Natural spring catchment protection [Tajikistan]

- Creation:

- Update:

- Compiler: Giuseppe Bonati

- Editor: –

- Reviewers: Alexandra Gavilano, David Streiff, Joana Eichenberger

technologies_1465 - Tajikistan

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

SLM specialist:

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Pilot Program for Climate Resilience, Tajikistan (WB / PPCR)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

CESVI (CESVI) - Tajikistan1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

The construction of a natural spring catchment pit for the collection and distribution of uncontaminated ground water.

2.2 Detailed description of the Technology

Description:

The technolgy consists of digging of a pit around the spring outlet and placing a 15cm perforated plastic pipe on a bed of gravel. The gravel acts as a natural sediment filter and protects the pipe from clogging. The pipe is buried in more gravel and covered with a plastic sheet to prevent animals from contaminating the spring source. The plastic pipe can be extended and attached to a flexible pipe to deliver clean ground water to the final destination.

Purpose of the Technology: There are two main aims of the technology, the first is to prevent contamination of the spring source from livestock which uses the spring head as a watering hole. The second goal is to optimise the springs capacity for irrigation and human consumption by capturing the water in the perforated pipe and channelling to the usage point.

Establishment / maintenance activities and inputs: The construction of the spring catchment is relatively straight forward. A 1m deep pit is dug around the spring head approximately 2m wide. A bed of washed gravel is placed in the foot of the pit, and a 15cm perforated plastic pipe is embedded into the gravel, this is attached to a flexible tube to transport the clean water away. The perforated pipe is covered in more clean gravel and covered with a heavy polythene sheet and covered in earth. The construction process can be completed in one day if the materials are available.

The only substantial maintenance required would be the cleaning of the pipe and gravel if it gets clogged with earth.

Natural / human environment: In many parts of Tajikistan water for human use and irrigation is scarce and plays a critical role in securing the livelihoods of the local population. The construction of the spring catchment increases not only the volume but also improves the quality of water available. This can and does have a dramatic effect on the productivity of the land and the health of the land users.

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Tajikistan

Region/ State/ Province:

Khatlon region

Further specification of location:

Khovaling

Specify the spread of the Technology:

- evenly spread over an area

If precise area is not known, indicate approximate area covered:

- < 0.1 km2 (10 ha)

Comments:

This technology is in one location.

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

Comments (type of project, etc.):

Spring Protection Project

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improved access to water

3.2 Current land use type(s) where the Technology is applied

Cropland

- Tree and shrub cropping

Tree and shrub cropping - Specify crops:

- fruits, other

Number of growing seasons per year:

- 1

Specify:

Longest growing period in days: 180Longest growing period from month to month: april - october

Forest/ woodlands

Products and services:

- Fuelwood

- Fruits and nuts

- Protection against natural hazards

Comments:

Major land use problems (compiler’s opinion): Lack of access to water. Contamination of the water due to animals using the spring.

Major land use problems (land users’ perception): Provides a better cleaner source of water for the land and the people.

Plantation forestry: Fruit tree orchards.

Problems / comments regarding forest use: The spring is located in natural woodland, however the water supply is directed towards the fruit orchards.

Forest products and services: fuelwood, fruits and nuts, protection against natural hazards

Future (final) land use (after implementation of SLM Technology): Forests / woodlands: Fn: Natural

3.3 Has land use changed due to the implementation of the Technology?

Forest/ woodlands

- (Semi-)natural forests/ woodlands

3.5 SLM group to which the Technology belongs

- water harvesting

3.6 SLM measures comprising the Technology

structural measures

- S3: Graded ditches, channels, waterways

management measures

- M6: Waste management (recycling, re-use or reduce)

Comments:

Main measures: structural measures

3.7 Main types of land degradation addressed by the Technology

soil erosion by water

- Wt: loss of topsoil/ surface erosion

- Wm: mass movements/ landslides

biological degradation

- Bc: reduction of vegetation cover

water degradation

- Hs: change in quantity of surface water

- Hp: decline of surface water quality

Comments:

Main type of degradation addressed: Bc: reduction of vegetation cover, Hs: change in quantity of surface water, Hp: decline of surface water quality

Secondary types of degradation addressed: Wt: loss of topsoil / surface erosion, Wm: mass movements / landslides

Main causes of degradation: other natural causes (avalanches, volcanic eruptions, mud flows, highly susceptible natural resources, extreme topography, etc.) specify (The land degradation was caused by uncontrolled natural spring run off.)

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

- reduce land degradation

Comments:

Main goals: mitigation / reduction of land degradation

Secondary goals: prevention of land degradation

4. Technical specifications, implementation activities, inputs, and costs

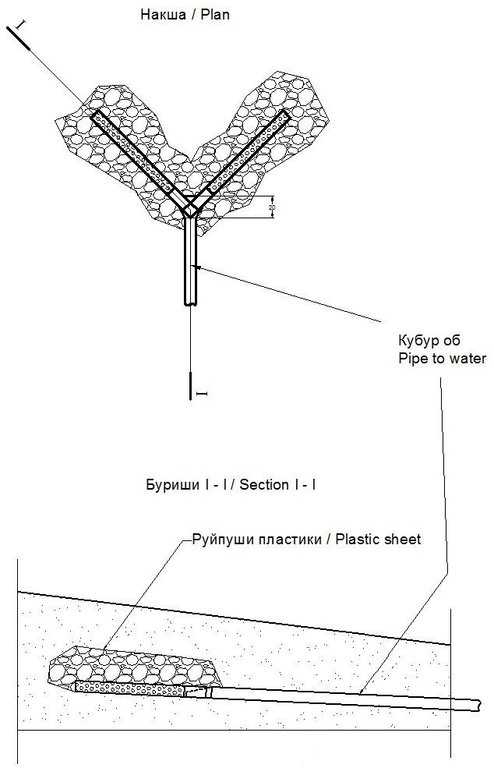

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

Basic sketch of perferated drainage collecting the spring water and flowing into a pipe. To take an increased quantity of water you can install more pipes (See section 2.1.3).

Location: Gulizor Nursary. Khovaling/Khatlo/Tajikistan

Date: 19/05/2011

Technical knowledge required for field staff / advisors: high (After training to increase their capacity)

Technical knowledge required for land users: high (After training to increase their capacity)

Main technical functions: control of concentrated runoff: drain / divert, water harvesting / increase water supply

Diversion ditch/ drainage

Depth of ditches/pits/dams (m): 1

Width of ditches/pits/dams (m): 1.5

Length of ditches/pits/dams (m): 1.5

Construction material (earth): The spring head is dug into the earth.

Construction material (stone): The stone is used to line the base of the spring head.

Author:

Foteh, CESVI

4.2 General information regarding the calculation of inputs and costs

other/ national currency (specify):

TJS

If relevant, indicate exchange rate from USD to local currency (e.g. 1 USD = 79.9 Brazilian Real): 1 USD =:

4.5

Indicate average wage cost of hired labour per day:

25

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Digging of the spring head | Spring |

| 2. | pipe positioning | Spring |

| 3. | Gravel positioning and covering with plastic sheet | Spring |

| 4. | Fill back the drainage | Spring |

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Digging of the spring head | Persons/day | 2.0 | 25.0 | 50.0 | 100.0 |

| Labour | Pipe positioning | Persons/day | 2.0 | 25.0 | 50.0 | 100.0 |

| Labour | Gravel positioning | Persons/day | 2.0 | 25.0 | 50.0 | 100.0 |

| Labour | Fill back the drainage | Persons/day | 2.0 | 25.0 | 50.0 | 100.0 |

| Equipment | Tools | Pieces | 4.0 | 10.0 | 40.0 | 100.0 |

| Equipment | Drill | Pieces | 1.0 | 250.0 | 250.0 | |

| Construction material | Drainage pipe | meter | 10.0 | 1.5 | 15.0 | |

| Construction material | Stone | tons | 0.5 | 136.0 | 68.0 | |

| Construction material | Plastic sheet to cover | sq m | 1.5 | 5.333333 | 8.0 | |

| Total costs for establishment of the Technology | 581.0 | |||||

| Total costs for establishment of the Technology in USD | 129.11 | |||||

If land user bore less than 100% of costs, indicate who covered the remaining costs:

CESVI

Comments:

Duration of establishment phase: 1 month(s)

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Cleaning the water channel after drainage | Spring |

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Cleaning the water channel | Persons/day | 2.0 | 25.0 | 50.0 | 100.0 |

| Equipment | Tools | Pieces | 2.0 | 10.0 | 20.0 | 100.0 |

| Total costs for maintenance of the Technology | 70.0 | |||||

| Total costs for maintenance of the Technology in USD | 15.56 | |||||

Comments:

Machinery/ tools: Shovel

Costs are based upon one spring at a depth of 1m at 2010 prices.

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

The cost is determined by the depth of the spring head. If it needs to be deeper it requires additonal labour and material costs.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Agro-climatic zone

- semi-arid

Thermal climate class: temperate

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- fine/ heavy (clay)

Topsoil organic matter:

- medium (1-3%)

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

Soil fertility is low

Soil drainage / infiltration is medium

Soil water storage capacity is medium

5.4 Water availability and quality

Ground water table:

< 5 m

Availability of surface water:

good

Water quality (untreated):

good drinking water

Comments and further specifications on water quality and quantity:

Availability of surface water is good at the location of the spring, but medium where the water is needed for the lands.

5.5 Biodiversity

Species diversity:

- medium

5.6 Characteristics of land users applying the Technology

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- very poor

- poor

Individuals or groups:

- groups/ community

Gender:

- women

- men

Indicate other relevant characteristics of the land users:

Land users applying the Technology are mainly Leaders / privileged

Population density: 10-50 persons/km2

Annual population growth: 1% - 2%

80% of the land users are poor.

20% of the land users are poor.

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- large-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- state

Land use rights:

- communal (organized)

Water use rights:

- communal (organized)

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Water availability and quality

drinking water availability

irrigation water availability

Socio-cultural impacts

food security/ self-sufficiency

health situation

SLM/ land degradation knowledge

Livelihood and human well-being

Comments/ specify:

It has improved access to running water for sanitation, hygiene, irrigation and animal husbandry purposes.

Ecological impacts

Water cycle/ runoff

water quantity

water quality

harvesting/ collection of water

surface runoff

excess water drainage

Climate and disaster risk reduction

drought impacts

6.2 Off-site impacts the Technology has shown

water availability

reliable and stable stream flows in dry season

downstream flooding

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | well |

Climate-related extremes (disasters)

Meteorological disasters

| How does the Technology cope with it? | |

|---|---|

| local rainstorm | well |

| local windstorm | well |

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | well |

Hydrological disasters

| How does the Technology cope with it? | |

|---|---|

| general (river) flood | not known |

Other climate-related consequences

Other climate-related consequences

| How does the Technology cope with it? | |

|---|---|

| reduced growing period | well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

slightly positive

Long-term returns:

positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

positive

Long-term returns:

positive

6.5 Adoption of the Technology

- single cases/ experimental

If available, quantify (no. of households and/ or area covered):

1 houshold

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 0-10%

Comments:

Comments on spontaneous adoption: In the course of the project 24 springs will be refurbished (2011-2013).

There is no trend towards spontaneous adoption of the Technology

Comments on adoption trend: The technology is new and in its infancy.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| Pleased at the increase in water and ability to improve the yield of his crops. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

|

Increased access to water through controlled piping. How can they be sustained / enhanced? Provision of guidance of which pipes to use. |

| Reduced the contamination at the spring head by animals. |

|

It is quick and cheap to install. How can they be sustained / enhanced? provide further training and support on maintenance. |

| It is easy to teach people how to install it. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| Difficult at times to find good cheap plastic pipe. |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| It incurs an initial financial outlay, which may be considerable if the spring is located far from where the water is needed. |

7. References and links

7.1 Methods/ sources of information

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules