No Till [Russian Federation]

- Creation:

- Update:

- Compiler: Peter Liebelt

- Editor: –

- Reviewers: Alexandra Gavilano, Deborah Niggli, David Streiff

Нулевая обработка

technologies_1319 - Russian Federation

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Book project: Making sense of research for sustainable land management (GLUES)Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Sustainable land management in the Russian steppes (KULUNDA / GLUES)1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

No tillage is based on direct seeding with the innovative/ modern direct seeder Condor and works without any kind of soil disturbance.

2.2 Detailed description of the Technology

Description:

"No-Till" is a key element of the ‘modern cropping system/ Canadian System’ in the Kulunda steppe. In contrast to minimum tillage an innovative modern direct seeding machine is used. The successful implementation of “No-Till” requires an adaptation of the whole cropping system including crop rotation. Rotation includes a succession of cereal crops (e.g. spring wheat), legumes (peas), and oil seed crops. In the study area predominantly spring cereals are grown. The direct seeder ‘Condor tine seeder’ (Amazone) was used for direct seeding. In contrast to the SZS 2.1 seeder used for minimum tillage it has flexible, individually depth-guided tine coulters, which ensure a high precision of seed placement. When opening the seed furrow, the narrow coulter moves little soil, so that the valuable soil moisture remains in the soil, and there is sufficient fine soil to ensure the optimum seed/ soil contact. Straw is safely cleared from the seed furrow, preventing the "hairpinning-effect" which is the pressing of straw by the coulter into the sowing slit. During the sowing period fertilizers are applied and broad spectrum herbicide in autumn and selective pesticides in the growing season are sprayed which help to increase yield.

No-till works without intensive primary tillage and stubble cultivation that saves time, fuel and reduces soil water evaporation. No-till increases soil aggregate stability, helps to reduce the risk of soil erosion, leads to a higher soil fertility and reduces soil water losses. Weed control through crop rotation and herbicide application allows to omit mechanical weeding and thus to protect the soil against fertility decline and soil water loss. Fertilization becomes more important, because of the decreased mineralization rate under no soil tillage, especially at the beginning of the conversion of the cropping system and until soil organic matter could build up in the soil.

The Technology including crop rotation was tested in the field in 4 test plots with 4 repetitions at the test site in Poluyamki. Results showed that the intensity of soil tillage and seeding methods used had a great influence on crop establishment and expected yields. It was demonstrated that no tillage leads to higher water use efficiency and highest yields. Positive effects were also observed regarding soil structure and soil fertility already after 3 years. Positive effects were also observed regarding soil structure and soil fertility already after 3 years. Minimized soil disturbance led to higher aggregate stability, which leads to a lower risk of wind erosion, increased soil organic carbon storage and soil fertility as well as available soil water content. The Modern Canadian system caused fixed production costs in form of annual depreciation and also additional costs due to the application of fertilizers and pesticides, the prices of which increased in the last four years. Due to not finalised land rights reforms, uncertain credits and harvest insurance farmers are reluctant to invest in new machines.

The test site in Poluyamki is located in the dry steppe of the border region next to Kazakhstan, where, due to the climatic conditions, no natural afforestation occurs, and the planted windbreaks don’t grow vigorously due to the prevailing aridity. The annual precipitation is under 300 mm a year. Probably the greatest climatic influence factor is the precipitation - in terms of quantity and space/ time distribution and, due to high summer temperatures, the high rates of evapotranspiration. The total yearly precipitation rate is the primary yield-limiting factor in all steppe regions. The ratio between precipitation and evaporation is negative. In the late weeks of spring, prolonged droughts must be expected in 5-year cycles, limiting germination and crop establishment. The soils are classed among those of cool-tempered grasslands. Due to their physical and chemical characteristics, these soils (Chernozems and Kastanozems) have high agronomic potential.

2.3 Photos of the Technology

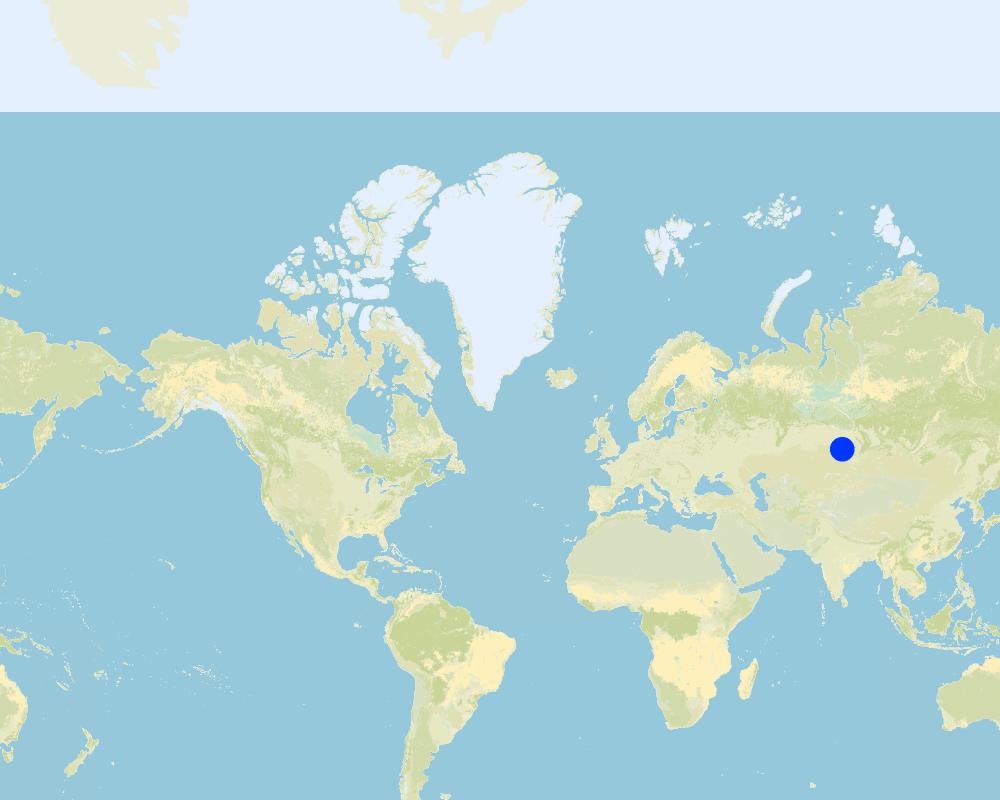

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Russian Federation

Region/ State/ Province:

Russian Federation/Altai Krai

Further specification of location:

Mikhaylovski district (Pavlovski district, Mamontovski district)

Specify the spread of the Technology:

- evenly spread over an area

If the Technology is evenly spread over an area, specify area covered (in km2):

0.13

If precise area is not known, indicate approximate area covered:

- 0.1-1 km2

Comments:

Boundary points of the Technology area: Centre latitude: _52° 4'3.00"N Centre longitude: 79°54'26.16"E Test site Poluyamki

Total area covered by the SLM Technology is 0.13 km2.

The total investigation area of the SLM Technology “Minimum Tillage” refers to our test site areas: 1. Poluyamki, Mikhaylovskiy Rayon: 13ha managed by Minimum Tillage; 2. Pervomayskiy, Mamontovskiy Rayon: 10ha managed by Minimum Tillage; 3. Komsomolskiy, Pavlovskiy Rayon: 3ha.

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- during experiments/ research

Comments (type of project, etc.):

Since the collapse of the Soviet Union increasingly innovative conservation technologies that are being developed in research experiments are implemented in practice. But the no technology of "No-till" as the most extreme form of conservation tillage is rarely applied in the study area. Thus the tested no-system is highly innovative for the Kulunda steppe.

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- reduce, prevent, restore land degradation

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

Number of growing seasons per year:

- 1

Specify:

Longest growing period in days: 110, Longest growing period from month to month: May-October

Comments:

Major land use problems (compiler’s opinion): It's the decrease of soil organic carbon content in the soils, topsoil thickness through deflation and soil compaction, which lead to a decrease of soil fertility. Additionally, the negative soil water balance due to the high summer temperatures and evaporation and in addition the high spatial and temporal variability of precipitation as a serious problem relating to the lack of soil water.

Major land use problems (land users’ perception): The land user that we work with and that implement the our new farming practices have a similar opinion relating the land use problems like the research staff of the project. But there are still a lot of farmer, that underestimate the ecological risks of soil degradation resulting from traditional soil management.

3.4 Water supply

Water supply for the land on which the Technology is applied:

- rainfed

3.5 SLM group to which the Technology belongs

- minimal soil disturbance

3.6 SLM measures comprising the Technology

agronomic measures

- A1: Vegetation/ soil cover

- A2: Organic matter/ soil fertility

- A3: Soil surface treatment

A3: Differentiate tillage systems:

A 3.1: No tillage

Comments:

Type of agronomic measures: better crop cover, mulching, green manure, mineral (inorganic) fertilizers, zero tillage / no-till

3.7 Main types of land degradation addressed by the Technology

soil erosion by water

- Wt: loss of topsoil/ surface erosion

soil erosion by wind

- Et: loss of topsoil

- Ed: deflation and deposition

- Eo: offsite degradation effects

chemical soil deterioration

- Cn: fertility decline and reduced organic matter content (not caused by erosion)

Comments:

Main causes of degradation: soil management (Conventional soil tillage by ploughing), crop management (annual, perennial, tree/shrub) (Bare fallow without vegetation cover), Capital for investments (Lack of capital for investment in modern adapted agricultural technologies)

Secondary causes of degradation: wind storms / dust storms (Strong winds and storms - Sukhoveijs - from the southwestern central-Asiatic semi-desert regions cause a higher risk of wind erosion especially on traditional cultivated cropland without plant cover), droughts (The frequently occurring early-summer drought periods are particularly problematic for agricultural production), education, access to knowledge and support services (Need for better know how how to manage no-till systems. Need for more effective measures for knowledge transfer and capacity building.)

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

- reduce land degradation

4. Technical specifications, implementation activities, inputs, and costs

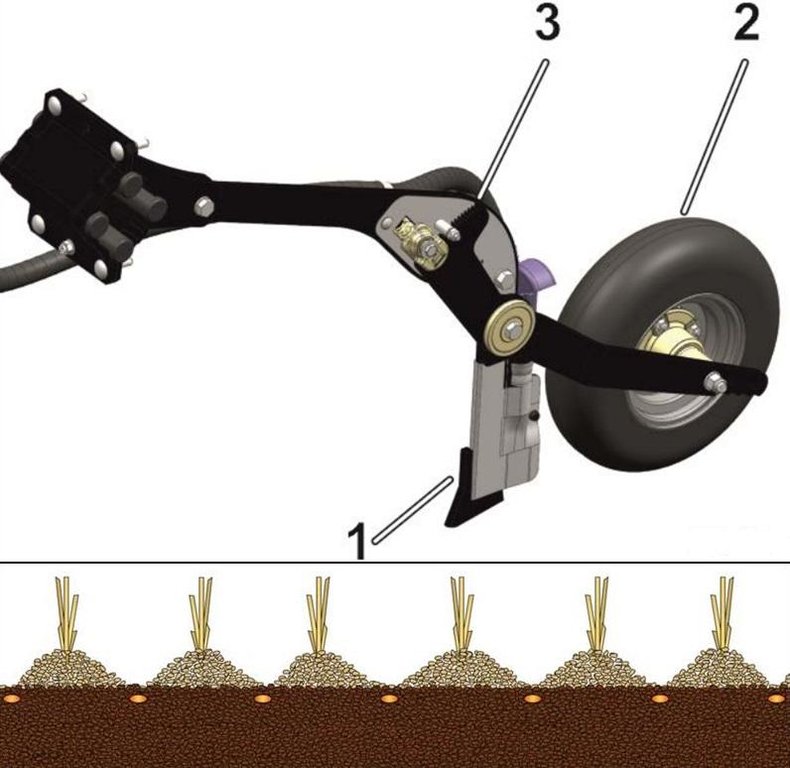

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

The coulter system of the direct seeder Condor based on an individually depth guided tine coulter. When opening the seed furrow, the narrow coulter moves little soil, so that the soil moisture remains in the soil. The accurate depth control and the packer wheel lead to an optimum contact between seed an soil, which is very important especially in dry regions like the Kulunda dry steppe in Poluyamki. 1-Chisel coulter 2- Packer wheel 3-Air diffuser. Illustration: seed grains placed between the former sowing rows

Technical knowledge required for field staff / advisors: high

Technical knowledge required for land users: high

Main technical functions: improvement of topsoil structure (compaction), increase in organic matter, increase of infiltration, increase / maintain water stored in soil, sediment retention / trapping, sediment harvesting, increase of biomass (quantity)

Secondary technical functions: control of raindrop splash, control of dispersed runoff: retain / trap, control of dispersed runoff: impede / retard, control of concentrated runoff: retain / trap, control of concentrated runoff: impede / retard, improvement of surface structure (crusting, sealing), improvement of subsoil structure (hardpan), stabilisation of soil (eg by tree roots against land slides), increase in nutrient availability (supply, recycling,…), reduction in wind speed

Better crop cover

Material/ species: Crop rotation without bare fallow

Green manure

Material/ species: Pea (once in a rotation)

Mineral (inorganic) fertilizers

Material/ species: with calcium ammonium nitrate

Quantity/ density: yearly

Remarks: 100kg/ha (spring wheat and rape), 50kg/ha (pea)

Rotations / fallows

Material/ species: wheat-pea-wheat-rape

Quantity/ density: 4 years

Zero tillage / no-till

Material/ species: Direct seeder Condor (Amazone company)

Author:

AMAZONE Werke GmbH & Co KG

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Direct seeding | Late april/ early may |

| 2. | Fertilizer application | |

| 3. | Pest management | period of vegetation |

| 4. | Harvest | september |

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | labour | ha | 1.0 | 4.12 | 4.12 | |

| Equipment | machine use | ha | 1.0 | 15.96 | 15.96 | |

| Equipment | fuel | ha | 1.0 | 25.49 | 25.49 | |

| Plant material | seeds | ha | 1.0 | 19.37 | 19.37 | |

| Plant material | seedlings | ha | 1.0 | 30.83 | 30.83 | |

| Fertilizers and biocides | fertilizer | ha | 1.0 | 9.42 | 9.42 | |

| Total costs for maintenance of the Technology | 105.19 | |||||

| Total costs for maintenance of the Technology in USD | 105.19 | |||||

Comments:

Machinery/ tools: Tractor MTS 1221, Tractor Kirovets K 701, Harvester Don 1500, Direct seeder Condor 15001, Sprayer UX 5200

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

High initial investment in new machines. Compared to the Traditional Soviet System with conventional deep ploughing without fertilizer application fertilizer and pesticides are the main additional cost factors.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Agro-climatic zone

- semi-arid

Thermal climate class: temperate

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Topsoil organic matter:

- medium (1-3%)

5.4 Water availability and quality

Ground water table:

5-50 m

5.5 Biodiversity

Species diversity:

- low

5.6 Characteristics of land users applying the Technology

Market orientation of production system:

- commercial/ market

Off-farm income:

- less than 10% of all income

Relative level of wealth:

- average

- very rich

Individuals or groups:

- employee (company, government)

Level of mechanization:

- mechanized/ motorized

Gender:

- men

Indicate other relevant characteristics of the land users:

Land users applying the Technology are mainly Leaders / privileged

Difference in the involvement of women and men: There are generally less woman than men in rural regions caused by rural-urban migration. Furthermore, jobs in the in the field of crop production are not so attractive for woman. Traditionally, much more women work in the field of livestock farming.

Population density: 10-50 persons/km2

Annual population growth: negative

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- large-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- state

- individual, not titled

Land use rights:

- communal (organized)

- leased

Water use rights:

- open access (unorganized)

Comments:

state: 45%, the data refer to the Altai Krai

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

risk of production failure

Comments/ specify:

In the first years after the change of the cropping system, there is an increased risk of crop losses due not correct/suitable management of the new cropping system

Income and costs

expenses on agricultural inputs

Comments/ specify:

Initial costs, first years for herbicides

farm income

Comments/ specify:

but increase of costs for pesticides and fertilizer, decrease for fuel and labor

Socio-cultural impacts

SLM/ land degradation knowledge

Comments/ specify:

in general yes, but food security is not a problem in this region

conflict mitigation

contribution to human well-being

Comments/ specify:

There is a moderate trend towards spontaneous adoption, but this trend depends on different natural and socioeconomic factors, like precipitation or the economic situation and financial power of the farmers

Ecological impacts

Water cycle/ runoff

harvesting/ collection of water

evaporation

Soil

soil moisture

soil cover

soil loss

soil compaction

Comments/ specify:

There is a lower risk for compaction damage than under under traditional ploughing

nutrient cycling/ recharge

soil organic matter/ below ground C

Biodiversity: vegetation, animals

beneficial species

Climate and disaster risk reduction

emission of carbon and greenhouse gases

wind velocity

Other ecological impacts

use of herbicide application

Comments/ specify:

The no-till system works without mechanical weed control, therefore it must be a chemical weed control especially in the first years of no-till system.

6.2 Off-site impacts the Technology has shown

water availability

Comments/ specify:

higher content of soil moisture

wind transported sediments

damage on neighbours' fields

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | well |

Climate-related extremes (disasters)

Meteorological disasters

| How does the Technology cope with it? | |

|---|---|

| local rainstorm | well |

| local windstorm | well |

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | well |

Other climate-related consequences

Other climate-related consequences

| How does the Technology cope with it? | |

|---|---|

| reduced growing period | not well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

negative

Long-term returns:

positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

slightly positive

Long-term returns:

positive

6.5 Adoption of the Technology

Comments:

100% of land user families have adopted the Technology without any external material support

The 3 farms where we have tested the technology of minimum tillage will partly apply this technology on their farming land. But it must be considered that the test farms of the KULUNDA project were interested in conservation technologies already at the beginning at the project and they are able to invest in new machinery to implement the tested SLM technology, that is not representative for the whole Kulunda-region.

There is a little trend towards spontaneous adoption of the Technology

There is a trend towards spontaneous adoption of the Technology, but this trend depends on different natural and socioeconomic factors like the precipitation or conditions an economic situation of the financial power of the farms. For example the drier the conditions, the more sense is to minimize the tillage. But there is a need to invest in new machinery. In contrast to the Adapted cropping system (with minimum tillage) the modern Canadian system require new seeding machinery that that means high establishment cost. Therefore the implementation growth is not so significant compared to the adapted system that use already existing Soviet seeding machinery.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Increase of soil aggregate stability and improved soil structure thus better erosion control and protection of soil organic matter will improve soil fertility and water holding capacity |

| Minimization of evaporation losses through better soil cover |

| Lower input costs (materials, fuel, labour, time) and quicker field operations |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| Application of chemical herbicides leads to higher costs and possible ecological risks. | Selective spraying using the “Amaspot” system that is based on infrared detection of weeds. |

| Higher requirements for fertilizers, especially at the beginning, due to lower mineralization rates and less nutrient availability compared to conventional cultivation. | Higher fertilizer application in the first years after conversion. |

| High initial investment costs for buying direct seeders | share machine and costs with other land users. |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

- interviews with land users

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules