Biogas plant [Bhutan]

- Creation:

- Update:

- Compiler: ONGPO LEPCHA

- Editor: Tashi Wangdi

- Reviewers: Rima Mekdaschi Studer, William Critchley

Kayden meylung (སྐྱེས་ལྡན་མེ་རླུང་༑)

technologies_6865 - Bhutan

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

land user:

Tshojay Rangsem

Bhutan

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Strengthening national-level institutional and professional capacities of country Parties towards enhanced UNCCD monitoring and reporting – GEF 7 EA Umbrella II (GEF 7 UNCCD Enabling Activities_Umbrella II)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

National Soil Services Centre, Department of Agriculture, Ministry of Agriculture & Livestock (NSSC) - Bhutan1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

Comments:

The technology involves the use of cattle dung in the production of energy which is used for cooking. Stall feeding is practiced for easy collection of cattle dung. Therefore, land degradation due to the movement of cattle and overgrazing in the forest is reduced.

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Biogas is a renewable fuel generated through the anaerobic digestion of organic matter like food or animal waste, typically within a biogas plant. The biogas plant is adapted to household conditions and animal waste production. While this technology benefits small-scale farmers, challenges include the cost of establishment and the need for consistent waste input. Adoption has significantly reduced costs for users, lowered greenhouse gas emissions, and provided organic fertilizer, enhancing crop productivity and livestock health.

2.2 Detailed description of the Technology

Description:

Biogas is a renewable fuel produced through the anaerobic digestion of organic matter, such as food or animal waste. Typically, biogas is intentionally generated in an enclosed environment (a biogas plant) for household consumption. This plant is constructed near a livestock shed for easy collection of animal waste and in proximity to households, mainly used for cooking, heating, and as an alternative to commercial LPG gas.

The plant can be adjusted based on the amount of animal waste, making it viable for smallholder farmers with just a few cows. In most parts of the country, the technology is modified so that even a small amount of animal waste can produce some gas. The digestion chamber is made smaller in diameter and height to generate enough pressure for the gas to reach the stove through the pipe. Initially, the Biogas project started to promote clean and renewable energy for household cooking, reducing the consumption of firewood. Currently, there are more than 8000 biogas plants of different sizes - 4 m3, 6 m3, 8 m3, and 10 m3, and a few large-scale biogas greater than 50 m3 in large individual dairy farms and government livestock farms.

The major activities and inputs required to establish and maintain the technology include having ample space around the residential area for the plant's construction. Additionally, materials such as cement, sand, gravel, stone, iron rods, pipes, pressure gauges, and a stove are necessary. Human resources are needed for the construction of the plant, and land users should have livestock (cows, buffaloes, horses, etc.) that can provide dung/waste for gas generation.

There are numerous benefits and impacts of the technology, including its positive effects on rural communities, greenhouse gas emission reduction, maintaining carbon neutrality, and minimizing the use of imported LPG gas and chemical fertilizers. It also reduces electricity bills needed for operating electric heaters, saving time for land users who would otherwise collect firewood. The by-product (bio-slurry) from the digester is used as organic fertilizer, enhancing crop productivity and serving as a nutritious feed supplement for animals.

Land users both appreciate and have concerns about the technology. They acknowledge the cost reduction benefits, citing the significant savings compared to market-priced commercial LPG gas and reduced expenses on operating electric heaters. The technology has also provided them with additional time by eliminating the need to gather firewood. The bio-slurry, a by-product of the biodigester, serves as fertilizer to enhance crop production and contributes to livestock waste management, improving livestock health and production.

However, land users note that biogas plant establishment is expensive and may not be suitable for economically disadvantaged individuals. Some users experience challenges, such as the biodigester chamber failing to produce enough gas despite being constructed according to technical specifications. The daily requirement of adding animal waste to the input tank is perceived as tedious, and for land users with only one or two milking cows, supplying the required amount of animal waste for the biodigester chamber is often a problem.

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Bhutan

Region/ State/ Province:

Shumar Gewog (Block), Pemagatshel Dzongkhag (District)

Further specification of location:

Darchung under Shumar Chiwog (Community)

Specify the spread of the Technology:

- applied at specific points/ concentrated on a small area

Is/are the technology site(s) located in a permanently protected area?

No

Comments:

Biogas technology is used mainly for cooking and heating at the household level.

Map

×2.6 Date of implementation

Indicate year of implementation:

2021

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

Comments (type of project, etc.):

Biogas technology was introduced as part of the Bhutan Biogas project under the then Department of Renewable Energy, Ministry of Economic Affairs and the Department of Livestock, Ministry of Agriculture and Livestock, Thimphu.

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- mitigate climate change and its impacts

- create beneficial economic impact

- The main purpose as discussed by the land user was to reduce the cost and effort invested in getting LPG. Getting LPG was difficult becuase of the distance.

3.2 Current land use type(s) where the Technology is applied

Land use mixed within the same land unit:

Yes

Specify mixed land use (crops/ grazing/ trees):

- Agro-silvopastoralism

Cropland

- Annual cropping

- Perennial (non-woody) cropping

- Tree and shrub cropping

- French bean, Potato, Onion, Chili, Cole crop (Cabbage, broccoli, Cauliflowers), Mustard green, etc.

- Avocado, Banana, Grapes, Mango, Papaya, Pomegranate, Pear

Number of growing seasons per year:

- 3

Specify:

Maize(fodder) is followed by vegetable like beans, which is again followed by Cole crops.

Is intercropping practiced?

No

Is crop rotation practiced?

Yes

If yes, specify:

Maize(fodder) is followed by vegetable like beans, which is again followed by Cole crops (Cabbage).

Grazing land

- Land user allow six months of grazing in pasture land. Six months cattle are stall fed.

- Land user had eight cows which were all Jersey breed.

Is integrated crop-livestock management practiced?

Yes

If yes, specify:

Crop residue is used as feed, and cow dung as manure to improve soil fertility.

Products and services:

- economic security, investment prestige

- manure as fertilizer/ energy production

- milk

Species:

cattle - dairy

Count:

8

3.3 Has land use changed due to the implementation of the Technology?

Has land use changed due to the implementation of the Technology?

- No (Continue with question 3.4)

3.4 Water supply

Water supply for the land on which the Technology is applied:

- mixed rainfed-irrigated

Comments:

In rainy seasons irrigation supplies are disturbed frequently, In such cases land users depend on rainwater for animals and irrigation.

3.5 SLM group to which the Technology belongs

- integrated crop-livestock management

- waste management/ waste water management

- energy efficiency technologies

3.6 SLM measures comprising the Technology

structural measures

- S9: Shelters for plants and animals

- S10: Energy saving measures

3.7 Main types of land degradation addressed by the Technology

physical soil deterioration

- Pu: loss of bio-productive function due to other activities

Comments:

Stall feeding can reduce land degradation by controlling movement of cow from one place to another. Dung is used for generation of fuel energy, and the waste produced after gas production, is applied to improve fertility of the land.

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

- reduce land degradation

Comments:

Stall feeding reduces land degradation that can occur from the movement of cows from one place to another. Growing of fodder species like Napier grass, Guatemala grass, Pakchong (Super Napier), and Ruzi grass can prevent land degradation.

4. Technical specifications, implementation activities, inputs, and costs

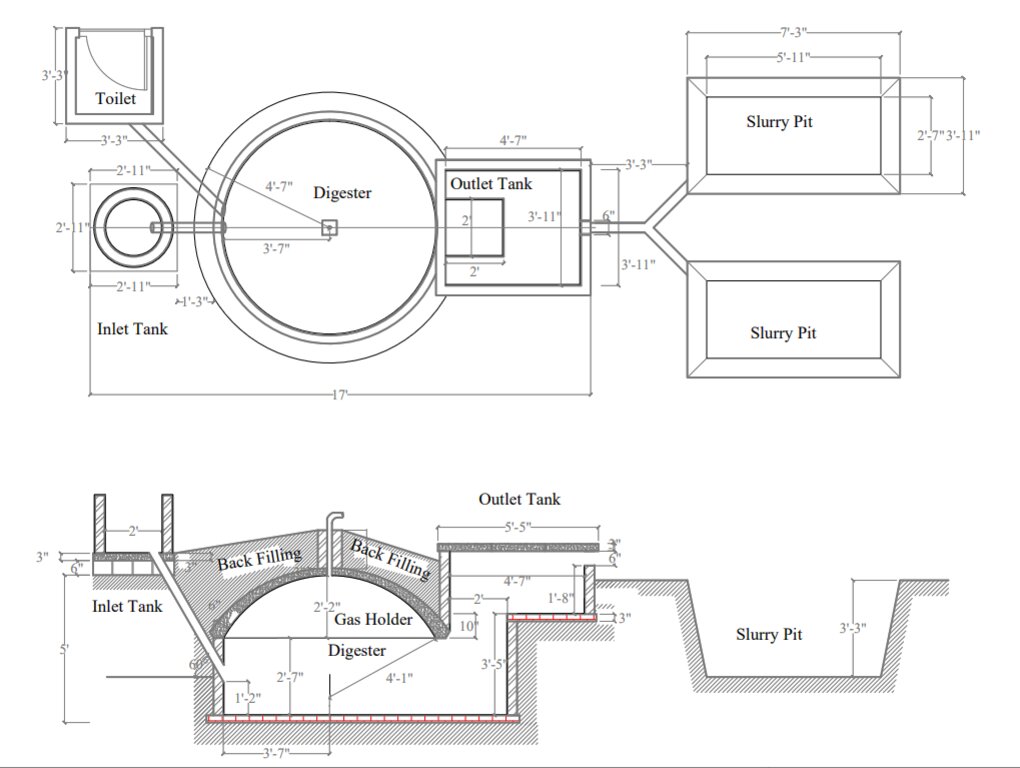

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

Technical design and specification of 4 cubic meter biogas plant capacity

Author:

Bhutan Biogas Project, Department of Livestock, Ministry of Agriculture & Livestock

4.2 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology unit

Specify unit:

inlet tank (mixing tank), inlet pipes, Digester, gas holder, manhole, outlet, main gas pipe turret, main gas valve, pipeline, water outlet, pressure gauge, gas tab, gas stove, gas lamp, slurry pit

Specify dimensions of unit (if relevant):

Dimensions of unit is given in technical diagram.

other/ national currency (specify):

Bhutanese Ngultrum

If relevant, indicate exchange rate from USD to local currency (e.g. 1 USD = 79.9 Brazilian Real): 1 USD =:

82.73

Indicate average wage cost of hired labour per day:

Nu 350

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Selection of construction site and layout of the plant | 1st March |

| 2. | Digging of pits | 15th April |

| 3. | construction of digester | May |

| 4. | construction of gas holder (dome) | May |

| 5. | Plastering of Digester and gas holder | May |

| 6. | construction of turret, manhole and outlet tank | May |

| 7. | Construction of Inlet Tank | June |

| 8. | Fitting pipelines and appliances | June |

| 9. | Construction of compost pit | June |

| 10. | Finishing and instruction to users | July |

Comments:

The land user could not mention the exact date for the initiation and completion of some activities. However, most activities were completed within May-June month.

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour | person-days | 18.0 | 350.0 | 6300.0 | |

| Labour | Masion | person-days | 12.0 | 1000.0 | 12000.0 | |

| Equipment | Mixture machine | no | 1.0 | 1740.0 | 1740.0 | |

| Equipment | GI nozzle | no | 1.0 | 113.0 | 113.0 | |

| Plant material | water draining pipe | no | 1.0 | 262.0 | 262.0 | |

| Plant material | Main gas valve | no | 1.0 | 523.0 | 523.0 | |

| Plant material | Paint brush | no | 1.0 | 85.0 | 85.0 | |

| Plant material | Iron brush | no | 1.0 | 85.0 | 85.0 | |

| Plant material | CPVC glue (50gm) | Jar | 1.0 | 390.0 | 390.0 | |

| Plant material | Teflon tape | roll | 1.0 | 25.0 | 25.0 | |

| Plant material | PVC pipe 4"10' (inlet) | no | 1.0 | 1050.0 | 1050.0 | |

| Construction material | Cement | Bag | 18.0 | 380.0 | 6840.0 | |

| Construction material | Bricks | No | 1000.0 | 11.0 | 11000.0 | |

| Construction material | Gravels | Truckload | 0.5 | 5000.0 | 2500.0 | |

| Construction material | Sand | Truckload | 0.25 | 6000.0 | 1500.0 | |

| Construction material | Arcrylic paint | litres | 3.0 | 350.0 | 1050.0 | |

| Construction material | Iron rod | kg | 10.0 | 70.0 | 700.0 | |

| Construction material | Dome pipe | No | 1.0 | 1170.0 | 1170.0 | |

| Other | Stove | No | 1.0 | 1399.0 | 1399.0 | |

| Other | CPVC Pipe (10') | No | 10.0 | 350.0 | 3500.0 | |

| Other | Gas tap | No | 1.0 | 465.0 | 465.0 | |

| Other | Pressure meter | No | 1.0 | 320.0 | 320.0 | |

| Other | Elbow joint | No | 4.0 | 350.0 | 1400.0 | |

| Other | T - union | No | 2.0 | 150.0 | 300.0 | |

| Total costs for establishment of the Technology | 54717.0 | |||||

| Total costs for establishment of the Technology in USD | 661.39 | |||||

If you are unable to break down the costs in the table above, give an estimation of the total costs of establishing the Technology:

50000.0

If land user bore less than 100% of costs, indicate who covered the remaining costs:

Raw material for construction of the plant was supported by the government.

Comments:

18 bags of cement, iron rods, pipes, a pressure gauge, and a stove were supported by government.

4.5 Maintenance/ recurrent activities

Comments:

It was a new plant so the land user did not mention anything on maintenance.

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Raw materials, transportation cost, labour charges.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Agro-climatic zone

- sub-humid

The study area is located in sub humid area

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- not relevant

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- coarse/ light (sandy)

- fine/ heavy (clay)

Soil texture (> 20 cm below surface):

- medium (loamy, silty)

Topsoil organic matter:

- high (>3%)

5.4 Water availability and quality

Water quality (untreated):

good drinking water

Water quality refers to:

surface water

Is water salinity a problem?

No

Is flooding of the area occurring?

Yes

Regularity:

episodically

Comments and further specifications on water quality and quantity:

Recently, staff from the Ministry of Health tested the water quality, and the land user told that the water is good and drinkable.

5.5 Biodiversity

Species diversity:

- high

Habitat diversity:

- high

Comments and further specifications on biodiversity:

Land users have planted almost all fruit trees, fooder species, annual crops, perennial vegetables like asparagus, etc., which indicated high species and habitat diversity.

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- mixed (subsistence/ commercial)

Off-farm income:

- less than 10% of all income

Relative level of wealth:

- rich

Individuals or groups:

- individual/ household

Level of mechanization:

- manual work

Gender:

- men

Age of land users:

- middle-aged

Indicate other relevant characteristics of the land users:

The land user's age at the time of the interview was 45 years old.

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- medium-scale

Comments:

According to the Land Act of Bhutan 2007. The maximum land ceiling per family is 25 acres, However, in Bhutan majority of land users are medium-scale i.e., less than 3 acres.

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, titled

Land use rights:

- individual

Water use rights:

- communal (organized)

Are land use rights based on a traditional legal system?

Yes

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

Comments:

The hospital is located 10 km away from Land users' places. Which makes it a little difficult during emergencies. The school is 2 Km away which is very near. There are also Gypsum Mining which provides off-farm activities to many land user in the locality. The land user is trained in making Biogas plants, this also provides him the opportunity to work off-farm. When it comes to energy, apart from energy to light the house, energy is required for cooking purposes. This energy was previously derived from LPG, however, after the Biogas plant land user is not having any difficulties with energy shortage. Land users have their own water source and the same water is used to feed Jersey cows. Land users also said that they get financial assistance from Bhutan Development Bank Limited.

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

Comments/ specify:

Land users didn't keep a record of the production, however, it was reported that crop production has improved.

crop quality

Comments/ specify:

land users reported that crops are healthier and green when manure prepared from cow dung/ biogas plants is applied on the land.

fodder production

Comments/ specify:

Land user is also members of milk cooperatives. He maintains different fodder species to have feed for his cows throughout the years. He said fodder production has increased over the years.

fodder quality

Comments/ specify:

Different species of fodder species like Napier, Ruzi, Guatemala, Super Napier, Banana, Rice straw, maize, and fooder tree species like Ficus auriculata, Ficus simicordata, etc., were observed.

energy generation

Quantity before SLM:

6 LPG cylinder per annum

Quantity after SLM:

0

Comments/ specify:

Each LPG cost around Nu. 1000. LPG is completely replaced by biogas technology.

Water availability and quality

drinking water quality

Comments/ specify:

Water was not a problem from the beginning. However, with an improved breed of cow (jersey), water sanitation is also given more importance. Because water can bring diseases to family members and livestock.

Income and costs

farm income

Comments/ specify:

Land user don't have to buy LPG cylinders. He saves around 7000 in a year.

workload

Comments/ specify:

Workload has increased since the biogas plant was constructed. Every day the land user have to collect cow dung and add it to the plant. He also has to collect slurry and add to the land to improve fertility.

6.2 Off-site impacts the Technology has shown

impact of greenhouse gases

Comments/ specify:

Scope to conduct research to estimate GHG emission reduction from biogas technology

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | well | |

| seasonal temperature | summer | increase | well |

| annual rainfall | increase | well | |

| seasonal rainfall | summer | increase | well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

very positive

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

very positive

Long-term returns:

very positive

Comments:

The investment cost is shared by the Government. Therefore, the land users felt the benefits are very positive.

6.5 Adoption of the Technology

- 11-50%

If available, quantify (no. of households and/ or area covered):

Only two households were interviewed, alothough, there are more than 300 households who have adopted biogas technology under study area (Shumar Gewog).

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 0-10%

Comments:

The biogas technology was initiated and promoted by the Department of Livestock and Department of Renewable Energy in Bhutan on a cost-sharing basis.

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

No

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| Land user need not buy LPG cylinders because the Biogas plant |

| No need to go to collect firewood |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Efficient use of livestock (cow dung) for generation energy which is used for cooking. |

| The technology is not easily damaged by pests, temperature, rainfall, etc. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| Cow dung has to be collected, and put into a mixing tank and mixing has to be done manually which is hectic. | |

| A huge amount of cow dung is required. |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| Sometimes, despite good construction material, small calculations in biodigester and gas compartments can lead to a technical error, and this can inhibit gas production. In such cases, the biogas plant becomes nonfunctional. | Being extra careful with the design and consulting the biogas focal person to monitor the construction work. |

| Low temperature has a deleterious effect on methanogenesis and can cause decreased gas yields. So the technology may not work effectively in winter. | Maintaining the temperature by covering the tank with warm material. |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

1

- interviews with land users

1

- interviews with SLM specialists/ experts

1

- compilation from reports and other existing documentation

5

When were the data compiled (in the field)?

13/07/2023

7.2 References to available publications

Title, author, year, ISBN:

Domestic Biogas Implementation Guidelines, Departement of Renewable Energy, Ministry of Economic Affairs, 2020

Available from where? Costs?

Online (free)

Title, author, year, ISBN:

Case study Green Growth Initiative in Bhutan: Bhutan Biogas Project, Chris Oestereich, 2018.

Available from where? Costs?

Online (free)

7.3 Links to relevant online information

Title/ description:

Case Study on Green Growth Initiative in Bhutan: Bhutan Biogas Project by Chris Oestereich,

URL:

https://sdghelpdesk.unescap.org/sites/default/files/2018-03/GG%20-%20Bhutan%20Biogas%20Project.pdf

Title/ description:

Biogas Project Overview: Bhutan, Dawa Penjor Dawa Zam (presentation)

URL:

https://www.saarcenergy.org/wp-content/uploads/2016/07/Bhutan%20presentation.pdf

Title/ description:

Biogas system at household level fed daily with cattle manure [Cambodia]

URL:

https://qcat.wocat.net/wocat/technologies/view/technologies_1645/

Title/ description:

Domestic Biogas Plant for Fuel and fertilizer[Uganda]

URL:

https://qcat.wocat.net/wocat/technologies/view/technologies_3371/

7.4 General comments

Some questions in the questionnaire are not applicable to Bhutan, However, we tried to provide the best information possible.

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules