Rapid method of hay transportation from highlands haymaking place by using of hay carrying mechanism [Tajikistan]

- Creation:

- Update:

- Compiler: Gulniso Nekushoeva

- Editor: –

- Reviewer: Deborah Niggli

Фуровардани босуръати ках аз алафзорхои баландкух

technologies_1667 - Tajikistan

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

SLM specialist:

Nazarov Sergey

+992902555505

nazarov.azal@mail.ru

Director of PO "Azal",124 N. Маkhsum Street, apt. 40,Dushanbe

Tajikistan

SLM specialist:

Miralibekov Behruz

(+992 37) 235 21 06 / (+992) 902 55 55 01

miralibekov.azal@mail.ru

Deputy Director Public Oragnization "Azal"

Tajikistan

Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH (GIZ) - GermanyName of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Deutsche Welthungerhilfe e. V. (Welthungerhilfe) - Tajikistan1.3 Conditions regarding the use of data documented through WOCAT

When were the data compiled (in the field)?

14/04/2015

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Rapid method of descent sheaves of hay from the highlands hayfields, by constructing hay carrying mechanism which greatly facilitate this long process, as well as reducing the process cutting down trees and soil degradation of downstream slopes

2.2 Detailed description of the Technology

Description:

There is not a lot of available land to grow fodder grass in the narrow valleys of the mountain rivers of Rasht. So people use slopes in highlands with high and thick grass cover - first as haymaking (in June, July, mow the grass, dried, July-August- lowered hay) and then in September allow to graze cattle. The common spread in the last 20-25 years, method of descent sheaves of hay takes a lot of time and causes great damage to slopes vegetation and soil cover.

It was as follows: 5-6 big branches of trees and shrubs, knot like sleigh on which the 20-30 sheaves of hay (each of them is 6-7 kg). Then drag on the down-slope. This process each year and many times was repeated by every family (each household lowers minimum 400-500 sheaves of hay. "Sleigh" left along the slope consequence devoid of vegetation and topsoil. Through which at spring the flow of water is concentrated, with time there formed gullies. Now, the cutting of trees, destruction of vegetation and soil down the hill in k.Shulmak stopped since descent sheaves of hay from alpine slopes areas down to the foot is carried through the air using a special device - hay carrying mechanism. One person knot each sheave with twine, a special metal hook catches, strung on steel wire and alternately releases. Under the influence of its own gravity, and due to a good tension steel wire, bundles rapid slide down. In the foot, the second person takes them. In one hour they can descend from an elevation of more than 1000m 100-150 sheaves of hay (before it took 3-5 days). Hay is immediately loaded into trucks and transported home.

This technology decreases the human made degradation of natural resources (mountain forests and soil on the slopes) by facilitating the process of hay descend for winter cattle, through the application of advanced resource-saving technologies.

This technology was also used 30-40 years ago, but the footholds were wooden, and all were destroyed and farmers were unable on their own to restore them. PO "Azal" has modified them, made entirely of metal and more durable. For the construction of the device of air transportation of hay, with financial support from BMZ all the necessary building materials were delivered and they carry out construction supervision. For each of the foothold (made of metal pipes with diameter 70-80mm) - preparing the site - 2 x 2.5m (x 1m depth of cement, sand, gravel). Pull between them steel wire is sometimes 1000-1200m long D 3-3.5mm it should be solid, without knots for good sliding sheaves down. Depending on the topography (slope elevation and steepness), hay carrying mechanism are constructed in different ways: on the straight slopes installed one long, if the slope has a step or hayfields are far from the mechanism consist of two step parts and all the sheaves first pull on the middle point, and then by using the second wire send hay sheaves further down. Such mechanism is two time intensive. In total for 2012 in jamoat Rahim-zoda nine of them were constructed.

The center of Rash district - Garm is 230 km far from Dushanbe. From Garm to the Shulmak village another 25 km. It refers to the jamoat Rahim -zoda, and is closely located to the leskhoz- "Kamarov" (4-5 km), at 1300 m a.s.l. The average annual rainfall is more than 800 mm, winter is long and snowy. Summer in the narrow valleys of mountain rivers is dry but in the highlands at this time cool and creates favorable conditions for germination of thick and high grass cover.

The main income-generating sector is livestock, in second place fruit production. Therefore it is very important for farmers to have enough storage of fodder for a long stall period (4.5-5 months, from November 20 until April). Sometimes the feed end in winter and farmers are forced to buy them very expensive (summer sheaf is -6s) or slaughter the cattle and sale very cheap. So hay storage for winter is one of the most important events in the village. The presence of a sufficient amount of food at the time of confinement also reduces the load on the near village pasture - because the greater the supply of food for the winter, the later in the spring they will bring the cattle on the mountain slopes and less soil will be degraded.

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Tajikistan

Region/ State/ Province:

Tajikistan, DRS

Further specification of location:

Rasht district, jamoat Rakhim-zoda, v. Shulmak.

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- 10-50 years ago

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through land users' innovation

- through projects/ external interventions

Comments (type of project, etc.):

before the technology was more accessible in terms of cost of necessary materials and it was used in the mountain villages, then everything was destroyed, and now the PO "Azal" in 2012 established and restored nine hay carrying mechanism in this jamoat and later 8 on other district

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- reduce, prevent, restore land degradation

- conserve ecosystem

3.2 Current land use type(s) where the Technology is applied

Grazing land

Extensive grazing land:

- Semi-nomadism/ pastoralism

Mixed (crops/ grazing/ trees), incl. agroforestry

- Silvo-pastoralism

Comments:

Major land use problems (compiler’s opinion): shortage of arable land, the majority of land located on the slopes, low productivity of near village pastures because of overgrazing, water erosion, deforestation, mudslides

Major land use problems (land users’ perception): little availability of flat lands, low productive soil, lack of sufficient fodder for cattle in pastures

Selective felling of (semi-) natural forests: Yes

Plantation forestry: Yes

Problems / comments regarding forest use: After 1993, due to the lack of sufficient energy for cooking and with heated 5 hours a day in the cold season, wood plantations on the slopes of the mountains and the surrounding villages were almost completely destroyed, gradually began to grow fast-growing willow and –poplar

Forest products and services: timber, fuelwood, fruits and nuts, grazing / browsing, protection against natural hazards

Livestock is grazing on crop residues

Constraints of Steep rocky slopes: Large terrain slopes

3.3 Further information about land use

Water supply for the land on which the Technology is applied:

- mixed rainfed-irrigated

Number of growing seasons per year:

- 1

Specify:

Longest growing period in days: 180, Longest growing period from month to month: April-October

Livestock density (if relevant):

50-100 УГ/км2

3.4 SLM group to which the Technology belongs

- natural and semi-natural forest management

- pastoralism and grazing land management

3.5 Spread of the Technology

Specify the spread of the Technology:

- evenly spread over an area

If the Technology is evenly spread over an area, indicate approximate area covered:

- 1-10 km2

Comments:

one hay carrying mechanism helps quickly release the hay of half households of the village - 200 households, each with an average of 1-1.5 hectares of hay. So one slope cable is servicing the 200- 300 hectares of haymaking area

3.6 SLM measures comprising the Technology

structural measures

- S11: Others

management measures

- M4: Major change in timing of activities

Comments:

Specification of other structural measures: tension the cable between the unit on top of the mountain slope and its foot for sliding the sheaves

3.7 Main types of land degradation addressed by the Technology

soil erosion by water

- Wt: loss of topsoil/ surface erosion

- Wg: gully erosion/ gullying

physical soil deterioration

- Pc: compaction

- Pu: loss of bio-productive function due to other activities

biological degradation

- Bc: reduction of vegetation cover

Comments:

Main causes of degradation: soil management (for a long time not to conduct any activities on SLM), deforestation / removal of natural vegetation (incl. forest fires) (Limited supply of electricity in the cold season -5 hours a day for over 20 years, leading to widespread felling of trees for heating and cooking.), over-exploitation of vegetation for domestic use (the annual descent of hay by repeatedly drawing cut tree branches laden with sheaves of hay down the hill leads to the destruction of forests and soil erosion.), overgrazing (For a long time the cattle graze on near village pastures, which led to their strong degradation), population pressure (the population is heavily dependent on the agricultural production), poverty / wealth (because of the lack of finance more people can not establish hay carrying mechanism by themself), war and conflicts (the civil war and its consequences led to severe degradation of forests and pastures)

Secondary causes of degradation: other natural causes (avalanches, volcanic eruptions, mud flows, highly susceptible natural resources, extreme topography, etc.) specify (natural denudation processes are also widespread . Mudslides.), labour availability (the ability to get a job is very small.)

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

- reduce land degradation

4. Technical specifications, implementation activities, inputs, and costs

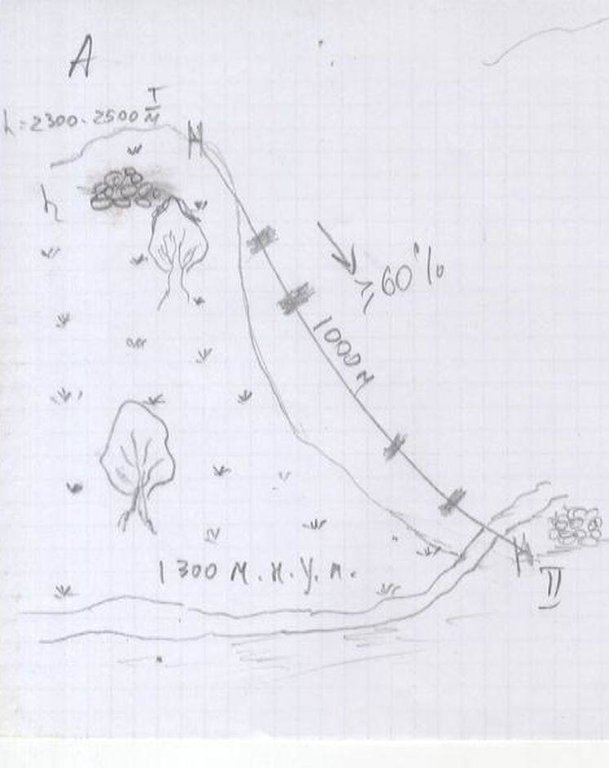

4.1 Technical drawing of the Technology

4.2 Technical specifications/ explanations of technical drawing

depending on the topography of the slopes the hay carrying mechanism can be simple straight from up to down, or if hayfields are far, it has to do this mechanism consisting of two parts

Location: Tajikistan. Rasht district, jamoat Rahim- zodа k.Shulmak

Date: 25.04.2015

Technical knowledge required for field staff / advisors: moderate (he should be able to calculate the length of the cable, the number of necessary cement, etc.)

Technical knowledge required for land users: moderate (they have to have some skills to gain a sustainable design)

Main technical functions: improvement of ground cover, stabilisation of soil (eg by tree roots against land slides), increase of biomass (quantity)

Secondary technical functions: improvement of topsoil structure (compaction), increase in organic matter, increase of infiltration, increase / maintain water stored in soil, promotion of vegetation species and varieties (quality, eg palatable fodder)

Structural measure: foothold (iron pipes) on top and foot of slopes

Vertical interval between structures (m): 1000m

Width of bunds/banks/others (m): D=70-80mm

Length of bunds/banks/others (m): 8m

Structural measure: Steel wire stretched between them.

Vertical interval between structures (m): 1000m

Width of bunds/banks/others (m): D=2-3,5mm

Length of bunds/banks/others (m): 1000-1200m

Construction material (stone): Gravel, sand

Construction material (concrete): cement

Construction material (other): Iron pipe D70- 80mm; steel wire D = 2-3,5mm

Major change in timing of activities: Job that required time (100 sheaves of hay took 3-5 days) is now done in an hour

4.3 General information regarding the calculation of inputs and costs

other/ national currency (specify):

Somoni

Indicate exchange rate from USD to local currency (if relevant): 1 USD =:

4.76

Indicate average wage cost of hired labour per day:

8.80

4.4 Establishment activities

| Activity | Type of measure | Timing | |

|---|---|---|---|

| 1. | Buying the necessary materials from Dushanbe | Structural | Before construction |

| 2. | Delivery of the necessary materials for 9 foothold-3000c;for one-333c and unloading | Structural | on dry season |

| 3. | Lifting to the elevation of 2500m: thick iron pipes-4m, cement-300kg,sand on donkeys | Structural | on dry season |

| 4. | Installation of the upper foothold (2 pits of 1m depth for installation of pipes. making cement platform 2 х 2.5m) | Structural | on dry season |

| 5. | Installation of the footholdIn the valley (2 pits at a depth of 1m for the installation of pipes H-shaped. making cement platform 2 х2.5m | Structural | on dry season |

| 6. | pulling steel wire between the footholds | Structural | Before the descent season |

| 7. | making metal hooks for descent sheaves of hay | Structural | before the descent season |

| 8. | buying solidol for the lubrication of the hook during the descent sheaves | Structural | During the work |

4.5 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour | 1.0 | 255.9 | 255.9 | 100.0 | |

| Equipment | Machine use | 1.0 | 70.0 | 70.0 | ||

| Equipment | Animal traction | 1.0 | 33.6 | 33.6 | 100.0 | |

| Equipment | welding apparatus | 1.0 | 21.0 | 21.0 | 100.0 | |

| Equipment | Gas for welding apparatus | 1.0 | 11.6 | 11.6 | ||

| Construction material | steel wire D=2-3,5mm | 1.0 | 96.6 | 96.6 | ||

| Construction material | thick iron pipes,D=70-80mm | 1.0 | 126.0 | 126.0 | ||

| Construction material | cement | 1.0 | 151.3 | 151.3 | ||

| Construction material | gravel, sand | 1.0 | 31.5 | 31.5 | ||

| Other | iron wire D=5-6mm for hooks | 1.0 | 16.8 | 16.8 | ||

| Other | solidol | 1.0 | 3.0 | 3.0 | 100.0 | |

| Total costs for establishment of the Technology | 817.3 | |||||

Comments:

Duration of establishment phase: 0.25 month(s)

4.6 Maintenance/ recurrent activities

| Activity | Type of measure | Timing/ frequency | |

|---|---|---|---|

| 1. | Uphill to the height of 2500m for the removing and descenting of the upper end of the wire | Structural | Every year, after the end of work |

| 2. | packing 1000m wire for storage after lubrication with solidol | Structural | After removing on the end of summer |

| 3. | Making iron hook - instead of the lost (for 100sht) | Structural | Before starting the work |

4.7 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour | 1.0 | 30.9 | 30.9 | 100.0 | |

| Other | iron wire D=5-6mm for hooks | 1.0 | 1.9 | 1.9 | 100.0 | |

| Other | solidol | 1.0 | 1.5 | 1.5 | 100.0 | |

| Total costs for maintenance of the Technology | 34.3 | |||||

Comments:

Machinery/ tools: machine, donkeys, picks, shovels, welding aparat

August 2012

4.8 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

The costs are directly affected by the elevation of the mountain slopes, the distance from the high mountain haymakings to the foothills, the steepness and shape of slopes - it affects the length of the cable, the amount of cement and the number of installed iron tubes

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specifications/ comments on rainfall:

average yearly Precipitation -830mm, normally on winter and spring time

Agro-climatic zone

- semi-arid

Thermal climate class: subtropics to temperate

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Topsoil organic matter:

- medium (1-3%)

- low (<1%)

5.4 Water availability and quality

Ground water table:

5-50 m

Availability of surface water:

good

Water quality (untreated):

good drinking water

5.5 Biodiversity

Species diversity:

- medium

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Semi-nomadic

Market orientation of production system:

- subsistence (self-supply)

- mixed (subsistence/ commercial

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- poor

- average

Individuals or groups:

- groups/ community

Level of mechanization:

- manual work

- animal traction

Gender:

- men

Indicate other relevant characteristics of the land users:

Land users applying the Technology are mainly common / average land users

Difference in the involvement of women and men: The construction of hay carrying mechanism is a heavy work - so mainly men are involved

Population density: 10-50 persons/km2

Annual population growth: 3% - 4%

5% of the land users are rich.

60% of the land users are average wealthy.

35% of the land users are poor.

Off-farm income specification: main income comes from labor migrants outside of Tajikistan, some also have income from the sale of fruit, potato

5.7 Average area of land owned or leased by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- medium-scale

Comments:

Average area of land owned or leased by land users applying the Technology: < 0.5 ha, < 0.5 ha, 0.5-1 ha, 2-5 ha, 5-15 ha

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- state

- communal/ village

Land use rights:

- communal (organized)

- leased

Water use rights:

- open access (unorganized)

Comments:

Proper state land, but put into long-term lease. All households have individual plots of land where they grow fruits and vegetables. Possibility of fodder grass is very limited. For this purpose they are using the lines in beetween the trees in orchards.

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

fodder quality

animal production

land management

Income and costs

farm income

Comments/ specify:

freed time for other types of profitable work

diversity of income sources

workload

Comments/ specify:

all of the obstacles on the descent (time, etc.) are eliminated

Socio-cultural impacts

food security/ self-sufficiency

Comments/ specify:

Hay lossless quickly stored., Then the fodder security is provided for cattle

health situation

Comments/ specify:

It excludes the hard work -the long distance descent of hay from the highlands

recreational opportunities

Comments/ specify:

These free days, they can relax in the family. Goin to the cinemai etc.

community institutions

SLM/ land degradation knowledge

situation of socially and economically disadvantaged groups

Comments/ specify:

The descent became very lightweight, so men neighbors can now find the time to help an elderly neighbor or women get the hay down etc

Human well-being

Comments/ specify:

many days they spent on the trigger of hay, they can now spend an amendment on health, or the acquisition of necessary goods for their livelihood as well as their education

Ecological impacts

Water cycle/ runoff

surface runoff

Comments/ specify:

With the reduction of number of artificial gullies and places devoid of vegetation, decrease runoff

Soil

soil cover

Comments/ specify:

the destruction of topsoil is decrease

soil loss

Comments/ specify:

Each descent of hay on the branches, disturbed topsoil, and later it washed off by rain

soil compaction

Comments/ specify:

reduced trampling

Biodiversity: vegetation, animals

biomass/ above ground C

Comments/ specify:

By reducing trampling and destruction of vegetation biomass increases

plant diversity

Comments/ specify:

With less trampling increased number of plant species

animal diversity

Comments/ specify:

The absence of trampling leads to the restoration of biodiversity

beneficial species

Comments/ specify:

If less trampling, the more insects and soil fauna will be safe

habitat diversity

Comments/ specify:

The absence of trampling leads to the restoration of biodiversity

6.2 Off-site impacts the Technology has shown

damage on neighbours' fields

Comments/ specify:

The destruction of vegetation and soil down the slope is stopped now

damage on public/ private infrastructure

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | Type of climatic change/ extreme | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | well |

Climate-related extremes (disasters)

Meteorological disasters

| How does the Technology cope with it? | |

|---|---|

| local rainstorm | not well |

| local windstorm | well |

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | well |

Hydrological disasters

| How does the Technology cope with it? | |

|---|---|

| general (river) flood | well |

Other climate-related consequences

Other climate-related consequences

| How does the Technology cope with it? | |

|---|---|

| reduced growing period | well |

Comments:

Technology is mostly constructed of iron, so when heavy rain metal rusts. Avoid damaging the wire rope during heavy rainfall (rust) or wind storm - (cable failure) after all the work on the slope of hay, the cable is removed and stored in a room until the next season

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

positive

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

very positive

Long-term returns:

very positive

Comments:

The technology is implemented with the help of the project, so the short-term and long-term benefits are positive. When introducing by yourself, of course it would be negative in the short-term.

6.5 Adoption of the Technology

- more than 50%

If available, quantify (no. of households and/ or area covered):

100% or 400 land user families

Comments:

k. Shulmak is a large village - 400 households, and there are two hay carrying mechanisms

All hay carrying mechanism were installed with external financial support, but the local community also contributed to digging holes. Rises to a high elevation all metalic pipes filled with cement made welding etc

There is no trend towards spontaneous adoption of the Technology. Hay carrying mechanism were established two years ago, in 2012, so after nobody established their own this is too expensive. Although 30 -40 years ago, they were in use more widely

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| greatly facilitated the process of descent harvested hay, without loss of its quality |

| also several families can jointly rent a big car, it will be cheaper because of the short distance |

| is not expensive to manage, just need to oil the cable and to produce new metal hooks if some were lost |

| спускали сено волоком на санях обычно подростки, а теперь они освободились от этого труда и могут больше времени посвятить учебе. |

| эксплуатация сеноспуска обходится не дорого, всего лишь надо смазывать солидолом крючки при спуске, а провод при хранении , и периодически изготавливать металлические крючки на замену утерянным |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

|

greatly reduced the negative impact of the accepted method of carrying hay sheaves (portage on tree branches), reduced tree cutting and soil degradation |

| the ability to self-repair of grass and land cover on the slopes |

| The design and exploitation of hay carrying mechanism are not difficult for farmers, technology can greatly facilitate the delivery of the chamfered and dried hay from alpine slopes to the village |

| if the head of household is absent (migration, death etc) women can also participate in the hay sheaves transportation using the hay carrying mechanism. This increases the families chance to be prepared for winter in time, without waiting for help and not lost income from livestock. |

| при условии отсутствия главы семьи (миграция, смерть и т.д.) спускать сено по сеноспуску могут и женщины. Что увеличивает шансы их семей быть вовремя подготовленными к зимнему сезону и обеспечить себя молочной продукцией |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| The lack of finances to purchase equipment | |

| The lack of commercially available steel wire - 2-2.5 mm in diameter |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

|

Shortcomings in the technology are not available. But for its wide implementation not all the conditions are fulfilled: In the country (according to the S. Nazarov, director of the PO "Azal") the demand is for thicker cable 3-5mm, because there is the creation of (netting) of protective metal mesh, so the desired diameter of 2 mm steel wire is difficult to purchase |

We need to find the communities - people with the same problems, same needs and together make a big total order to the bussinesmen for purchases in China or Russia because to brink a wire of =D2-2.5mm is not profitable for them because there is no demand |

| В республике (со слов Назарова С, директора ОО «Азал»)спросом пользуется проволока потолще 3.5-5мм, которая идет на создание (плетение) оградительных сеток , а стальную проволоку D=2-3мм не завозят. т.к. её редко покупают |

7. References and links

7.1 Methods/ sources of information

- interviews with land users

7.2 References to available publications

Title, author, year, ISBN:

reports and information from Data Base of PO "Azal" , GIZ video-clip about this hay carrying mechanism

Available from where? Costs?

contact persons

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules