Rooftop rainwater harvesting system [Nepal]

- Creation:

- Update:

- Compiler: Madhav Dhakal

- Editor: –

- Reviewers: David Streiff, Deborah Niggli, Alexandra Gavilano

Akase paani sankalan pranali - Nepali

technologies_1497 - Nepal

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

SLM specialist:

SLM specialist:

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Book project: Water Harvesting – Guidelines to Good Practice (Water Harvesting)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

ICIMOD International Centre for Integrated Mountain Development (ICIMOD) - Nepal1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

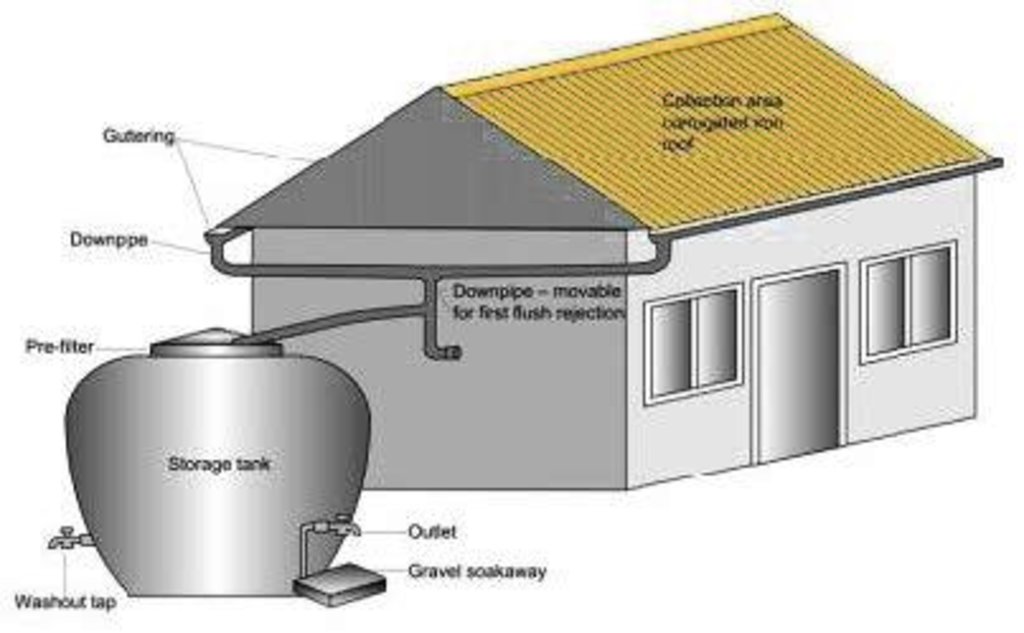

A water harvesting system in which rain falling on a roof is led through connecting pipes into a ferro-cement water collecting jar.

2.2 Detailed description of the Technology

Description:

Many households in Nepal’s midhills suffer from water shortages during the pronounced dry season. The technology described here - harvesting roofwater during times of heavy rainfall for later use - is a promising way of improving people’s access to water for household use, especially for households with no or only limited access to spring or stream water. The technology has yet to be extensively adopted in Nepal’s midhills.

Purpose of the Technology: The technology was introduced in the Jhikhu Khola watershed to demonstrate an alternative source of water for domestic use (mainly drinking water). This technology is appropriate for scattered rural households in mountaineous areas. The harvesting system consists of a catchment roof, conveyance pipes, and a storage jar. The pipes include a gutter system made from longitudinally split polythene pipe which has a flushing system that allows the system to be periodically flushed clean.

The collected water enters a 500 or 2000 litre capacity ferro-cement jar made using a mould (see photo). A preconstructed mould made from iron rods and polythene pipes is installed on a concrete base plate. Metal wires are extended from the base plate over the main mould to the top. Chicken mesh is then wrapped over the mould and tied securely with thin wire. A cement coating is applied over the metal structure. The jar is finished with three coatings of cement and the opening is covered with a fine nylon mesh to filter out undesired coarse matter. A tin lid is placed over the top.

Establishment / maintenance activities and inputs: A tap is fixed about 20 cm above the ground. This height allows for water to be collected in the typical 15 litre local water vessels (gagri) and avoids collection of too much water in bigger vessels as well as minimising the dead storage of water (Nakarmi et al. 2003). Trained masons can easily install the entire system. Provided all the materials and the mould are available, the entire system can be put together in about a week. The main maintenance task is to keep the roof clean, especially after long dry periods. This is done using the gutter pipe flushing system in which the first dirty water from the roof is diverted away from the jar.

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Nepal

Region/ State/ Province:

Kharelthok, Sathighar, Panchkhal, Hokse and Patalekhet VDCs of the Jhikhu Khola watershed

Further specification of location:

Kavrepalanchowk district

Specify the spread of the Technology:

- applied at specific points/ concentrated on a small area

Comments:

Roof rainwater harvesting jars were demonstrated mostly in the villages located at the watershed divides, hilltops, and elevated terraces where communities face chronic water shortage particularly during the dry period.

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

Comments (type of project, etc.):

Water harvesting is an ancient practice, the system used in the Jhikhu Khola watershed came from Thailand, so the technology is often called 'Thai jar". In Nepal, the Rural Water Supply and Sanitation Support Programme (RWSSSP), which is jointly funded by the Government of Finland and His Majesties Government of Nepal, introduced it in the water deficit districts of western Nepal (Arghakhanchi, Gulmi, Kapilvastu, Nawalparasi, Palpa, Parbat, and Rupandehi).

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- Access to water

3.2 Current land use type(s) where the Technology is applied

Settlements, infrastructure

- Settlements, buildings

Remarks:

courtyard

Comments:

Major land use problems (compiler’s opinion): Inadequate water supply during the late winter and pre-monsoon months and sediment contamination during the wet season. The discharge from traditional water sources like dug-out ponds, springs, seepage ‘holes’, shallow wells and streamlets becomes limited soon after the end of the monsoon.

Major land use problems (land users’ perception): Many settlements are located on ridge tops and most water sources are located below making it difficult to provide water to households through networks of pipes. Women and girls often face hardship in carrying the water uphill, especially during the monsoon when trails are slippery.

Constraints of settlement / urban

Number of growing seasons per year: 3

Longest growing period in days: 150; Longest growing period from month to month: Jun - Oct; Second longest growing period in days: 120; Second longest growing period from month to month: Nov - Feb

3.5 SLM group to which the Technology belongs

- water harvesting

3.6 SLM measures comprising the Technology

structural measures

- S5: Dams, pans, ponds

3.7 Main types of land degradation addressed by the Technology

physical soil deterioration

- Pw: waterlogging

Comments:

Main causes of degradation: change of seasonal rainfall

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- reduce land degradation

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

A water harvesting system with roof catchment, connecting pipes and storage tank.

Technical knowledge required for field staff / advisors: high

Technical knowledge required for land users: high

Main technical functions: water harvesting / increase water supply

Structural measure: Dam/ pan/ pond

Material: Concrete

Structural measure: Jar

Structural measure: Gutter

Structural measure: pipes

Construction material (other): Cement

Author:

A.K. Thaku

4.2 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology unit

Specify unit:

Rooftop rainwater harvesting system

Specify currency used for cost calculations:

- USD

Indicate average wage cost of hired labour per day:

2.10

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Construct the concrete base plate with the help of base moluld | 1st day of a week |

| 2. | Curing work | 2nd to 7th days of a week |

| 3. | Final checking and metal cap putting over the top of the jar | 7th day of a week |

| 4. | First coat of cement | 2nd day of a week |

| 5. | Gutter and pipe fitting; including flush pipe | 4th day of a week |

| 6. | Inner coat of cement | 6th day of a week |

| 7. | Main mould installation with the help of metal wires, wrapping of chicken mesh | 2nd day of a week |

| 8. | Removal of mould | 6th day of a week |

| 9. | Second coat of cement | 3rd day of a week |

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Construction of rooftop rainwater harvesting system | Persons/unit | 19.5 | 2.1 | 40.95 | 25.0 |

| Construction material | Cement | unit | 1.0 | 23.6 | 23.6 | |

| Construction material | Sand and aggregate | unit | 1.0 | 1.4 | 1.4 | 100.0 |

| Construction material | Chicken wire mesh | unit | 1.0 | 20.9 | 20.9 | |

| Construction material | Metal jar cover | unit | 1.0 | 5.5 | 5.5 | |

| Construction material | Plastic sheet/mosquito screen | unit | 1.0 | 1.5 | 1.5 | |

| Construction material | Polyethylene, pipes, reducer | unit | 1.0 | 23.7 | 23.7 | |

| Construction material | Nail, clamps, pipe elbow etc. | unit | 1.0 | 3.6 | 3.6 | |

| Construction material | Brass tap. socket, seal tap | unit | 1.0 | 3.5 | 3.5 | |

| Other | Paint | unit | 1.0 | 2.1 | 2.1 | |

| Total costs for establishment of the Technology | 126.75 | |||||

| Total costs for establishment of the Technology in USD | 126.75 | |||||

Comments:

Duration of establishment phase: 0.25 month(s)

Materials: cement (kg) 23.6 materials sand,aggregate (m3) 1.4 100 materials chicken wire mesh (m) 17.5 materials Iron wire (kg) 3.3 materials metal jar cover (no) 5.5 materials mosquito screen (m) 0.5 materials plastic sheet (m) 1 materials binding wire (kg) 0.1 materials snowcem paint (kg) 1.4 materials enamail paint (litre) 0.7 materials 90 mm HDP pipe (m) 10.3 materials 63 mm HDP pipe (m) 6.2 materials 40 mm HDP pipe (m) 6.8 materials reducer (no) 0.4 materials plain and roofing nails (kg) 0.2 materials metal clamp (no) 1.4 materials elbow, tee,end cap (no) 2.1 materials brass tap with latches (no) 2.1 materials 0 .5*10 inch GI nipple(no) 0.2 materials 1*10 inch GI nipple(no) 0.2 materials 1inch end cap (no) 0.7 materials GI socket (no) 0.2 materials thread seal tap (no) 0.1 Additional info Q 3.1.1.4: - less chance of disputes over turns to fetch water - medium General comments: Water harvesting is an ancient practice. The system used in the Jhikhu Khola watershed comes from Thailand, so the technology is often called ‘Thai jar’. In Nepal, the Rural Water Supply and Sanitation Support Programme (RWSSSP) introduced it in the water deficit districts of western Nepal.

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Cleaning the jar | dry months/one or twice in a year |

| 2. | Flushing contaminated water | After a long dry spell/whenever required |

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Cleaning the system | Persons/unit | 7.0 | 2.1 | 14.7 | 100.0 |

| Total costs for maintenance of the Technology | 14.7 | |||||

| Total costs for maintenance of the Technology in USD | 14.7 | |||||

Comments:

Machinery/ tools: hacksaw, steel scissors, hammer, pliers, wrench, trowel, steel pan bucket, and jug

Per unit cost of structure. The above mentioned cost is for unit water harvesting system. It can not be converted into hectare basis. It was estimated in 2006.

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

The mould and tools were provided by the project and can be used to install many water harvesting systems. Therefore, the cost of tools are not included here. Material costs fluctuate from time to time. The transport costs will vary according to the remoteness of the site. During 1999/2000, the cost of a system varied from US$80 to US$120, of which land users contributed about US$40 by providing the unskilled labour and locally available materials like sand and fine aggregates (calculated at an exchange rate of US$1 = NRs 73).

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Agro-climatic zone

- humid

Thermal climate class: subtropics

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Comments and further specifications on topography:

Landforms: Also valley floors

5.4 Water availability and quality

Water quality (untreated):

poor drinking water (treatment required)

Comments and further specifications on water quality and quantity:

Water quality (untreated): More in rainy season (June- September), less in April/May

5.6 Characteristics of land users applying the Technology

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- poor

Individuals or groups:

- individual/ household

Gender:

- women

- men

Indicate other relevant characteristics of the land users:

Land users applying the Technology are mainly common / average land users

Population density: 200-500 persons/km2

Annual population growth: 2% - 3%

15% of the land users are rich and own 35% of the land.

35% of the land users are average wealthy and own 40% of the land.

50% of the land users are poor and own 25% of the land (as ranked by the land users).

Off-farm income specification: In most farm households off-farm income plays at least a minor and increasingly a major role. Occasional opportunities for off-farm income present themselves in the form of daily

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- medium-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, titled

Land use rights:

- individual

Water use rights:

- communal (organized)

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

production area

Comments/ specify:

by the house to accommodate the water jar

Water availability and quality

drinking water availability

Comments/ specify:

in dry seasons

harvested water can be used during busy periods ( field preparation, vegetable planting, rice harvesting, and festivals).

Income and costs

workload

Quantity before SLM:

1 hour

Quantity after SLM:

5 minutes

Comments/ specify:

greatly reduced time needed to fetch water

reduced women's workload i.e. per day water fetching time reduced from about 12 hours to about 1 hour ( for the households having ~10 family members).

Other socio-economic impacts

Water is available near the house

Comments/ specify:

A house hold having 10 family member require about 12 gagree ( 1 gagree is equivalent to15 litre)

Socio-cultural impacts

community institutions

Comments/ specify:

together with adopters, other potential local adopters have started discussing options

SLM/ land degradation knowledge

Comments/ specify:

through training, demonstration, and knowledge sharing

livelihood and human well-being

Comments/ specify:

Improved heath condition due to clean water availability

Sanitation

Comments/ specify:

more water avilable forwashing leading to improved health

Risk of injury from carrying water along slippery and steep tracks

6.2 Off-site impacts the Technology has shown

downstream flooding

Comments/ specify:

a little portion of rainfall traped directly from the roof and collected at the courtyard

downstream siltation

Comments/ specify:

reduced eroded materials from the courtyard.

availability of water for neighbours during scarce period

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | well |

Climate-related extremes (disasters)

Meteorological disasters

| How does the Technology cope with it? | |

|---|---|

| local rainstorm | well |

| local windstorm | well |

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | not well |

Hydrological disasters

| How does the Technology cope with it? | |

|---|---|

| general (river) flood | well |

Other climate-related consequences

Other climate-related consequences

| How does the Technology cope with it? | |

|---|---|

| reduced growing period | well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

slightly negative

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

very positive

Long-term returns:

very positive

Comments:

Although the initial investment is high, the users immediately get more water. The high cost of installing the system means that the short term benefits are slightly negative.

6.5 Adoption of the Technology

- single cases/ experimental

If available, quantify (no. of households and/ or area covered):

46 households in an area of 1 - 10 sq km (200 - 500 persons/sq km)

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 11-50%

Comments:

74% of land user families have adopted the Technology with external material support

34 land user families have adopted the Technology with external material support

Comments on acceptance with external material support: survey results

26% of land user families have adopted the Technology without any external material support

12 land user families have adopted the Technology without any external material support

Comments on spontaneous adoption: survey results

There is a little trend towards spontaneous adoption of the Technology

Comments on adoption trend: The number of households applying the technology is increasing without further incentives being provided.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

|

The stored water can be kept for use in emergencies such as to prepare food for guests during busy times like rice planting and harvesting, and during festivals. How can they be sustained / enhanced? Share experiences to extend adoption of the technology |

|

Harvested water is tastier due to being cooler compared to the water collected in the polythene tank. How can they be sustained / enhanced? Laboratory analysis of the harvested rainwater in different time period, i.e. from 1st month of harvest to 12th month could help to know the quality status. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

|

Harvested rainwater has saved almost one workday per day per family due to reduced water fetching time in this case referring to the rainy season, however water will generally be used during the dry season. How can they be sustained / enhanced? Publicise the economic benefits of the technology through experience sharing programmes. |

|

Women are responsible for fetching water and so the technology reduces their workloads. How can they be sustained / enhanced? Implement a larger scale programme to promote the technology. |

|

The jars are more durable than plastic tanks. How can they be sustained / enhanced? Carry out regular maintenance to keep systems in good working order. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| The technology is expensive for poor households. | External support is needed for poor households to afford this system. |

| The height of the tap is very low which makes it inconvenient to collect water in the gagree. | It was designed to use collected water efficiently, the tap height can be raised, which means that the dead storage is increased, i.e. more water is unavailable for use. |

| There are chances of the jar’s base plate subsiding due to lack of compactness of foundation. | The area of base plate should be made more compact. |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| 2,000 litre capacity jars barely meet the dry season needs of a household. | Larger sized jars or more than one jar need to be built to meet most household’s requirements. |

| Microbiological contamination (total and faecal coliform bacteria) and levels of phosphate above the EC maximum were found in a number of the jars caused by bird droppings and dust particles from the roof. | Regularly clean catchment roofs and treat water before drinking by boiling or chlorinating. Rainwater has a low mineral content which can be harmful for the human body, if taken in large quantities (due to reverse osmosis process). |

| This technology is not suitable for temple roofs because such roofs are usually home to large numbers of pigeons, and their excreta will contaminate rainwater that falls there. | Avoid badly contaminated catchments. |

7. References and links

7.1 Methods/ sources of information

7.2 References to available publications

Title, author, year, ISBN:

Sharma, C. (2001) Socioeconomic IndicativeImpact Assessment and Benchmark Study on Rooftop Rainwater Harvesting, Kabhrepalanchok District, Nepal, a report submitted to ICIMOD, Kathmandu, Nepal

Available from where? Costs?

ICIMOD

Title, author, year, ISBN:

ICIMOD (2000) Water Harvesting Manual, unpublished manual prepared for PARDYP Project, ICIMOD

Available from where? Costs?

ICIMOD

Title, author, year, ISBN:

ICIMOD (2007) Good Practices in Watershed Management, Lessons Learned in the Mid Hills of Nepal. Kathmandu: ICIMOD

Available from where? Costs?

ICIMOD

Title, author, year, ISBN:

Lessons Learned from the People and Resource Dynamics Project , PARDYP/ICIMOD. 2006.

Available from where? Costs?

ICIMOD

Title, author, year, ISBN:

Nakarmi, G.; Merz, J.; Dhakal, M. (2003) ‘Harvesting Roof Water for Livelihood Improvement: A Case Studyof the Yarsha Khola Watershed, Eastern Nepal’. In News Bulletin of Nepal Geological Society, 20: 83-87

Title, author, year, ISBN:

Nakarmi, G.; Merz, J. (2001) Harvesting Rain Water for Sustainable Water Supplies to Rural Households in the Yarsha Khola Watershed, a report submitted to Kirchgemeinde Zuoz, Switzerland and ICIMOD, Kathmandu, Nepal

Available from where? Costs?

ICIMOD

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules