Biogas Digester for Biomass Energy [China]

- Creation:

- Update:

- Compiler: Yaolin Wang

- Editor: –

- Reviewers: Deborah Niggli, Alexandra Gavilano

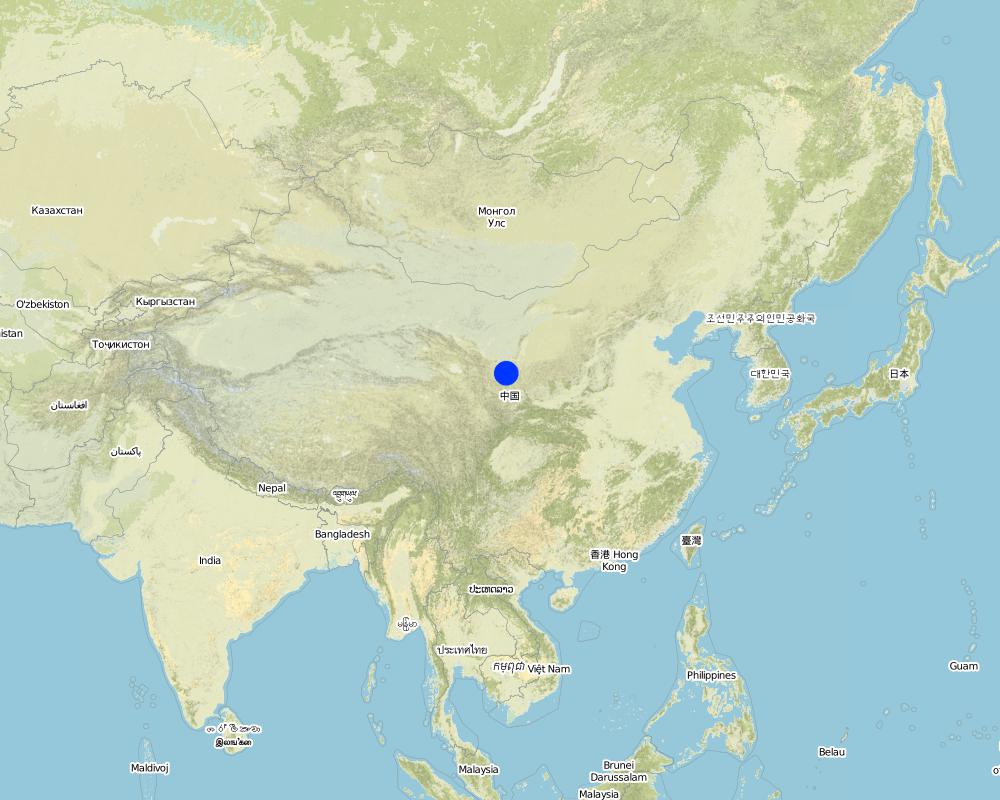

technologies_1576 - China

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Best Practices for Land Degradation Control in Dryland Areas of China (Best Practices China)1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

By established facilities and use organic matter of animal manure, human waste, plant straw for anaerobic fermentation to produce inflammable biogas for uses of lighting, cooking with the residue liquid and dreg for high quality organic fertilizer.

2.2 Detailed description of the Technology

Description:

The demonstration site is located at Jingyuan County of central Gansu Province, an arid county with annual rainfall of 240 mm for rainfed agriculture. The vegetation cover of the county is 5.6% and the water and soil erosion affected area is 5359 square kilometers or 92.2% of the total land area. The fragile ecologie and serious land degradation made the locality a very poor place, short of fuel. Poverty and ecological degradation has formed a vicious circle. Energy scarcity problem that needs to be solved urgently is also a cutting point for curbing land degradation.

Since 2000, with the support of relevant departments, the biogas production technology has been introduced and extended in Jingyuan County. Due to its multiple functions in the kitchen, toilets, animal houses etc., it has obvious social, ecological and economic benefits. The technology is easy and the maintenance is simple, so the extension is quick.

The construction procedures include: location identification, digester type selection (e.g. rotational-flowed digester), determination of elevation, earthwork, and construction of digester base, digester wall, feed and discharge chutes, proof seal layer and digester cover etc..

Biogas digester operation preparation: inoculum input, raw material pretreatment and ratio, prohibition of input materials (poisonous farm chemicals, oil dregs, bones or bone powder etc).

The operational management: pH value must be kept at 6.8-7.5 and digester fermentation temperature maintained over 10 degrees Celsius; Replace desulfurizer every three months, stir frequently to ferment raw material, inspect often to ensure no leakage in the cover, pipeline etc.; frequent work in feeding and discharging, control the density of liquid material.

(1) Ecologically, the use of biogas can reduce vegetation damage and prevent land degradation. A biogas digester with a capacity of 10 m3 can economize 2 tons of firewood every year, which is equivalent to the annual increment of 3.5 mu firewood forest; The dregs and residue liquid are organic fertilizers, the liquid can also be used for the treatment of plant diseases and pests;

(2) Social benefits: The biogas digester may offer over 70% clean energy for the household while reducing the consumption of the conventional energies of firewood and coal; The life quality, sanitary condition are improved and the workload of women is decreased; The use of biogas digester promotes social progress by raising the awareness of science and technology of the farmers to promote the construction of new socialist countryside.

(3) Economically the biogas will increase the income of farmers. It can cut down the expenditure by 1500 Yuan for one year. Biogas use can promote livestock development and as an environmental-friendly agriculture development model.

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

China

Region/ State/ Province:

Gansu Province

Further specification of location:

Jingyuan

Comments:

Total area covered by the SLM Technology is 5809.4 km2.

Map

×3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- create beneficial economic impact

- create beneficial social impact

3.2 Current land use type(s) where the Technology is applied

Land use mixed within the same land unit:

Yes

Specify mixed land use (crops/ grazing/ trees):

- Agroforestry

Cropland

- Annual cropping

Number of growing seasons per year:

- 1

Specify:

Longest growing period in days: 180, Longest growing period from month to month: April to September

Settlements, infrastructure

- Settlements, buildings

Comments:

Major land use problems (compiler’s opinion): low vegetation cover, wind erosion, water erosion, barren soil, arid climate, fragile ecological condition.

3.5 SLM group to which the Technology belongs

- energy efficiency technologies

3.6 SLM measures comprising the Technology

other measures

3.7 Main types of land degradation addressed by the Technology

soil erosion by wind

- Et: loss of topsoil

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

Main technical functions: Protect vegetation, reduce water erosion, prevent wind erosions

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Materials, cement, sand, cooker | |

| 2. | Labour 7.5 person days | |

| 3. | Other: Transport fee |

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | labour | person days | 7.5 | 5.333 | 40.0 | 100.0 |

| Construction material | Cemet, sand, cooker | 1.0 | 267.0 | 267.0 | ||

| Other | transport fee | 1.0 | 40.0 | 40.0 | 100.0 | |

| Total costs for establishment of the Technology | 347.0 | |||||

| Total costs for establishment of the Technology in USD | 347.0 | |||||

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Agro-climatic zone

- arid

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Topsoil organic matter:

- medium (1-3%)

5.6 Characteristics of land users applying the Technology

Market orientation of production system:

- subsistence (self-supply)

Off-farm income:

- 10-50% of all income

5.8 Land ownership, land use rights, and water use rights

- collectives

Land use rights:

- individual

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Income and costs

farm income

Socio-cultural impacts

Improve knowledge level and technology dissemination

Alliviate women’s labor burden

Ecological impacts

Water cycle/ runoff

surface runoff

Soil

soil cover

Biodiversity: vegetation, animals

Vegetation cover

Climate and disaster risk reduction

wind velocity

Other ecological impacts

Save energies of coal, firewood etc

Improve living environment

Promote development of environmental friendly agriculture

6.2 Off-site impacts the Technology has shown

downstream siltation

wind transported sediments

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

negative

Long-term returns:

positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

positive

Long-term returns:

positive

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Protect vegetation |

| Prevent soil and water erosion |

| Economical use of energy |

| Serve the development of organic agriculture |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| high initial investment | get more project support |

| low gas production | strengthen training for correct operation |

| biogas can be dangerous | strengthen training |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

- interviews with land users

When were the data compiled (in the field)?

06/09/2007

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules