V shaped catchment fence using Izote (Yucca sp.) [Honduras]

- Creation:

- Update:

- Compiler: Helen Gambon

- Editor: Anton Jöhr

- Reviewers: Johanna Jacobi, Alexandra Gavilano

technologies_736 - Honduras

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

land user:

Guillén José Isais

Honduras

land user:

Morales Lisandro

Honduras

SLM specialist:

Paguada Carmen

Cruz Roja Hondureña/Suiza

Honduras

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Book project: where people and their land are safer - A Compendium of Good Practices in Disaster Risk Reduction (DRR) (where people and their land are safer)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Swiss Red Cross (Swiss Red Cross) - Switzerland1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

1.5 Reference to Questionnaire(s) on SLM Approaches (documented using WOCAT)

Participative Slope Stabilization [Honduras]

Bioengineering includes a series of techniques based on the use of live vegetation to protect slopes and embankments from erosion and landslides. Bioengineering works are applied according to comprehensive risk assessment; they are multipurpose as a whole, have a low cost of consdtruction and maintenance cost,they enhance the capacities of …

- Compiler: Helen Gambon

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

V shaped catchment fences are used to stabilize gullies and prevent soil sediments from being removed by surface rain water runoff. It consists of planting izote (Yucca sp.) to create a V shaped fence around a gully.

2.2 Detailed description of the Technology

Description:

The Department of Olancho is a rainforest located at 1500 masl in the mountain range regions of Cordillera Central and Sierra de Agalta. Even though most of the area is protected as a natural reserve or natural park, it suffers from extensive deforestation from livestock practices and intensive industrial forest management practices. However, small land holders also clear forests. This causes rampant forest fires, soil degradation and erosion. The Department of Olancho is frequently affected yearly by tropical storms and hurricanes coming from the Atlantic. This combination of strong natural phenomena, topographic exposure and misuse of natural resources frequently results in significant property damage and even human deaths.

Gullies are formed by intense rain falling on degraded soils and, thus, gullies grow larger with each rainstorm. This increases the risk of land slides and reduces production areas. V shaped catchment fences using izote plants are set in place to control the gully head because they reduce the effective slope of erosion.

The izote plant (Yucca sp.) takes root and keeps on growing after being planted. By planting izote (Yucca sp.) in a V shaped pattern throughout the gully, the resulting fence contains the flow of water and sediment, thus increasing water filtration into the ground. Trenches are dug out with a depth of 30-50 cm in a V shape across the gully. The izote plants are cut in pieces 5-10 cm pieces, with an average length of 1.5 meters, depending on the depth of the gully. The plants are placed vertically in the trench, in tight clusters, and then the trench is filled with soil. The length of the fence depends on the width of the gully, an average of 3 meters (1.5 per side). The space between fences varies between 2 and 6 meters, depending on the slope. In time, the catchment fence becomes filled with sediment, thus reducing the speed of water runoff and promoting the accumulation of nutrients. Thus, in time, deep gullies can turn into a series of narrow fertile terraces on which crops may be grown.

However, the catchment fences must be included as part of a comprehensive plan for basin management and protection and, thus, must be supported with other SLM/RHR measures on the side slopes, such as live fences along the edge.

Catchment fences must be trimmed once a year so the izote plants don’t grow branches. The upper area where the sediments are collected must be cleared of unwanted material once a month during the winter.

In this case study, V shaped catchment fences were implemented through the project “Resiliencia”, which is undertaken by the Honduran/ Swiss Red Cross. This project aims at providing sustainable support to enhance resilience in the rural regions in Olancho, as well as coordinating efforts to reduce risk and to promote health at all levels (home, community, municipality). Bioengineering works are highly vulnerable and exposed to natural disasters.

2.3 Photos of the Technology

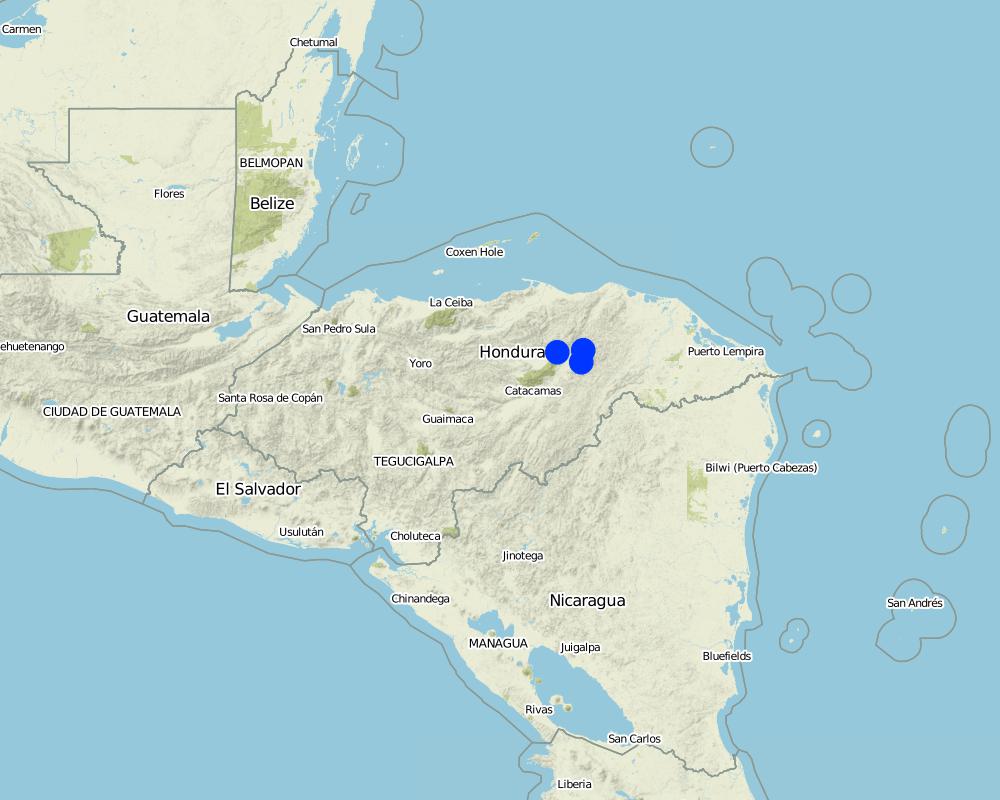

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Honduras

Region/ State/ Province:

Departament of Olancho

Further specification of location:

Dulce Nombre de Culmí municipality, La Felicidad community

Specify the spread of the Technology:

- applied at specific points/ concentrated on a small area

Map

×2.6 Date of implementation

Indicate year of implementation:

2016

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- reduce, prevent, restore land degradation

- reduce risk of disasters

- adapt to climate change/ extremes and its impacts

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

- Perennial (non-woody) cropping

Annual cropping - Specify crops:

- root/tuber crops - cassava

Perennial (non-woody) cropping - Specify crops:

- banana/plantain/abaca

Specify:

contínuo

Comments:

Main crops (cash and food crops): Banana, yucca (Manihot esculenta)

3.3 Has land use changed due to the implementation of the Technology?

Grazing land

- Extensive grazing

3.4 Water supply

Water supply for the land on which the Technology is applied:

- rainfed

3.5 SLM group to which the Technology belongs

- cross-slope measure

3.6 SLM measures comprising the Technology

structural measures

- S6: Walls, barriers, palisades, fences

3.7 Main types of land degradation addressed by the Technology

soil erosion by water

- Wg: gully erosion/ gullying

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- reduce land degradation

4. Technical specifications, implementation activities, inputs, and costs

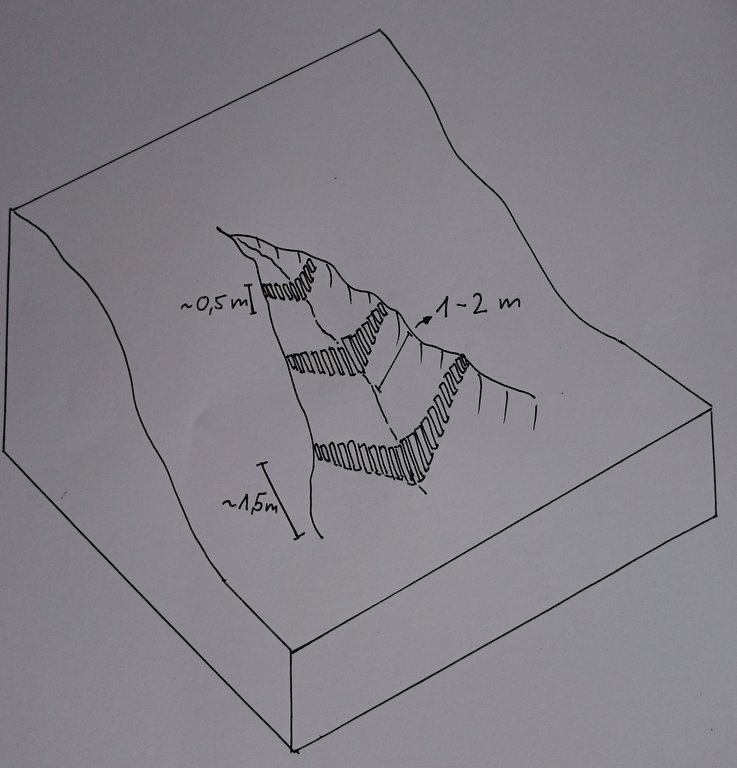

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

30-50 cm trenches are dug out in a V shape across the gully. Izote plants are cut in pieces 5-10 cm thick with an average length of 1.5 meters, depending on the depth of the gully. The plants are placed vertically in the gully in tight clusters and the trench is filled with soil. The length of the fence depends on the width of the gully, which is on average around 3 meters (1.5 per side). The space between the fences varies between 2 and 6 meters, according to the slope. In time, the containment fence becomes filled with sediments, thus water runnoff speed is reduced and more nutrients are accumulated.

Author:

Helen Gambon, Swiss Red Cross

Date:

01/12/2016

4.2 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology unit

Specify unit:

system of 3-4 containment fences

other/ national currency (specify):

Lempiras

If relevant, indicate exchange rate from USD to local currency (e.g. 1 USD = 79.9 Brazilian Real): 1 USD =:

23.0

Indicate average wage cost of hired labour per day:

150 Lempiras

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Bring and prepare izote plants (length corresponds to depth of gully) | Any time during the year |

| 2. | Determine distance between fences and terraced curves | |

| 3. | Dig small V shaped trenches at bottom of gully | |

| 4. | Plant tight clusters of izote vertically inside the trenches | |

| 5. | Fill with soil |

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Trained labor | person half-day | 1.0 | 200.0 | 200.0 | |

| Labour | Untrained labor | person half-day | 12.0 | 150.0 | 1800.0 | |

| Equipment | Manual excavator | piece | 1.0 | 180.0 | 180.0 | |

| Plant material | Izote | unit | 75.0 | 3.0 | 225.0 | |

| Other | Plant transportation | trip | 1.0 | 500.0 | 500.0 | |

| Total costs for establishment of the Technology | 2905.0 | |||||

| Total costs for establishment of the Technology in USD | 126.3 | |||||

If land user bore less than 100% of costs, indicate who covered the remaining costs:

Honduran/ Swiss Red Cross

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Trim plants to avoid izote from developing branches | Once a year |

| 2. | Clean the area surrounding the fence | Winter, once a month |

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Untrained labor | person half-day | 1.0 | 150.0 | 150.0 | 100.0 |

| Equipment | Machete | piece | 1.0 | 15.0 | 15.0 | 100.0 |

| Equipment | Manual excavator | piece | 1.0 | 180.0 | 180.0 | |

| Total costs for maintenance of the Technology | 345.0 | |||||

| Total costs for maintenance of the Technology in USD | 15.0 | |||||

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Transport plant material not previously available in the area.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specify average annual rainfall (if known), in mm:

1400.00

Specifications/ comments on rainfall:

Dry season from January to June, rainy season between June and October, with a heatwave in August.

Agro-climatic zone

- sub-humid

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- concave situations

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Soil texture (> 20 cm below surface):

- medium (loamy, silty)

Topsoil organic matter:

- medium (1-3%)

5.4 Water availability and quality

Ground water table:

5-50 m

Availability of surface water:

good

Water quality (untreated):

poor drinking water (treatment required)

Is water salinity a problem?

No

Is flooding of the area occurring?

No

5.5 Biodiversity

Species diversity:

- medium

Habitat diversity:

- low

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- mixed (subsistence/ commercial)

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- poor

Individuals or groups:

- individual/ household

Level of mechanization:

- manual work

Gender:

- men

Age of land users:

- middle-aged

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, not titled

Land use rights:

- individual

Water use rights:

- communal (organized)

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

Quantity before SLM:

0

Quantity after SLM:

2

Comments/ specify:

The Technology allows using perennial crops such as banana or cassava in gullies once barren. In time, the fences are filled with soil, thus increasing crop areas.

product diversity

Quantity before SLM:

0

Quantity after SLM:

2

Comments/ specify:

Before the Technology was implemented, the slope was not apt for crops.

production area

Quantity before SLM:

0

Quantity after SLM:

2

Income and costs

farm income

Quantity before SLM:

0

Quantity after SLM:

1

diversity of income sources

Quantity before SLM:

0

Quantity after SLM:

1

workload

Quantity before SLM:

0

Quantity after SLM:

-1

Comments/ specify:

According to Land Users, the workload increased slightly, since the slopes weren't used for anything before. Now, it is necessary to provide maintenance to the different bioengineering projects, which also include containment fences. However, the Land Users stated this is not a bad thing.

Socio-cultural impacts

food security/ self-sufficiency

Quantity before SLM:

0

Quantity after SLM:

2

community institutions

Quantity before SLM:

0

Quantity after SLM:

2

SLM/ land degradation knowledge

Quantity before SLM:

0

Quantity after SLM:

3

Comments/ specify:

Members from neighboring communities are trained by the Land Users on how to implement the Technology.

Ecological impacts

Water cycle/ runoff

surface runoff

Quantity before SLM:

0

Quantity after SLM:

2

Soil

soil cover

Quantity before SLM:

0

Quantity after SLM:

2

soil loss

Quantity before SLM:

0

Quantity after SLM:

3

soil accumulation

Quantity before SLM:

0

Quantity after SLM:

3

nutrient cycling/ recharge

Quantity before SLM:

0

Quantity after SLM:

3

Climate and disaster risk reduction

landslides/ debris flows

Quantity before SLM:

0

Quantity after SLM:

3

6.2 Off-site impacts the Technology has shown

damage on public/ private infrastructure

Quantity before SLM:

0

Quantity after SLM:

3

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | very well | |

| seasonal temperature | summer | increase | very well |

| seasonal rainfall | summer | decrease | very well |

Climate-related extremes (disasters)

Meteorological disasters

| How does the Technology cope with it? | |

|---|---|

| tropical storm | not known |

| extra-tropical cyclone | well |

Hydrological disasters

| How does the Technology cope with it? | |

|---|---|

| landslide | well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

very positive

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

very positive

Long-term returns:

very positive

Comments:

The Technology needs no further investment; it has a long lifespan; it significantly reduces the flow of surface water and thus prevents the formation of gullies. It also allows expanding crop areas and helps the soil to retain nutrients.

6.5 Adoption of the Technology

- 1-10%

If available, quantify (no. of households and/ or area covered):

20 out of 250 critical sites

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 0-10%

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

No

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| Protects houses from damage. |

| Crops grow faster due to improved soil quality caused by greater retention of nutrients. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| The Technology does not need further investments; its lifespan is long; it significantly reduces the flow of surface water and, thus, the formation of gullies. It allows to expand the crop areas and helps the soil to retain nutrients. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| If not trimmed, izote extends and overwhelms productive crops | Performing maintenance continuously. |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

2

- interviews with land users

2

- interviews with SLM specialists/ experts

1

When were the data compiled (in the field)?

21/11/2016

Links and modules

Expand all Collapse allLinks

Participative Slope Stabilization [Honduras]

Bioengineering includes a series of techniques based on the use of live vegetation to protect slopes and embankments from erosion and landslides. Bioengineering works are applied according to comprehensive risk assessment; they are multipurpose as a whole, have a low cost of consdtruction and maintenance cost,they enhance the capacities of …

- Compiler: Helen Gambon

Modules

No modules