Khuwa Production and Marketing in Chyamrangbesi [Nepal]

- Creation:

- Update:

- Compiler: Sabita Aryal

- Editor: –

- Reviewer: Fabian Ottiger

Khuwa Utpadan Tatha Bazaar

approaches_2482 - Nepal

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Approach

SLM specialist:

Ghimire Shomnath

Nepal

Name of the institution(s) which facilitated the documentation/ evaluation of the Approach (if relevant)

Kathmandu University (KU) - Nepal1.3 Conditions regarding the use of data documented through WOCAT

When were the data compiled (in the field)?

17/01/2014

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Reference(s) to Questionnaire(s) on SLM Technologies

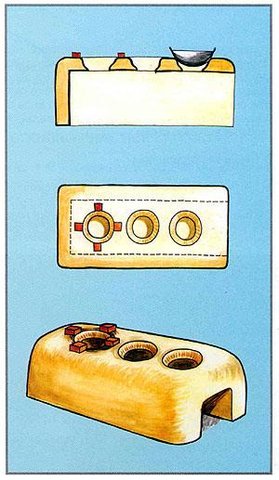

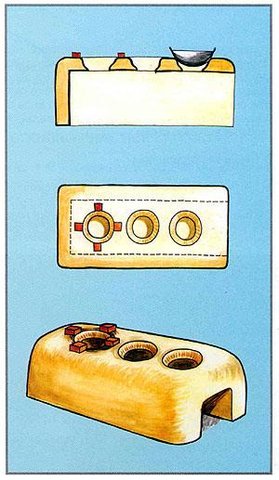

Khuwa making by the use of Improved stove [Nepal]

The technology used is improved stove. An improved stove is a device that is designed to consume less fuel and save cooking time,convenient in cooking process and creates smokeless environment or reduction in volume of smoke against the traditional stove.

- Compiler: Sabita Aryal

2. Description of the SLM Approach

2.1 Short description of the Approach

This SLM Approach deals with the making of Khuwa (dairy product base), using traditional as well as improved methods and further its supply and marketing.

2.2 Detailed description of the Approach

Detailed description of the Approach:

Aims / objectives: This approach's goal is to preserve traditional khuwa production methods, while also applying new and rather sustainable technologies on the current process. Further, the local khuwa production creates employment - at the factory itself, as well as during supply and distribution processes.

Methods: This focusses mainly on the methods applied during khuwa production:

1. Milk is collected from local farmers.

2. Milk is boiled for approximately 30mins on improved stoves, using locally collected firewood.

3. Boiled is continued until milk's volume has reduced to half.

4. After around 1 hour of simmering milk has turned into a thick paste, which is known as khuwa.

5. Paste needs to be cooled.

Stages of implementation: The Khuwa Utpadan factory was founded in 2050 B.S. by locals, whose ancestors had already been involved in Khuwa production.

Firstly necessary utensils and materials were purchased. Later improved cooking stoves were installed to reduce the smoke formation and amount of required fire wood.

Role of stakeholders: 1. Providing employment opportunities to local villagers .

2. Buying milk from locals, creating a source of income for them.

3. Maintaining a regular flow of Khuwa production to purchasers in surrounding cities, including Kathmandu.

4. Preserving traditional Khuwa production methods among the local community.

Other important information: On the one hand, khuwa production has helped to create employment opportunities and to make use of locally produced milk, on the other hand stakeholders have been facing problems in supplying khuwa by paying more money .

2.5 Country/ region/ locations where the Approach has been applied

Country:

Nepal

Region/ State/ Province:

Nepal

Further specification of location:

Kavre/Palanchowk

Map

×2.6 Dates of initiation and termination of the Approach

Indicate year of initiation:

2050

2.7 Type of Approach

- traditional/ indigenous

2.8 Main aims/ objectives of the Approach

The Approach focused mainly on SLM with other activities (Improving efficiency of production, ways of supply and marketing strategies)

The main aim of the Approach is to establish and maintain a Khuwa production factory, where traditional as well as modern technologies are being applied. That way employment is created for locals, locally produced milk is utilized and the overall economic situation of the region is improved.

The SLM Approach addressed the following problems: Firstly, consistent maintaining of production rates can be difficult, due to unreliable supply of firewood (shortages, weather etc.).

Secondly, for employees the constant influence of smoke can lead to several irritations, although the instalment of impoved stoves has already led to an improvement of the working conditions.

2.9 Conditions enabling or hindering implementation of the Technology/ Technologies applied under the Approach

availability/ access to financial resources and services

- hindering

Insufficient funds to make larger investments.

Treatment through the SLM Approach: Loan was granted by Chakresor baehat, as well as an government organization.

legal framework (land tenure, land and water use rights)

- enabling

The existing land ownership, land use rights / water rights greatly helped the approach implementation: Since this is an undertaking established and implemented by locals, already existing land ownership has helped to provide base for the factory, without the involvement of external persons.

knowledge about SLM, access to technical support

- hindering

Lack of technical knowledge has been creating lots of difficulties.

Treatment through the SLM Approach: It is advise to provide training by a professional technician.

workload, availability of manpower

- hindering

Lack of new personnel to share workload

Treatment through the SLM Approach: It is advised to train new staff.

3. Participation and roles of stakeholders involved

3.1 Stakeholders involved in the Approach and their roles

- local land users/ local communities

Mr. Shomnath Ghimire. Local milk suppliers, locals with experience in khuwa making

Construction of stoves and other utensils, manpower required for khuwa production. Women were rather involved in several housework related activities, while men were responsible for external work, such us construction and land conversion processes. Locals in Chyamrangbesi region are generally not in a very good economic condition

- private sector

Loans from a local finance

- local government

Local milk suppliers

3.2 Involvement of local land users/ local communities in the different phases of the Approach

| Involvement of local land users/ local communities | Specify who was involved and describe activities | |

|---|---|---|

| initiation/ motivation | interactive | Mr. Shomnath Ghimire initiated this approach, including involvement of locals |

| planning | interactive | locals, using own knowledge in production methods |

| implementation | interactive | locals, providing land and expertise |

| monitoring/ evaluation | interactive | discussion among the villagers. |

| Research | none |

3.4 Decision-making on the selection of SLM Technology/ Technologies

Specify who decided on the selection of the Technology/ Technologies to be implemented:

- land users alone (self-initiative)

Explain:

The applied technology (khuwa making) was already well-known and practised among locals, but for a long time only on a private basis. The establishment of a factory has lead to the collective purchase of locally produced milk as well as the production and supply of khuwa.

Decisions on the method of implementing the SLM Technology were made by by land users* alone (self-initiative / bottom-up). Locals self-implemented the technologies under guidance of Mr. Shomnath Ghimire place, ward no. 2. Chyamrangbesi.

4. Technical support, capacity building, and knowledge management

4.1 Capacity building/ training

Was training provided to land users/ other stakeholders?

Yes

Specify who was trained:

- land users

- field staff/ advisers

If relevant, specify gender, age, status, ethnicity, etc.

n/a

Form of training:

- on-the-job

- farmer-to-farmer

- demonstration areas

- public meetings

- courses

Subjects covered:

Knowledge and expertise in the different processes of khuwa making

4.2 Advisory service

Do land users have access to an advisory service?

Yes

Describe/ comments:

Name of method used for advisory service: n/a

n/a

4.3 Institution strengthening (organizational development)

Have institutions been established or strengthened through the Approach?

- no

4.4 Monitoring and evaluation

Is monitoring and evaluation part of the Approach?

Yes

Comments:

technical aspects were regular monitored by project staff through observations; indicators: observation of application of khuwa making methods

economic / production aspects were monitored by project staff, land users through observations

There were no changes in the Approach as a result of monitoring and evaluation

There were few changes in the Technology as a result of monitoring and evaluation: installation of improved cooking stoves to increase sustainability value of project

4.5 Research

Was research part of the Approach?

Yes

Specify topics:

- sociology

- economics / marketing

- technology

Give further details and indicate who did the research:

Research was done by the students of Kathmandu University.

Research was carried out on station

5. Financing and external material support

5.1 Annual budget for the SLM component of the Approach

If precise annual budget is not known, indicate range:

- 10,000-100,000

Comments (e.g. main sources of funding/ major donors):

Approach costs were met by the following donors: international (n/a): 15.0%; government (n/a): 85.0%; international non-government (n/a); national non-government (n/a); private sector (minor involvement); local government (district, county, municipality, village etc) (n/a); local community / land user(s) (mainly from land users); other (n/a)

5.2 Financial/ material support provided to land users

Did land users receive financial/ material support for implementing the Technology/ Technologies?

Yes

5.3 Subsidies for specific inputs (including labour)

- equipment

| Specify which inputs were subsidised | To which extent | Specify subsidies |

|---|---|---|

| machinery | fully financed | |

| tools | fully financed | |

- agricultural

| Specify which inputs were subsidised | To which extent | Specify subsidies |

|---|---|---|

| seeds | partly financed | |

| fertilizers | partly financed | |

- construction

| Specify which inputs were subsidised | To which extent | Specify subsidies |

|---|---|---|

| stone | fully financed | |

| wood | fully financed | |

- infrastructure

| Specify which inputs were subsidised | To which extent | Specify subsidies |

|---|---|---|

| roads | fully financed | |

| schools | fully financed | |

- other

| Other (specify) | To which extent | Specify subsidies |

|---|---|---|

| Milk | fully financed |

If labour by land users was a substantial input, was it:

- paid in cash

Comments:

Rs 5000-6000 per month

Tools, Wood, others(milk) were fully financed by land users.

5.4 Credit

Was credit provided under the Approach for SLM activities?

Yes

Specify conditions (interest rate, payback, etc.):

Interest rate charged: 14.0%; repayment conditions: has to be paid off within 5 years..

Interest was equal to market rate.

Specify credit receivers:

Mr. Shomnath Ghimire

6. Impact analysis and concluding statements

6.1 Impacts of the Approach

Did the Approach help land users to implement and maintain SLM Technologies?

- No

- Yes, little

- Yes, moderately

- Yes, greatly

Due to the installation of improved cooking stoves, the amount of required firewood could be reduced, havong a positive effect on progressing deforestation.

Did the Approach empower socially and economically disadvantaged groups?

- No

- Yes, little

- Yes, moderately

- Yes, greatly

The financial situation of many poor local villagers has been improved.

Did other land users / projects adopt the Approach?

- No

- Yes, little

- Yes, moderately

- Yes, greatly

Did the Approach lead to improved livelihoods / human well-being?

- No

- Yes, little

- Yes, moderately

- Yes, greatly

Khuwa Production has helped to economic growth of the region, which has improved the financial situation of many locals.

Did the Approach help to alleviate poverty?

- No

- Yes, little

- Yes, moderately

- Yes, greatly

Certainly, since khuwa production has provided employment for locals, also including farmers involved in milk supply.

6.2 Main motivation of land users to implement SLM

- increased production

increased production

- increased profit(ability), improved cost-benefit-ratio

good marketing of khuwa

- environmental consciousness

creating healthier work environment

6.3 Sustainability of Approach activities

Can the land users sustain what has been implemented through the Approach (without external support)?

- uncertain

If no or uncertain, specify and comment:

As long as khuwa is being sold in sufficiently high amounts, expenses needed for milk, firewood, wages etc can be covered.

6.4 Strengths/ advantages of the Approach

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| Ashes after burning firewood can be used as organic material for soil |

| Reduced pollution (How to sustain/ enhance this strength: Enhancing by wing modern machine which operates by electricity , and there would be no pollution.) |

| Increased economic condition |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Utilzation of milk |

| Unity among Villagers. |

|

Improved economic condition (How to sustain/ enhance this strength: by sharing and passing on of existing knowledge) |

6.5 Weaknesses/ disadvantages of the Approach and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| Scarcity of wood | New technologies should be implemented, which require less firewood |

| Difficult to ensure regular supply of milk | Domestication of Buffalo and cows. |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| Production of smoke by the use of wet wood. | Overcome by using dry wood |

| Damage of Khuwa in summer season in few days. | By storing khuwa refrigerator. |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

- interviews with land users

Links and modules

Expand all Collapse allLinks

Khuwa making by the use of Improved stove [Nepal]

The technology used is improved stove. An improved stove is a device that is designed to consume less fuel and save cooking time,convenient in cooking process and creates smokeless environment or reduction in volume of smoke against the traditional stove.

- Compiler: Sabita Aryal

Modules

No modules