field staff and spread to farmers.)

Technical knowledge required for land users: moderate (Skills and knowledge on contour ridging cultivation, use of tiles and manuring are simple and can easily be learn and adopted by farmers through FFS training.)

Main technical functions: control of dispersed runoff: impede / retard, control of concentrated runoff: retain / trap, increase in nutrient availability (supply, recycling,…), increase of infiltration, increase / maintain water stored in soil

Contour planting / strip cropping

Material/ species: Cassava cuttings

Quantity/ density: 10000/ha

Remarks: crop stand per hactere (spacing 1mx1m)

Agronomic measure: tile pit stabilization

Material/ species: Pineapples planted to stabilize pits

Quantity/ density: 180

Remarks: pineapples sucker in one ha

Manure / compost / residues

Material/ species: Cow dung (tonnes)

Quantity/ density: 35 t/ha

Remarks: Spread along farm

Contour ridging

Material/ species: Cultivated ridges across the slope

Quantity/ density: 24 r/ha

Remarks: Space between rows is 1m

Furrows (drainage, irrigation)

Material/ species: Tiles dug along the slope

Quantity/ density: 6 tiles/ha

Remarks: Space between tiles is 8m

Pits

Material/ species: Water collection pits dug within furrow/tile

Quantity/ density: 12pits/ha

Remarks: 2 pits/tile. each tile stabilized by 3-4 pinneapples

4.2 General information regarding the calculation of inputs and costs

other/ national currency (specify):

Tanzanian shillings

If relevant, indicate exchange rate from USD to local currency (e.g. 1 USD = 79.9 Brazilian Real): 1 USD =:

1700.0

Indicate average wage cost of hired labour per day:

1.50

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | tools |

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Equipment | Tools | pieces | 36.0 | 2.9167 | 105.0 | 100.0 |

| Plant material | cassava cuttings | 1.0 | ||||

| Fertilizers and biocides | compost/manure | 1.0 | ||||

| Total costs for establishment of the Technology | 105.0 | |||||

| Total costs for establishment of the Technology in USD | 0.06 | |||||

Comments:

Duration of establishment phase: 1 month(s)

Lifespan of the tools: 5 years

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Land preparation (clearing and ploughing) | November |

| 2. | Contour ridging cultivation combined with tiles. | December |

| 3. | Manure application | December |

| 4. | Procurement of improved cassava varieties (Mkombozi) and pineapple suckers. | December |

| 5. | Planting cassava and pineapple | December |

| 6. | Weeding | February and September |

| 7. | Harvesting | Once annualy |

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Land preparation | person/days | 45.0 | 1.17777 | 53.0 | 100.0 |

| Labour | Contour ridging cultivation combined with tiles. | person/days | 60.0 | 1.46666 | 88.0 | 100.0 |

| Labour | Manure application | person/days | 30.0 | 1.46666 | 44.0 | 100.0 |

| Labour | Planting cassava and pineapple | person/days | 13.0 | 1.154 | 15.0 | 100.0 |

| Equipment | Tools | 1.0 | 100.0 | |||

| Plant material | cassava cuttings | pieces | 10000.0 | 0.017648 | 176.48 | |

| Plant material | pineapple suckers | pieces | 180.0 | 0.28888888 | 52.0 | |

| Fertilizers and biocides | Compost/manure | Tons | 12.0 | 49.0 | 588.0 | |

| Other | Labour: Weeding | person/days | 26.0 | 0.577 | 15.0 | 100.0 |

| Other | Labour: Harvesting | person/days | 26.0 | 0.7307 | 19.0 | 100.0 |

| Total costs for maintenance of the Technology | 1050.48 | |||||

| Total costs for maintenance of the Technology in USD | 0.62 | |||||

Comments:

Machinery/ tools: machete, hand hoe (flat and fork) and sickles.

Labour, tools, manure and planting materials per hectare of land subjected to technology/under cassava production.

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Manuring is the most determinant factor affecting the costs.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specifications/ comments on rainfall:

Long sesaon September to December, short season March to May. September to December 180 days, March to May 90 days, Total 210

Agro-climatic zone

- sub-humid

Thermal climate class: tropics. Average 21°C

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- convex situations

Comments and further specifications on topography:

Slopes on average: Moderate (Convex foot slope of average slope category of 5-8%)

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Topsoil organic matter:

- medium (1-3%)

- low (<1%)

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

Soil depth on average: Moderately deep (moderate deep loam soil)

Soil fertility: Low

Soil drainage/infiltration: Medium

Soil water storage capacity: Medium

5.4 Water availability and quality

Ground water table:

> 50 m

Availability of surface water:

medium

5.6 Characteristics of land users applying the Technology

Off-farm income:

- less than 10% of all income

Relative level of wealth:

- poor

- average

Indicate other relevant characteristics of the land users:

4% of the land users are rich and own 32% of the land.

32% of the land users are average wealthy and own 64% of the land.

64% of the land users are poor and own 4% of the land.

Off-farm income specification: Most run local bar

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Comments:

Average area of land owned or leased by land users applying the Technology:

< 0.5 ha (ranked 2, poor farmers account for about 25%)

0.5-1 ha (ranked 1, medium farmer account for about 60%)

1-2 ha (ranked 3, rich farmers account for about 15%)

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, not titled

Comments:

Land is acquired through inheritance or purchase from farmers owning the land.

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

Quantity before SLM:

12

Quantity after SLM:

24

wood production

risk of production failure

Quantity before SLM:

12

Quantity after SLM:

0

product diversity

Comments/ specify:

Only food

production area

Comments/ specify:

Few adopters

land management

Income and costs

expenses on agricultural inputs

Quantity before SLM:

30 dollars

Quantity after SLM:

940 dollas

Comments/ specify:

Due to manue application, purchase of improved cartivars and suckers

farm income

Quantity before SLM:

600

Quantity after SLM:

1200

workload

Comments/ specify:

Weeding is done once. Needs a lot more labour, hired labourers

Socio-cultural impacts

food security/ self-sufficiency

Quantity before SLM:

0.3

Quantity after SLM:

0.7

Comments/ specify:

Demo site only

SLM/ land degradation knowledge

Comments/ specify:

Very few adoption

situation of socially and economically disadvantaged groups

Comments/ specify:

Few widows

Improved livelihoods and human well-being

Comments/ specify:

Increased productivity above 50% leading to increase income and farmers capacity to invest in education and health.

Ecological impacts

Water cycle/ runoff

harvesting/ collection of water

surface runoff

Comments/ specify:

Close ridges

excess water drainage

Soil

soil cover

nutrient cycling/ recharge

Comments/ specify:

Residuals

soil organic matter/ below ground C

Comments/ specify:

Manure application

Biodiversity: vegetation, animals

biomass/ above ground C

Comments/ specify:

Residuals

pest/ disease control

Comments/ specify:

Pure stand

Climate and disaster risk reduction

fire risk

Comments/ specify:

Guarding

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | not well |

Climate-related extremes (disasters)

Meteorological disasters

| How does the Technology cope with it? | |

|---|---|

| local rainstorm | not well |

| local windstorm | not known |

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | not well |

Hydrological disasters

| How does the Technology cope with it? | |

|---|---|

| general (river) flood | not known |

Other climate-related consequences

Other climate-related consequences

| How does the Technology cope with it? | |

|---|---|

| reduced growing period | not well |

Comments:

Contour ridging cultivation strengthened with Tiles or furrow dug along the slope intercepting ridges almost perpendicular. Each tile has 2 pits dug at an average distance of 5meters. The dug pits have supportive bunds on the lower side of the slope and the bunds is stabilized by planting pineapples. Tiles improve tolerance of ridge to seasonal rainfall decrease.

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

positive

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

positive

Long-term returns:

very positive

Comments:

The quality of cassava has improved and there is an increase in productivity. In general rewards are realized within a short term i.e. benefit accrued from cassava surpass the initial investment costs.

6.5 Adoption of the Technology

If available, quantify (no. of households and/ or area covered):

50 households and 10% of the area covered

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 11-50%

Comments:

25 land user families have adopted the Technology with external material support

Comments on acceptance with external material support: 80% of farmers accepted the technology through material support.

25% of land user families have adopted the Technology without any external material support

25 land user families have adopted the Technology without any external material support

Comments on spontaneous adoption: As the technology was introduced recently percentage adoption through own investment is low but farmers are impressed by benefit accrued from the technology and there is expectation that in the long run voluntary adoption is to be observed.

There is a little trend towards spontaneous adoption of the Technology

Comments on adoption trend: There is a vivid evidence of technology adoption and in the near future significant technology adoption is expected to be realized.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| Group strength and cohesiveness. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| The technology contributes to soil erosion control, improved soil fertility and improved soil moisture. |

| There is increase in cassava productivity and income accrued from sell of cassava. |

| The technology promote diversification of income sources (cassava and pineapples) |

| Poorly managed land is changed into well managed and beneficial productive agricultural land. |

| Increased farmers commitment to mitigate land degradation |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| High expectation due to promissory at the project beginning | Stick and give emphasis to project objectives. |

| Slow and weak response of some farmers (group dynamics) | Enhance access to quality extension services. |

| Material support ideology | Change mindset of farmer from material incentive to self mobilization |

| Community ignorance in land protective bylaws | Awareness creation of farmers to laws and act guiding environmental conservation and reinforce use of bylaws. |

| Never attended any study tours | Introduce look and learn tour for farmers to see and learn best practices. |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| High initial investment capital (manure is the most cost determinant factor) | Establishment of rural micro finance institutions and formation of inter group farmer associations and networks. |

| Post harvest losses, farmer ignorance in Cassava value addition technologies and tendencies to sell cassava at farm gate dilutes maximum profit realization. | Support to post harvest technology and value addition technologies for maximum realization of profit. |

| Shortage of improved planting materials (germ plasma) | Liaise with research station for adequate multiplication and distribution of improved planting materials. |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

- interviews with land users

When were the data compiled (in the field)?

26/05/2014

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules