Production and application of biohumus [Kyrgyzstan]

- Creation:

- Update:

- Compiler: Abdybek Asanaliev

- Editor: –

- Reviewers: Fabian Ottiger, Alexandra Gavilano

Биогумусту ондуруунун жана колдонуунун технологиясы

technologies_1125 - Kyrgyzstan

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Kyrgyz Agrarian University (Kyrgyz Agrarian University) - Kyrgyzstan1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

By letting Californian red worms processing fresh manure filled into a trench, biohumus is produced to improve soil fertility in kitchen gardens.

2.2 Detailed description of the Technology

Description:

Since the 1990ies, farmers from Borulu village have not been applying fertilizers in kitchen gardens due to their high costs. As a result, the soil fertility has decreased. Facing this problem Kalmurat Koshaliev decided to produce biohumus by himself.

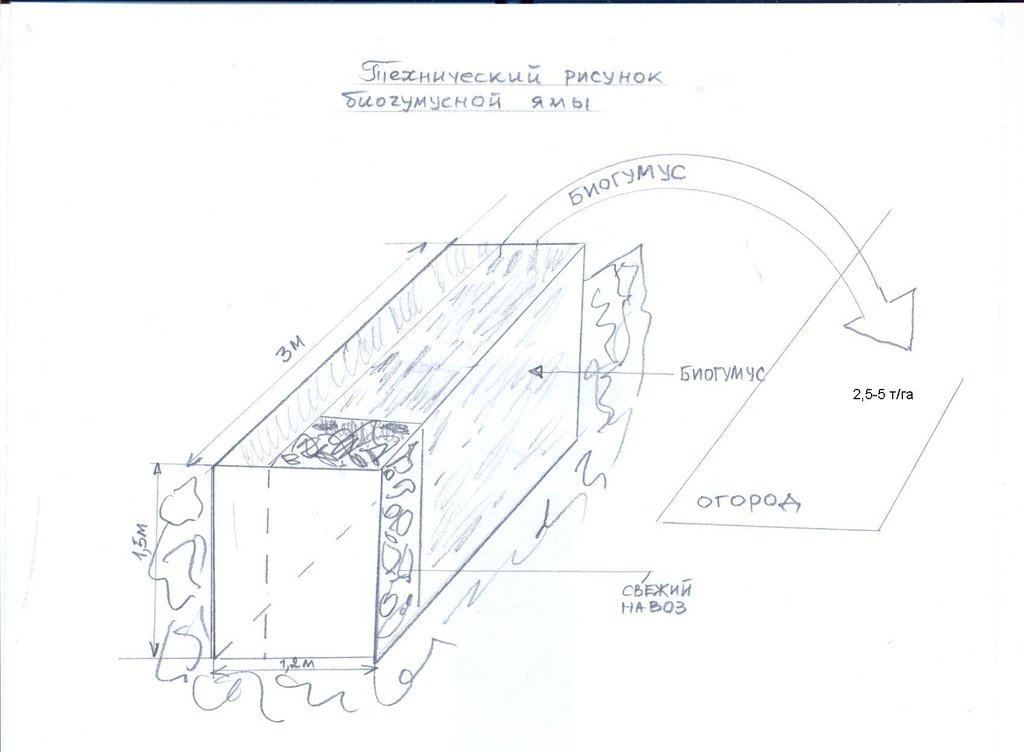

For manure processing, a trench with 3 m length, 1,2 m width and 1,5 m depth was prepared. The trench was fenced with a mesh to protect worms from poultry. In May the trench was filled with fresh manure and 5 kg of worms were released on top of it. These worms feed on manure and process it. In the hot season the mass of manure should be moist, and therefore it is watered once a week (60-70% moisture needed). Within 20-25 days the worms process the fresh manure. Manure obtains a dark colour and becomes crumbly. Biohumus is then separated from worms by using a metal mesh. Separated worms are placed into a corner of the trench and fresh manure is filled in again. After 20-25 days the same work is repeated, until the weather becomes colder. With the onset of the cold, the surface of the trench is covered with straw and leaves (30 cm) in order to prevent freezing of the biohumus. In spring the cycle is repeated. Once there are too many worms in the trench, a part of them can be separated and another biohumus producing trench can be established. The produced biohumus is used as an organic fertilizer for potatoes, carrots and tomatoes. Application norms are 2.5-5 tons of biohumus per ha.

Purpose of the Technology: As a result of the regular application of biohumus soil fertility has significantly improved.

Establishment / maintenance activities and inputs: The technology was realized after a workshop on "Sustainable use of natural resources by implementation of SWC technologies" organized by "CAMP Alatoo". During this workshop, participants from Tosh-Bulak, Chetindi and Borulu villages developed the project using the CAMP Alatoo's collection of SWC technologies. Kalmurat Koshaliev and his team developed a project on biohumus production. The group made a certain labour and financial contribution to the implementation of the technology, whereas CAMP Alatoo covered the rest of the cost. The group bought Californian worm and cement. Maintenance costs are borne by the households.

Natural / human environment: Borulu village is located 1600-1630 m a.s.l. on the northern slope of the gorge Sokuluk. Kitchen garden plots are at the foot of the mountains. Mountains are covered with shrub-juniper forest. Animal husbandry is considered as the main activity. Livestock is grazed in close-to-village and intensive pastures. The village also has far away pastures located up in Suusamyr valley. Close-to-village pastures are in use 12 months a year. In winter, animals are fed with hay and concentrated feed. In the kitchen gardens, potatoes, carrots and garlics are planted. From 1 ha of land fertilized with biohumus up to 350-400 kg potatoes can be produced. Soil becomes rich and allows obtaining a good yield.

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Kyrgyzstan

Region/ State/ Province:

Sokuluk rayon, Chuy oblast

Further specification of location:

Kyrgyz Republic

Comments:

Total area covered by the SLM Technology is 0.001 km2.

Total SLM technology area: 0.10 ha

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- more than 50 years ago (traditional)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

3. Classification of the SLM Technology

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

Number of growing seasons per year:

- 2

Specify:

Longest growing period in days: 140Longest growing period from month to month: from May to SeptemberSecond longest growing period in days: 150

Comments:

Major land use problems (compiler’s opinion): Reduced soil productivity

Major land use problems (land users’ perception): Increase of prices for fertilizers, pesticides, seeds and deterioration of land

3.6 SLM measures comprising the Technology

agronomic measures

- A2: Organic matter/ soil fertility

Comments:

Type of agronomic measures: manure / compost / residues

3.7 Main types of land degradation addressed by the Technology

chemical soil deterioration

- Cn: fertility decline and reduced organic matter content (not caused by erosion)

Comments:

Main causes of degradation: crop management (annual, perennial, tree/shrub) (Lack of crop rotation and fertilizer application.), population pressure (The absence of fallow land, minor contributions to the maintenance of soil fertility.)

Secondary causes of degradation: poverty / wealth (Inability to buy agricultural inputs due to high prices), education, access to knowledge and support services (Lack of expertise on the use of agricultural land and underdevelopment of the advisory services.)

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- reduce land degradation

Comments:

Основная цель: предотвращение / сокращение деградации

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

A technical drawing of the trench for biohumus production

Location: Borulu village. Chuy oblast

Date: 27/12/2011

Technical knowledge required for field staff / advisors: high

Technical knowledge required for land users: moderate

Main technical functions: increase in organic matter

Manure / compost / residues

Material/ species: Organic fertilizer (biohumus)

Quantity/ density: 2.5-5 t

Remarks: Rates depend on the type of crops and the height of the yield

Author:

Asanaliev A.J., Bishkek, 11-27-1

4.2 General information regarding the calculation of inputs and costs

other/ national currency (specify):

kyrgyz som

If relevant, indicate exchange rate from USD to local currency (e.g. 1 USD = 79.9 Brazilian Real): 1 USD =:

40.0

Indicate average wage cost of hired labour per day:

12.00

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Construction of the trench | |

| 2. | Purchase of the Californian red worms |

Comments:

Life span of the products: 25 years

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Trench construction | piece | 1.0 | 50.0 | 50.0 | 100.0 |

| Construction material | Cement | kg | 5.0 | 50.0 | 250.0 | 50.0 |

| Other | Californian red worms | kg | 5.0 | 10.0 | 50.0 | 100.0 |

| Total costs for establishment of the Technology | 350.0 | |||||

| Total costs for establishment of the Technology in USD | 8.75 | |||||

Comments:

Duration of establishment phase: 2 month(s)

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Watering the manure | Every 20-25 until the end of the hot season |

| 2. | Separating biohumus from the humus | Every 20-25 until the end of the hot season |

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Watering the manure and separating biohumus from the humus | times | 1.0 | 38.0 | 38.0 | 100.0 |

| Total costs for maintenance of the Technology | 38.0 | |||||

| Total costs for maintenance of the Technology in USD | 0.95 | |||||

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Costs depend on the volume of the trench, the amount of biohumus to be applied and the frequency of biohumus production.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Agro-climatic zone

- semi-arid

Thermal climate class: temperate. Temperate zone, 4 seasons are clearly distiquished

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- coarse/ light (sandy)

Topsoil organic matter:

- medium (1-3%)

5.4 Water availability and quality

Availability of surface water:

good

Water quality (untreated):

good drinking water

5.5 Biodiversity

Species diversity:

- medium

5.6 Characteristics of land users applying the Technology

Off-farm income:

- less than 10% of all income

Individuals or groups:

- individual/ household

Gender:

- women

- men

Indicate other relevant characteristics of the land users:

Land users applying the Technology are mainly disadvantaged land users

Population density: < 10 persons/km2

Annual population growth: 2% - 3%

2% of the land users are average wealthy and own 7% of the land.

78% of the land users are poor and own 85% of the land.

20% of the land users are poor and own 8% of the land.

Off-farm income specification: Non-farmers are engaged in animal husbandry or work as a drivers.

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, titled

Land use rights:

- individual

Water use rights:

- open access (unorganized)

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

Quantity before SLM:

150 c/ha

Quantity after SLM:

250 c/ha

Income and costs

expenses on agricultural inputs

Quantity before SLM:

0

Quantity after SLM:

20

farm income

Quantity before SLM:

0.%

Quantity after SLM:

20%

Socio-cultural impacts

health situation

Quantity before SLM:

10%

Quantity after SLM:

20%

cultural opportunities

Quantity before SLM:

0

Quantity after SLM:

0.10 ha

community institutions

Quantity before SLM:

0

Quantity after SLM:

1gr.

conflict mitigation

Quantity before SLM:

0

Quantity after SLM:

4p.trained

Ecological impacts

Biodiversity: vegetation, animals

biomass/ above ground C

Climate and disaster risk reduction

fire risk

Quantity before SLM:

2%

Quantity after SLM:

10%

6.2 Off-site impacts the Technology has shown

buffering/ filtering capacity

Quantity before SLM:

30 %

Quantity after SLM:

50%

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | not well |

Climate-related extremes (disasters)

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | not well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

neutral/ balanced

Long-term returns:

positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

positive

Long-term returns:

positive

Comments:

Short term: 1-3 years; long term: 10 years

6.5 Adoption of the Technology

Comments:

10% of land user families have adopted the Technology with external material support

1 land user families have adopted the Technology with external material support

Comments on acceptance with external material support: There are 30 plots (households) in the village. One of them implemented this technology. In total, 10 ha land area could be used for crop production.

6% of land user families have adopted the Technology without any external material support

2 land user families have adopted the Technology without any external material support

Comments on spontaneous adoption: 2 households implemented this technology on the 0.20 ha land area (0,1+0,1 ha) out of 10 ha available land.

There is a little trend towards spontaneous adoption of the Technology

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

|

An opportunity to improve crop production and to demonstrate this technology to other land users. How can they be sustained / enhanced? People need to realize the need to receive high yields. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

|

Mitigation of land degradation by increasing organic mass of the soil. How can they be sustained / enhanced? People need to realize the need of fertiliers. |

|

Increase in crop production. How can they be sustained / enhanced? People need to continue looking after their lands. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| It is time-consuming work. | Teach children and make an agreement with neighbors to receive biohumus. |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| There are only few adoptions of the technology. | Introductive trainings for villagers are needed. |

7. References and links

7.1 Methods/ sources of information

7.2 References to available publications

Title, author, year, ISBN:

Отчеты и протоколы семинара «ОФ САМР-Алатоо»,

Available from where? Costs?

Офис «ОФ САМР-Алатоо»

Title, author, year, ISBN:

Отчеты «ОФ САМР-Алатоо» по мониторингу и оценке внедренных ПВСТ в селе Саз

Title, author, year, ISBN:

Документы домашнего архива Калмурата Кошалиева.

Available from where? Costs?

Библиотека Кыргызского НИИ Земледелия.

Title, author, year, ISBN:

Абасов В.С. Влияние биогумуса на продуктивность сельскохозяйственных культур на сероземных почвах Чуйской долины.- Автореферат диссертации на соискание ученой степени кандидата сельскохозяйственных наук.- Бишкек, 2002.

Available from where? Costs?

Библиотека Кыргызского НИИ Земледелия.

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules