Soil Cement Water Collection Pond for Supplemental Irrigation Purpose in Dry Season [Nepal]

- Creation:

- Update:

- Compiler: Kabita Nhemhafuki

- Editor: –

- Reviewers: Rima Mekdaschi Studer, Isabelle Providoli

Mato, Baluwa ra Cement bata Nirmit Sinchai Pokhari - Nepali

technologies_5684 - Nepal

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

SLM specialist:

Shah Ram Deo

The Center for Environmental and Agricultural Policy Research, Extension and Development (CEAPRED)

Nepal

land user:

Gautam Laxmi

Nepal

land user:

K.C Prashuram

Nepal

land user:

Neupane Kumar

Nepal

land user:

Adhikari Apsara

Nepal

land user:

Shrestha Jay Ram

Nepal

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Resilient Mountain Solutions Initiative, ICIMOD (RMS initiative)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

ICIMOD International Centre for Integrated Mountain Development (ICIMOD) - Nepal1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

A soil cement water collection pond to store rainwater, runoff and household kitchen waste water free from soap and detergent for supplemental irrigation purpose during dry seasons.

2.2 Detailed description of the Technology

Description:

In Nepal's mid-hills mountain farmers face problems during dry seasons to irrigate their fields, as they entirely depend on rain- water. Soil cement water collection pond are ideal to tackle this challenge, as they can capture excess rainfall during monsoon, which is later available during prolonged seasonal water shortage.

The Resilient Mountain Village (RMV) project of ICIMOD together with its local partner, CEAPRED tested and demonstrated soil cement ponds with a capacity of 24000 liters. The conservation ponds were used for irrigating high value off-season horticultural crops (vegetables, fruit, and spices). These crops were irrigated with drip irrigation and micro sprinklers. The ponds were fed from rainwater, upland springs and taps, and household wastewater from kitchen free from soap and detergent. They were established during the dry season during 3 months. They were prepared by selecting a suitable site with a sufficient catchment; mapping out the area and depth of the pond; digging out the soil; removing protruding stones and roots; and compacting and smoothing the sides and bottom of the pond. Then gravel and pebbles were used for the base and the floor and side walls were leveled off. Initial mixture of soil, sand and cement (3:3:1) was applied to roughly plaster all the side walls and gravel was mixed in the mixture while plastering the floor. The following day, the roughly plastered pond was watered and was covered with wet jute sack to keep it moist. This was continued for 3-4 days. Then again a second mixture of soil, sand and cement (2:2:1) was applied to smoothly plaster the floor and side walls. The pond was watered for the next 3-4 days and was covered with wet jute sacks. Around 4-5 days after the second plaster, the pond was filled with water. For safety, pond was enclosed with a gabion wire/ bamboo fence (or using any locally available material). The total establishment cost for a soil cement pond with 24000 liters capacity was USD 311.

The main maintenance activity was to maintain the gabion wire/bamboo fence to prevent livestock and people from entering the pond, and to remove the sediment that accumulates in the pond. The sediment has to be removed once a year carefully by hand and if cracks occur, it should be sealed with a mixture of soil, sand and cement (3:3:1). The total annual maintenance cost for 24000 liters soil cement tank was USD 68.

This technology has somehow helped small-land holding farmers to irrigate their rain-fed land during dry months which has increased the crop production and their income as well.

Land user's particularly liked that their production increased and that they were able to grow up to three crops per year. Trough this the farmers were able to diversify their crops, and they were less vulnerable to the dry season. In addition, soil cement water ponds are more efficient than plastic-lined conservation ponds which are easily damaged by rats. Although cost effective, the fixed price for this technology is quite high, particularly for smallholder farmers. To lessen this financial burden, local governments can provide subsidies to women and marginalized groups interested in this technology. Self-help groups with a revolving grants system would help expand the use of these ponds and ensure sustained use across Nepal.

2.3 Photos of the Technology

General remarks regarding photos:

Size of soil cement pond depends upon the area of land to be irrigated.

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Nepal

Region/ State/ Province:

Province no: 3

Further specification of location:

Namobuddha Municipality, Kavrepalanchowk District, Nepal

Specify the spread of the Technology:

- applied at specific points/ concentrated on a small area

Is/are the technology site(s) located in a permanently protected area?

No

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

Comments (type of project, etc.):

ICIMOD demonstrated this technology through the program of Resilient Mountain Village (RMV) with the help of its implementing local partner, The Center for Environmental and Agricultural Policy Research, Extension and Development (CEAPRED) in its pilot project sites in Kavrepalanchok district.

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- Improve water availability during dry seasons

3.2 Current land use type(s) where the Technology is applied

Land use mixed within the same land unit:

No

Cropland

- Annual cropping

Annual cropping - Specify crops:

- cereals - maize

- cereals - rice (upland)

- legumes and pulses - beans

- root/tuber crops - potatoes

- seed crops - sesame, poppy, mustard, other

- vegetables - leafy vegetables (salads, cabbage, spinach, other)

Number of growing seasons per year:

- 3

Specify:

Longest growing period in days: 150; Longest growing period from month to month: Jun - Oct; Second longest growing period in days: 120; Second longest growing period from month to month: Nov - Feb

Is intercropping practiced?

Yes

If yes, specify which crops are intercropped:

Tomato and raddish

Is crop rotation practiced?

No

3.3 Has land use changed due to the implementation of the Technology?

Has land use changed due to the implementation of the Technology?

- No (Continue with question 3.4)

3.4 Water supply

Water supply for the land on which the Technology is applied:

- rainfed

3.5 SLM group to which the Technology belongs

- water harvesting

- irrigation management (incl. water supply, drainage)

3.6 SLM measures comprising the Technology

structural measures

- S4: Level ditches, pits

- S7: Water harvesting/ supply/ irrigation equipment

3.7 Main types of land degradation addressed by the Technology

water degradation

- Ha: aridification

- Hs: change in quantity of surface water

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- reduce land degradation

4. Technical specifications, implementation activities, inputs, and costs

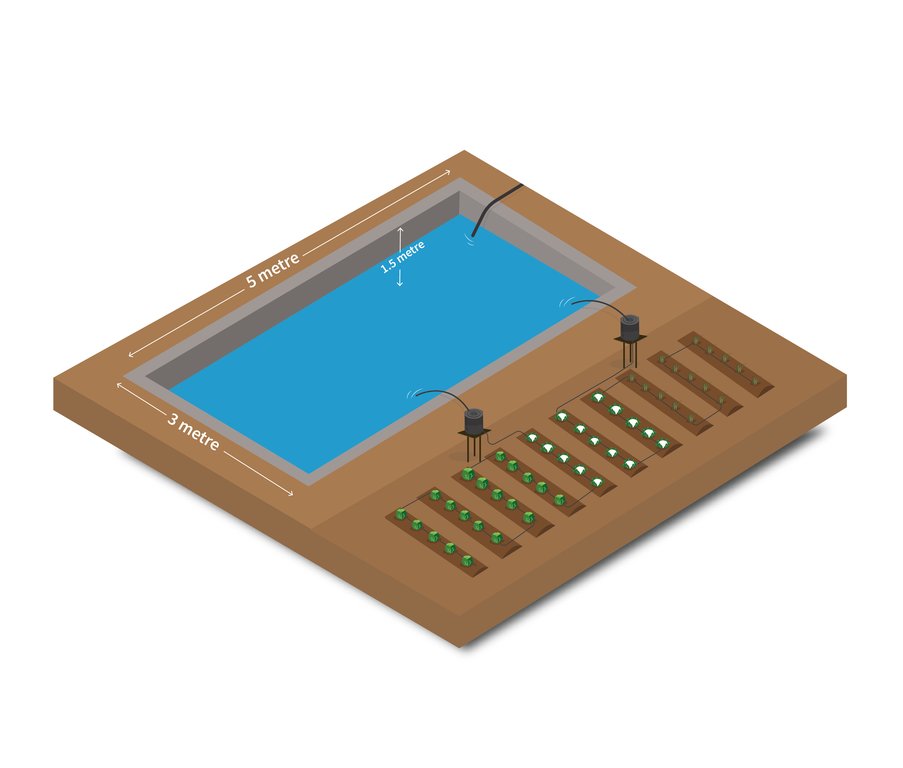

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

Soil Cement Water Collection Pond for Irrigation Purpose in Dry Seasons

Location: Charange fedi, 03, Namobuddha Municipality, Kavrepalanchowk

Technical knowledge required for field staff / advisors: moderate

Technical knowledge required for land users: moderate

Main technical functions: water harvesting / increase water supply

Secondary technical functions: control of dispersed runoff: retain / trap

Structural measure: pond

Depth of ditches/pits/dams (m): 1.5

Width of ditches/pits/dams (m): 3

Length of ditches/pits/dams (m): 5

Capacity of the tank= 24000 litres.

Construction material (earth): Clay

Construction material (other): Cement, sand and water-proofing liquid

Author:

Kabita Nhemhafuki, Ram Dev Shah

Date:

01/12/2020

4.2 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology area

Indicate size and area unit:

0.0024 ha

If using a local area unit, indicate conversion factor to one hectare (e.g. 1 ha = 2.47 acres): 1 ha =:

1 ha = 10000 square metres

Specify currency used for cost calculations:

- USD

Indicate average wage cost of hired labour per day:

5.68

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Select a preferably stable ground with a sufficient catchment area | dry months |

| 2. | Measure the area to be irrigated and estimate the size of the pond | dry months |

| 3. | Measure and mark out the pond | 1st day |

| 4. | Dig out the soil to the pre-determined depth and remove protruding stones and roots | 1st day |

| 5. | Compacting and smoothing the sides and bottom of the pond | 2nd day |

| 6. | Apply initial mixture of soil, sand, cement (3:3:1) to roughly plaster all the the side walls and mix gravel in the mixture while plastering the floor. | 2nd day |

| 7. | The following day, the roughly plastered pond should be watered and covered with wet jute sack to keep it moist. This should be continued for 3-4 days. | 3rd day |

| 8. | Apply a second mixture of soil, sand, and cement (2:2:1) to smoothly plaster the floor and side walls. | 5th day |

| 9. | Water the pond for the next 3-4 days and cover with wet jute sack. | 8th day |

| 10. | Around 4-5 days of second plaster, fill the pond with water. | 13th day |

| 11. | For safety, the pond can be enclosed with gabion wire/ bamboo fence (or using other locally available materials) | 14th day |

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Dig out pond | persons/unit | 7.0 | 5.68 | 39.76 | 100.0 |

| Labour | Stone soiling | persons/unit | 1.0 | 8.74 | 8.74 | |

| Labour | Cementing | persons/unit | 10.0 | 8.74 | 87.4 | |

| Labour | Wiring | persons/unit | 2.0 | 8.74 | 17.48 | |

| Equipment | Spade | piece | 3.0 | 2.0 | 6.0 | 100.0 |

| Equipment | Measuring tape | piece | 2.0 | 1.0 | 2.0 | 100.0 |

| Equipment | Shovel | piece | 3.0 | 7.0 | 21.0 | 100.0 |

| Equipment | Hammer | piece | 3.0 | 4.0 | 12.0 | 100.0 |

| Equipment | Cement mixing iron pan | piece | 2.0 | 3.0 | 6.0 | 100.0 |

| Equipment | Trowel | piece | 3.0 | 2.0 | 6.0 | 100.0 |

| Construction material | Sand | bags | 24.0 | 0.87 | 20.88 | |

| Construction material | Cement | bags | 6.0 | 7.43 | 44.58 | |

| Construction material | Water proofing liquid | bottle | 1.0 | 2.62 | 2.62 | |

| Construction material | Gabion wire sheets | sq.ft | 120.0 | 0.31 | 37.2 | |

| Total costs for establishment of the Technology | 311.66 | |||||

| Total costs for establishment of the Technology in USD | 311.66 | |||||

If land user bore less than 100% of costs, indicate who covered the remaining costs:

The Center for Environmental and Agricultural Policy Research, Extension and Development (CEAPRED) covered the remaining cost

Comments:

Duration of establishment phase: 3 month(s)

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Maintain and repair wire fence to prevent livestock and humans from entering the pond | once in a year |

| 2. | Removing accumulated sediment once a year carefully by hand | dry months/once in a year |

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Clean and maintaining the pond | persons/unit | 3.0 | 5.68 | 17.04 | 100.0 |

| Labour | Maintain and repair wire fence | persons/unit | 2.0 | 7.0 | 14.0 | 100.0 |

| Construction material | Gabion wire | sq.ft | 120.0 | 0.31 | 37.2 | 100.0 |

| Total costs for maintenance of the Technology | 68.24 | |||||

| Total costs for maintenance of the Technology in USD | 68.24 | |||||

Comments:

The cost given above is for unit technology having 24000 liters capacity as in 2020.

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Cost of cement and sand

Members of a household contributed as labour in all sites.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specify average annual rainfall (if known), in mm:

1584.00

Agro-climatic zone

- humid

Thermal climate class: subtropics

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- not relevant

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

- fine/ heavy (clay)

Soil texture (> 20 cm below surface):

- medium (loamy, silty)

Topsoil organic matter:

- medium (1-3%)

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

Soil fertility is medium

Soil drainage / infiltration is good

Soil water storage capacity is medium

5.4 Water availability and quality

Ground water table:

5-50 m

Availability of surface water:

medium

Water quality (untreated):

poor drinking water (treatment required)

Water quality refers to:

both ground and surface water

Is water salinity a problem?

No

Is flooding of the area occurring?

No

Comments and further specifications on water quality and quantity:

Water source is mainly spring.

More in rainy season (June- September), less in April/May; source: spring

5.5 Biodiversity

Species diversity:

- high

Habitat diversity:

- high

Comments and further specifications on biodiversity:

Nepal harbors 3.2 % and 1.1 % world's known flora and fauna respectively despite occupying only 0.1 % of global area. Particularly, beta diversity is high in Nepal (BCN and DNPWC, 2011).

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- mixed (subsistence/ commercial)

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- poor

- average

Individuals or groups:

- individual/ household

Level of mechanization:

- manual work

- animal traction

Gender:

- women

- men

Age of land users:

- middle-aged

Indicate other relevant characteristics of the land users:

Land users applying the Technology are mainly common / average land users

Population density: 154 - 453 persons per km2 ( Census, 2011)

Annual population growth : 2% - 3%

Among 100% land users, 80% of the land users are average wealthy and own 90% of the land (ranked by land users). 20% of the land users are poor and own 10% of the land.

Off-farm income specification:

Occasional opportunities for off-farm income present themselves in the form of daily labour wages.

Due to loss of farmland and increasing urbanization and loss of farmlands many people are switching from agriculture to non-farm occupations such as working in brick kilns.

The opening of the BP Highway has led to the establishment of many hotels and restaurants and the development of local market places such as Bhakundebesi.

Most local businesspersons are small entrepreneurs with limited investment capacity.

Some households’ members receive regular salaries, whilst an increasing number of Nepalis are working in India, the Middle East, Malaysia, and elsewhere and sending remittance incomes home.

Market orientation of production system: Vegetables- commercial

Level of mechanization: Manual labor consists of planting, irrigation , harvesting, while field preparation is carried out by animals, also machines but just in valley bottom.

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- medium-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, titled

Land use rights:

- individual

Water use rights:

- open access (unorganized)

- communal (organized)

Are land use rights based on a traditional legal system?

Yes

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

Waste management:

- poor

- moderate

- good

Comments:

Health facilities: There are nine health facilities centre in Namobuddha municipality, Kavre. The main health facilities are Methinkot Hospital, which is a 15-bed district level government hospital, and Dapcha Health Center, which is run by Kathmandu.

Education: There are eight academic institutes for higher studies ( higher secondary schools and colleges). The main academic institutes are:

Dapcha Krishna

Multiple Campus (community), Dapcha;

Janahit Secondary School (public), Khanalthok

Janak Multiple Campus (community), Methinkot

Janak Secondary School (public), Methinkot

Kanpur Campus(community), Kanpur and

Kanpur Secondary School

(public), Kanpur.

Employment ( off-farm): Due to loss of farmlands and increasing urbanization, many people are switching from agriculture to non-farm occupations such as working in brick kilns. The opening of the BP Highway has led to the establishment of many hotels and restaurants and the development of local market places such as Bhakundebesi. Most local businesspersons are small entrepreneurs with limited investment capacity.

Market: Bhakundebesi is the emerging marketplace due to its strategic location in the middle of the municipality astrid the BP Highway. Most local business activities in the municipality take place in Bhakundebesi bazaar. It is a major place for local people to purchase consumer goods.

Energy

Cooking fuel:

In 2011, 88% of households mainly used firewood for cooking, followed by liquefied petroleum gas (LPG) (4.92%). In Puranogaun Dapcha, almost all households (99.8%) relied on firewood for cooking. LPG was relatively popular in Dapcha Chatrebhanjh (10.3%) and Khanalthok (11.5%). Less than 6% of households used biogas for cooking, with its use relatively high in Mathurapati Fulbari (19.3%) and Methinkot (15.9%) (CBS, 2011).

Lighting :

93% of households used electricity for lighting while 5% depended on kerosene. Dependency on kerosene was relatively high in Khanalthok (8.1%) and Methinkot (7.4%). There was little solar lighting except for in Khanalthok where 3% of households relied on it (CBS, 2011).

Roads and Transportation:

Namobuddha Municipality is easily accessible by motorable road from neighboring areas via the BP Highway, which splits the municipality into almost two equal halves . The highway, which runs from Banepa to Bardibas in the Terai, is the shortest route from the Kathmandu Valley to the eastern hills and Terai. The limited width of the road and its sharp bends mean that public transportation along the BP Highway is mostly by small buses and jeeps.

Drinking water and Sanitation:

In 2011, about 60% of households had access to taps or piped water with accessibility varying across the municipality. While about 80% of PuranogauDapcha households had taps or piped water, only 37.5% of households in Simalchour Syampati enjoyed such services. Other sources of drinking water were covered wells (12.3%), uncovered wells (20.2%) and water spouts (6.3%). Methinkot (40.8%) and Simalchour Syampati (31.4%) residents were most reliant on uncovered wells. Covered wells served sizeable household populations in Dapcha Chatrebhanjh (35.3%) and Simalchour Syampati (23%) (CBS, 2011).

Toilet facilities: In 2011, about 63% of households had accessto toilet facilities, with about 40% overall having flushtoilets. The least toilet coverage was in Kanpur Kalapaniand Simalchour Syampati VDCs where 63% and 58% ofhouseholds respectively did not have their own toilets. Almost all households in Puranogaun Dapcha had their own toilets, mostly flush toilets (CBS, 2011).

Waste Management: – Namobuddha is in the early phase of urbanization with no systematic waste management.The Municipality Office is searching for a landfill site.

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

Comments/ specify:

Before they used to plant only one crop per year but now due to adoption of this technology, crop production has increased as they plant three crops per year.

crop quality

Comments/ specify:

Crop quality has become good due to availability of more water for irrigation and integration of this technology with bio-pesticide jholmol and mulching.

production area

Comments/ specify:

Due to availability of water for irrigation, farmers have turned many fallow land into agricultural land.

Water availability and quality

irrigation water availability

Comments/ specify:

Water needed for irrigation has increased as all the waste water from households, rainwater and taps waters are stored in this tank for irrigation in dry seasons.

Income and costs

farm income

Comments/ specify:

Irrigation water availability has increased crop production in turn farmer income has increased by selling those crops in market.

Socio-cultural impacts

food security/ self-sufficiency

Comments/ specify:

Farmers are becoming more self sufficient due to high production of crops.

community institutions

Comments/ specify:

Due to informal network of farmers with pond has strengthened community institutions.

SLM/ land degradation knowledge

Comments/ specify:

Farmers share their knowledge and experiences with each other and discuss on how they can overcome the challenges they have been facing recently.

Ecological impacts

Soil

soil moisture

Comments/ specify:

Due to availability of more irrigation water.

soil cover

Comments/ specify:

Most of the fallow land are turned into crop land.

6.2 Off-site impacts the Technology has shown

downstream flooding

Comments/ specify:

Due to trapped runoff

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | not known |

Climate-related extremes (disasters)

Meteorological disasters

| How does the Technology cope with it? | |

|---|---|

| local rainstorm | well |

| local windstorm | well |

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | moderately |

Hydrological disasters

| How does the Technology cope with it? | |

|---|---|

| general (river) flood | not well |

Other climate-related extremes (disasters)

| other (specify) | How does the Technology cope with it? |

|---|---|

| reducing growing period | well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

positive

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

very positive

Long-term returns:

very positive

6.5 Adoption of the Technology

- > 50%

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 11-50%

Comments:

Till now 24 land user families of Namobuddha Municipality have adopted this technology.

Among 24 land user families, 18 have adopted this technology with external material support through Resilient Mountain Village (RMV) project and 6 land users families have adopted this technology without any external support.

Comments on spontaneous adoption (Through survey results) : There is no trend towards spontaneous adoption of the technology because this technology is quiet expensive, compared to plastic- lined conservation pond.

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

No

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| Water stored in this tank is sufficient to irrigate 2-3 ropani (1 ropani = 508 sq.m.) land in one season. |

| This technology can be enhanced by sharing the advantages of this technology with large number of people. |

| It is more sustainable and efficient than plastic-lined conservation pond. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Good income can be achieved even from a small piece of land by sales of vegetables in the dry season . |

| These ponds are fed with rainwater and household kitchen wastewater free from soap and detergent and from springs and taps. The pond water was mainly used for micro irrigation including drip irrigation and micro-sprinkler. |

| It helps to promote the use of other water conserving techniques like mulching when using the harvested water. |

| It has reduced the dependence on large scale water supply schemes. |

| How can they be sustained / enhanced? Harvest all possible sources of water. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| Soil cement tank is expensive for poor farmers. | Subsidized cost for poor farmers. |

| It is unsafe for small children. | Protection structures should be constructed. |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| Cement and sand rate is very expensive for poor farmers. | Make it available in the local market at a subsidized cost for poor farmers. |

| The ponds attract insects, mainly mosquitoes, that cause disease; and the ponds are unsafe for small children. | Regularly clean the pond and fence them. |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

6

- interviews with land users

5

- interviews with SLM specialists/ experts

1

- compilation from reports and other existing documentation

2

When were the data compiled (in the field)?

20/02/2020

7.2 References to available publications

Title, author, year, ISBN:

ICIMOD (2018) Building Mountain Resilience: Solutions from the Hindu Kush Himalaya. Kathmandu: ICIMOD

Available from where? Costs?

ICIMOD

Title, author, year, ISBN:

SCWMC (2004) Soil Conservation and Watershed Management Measures and Low Cost Techniques. Kathmandu: Government of Nepal, Soil Conservation and Watershed Management Component - Department of Soil Conservation and Watershed Management

Available from where? Costs?

DSCWM, Kathmandu

7.3 Links to relevant online information

Title/ description:

Namobuddha Municipality, Nepal Situation Analysis for Green Municipal Development, 2018

URL:

https://gggi.org/site/assets/uploads/2018/07/GGGI_GMD-Assessment_Namobuddha.pdf

Title/ description:

Farmers in Kavre reaping benefits from soil cement tanks, 2021

URL:

https://www.icimod.org/article/farmers-in-kavre-reaping-the-benefits-of-soil-cement-tanks/

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules