Moo Lum Pig Farming: A Zero-Waste Management Technology [Thailand]

- Creation:

- Update:

- Compiler: Kukiat SOITONG

- Editor: –

- Reviewers: Rima Mekdaschi Studer, William Critchley

Organic Moo Lum Community’s Way of Life

technologies_4252 - Thailand

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

land user:

Singtosri Supoj

The Zero Waste Pig Farm group

Thailand

1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

Comments:

-

1.5 Reference to Questionnaire(s) on SLM Approaches (documented using WOCAT)

Moo Lum Zero-Waste Pig Farm Technology Transfer (Thailand) [Thailand]

Moo Lum Zero-Waste Pig Farm Technology Transfer Center is a center of learning and knowledge transfer from successful farmers to others, as well as helping to build a network of Moo Lum zero-waste pig farmers to exchange knowledge and learn to solve their problems together.

- Compiler: Kukiat SOITONG

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

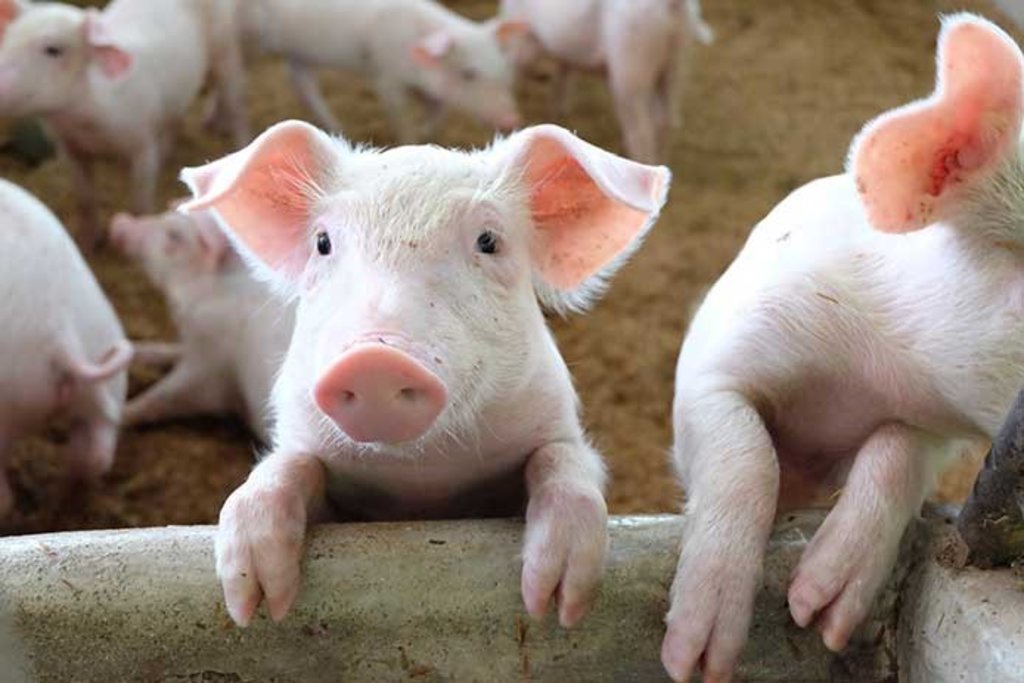

The Zero-Waste Pig Farm or Moo Lum is the integrated management of pigs in pens with the use of microorganisms that lead to the safety of pork products. This technique has become beneficial, as the pig waste can be used as organic fertilizer that produces no pollution to the community.

2.2 Detailed description of the Technology

Description:

-The Zero-Waste Pig Farm or Moo Lum is the integrated management of pigs in pens with the use of microorganisms that lead to the safety of pork products. This technique has become beneficial, as the pig waste can be used as organic fertilizer that produces no pollution to the community.

Pig farming in a community generally causes unwanted waste products: pig manure with its strong odor, and polluted water. This causes conflict about the use of land in the community too. The management of the ‘Zero-Waste Pig Farm’ or ‘Moo Lum’ is an alternative practice which greatly reduces the environmental problems caused by traditional pig farming. There are two key elements of the Zero-Waste Pig Farm or Moo Lum management: one is the pig farm and the other is the waste.

A. Pig farm management: housing and feeding.

Housing: pig houses should be built in dry areas, not-to-be-flooded with rainwater in the rainy season. Locally available materials should be used, such as bamboo, grass, etc. The pig house should have good ventilation. Pig pens, on the other hand, should be on bare soil with no cement. In each pig pen there should be a pit, 60-70 cm deep, while the floor of the pig pen one should be covered with rice husks, sawdust or coconut coir. Feeding: Pig raising involves pig food management with concentrated and fermented foods. The raw material is selected from non-chemically treated materials that have gone through processes with use of herbal powder mixed with bio-fermented water. This is the technique to promote animal health and to prevent animal diseases. The pig types in the farm are the popular species of Duroc CLD, Landrace and Large White, from when they are weaned (at about 1 month old).

B. Waste management: Lay the husks or any organic materials on the bottom of the pit in the pen, divided into two layers (about 30 cm thick for each layer), then put salt and bio-fermented solution. Each week, apply the bio-fermented solution to improve the efficiency of the decomposition of pig waste. After a cycle of pig feeding one will get an amount of compost from the pigpen hole. The objective of the zero-waste pig farm or Moo Lum technology is to produce safe pork products through the production process of an environmentally friendly animal farm without pollution and then obtain quality pig manure compost to be used quite beneficially in the organic production process. The zero-waste pig farm or Moo Lum technology processes are as follow:

1. Build the pig houses on an unfloodable area with good ventilation.

2. Build a stall about 4 x 4m wide which can hold 8 pigs.

3. Prepare the stall.

4. Choose the breeds of pigs that are popular.

5. Select the food for the pig obtained through non-chemical processes.

6. Apply bio-degradable pesticides on the floor. Feed the pigs with bio-fermented water. When the pigs get sick, they are treated according to the symptoms with herbal medicine.

7. Take care of them.

The benefit as commented by the users of this technology are as follows:

The user can establish a pig farm in a community with no odour and no flies swarming around. The organic fertilizer from pig manure will improve the quality of the soil in the area, which will benefit the user even further. Another saving is reduced labour from the various cleaning operations needed under conventional management.

However, there are some limitations, as some processes of the technology take unusually longer time. The pork products are not widely known as a ‘safe pork products’ as there is no standard set for such farming by the government. Finally, there is often a shortage of pig food; there should be more production of pig food in the community.

2.3 Photos of the Technology

2.4 Videos of the Technology

Comments, short description:

-

Location:

-

Name of videographer:

-

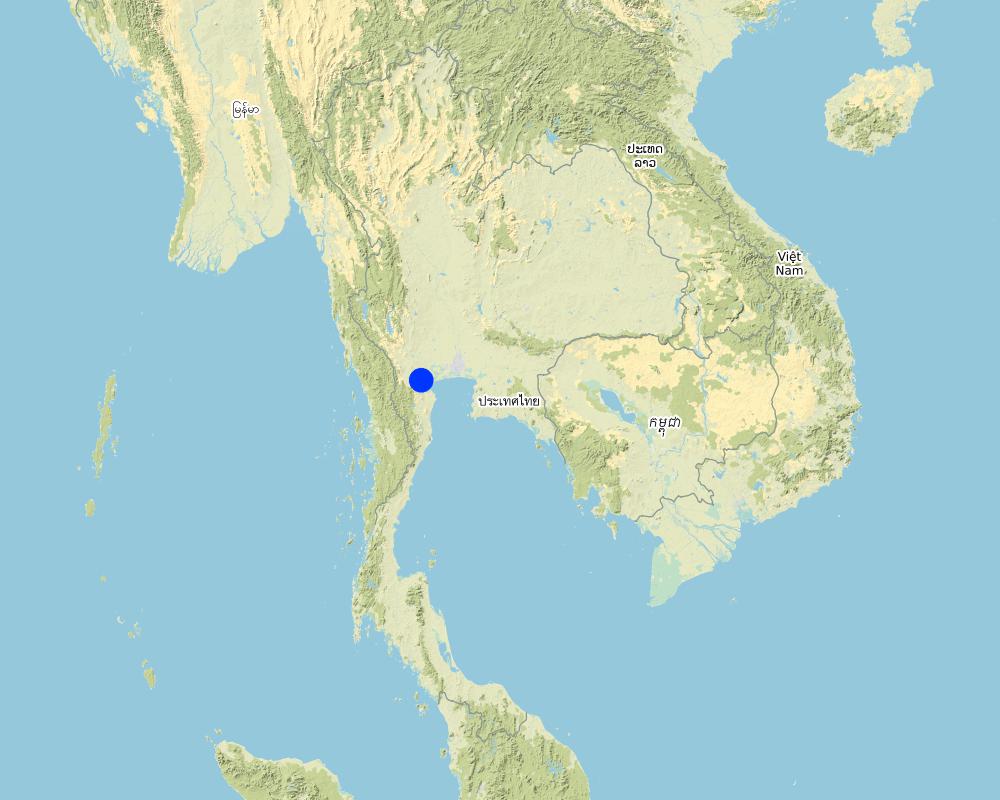

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Thailand

Region/ State/ Province:

Ratchaburi

Further specification of location:

Tambon Don Rae Muang District Ratchaburi province

Comments:

Mr Supoj Singtosri 95/1 Moo .9 Don Rae Sub-district, Muang District, Ratchaburi Province, Thailand

Map

×2.6 Date of implementation

Indicate year of implementation:

1969

If precise year is not known, indicate approximate date:

- more than 50 years ago (traditional)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- as part of a traditional system (> 50 years)

- study tour

Comments (type of project, etc.):

-

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- reduce, prevent, restore land degradation

- create beneficial economic impact

- create beneficial social impact

3.2 Current land use type(s) where the Technology is applied

Forest/ woodlands

- Tree plantation, afforestation

Tree plantation, afforestation: Specify origin and composition of species:

- Mixed varieties

Comments:

-

3.3 Has land use changed due to the implementation of the Technology?

Comments:

-

3.4 Water supply

other (e.g. post-flooding):

- for livestock,pond

Comments:

-

3.5 SLM group to which the Technology belongs

- integrated soil fertility management

- waste management/ waste water management

3.6 SLM measures comprising the Technology

management measures

- M6: Waste management (recycling, re-use or reduce)

other measures

Specify:

-

Comments:

no waste /environmental friendly activities

3.7 Main types of land degradation addressed by the Technology

water degradation

- Hp: decline of surface water quality

Comments:

normal pig farm make more pollution to community and environment.

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- reduce land degradation

Comments:

pig manure compost for soil improvement

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

The special technique of the pig farming

1. The pig house

Build houses in dry areas. Do not use cement for the flooring but use locally available materials, such as bamboo, grass, etc. The house should have good ventilation.

2. The preparation of the animal stalls

The dimension of the house must be related to the number of pigs. A 4x4m wide area can house 8 pigs. A female pig will have a 2 x 3 m stall. The brick pavement is 60cm wide. The roof should be wide to spread the rain, so not to splash into the stall and use a brick block or bamboo barrier around and deep from the ground about 40-50 cm to

prevent the pig from digging its way out out. Barriers and gates are required.

3. Preparation of flooring materials

Cover the floor using 60 centimeters of rice husks, and sprinkle bio-fermented over floor material which will remain hot from the work of microorganisms. Leave it for about 7 days, before bringing the pigs in. Then pour bio-fermented water on the floor every 5-7 days, 10 liters each time to help increase the efficiency of decomposing various sewage

Rice husks will absorb moisture and waste; this reduces gas generation from waste collection. A soft rice husk floor, comfortable to walk on, prevents trotter (pig's feet) problems. Pigs like to dig out cool soil. In addition, it does not require a lot of labour and water to clean the house. Rice husks after use is also sold as manure. The surrounding environment is dry, clean and there is no sewage as a source of germs.

4. Breeding

The popular breeds of pigs are Duroc CLD, Landrace and Large White in the weaning range (about 1 month).

5. The pig food

Concentrated foods and fermented foods: Mix in half-half of concentrated and fermented foods to reduce food costs. In addition, fresh grass is added to eat every day (about 0.5 kg/pig). For the fermented food will applied the natural plant as bananas 100 kg, 4 kg of brown sugar, 1 kg of salt, fermented for 4-5 days. The raw material to be used for fermented food will be chosen as from non-chemical process products.

The production of bio-fermented pig food is applied from the bio-fermentation extract which was a local wisdom biotechnology that villagers can do by themselves. The use of vegetables, fruits , carcasses be mixed and fermented with microorganisms from the atmosphere or selected concentrated microorganisms. Molasses was used as fed to the microorganisms.

The usage of herbal extracts and plant extracts which processes under the fermentation by microorganisms with proper timing and methods of fermentation. The animal products that using herbal extracts and the bio-fermented extracts will promote animal health, be prevented and treated from disease.

6. Feeding and watering

(1) Small pig, 15-30 kg, concentrated food: fermented food = 2:1

(2) Medium pig, 30-60 kg, concentrated food: fermented food = 1:1

(3) Large pig, 60 kg – upto weight to send to the market), concentrated food: fermented food = 1:2

(4) Breeders: fermented foods:fermented food = 1:2

The watering for pigs should be normal

7. Medication and prevention

(1) To make the pigs strong, feed them with bio-fermented water. If the food or water is not clean enough the pigs may be affected with diarrhea or liquid (not often) to be treated with fresh guava leaves, blueberries and wormwood.

(2) Use mosquito nets during the night,but if it is an area that has abundant of gnats should use the smashed citronella water and spray the pig at the early evening.

8. Taking care of pigs:

(1) Spray the bio-fermented solution on the floor for the pigs every 7 days.

(2) Clean the house every month. Add husk ash 1-2 times per month.

(3) Monitor pork drinking water often.

Author:

Kulwadee Sutthawas

4.2 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology area

Indicate size and area unit:

27 rai

If using a local area unit, indicate conversion factor to one hectare (e.g. 1 ha = 2.47 acres): 1 ha =:

Costs are calculated: per Technology area (size and area unit: 27 Rai; conversion factor to one hectare: 1 ha = 6.25 rai)

other/ national currency (specify):

Thai Baht (THB)

If relevant, indicate exchange rate from USD to local currency (e.g. 1 USD = 79.9 Brazilian Real): 1 USD =:

32.0

Indicate average wage cost of hired labour per day:

300 THB

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Moo Lum management | 2 times a year |

| 2. | Moo Lum pig waste management | 2 times a year |

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | 1Moo Lum management | man | 210.0 | 300.0 | 63000.0 | 100.0 |

| Labour | 2.Moo Lum food management | man | 60.0 | 300.0 | 18000.0 | 100.0 |

| Labour | 3.Moo Lum waste management | man | 300.0 | 300.0 | 90000.0 | 100.0 |

| Labour | 4.Housing | man | 120.0 | 300.0 | 36000.0 | 100.0 |

| Construction material | 1.Housing material | โรง | 1.0 | 84000.0 | 84000.0 | 100.0 |

| Other | 1.pig food | animal | 90.0 | 3800.0 | 342000.0 | 100.0 |

| Other | 2. breeding pig | animal | 90.0 | 1500.0 | 135000.0 | 100.0 |

| Total costs for establishment of the Technology | 768000.0 | |||||

| Total costs for establishment of the Technology in USD | 24000.0 | |||||

If land user bore less than 100% of costs, indicate who covered the remaining costs:

-

Comments:

-

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Moo Lum management | 2 times a year |

| 2. | Moo Lum food management | 2 times a year |

| 3. | Moo Lum waste management | 2 times a year |

Comments:

-

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | 1.Moo Lum management | man | 210.0 | 300.0 | 63000.0 | 100.0 |

| Labour | 2. Moo Lum food management | man | 60.0 | 300.0 | 18000.0 | 100.0 |

| Labour | 3. Moo Lum waste management | man | 300.0 | 300.0 | 90000.0 | 100.0 |

| Total costs for maintenance of the Technology | 171000.0 | |||||

| Total costs for maintenance of the Technology in USD | 5343.75 | |||||

If land user bore less than 100% of costs, indicate who covered the remaining costs:

-

Comments:

-

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

ค่าแรง

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specify average annual rainfall (if known), in mm:

1210.00

Specifications/ comments on rainfall:

The area is under the influence of two monsoons: in the rainy season from the southwest, bringing rainfall and in the winter time from the northeast, bringing cold and dry air.

Indicate the name of the reference meteorological station considered:

-

Agro-climatic zone

- humid

-

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- concave situations

Comments and further specifications on topography:

ราชบุรีเป็นจังหวัดทีมีเทือกเขาใหญ่น้อยเป็ นอันมาก โดยเฉพาะทางด้านตะวันตก ของจังหวัดมีเทือกเขาตะนาวศรี เป็ นแนวยาวกันเขตแดนไทยกับพม่า ทางตอนกลางของจังหวัดมีทีราบลุ่ม แม่นํ าแม่กลอง ซึงเหมาะแก่การเพาะปลูก และทางด้านตะวันออกเฉียงใต้เป็ นทีราบตํา ซึงได้รับอิทธิพลจาก การหนุนเนืองของนําทะเล

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Soil texture (> 20 cm below surface):

- medium (loamy, silty)

Topsoil organic matter:

- medium (1-3%)

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

-

5.4 Water availability and quality

Ground water table:

> 50 m

Availability of surface water:

good

Water quality (untreated):

for agricultural use only (irrigation)

Is water salinity a problem?

No

Is flooding of the area occurring?

No

Comments and further specifications on water quality and quantity:

-

5.5 Biodiversity

Species diversity:

- medium

Habitat diversity:

- medium

Comments and further specifications on biodiversity:

-

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- commercial/ market

Off-farm income:

- less than 10% of all income

Relative level of wealth:

- rich

Individuals or groups:

- individual/ household

- groups/ community

Level of mechanization:

- manual work

- mechanized/ motorized

Gender:

- men

Age of land users:

- middle-aged

Indicate other relevant characteristics of the land users:

-

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- medium-scale

Comments:

-

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, titled

Land use rights:

- individual

Water use rights:

- individual

Specify:

-

Comments:

-

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

Comments:

-

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop quality

Comments/ specify:

Better due to the use of quality manure from Moo Lum

animal production

Quantity after SLM:

10%

Comments/ specify:

ลดการตายของประชากรหมูหลุม

risk of production failure

Comments/ specify:

More diversity of markets

product diversity

Comments/ specify:

More value-added products

land management

Comments/ specify:

Suitable land management

Water availability and quality

water availability for livestock

water quality for livestock

Income and costs

farm income

diversity of income sources

workload

Comments/ specify:

More intensive care

Socio-cultural impacts

food security/ self-sufficiency

Comments/ specify:

Sustainable production

health situation

Comments/ specify:

Good health

land use/ water rights

Comments/ specify:

Well utilized land use

conflict mitigation

Comments/ specify:

No odor pollution

Ecological impacts

Soil

nutrient cycling/ recharge

Comments/ specify:

The pig waste is used as manure/ compost locally.

salinity

Comments/ specify:

Soil improvement by using manure/ compost from the pig farm

acidity

Comments/ specify:

Using manure compost for soil improvement

Other ecological impacts

Reduced bad smell in the community

Comments/ specify:

Reduced bad odor from the farm

no waste from farm

6.2 Off-site impacts the Technology has shown

Specify assessment of off-site impacts (measurements):

-

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | not well | |

| seasonal temperature | increase | not well |

Climate-related extremes (disasters)

Biological disasters

| How does the Technology cope with it? | |

|---|---|

| epidemic diseases | not well at all |

Comments:

ระบุสัตว์ตายมากขึ้น

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

positive

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

positive

Long-term returns:

very positive

Comments:

-

6.5 Adoption of the Technology

- 1-10%

If available, quantify (no. of households and/ or area covered):

15 families

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 0-10%

Comments:

-

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

Yes

If yes, indicate to which changing conditions it was adapted:

- changing markets

Specify adaptation of the Technology (design, material/ species, etc.):

An appropriate breed of pig for Moo Lum. Management system amended to reduce odor.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| Adaptation of the availability of local materials reduces the cost. |

| The waste of a pig farm is organic fertilizer. |

| Safe food products |

| Environmentally friendly and not disturbing the neighborhood |

| Is able to establish a pig farm in the community. |

| Makes their farming occupation sustainable. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Make more forms of land use possible. |

| Easy technology, easy to adopt. |

| The technology is adapted to locality. |

| Community accepted and credited. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| Takes longer time than ordinary pig farming. | Do more research |

| The products from the technology are not well known. | Do more PR, by public and related sectors. |

| No guarantee for the standard of the products from this technology esp. the public sector | Public sector should consider to set up the standard to make confidence inside and outside country. |

| Increase locally feeding crop production ,so need more area/farmers to produce | Gathering farmers into groups /needs more community participation |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| - |

7. References and links

7.1 Methods/ sources of information

7.2 References to available publications

Title, author, year, ISBN:

-

Available from where? Costs?

-

7.3 Links to relevant online information

Title/ description:

-

URL:

-

7.4 General comments

-

Links and modules

Expand all Collapse allLinks

Moo Lum Zero-Waste Pig Farm Technology Transfer (Thailand) [Thailand]

Moo Lum Zero-Waste Pig Farm Technology Transfer Center is a center of learning and knowledge transfer from successful farmers to others, as well as helping to build a network of Moo Lum zero-waste pig farmers to exchange knowledge and learn to solve their problems together.

- Compiler: Kukiat SOITONG

Modules

No modules