No-till technology [Morocco]

- Creation:

- Update:

- Compiler: Rachid Mrabet

- Editor: –

- Reviewers: Alexandra Gavilano, David Streiff, Deborah Niggli

technologies_1253 - Morocco

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Book project: where the land is greener - Case Studies and Analysis of Soil and Water Conservation Initiatives Worldwide (where the land is greener)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Institut National de la Recherche Agronomique Morocco (INRA-Morocco) - Morocco1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.5 Reference to Questionnaire(s) on SLM Approaches (documented using WOCAT)

Applied research and knowledge transfer [Morocco]

Innovative, cross-disciplinary community-based approach for development and transfer of no-till technology at the farm level.

- Compiler: Rachid Mrabet

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

A no-till system with crop residue management for mediumscale wheat and barley farming.

2.2 Detailed description of the Technology

Description:

This no-till technology (NTT) system, with direct seeding and crop residue management, was designed by the National Institute of Agricultural Research (INRA) in Settat, Morocco. A special no-till drill was developed to simultaneously seed and fertilize annual crops: the drill cuts through residue, opens a 20 cm wide slot which, after seed and N/P-fertilizers are dropped into it, is closed firmly to encourage contact between seed and soil. Seeding is earlier than in the case of conventional tillage – which requires seedbed preparation. Spacing between rows is adjusted according to crop type: 20 cm for wheat or barley, and 40 cm for lentils and chickpeas. Tillage depth is between 5–12 cm depending on soil workability and moisture content.

Establishment / maintenance activities and inputs: Crops, planted in rotation with a fallow period, are barley, wheat, legumes (lentils and chickpea) and also fodder species. Application of special herbicides replaces tillage for weed control, and enables the farmer to have an 18-month fallow period (a ‘chemical fallow’) after two crops have been taken over a 6-month period. Fallowing is essential for water conservation in this semi-arid area. NTT reduces passes with heavy machines to three times per year. Residue management involves maintaining the soil partially covered with stubble and straw. Overall, yields are higher and costs are lower than under conventional tillage. NTT reduces soil erosion and soil compaction while conserving water in the soil. Optimum use of scarce and low rainfall to stabilise/increase crop yields is essential in this area.

Natural / human environment: The use of the special no-till drill ensures both minimal working of the soils, and precise incorporation of phosphate fertilizer beneath seeds. Depending on the specific site, residue management is adjusted from low residue maintenance (stubble/controlled grazing) to medium surface cover (stubble/straw maintenance, forage crops and exclusion of grazing). Erosion and evaporation suppression/control are the main impacts of the system: runoff and concentrated flow in watersheds are reduced. Chemicals are applied for weed control, but this takes into account the environment, and can be reduced over time. Maintaining crop residues in the fields increases soil organic matter and thus the amount of carbon sequestered, as well as nutrient levels. Hence application of inorganic fertilizers can be reduced.

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Morocco

Region/ State/ Province:

Settat, Khourigba and Benslimane Provinces, Chaouia Ouardigha Region, Morocco

Specify the spread of the Technology:

- evenly spread over an area

If the Technology is evenly spread over an area, specify area covered (in km2):

20.0

Comments:

Total area covered by the SLM Technology is 20 km2.

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- during experiments/ research

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- reduce, prevent, restore land degradation

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

Specify:

Longest growing period in days: 180; Longest growing period from month to month: November to April

Comments:

Major land use problems (compiler’s opinion): Conventional tillage practices are often inappropriate, leading to various problems: disk plough operations make soils more vulnerable to erosion, evaporation, loss of organic matter and nutrients (due to inversion of soil) and thus reduce soil fertility. Furthermore, land preparation often takes place when soils are too dry or too wet. The soils in this area have a weak structure, due to low organic matter content, and are thus susceptible to compaction. Energy input in conventional tillage is much higher than in NTT.

3.5 SLM group to which the Technology belongs

- improved ground/ vegetation cover

- minimal soil disturbance

3.6 SLM measures comprising the Technology

agronomic measures

- A3: Soil surface treatment

A3: Differentiate tillage systems:

A 3.1: No tillage

management measures

- M2: Change of management/ intensity level

Comments:

Основные мероприятия: агрономические, управленческие

3.7 Main types of land degradation addressed by the Technology

soil erosion by water

- Wt: loss of topsoil/ surface erosion

Comments:

Основные типы деградации: Вв (Wt): потеря верхнего слоя почвы / поверхностная эрозия

Основные причины деградации: управление с/х культурами (однолетние, многолетние, деревья/кустарники) (пахота, выпас скота, отсутствие менеджмента, отсутствие затрат на производство), чрезмерное использование растительного покрова для бытовых целей (перевыпас / чрезмерное использование биомассы), чрезмерный выпас

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- reduce land degradation

Comments:

Основная цель: снижение деградации земель

4. Technical specifications, implementation activities, inputs, and costs

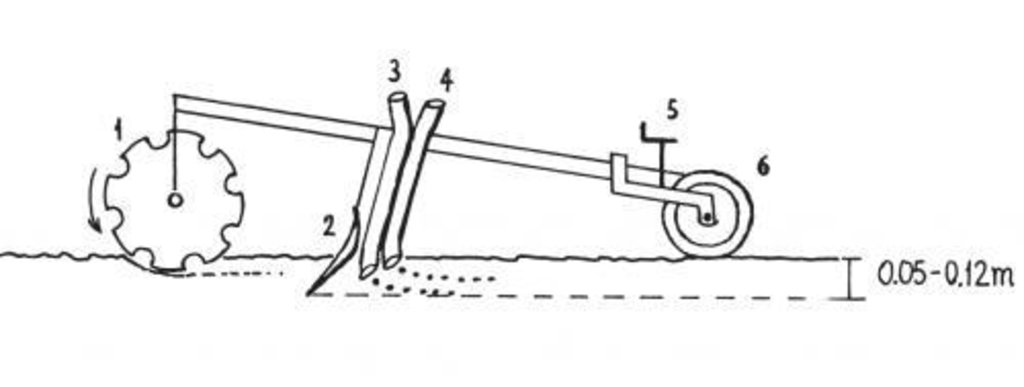

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

Schematic view of the specially designed no-till drill that simultaneously plants and applies fertilizer. Note the key components of the drill: 1) disc/opener, 2) hoe, 3) fertilizer tube, 4) seed tube, 5) seeding depth control, 6) wheel packer.

Main technical functions: control of raindrop splash, increase in organic matter, increase / maintain water stored in soil

Secondary technical functions: control of dispersed runoff: impede / retard, control of concentrated runoff: impede / retard, reduction in wind speed, increase in soil fertility, improvement of soil structure

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Equipment | No-till drill | Unit | 1.0 | 600.0 | 600.0 | |

| Total costs for establishment of the Technology | 600.0 | |||||

| Total costs for establishment of the Technology in USD | 600.0 | |||||

Comments:

Duration of establishment phase: 12 month(s)

Usually agronomic measures do not have initial establishment costs. But in this case a major investment is needed to buy the special drill.

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Stubble maintenance (no grazing, only partial straw removal after harvest). | После уборки урожая/ежегодно |

| 2. | Direct seeding/fertilizer (N/P) banding using no-till drill (early November). | В начале ноября ежегодно |

| 3. | Chemical weed control (December/January). | Дек/янв ежегодно |

| 4. | Nitrogen fertilization (March). | Март ежегодно |

| 5. | Harvest (May: after 6 months crop period). | Май, после 6-месячного периода / ежегодно |

| 6. | Leave fields to fallow for 18 months; apply herbicides if needed. |

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Seeding, maintenance, harvesting | unit | 1.0 | 160.0 | 160.0 | 100.0 |

| Equipment | Machine use | unit | 1.0 | 110.0 | 110.0 | |

| Plant material | Seeds | unit | 1.0 | 60.0 | 60.0 | |

| Fertilizers and biocides | Fertilizer | unit | 1.0 | 30.0 | 30.0 | |

| Fertilizers and biocides | Biocides | unit | 1.0 | 40.0 | 40.0 | |

| Total costs for maintenance of the Technology | 400.0 | |||||

| Total costs for maintenance of the Technology in USD | 400.0 | |||||

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Annual recurrent costs are calculated on a two years basis, including a 6-month cropping and 18-month fallow period, divided by two. The initial cost for the no-till drill is calculated – on a per hectare basis – for an average farm size of 10 ha. In this case a ‘pilot’ farmer’s case is taken, where the drill is supplied free. As with conventional drills, a new no-till drill costs US$ 6,000 but it is subsidised by up to 50% by the Government. Thus farmers can buy it for US$ 3,000 (though ‘pilot’ farmers receive it free of charge – as noted above). They have no extra costs (compared to conventional tillage) and they can share the price of the drill between them if they wish. The price of certified seeds and fertilizers, energy and equipment are the main factors affecting the costs of no-till, when subsidies are cut after the pilot phase. However, the costs of NTT are lower than for conventional farming, even when the cost of the drill is included.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

- fine/ heavy (clay)

Topsoil organic matter:

- medium (1-3%)

- low (<1%)

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

Soil texture (topsoil): Mostly fine/heavy and partially medium

Topsoil organic matter: Mostly low and partially medium

Soil fertility is low

Soil drainage / infiltration is mostly poor and partially good

5.6 Characteristics of land users applying the Technology

Market orientation of production system:

- mixed (subsistence/ commercial)

Level of mechanization:

- mechanized/ motorized

Indicate other relevant characteristics of the land users:

Off-farm income specification: the younger generation works either in cities or overseas (in Europe), others in manufacturing or industry.

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, titled

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

fodder production

Income and costs

expenses on agricultural inputs

farm income

workload

Other socio-economic impacts

flexible labour inputs

Comments/ specify:

seeding is independent of rain onset

timeliness

costs

Comments/ specify:

fewer tractor passes in field

Initial costs

Comments/ specify:

For special drill/tractor

Socio-cultural impacts

national institutions

SLM/ land degradation knowledge

conflict mitigation

Comments/ specify:

stubble grazing by neighbours can cause socio-cultural conflicts (it is no longer allowed)

economic inequity

Ecological impacts

Water cycle/ runoff

excess water drainage

Soil

soil moisture

soil loss

soil organic matter/ below ground C

Biodiversity: vegetation, animals

biomass/ above ground C

Other ecological impacts

biodiversity

soil fertility

6.2 Off-site impacts the Technology has shown

reliable and stable stream flows in dry season

downstream flooding

groundwater/ river pollution

6.4 Cost-benefit analysis

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

slightly positive

Long-term returns:

very positive

Comments:

Pilot farmers receive the no-till drill fully financed by the project (thus no benefits under investment costs’ above). Farmers who purchase the drill on their own (with a 50% subsidy)

will recover its cost in less than two years.

6.5 Adoption of the Technology

- 1-10%

If available, quantify (no. of households and/ or area covered):

14 households in an area of 20 km2

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 0-10%

Comments:

14 land user families have adopted the Technology with external material support

Comments on acceptance with external material support: All the 14 pilot farmers accepted the technology with incentives, receiving all inputs (machinery, seeds, fertilizers and biocides) in the first 3 years.

Comments on adoption trend: These pilot farmers are still in the phase of adoption. Out of the 14 farmers, there are two or three that still resist the change. Farmers’ attitudes alter slowly and complete acceptance is only reached after several years.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

|

More flexibility in planting, early land access and easier management of soils How can they be sustained / enhanced? Continue to cover soils with residues at planting/seeding to ensure sufficient soil moisture. |

|

Reduced energy, labour and cost: in NTT the tillage and seedbed preparation operations are eliminated; the no-till drill applies P and N fertilizers with the seed How can they be sustained / enhanced? Stress the use of appropriate equipment and inputs. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

|

Erosion control How can they be sustained / enhanced? Maintaining sufficient soil cover. |

|

Soil quality improvement How can they be sustained / enhanced? Controlled biomass exportation and grazing; on-time seeding. |

|

Efficient use of soil water: increased infiltration, water loss reduced, increased water availability for plants How can they be sustained / enhanced? Fallowing, maintaining sufficient soil cover. |

|

Increased crop production and yield stability How can they be sustained / enhanced? Promote productive and pest-resistant crop varieties and early seeding in order to cover soils and protect them from rainfall impact. |

|

Improved land use and diversified cropping systems with higher yields than in conventional system How can they be sustained / enhanced? Refine the integrated crop management and pest control system. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| Costly machinery (drills, tractor, sprayer) required |

Subsidies, purchase of equipment by groups of farmers. |

|

Weed control in NTT is critical: weed infestation if not well managed; high cost of herbicides |

Apply environment-friendly herbicides, crop diversification; hand weeding. |

| Socio-economic constraints of Moroccan farmers | Technology needs a long-term approach for full acceptance and implementation. |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| High level of management is required | Training of land users. |

| Sensitive to nitrogen level management |

Soil tests/apply N according to needs of crops under NTT. |

| High disease and pest prevalence if crop residues are not well managed | Resistant varieties and early seeding of diverse crops. |

| Reduced availability of straw (fodder) | Optimise crop/livestock integration: straw production under NTT is higher but farmers have to be convinced to remove only part it; use fodder crops in rotation. |

|

Unforeseen environmental risks: eg soil or ground water contamination with herbicides/phosphate |

Training, video presentations etc. |

7. References and links

7.1 Methods/ sources of information

Links and modules

Expand all Collapse allLinks

Applied research and knowledge transfer [Morocco]

Innovative, cross-disciplinary community-based approach for development and transfer of no-till technology at the farm level.

- Compiler: Rachid Mrabet

Modules

No modules