Vetiver grass soil conservation system [South Africa]

- Creation:

- Update:

- Compiler: Unknown User

- Editor: –

- Reviewers: David Streiff, Alexandra Gavilano, Deborah Niggli

Vetiver system

technologies_938 - South Africa

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

land user:

Stranic Rowan

South African Sugar Association

South Africa

SLM specialist:

Grimshaw Dick

The Vetiver Network

United States

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Book project: where the land is greener - Case Studies and Analysis of Soil and Water Conservation Initiatives Worldwide (where the land is greener)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

The Vetiver Network International (TVNI) - United StatesName of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

South African Sugar Association (SASA) - South Africa1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.5 Reference to Questionnaire(s) on SLM Approaches (documented using WOCAT)

Self teaching [South Africa]

Learning how to use vetiver grass as a vegetative conservation barrier through instructions from a booklet and hands-on practical experience.

- Compiler: Philippe Zahner

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Contour lines of vetiver grass planted within fields of sugar cane, on stream banks and roadsides, to act as ‘hedges against erosion’.

2.2 Detailed description of the Technology

Description:

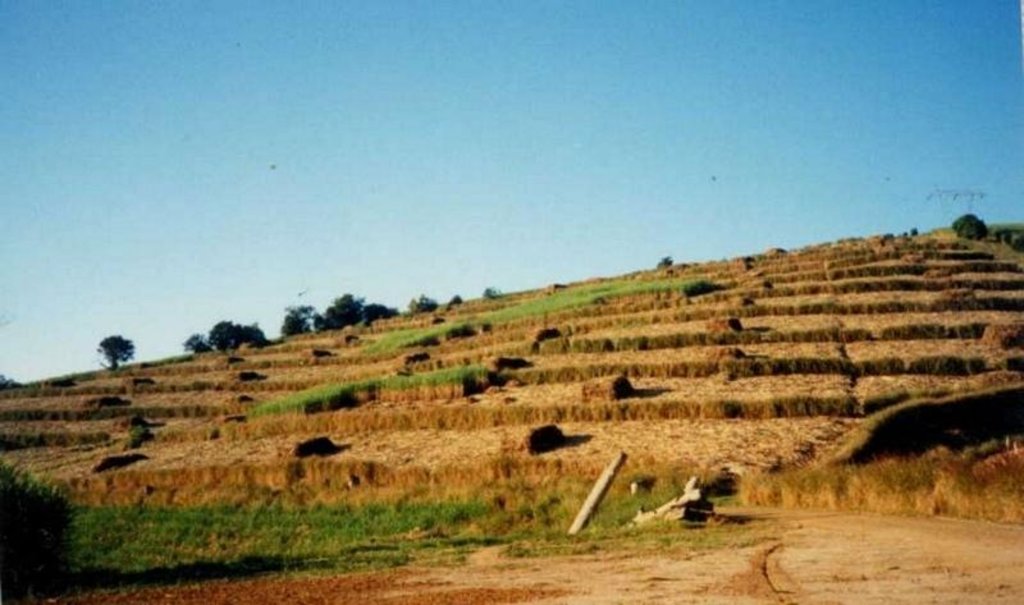

This example of vetiver grass barriers comes from a commercial farm in Kwa-Zulu Natal, South Africa, where sugar cane is grown on a large scale under a rainfall regime of around 1,000 mm per year. Vetiver grass (Vetiveria zizanioides), which had been growing naturally on the farm for years in isolated clumps, began to be used in 1989 to form vegetative hedges along the contour.

The purpose of these hedges is to protect the land from surface erosion by creating semi-permeable barriers, allowing excess runoff to filter through but holding back sediment. Infiltration is thus increased and moisture conserved in-situ. Although sugar cane in itself protects the soil quite well when the canopy is closed, after harvest on the moderate to steep slopes (10% to >30%) and erodible soils of the north coast of Kwa-Zulu Natal, extra protection is required. The vetiver system is supplemented by other soil conservation measures such as strip cropping, terraces, mulching and minimum tillage – all of which are used to some extent on this farm. Vetiver also helps by permanently marking the contour line, which then guides land preparation. In common with other vegetative barriers, vetiver lines lead to the formation of terraces over time, through the effect of tillage and water erosion between the strips.

Vetiver clumps are dug up and separated into slips (tillers), cut to a length of 10 cm and then planted 10–15 cm apart along the contour, also by stream banks, and by roadsides, just before the rains. This ensures good establishment. Single lines are used in this farm, though double lines are more effective at creating a hedge, and are the normal recommendation. Work starts at the top of the slope, and continues downwards. The cross-slope grass hedges are sited at 5 m vertical intervals on slopes of more than 10%, in lines about 200 m long. The cost of vetiver grass planting depends very much on slope (and thus the number of lines to be planted), availability of materials and labour.

Maintenance is very important, as vetiver often requires ‘gapping-up’ to keep the barrier dense, and it needs also to be cut back before the dry season to prevent it burning. The cut material can be used for mulching. Vetiver is poorly palatable, and therefore not useful as fodder. The maximum height of a vetiver hedge is kept down to approximately 50 cm. This minimises shading and competition, keeps the fire risk low, increases tillering (for production of vegetative splits) and ensures adequate density.

2.3 Photos of the Technology

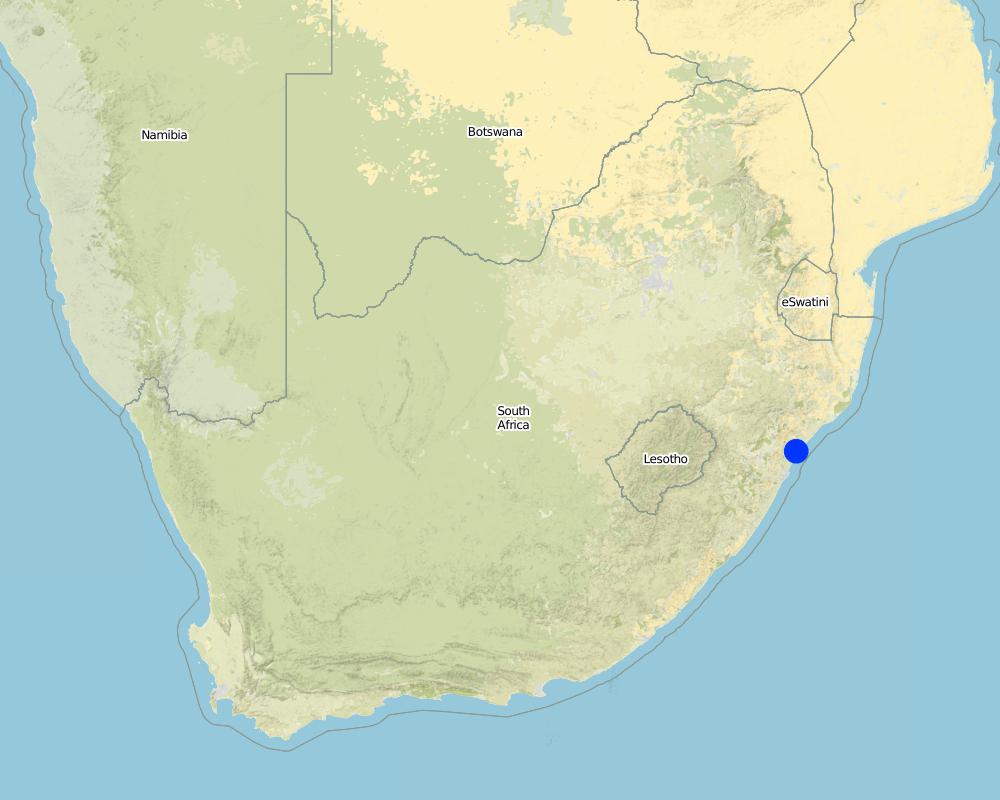

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

South Africa

Region/ State/ Province:

KwaZulu/Natal

Further specification of location:

Lower Tugela district

Specify the spread of the Technology:

- evenly spread over an area

If the Technology is evenly spread over an area, specify area covered (in km2):

8.0

If precise area is not known, indicate approximate area covered:

- 1-10 km2

Comments:

Total area covered by the SLM Technology is 8 km2.

The vetiver system has been applied on my own properties. Neighbouring farms have adopted other methods of conserving the soil. i.e. vegetative, agronomic and structural in various combinations (= farm)

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- during experiments/ research

Comments (type of project, etc.):

The grass originally came to this country from Mauritius.

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- reduce, prevent, restore land degradation

3.2 Current land use type(s) where the Technology is applied

Cropland

- Perennial (non-woody) cropping

Perennial (non-woody) cropping - Specify crops:

- sugar cane

Number of growing seasons per year:

- 1

Specify:

Longest growing period in days: 200; Longest growing period from month to month: Oct - April

Comments:

Major cash crop: sugar cane

Major land use problems (compiler’s opinion): The steep topography and shallow soils limit the types of land use possible e.g.. perennial grass cover (sugarcane or grazing) or commercial timber production. Annual cropping is not possible without major alteration to the landscape e.g. terracing.

3.4 Water supply

Water supply for the land on which the Technology is applied:

- rainfed

3.5 SLM group to which the Technology belongs

- improved ground/ vegetation cover

- cross-slope measure

3.6 SLM measures comprising the Technology

vegetative measures

- V5: Others

Comments:

Main measures: vegetative measures

Secondary measures: agronomic measures, structural measures, management measures

Specification of other vegetative measures: grass strip as hedges

Type of agronomic measures: mulching, minimum tillage, contour ridging

3.7 Main types of land degradation addressed by the Technology

soil erosion by water

- Wt: loss of topsoil/ surface erosion

- Wg: gully erosion/ gullying

soil erosion by wind

- Et: loss of topsoil

water degradation

- Hg: change in groundwater/aquifer level

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- reduce land degradation

- restore/ rehabilitate severely degraded land

Comments:

Secondary goals: rehabilitation / reclamation of denuded land

4. Technical specifications, implementation activities, inputs, and costs

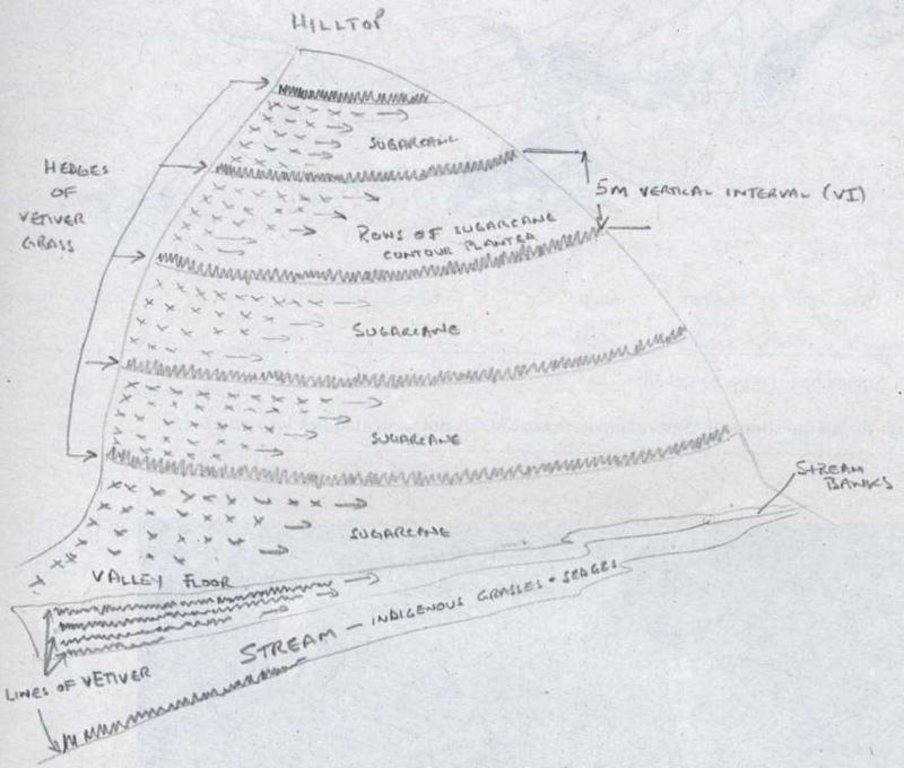

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

Vetiver grass is planted as a vegetative barrier (hedge), on the contour at 5 metre vertical intervals within fields of sugarcane.

Location: Lower Tugela district. KwaZulu/Natal

Technical knowledge required for field staff / advisors: low

Technical knowledge required for land users: low

Main technical functions: control of dispersed runoff: impede / retard

Secondary technical functions: control of concentrated runoff: impede / retard, increase / maintain water stored in soil

Mulching

Material/ species: Sugarcane

Remarks: Full ground cover

Minimum tillage

Material/ species: Chemical crop eradication

Contour ridging

Material/ species: Planting lines ridged on contour

Vegetative measure: contour

Vegetative material: G : grass

Vertical interval between rows / strips / blocks (m): 5

Spacing between rows / strips / blocks (m): 2

Vertical interval within rows / strips / blocks (m): 0

Width within rows / strips / blocks (m): 0.5

Vegetative measure: Vegetative material: G : grass

Grass species: Vetiver grass

Slope (which determines the spacing indicated above): 20.00%

If the original slope has changed as a result of the Technology, the slope today is (see figure below): 20.00%

Gradient along the rows / strips: 0.00%

Other type of management: Cane is planted on suitability (slope, soil depth)

Author:

Marie Joseph Maxime Robert

4.2 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology area

Indicate size and area unit:

ha

Specify currency used for cost calculations:

- USD

Indicate average wage cost of hired labour per day:

2.00

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Plant with fertilizer & water | Rainy season (Sept - Mrch) |

| 2. | Weed & gap plant | |

| 3. | Cut back to promote tillering | |

| 4. | Crop gradication | Nov-Jan |

| 5. | Ridging of planting furrows | +- 1-2 months before |

| 6. | Planting of sugarcane - fertiliser in furrow | |

| 7. | Top dress fertiliser | 9 week after planting |

| 8. | Herbicide application | Anytime necessary after planting |

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Plant and fertilize | persons/day/ha | 15.0 | 2.0 | 30.0 | 100.0 |

| Equipment | hoe | ha | 1.0 | 4.0 | 4.0 | 100.0 |

| Plant material | Vetiver | cubic meter | 1.0 | 66.0 | 66.0 | 100.0 |

| Fertilizers and biocides | Fertilizer | ha | 1.0 | 40.0 | 40.0 | 100.0 |

| Total costs for establishment of the Technology | 140.0 | |||||

| Total costs for establishment of the Technology in USD | 140.0 | |||||

Comments:

Duration of establishment phase: 24 month(s)

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | minimum tillage | mulching at harvest |

| 2. | minimum tillage | |

| 3. | mulching at harvest | April-Dec / Every year |

| 4. | Weed | /3 times |

| 5. | Gap plant | /Once |

| 6. | Weed | /When required |

| 7. | Spray for creeper grasses | /When required |

| 8. | Plaint unwanted trees etc. | /When required |

| 9. | Harvest sugarcane | / Annual |

| 10. | Trash management (mulch spreading) | After harvest completed / Annual |

| 11. | Fertiliser application | 1-2 months after harvest / Annual |

| 12. | Herbicide application | Required / Annual |

| 13. | Hand weeding | / Annual & when required |

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Maintaining plot | persons/day/ha | 5.0 | 2.0 | 10.0 | 100.0 |

| Equipment | hoe | ha | 1.0 | 4.0 | 4.0 | 100.0 |

| Fertilizers and biocides | Biocides | ha | 1.0 | 5.0 | 5.0 | 100.0 |

| Fertilizers and biocides | Slips | ha | 1.0 | 6.0 | 6.0 | 100.0 |

| Total costs for maintenance of the Technology | 25.0 | |||||

| Total costs for maintenance of the Technology in USD | 25.0 | |||||

Comments:

Machinery/ tools: 1 hoe

1) Labour,

2) Transport,

3) Price of grass,

4) Fertiliser,

5) Equipment

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

1) Labour,

2) Transport from nursery to field,

3) The steeper the gradient the more contour lines of vetiver grass will be used,

4) Fertiliser

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specifications/ comments on rainfall:

Not usually less than 900 and not usually more than 1200

Agro-climatic zone

- sub-humid

Thermal climate class: subtropics

Thermal climate class: temperate

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Comments and further specifications on topography:

Slopes on average: Also moderate, mostly in footslopes & valleys (steep sides)

Landforms: Also ridges

Altitudinal zone: 360 - 380 m a.s.l.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- coarse/ light (sandy)

- medium (loamy, silty)

Topsoil organic matter:

- high (>3%)

- medium (1-3%)

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

Soil depth on average: Als very shallow. But mostly moderately deep

Soil texture: Mostly medium

Soil fertility is medium

Topsoil organic matter: Mostly medium and high in very small areas

Soil drainage / infiltration is good - medium

Soil water storage capacity is medium - high

5.6 Characteristics of land users applying the Technology

Market orientation of production system:

- commercial/ market

Off-farm income:

- less than 10% of all income

Level of mechanization:

- manual work

- mechanized/ motorized

Indicate other relevant characteristics of the land users:

Market orientation of production system: All commercial

Level of mechanization: Manual labour for fertilising, weeding, planting, harvesting and mechanised for crop extraction

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Comments:

Per farm where SWC technology is used

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, not titled

Land use rights:

- individual

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

production area

land management

Income and costs

farm income

Socio-cultural impacts

national institutions

SLM/ land degradation knowledge

Ecological impacts

Water cycle/ runoff

excess water drainage

Soil

soil moisture

soil cover

soil loss

Climate and disaster risk reduction

fire risk

Comments/ specify:

Contains a lot of oil, only when mature (after 2 years) but does not affect the roots

wind velocity

Comments/ specify:

Row spacing

Other ecological impacts

demarcates the contour

Comments/ specify:

The planting is aligned for next planting

longer last of crop (sugarcane)

Comments/ specify:

From 8-12 cuttings before replanting sugarcane (+-15 years); 3000-3500 R/ha cost for replanting the sugarcane.

6.2 Off-site impacts the Technology has shown

reliable and stable stream flows in dry season

downstream flooding

downstream siltation

groundwater/ river pollution

wind transported sediments

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

neutral/ balanced

Long-term returns:

positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

positive

Long-term returns:

very positive

6.5 Adoption of the Technology

- > 50%

If available, quantify (no. of households and/ or area covered):

3 households

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 91-100%

Comments:

100% of land user families have adopted the Technology without any external material support

3 land user families have adopted the Technology without any external material support

Comments on spontaneous adoption: estimates

There is a little trend towards spontaneous adoption of the Technology

Comments on adoption trend: Some local growers are experimenting with the vetiver system or with vetiver grass used in other applications (gullies, road embankments, etc.)

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| The author is the land user |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

|

When planted correctly, vetiver forms a dense, permanent hedge which retains soil and water so increases crop yield How can they be sustained / enhanced? Make sure there are no gaps between slips in order to maintain a dense vegetative barrier. |

|

It has a strong fibrous root system that penetrates and binds the soil to a depth of up to 3 meters and can withstand the effects of tunnelling and cracking. Its many uses e.g.. Thatching, mulching etc. |

| Vetiver grass seed is sterile so it doesn’t spread. |

| Not very competitive to crops growing alongside. |

|

The cut material can be used for mulching and has multiple secondary uses (thatching, basket making, etc). Once established it can withstand periods of drought and waterlogging. It is also resistant to grazing and to most pests and diseases. Adaptability: can be planted in various environments and grows well in most soil types. Depending on the availability of planting materials and the spacing adopted, can be relatively cheap and easy to establish and – once well established – vetiver requires minimal maintenance. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| The author is the land user |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| Sugarcane residue is often blown against the hedges & this can form a thick blanket thus preventing ratooning of crop | Strategic/controlled burning at end of growing season or trimming back |

| The grass burns very easily when mature, due to its density | Keep chemicals off vetiver. |

| Susceptible to certain chemicals used in sugar cane | Establish own nursery. |

| Planting material expensive to buy: therefore costs increase considerably unless farmer has own nursery | |

| Takes time to plant a large area (in this case 2.5 ha per year). |

7. References and links

7.1 Methods/ sources of information

Links and modules

Expand all Collapse allLinks

Self teaching [South Africa]

Learning how to use vetiver grass as a vegetative conservation barrier through instructions from a booklet and hands-on practical experience.

- Compiler: Philippe Zahner

Modules

No modules