Nine Maize Pits [Kenya]

- Creation:

- Update:

- Compiler: Paul Kahiga

- Editor: –

- Reviewers: Fabian Ottiger, Alexandra Gavilano

Maize Pits

technologies_1676 - Kenya

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

SLM specialist:

Gathenya Mwangi

Jomo Kenyatta University of Agriculture and Technology

Kenya

SLM specialist:

Home Patrick

Jomo Kenyatta University of Agriculture and Technology

Kenya

SLM specialist:

Chege Timothy

Jomo Kenyatta University of Agriculture and Technology

Kenya

SLM specialist:

Abamba Omwange

Jomo Kenyatta University of Agriculture and Technology

Kenya

SLM specialist:

Baobab Kimengich

Jomo Kenyatta University of Agriculture and Technology

Kenya

SLM specialist:

Wamuongo Jane

Kenya Agricultural Research Institute

Kenya

SLM specialist:

Karanja Andrew

Kenya Agricultural Research Institute

Kenya

SLM specialist:

Namirembe Sara

World Agroforestry Centre (ICRAF)

Kenya

Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

International Centre for Research in Agroforestry (ICRAF) - KenyaName of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

KARI Headquarters (KARI Headquarters) - KenyaName of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Jomo Kenyatta University (Jomo Kenyatta University) - Kenya1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

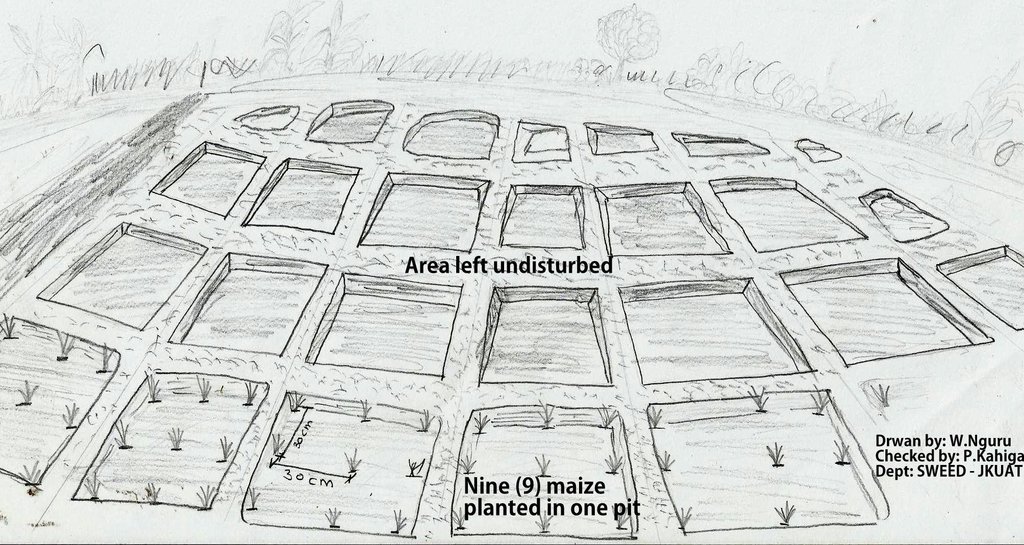

The nine maize pits is a type of SLM technology whereby, a planting pits measuring (2*2*2) feet are dug along a contour and maize planted in the pit at a spacing of (30*30) cm. The top soil is mixed with FYM and the spaces in between are left un-ploughed.

2.2 Detailed description of the Technology

Description:

Maize pits commonly referred as zai is a traditional land rehabilitation technology “invented” to rehabilitate degraded dry lands and to restore soil fertility to the benefit of farmers living there.They are made on land which is not very permeable so that runoff can be collected. Improvements in the traditional pits by the addition of organic matter (compost) have resulted in dramatic improvements in yield. The planting pits are suitable for semi-arid area like the lower Mbeere District to enable crops to survive dry spells. They are used on a wide variety soil types but most suitable on silt and clay soils where runoff can be generated due to limited permeability.

Purpose of the Technology: Apart from establishment of a nine maize crop stand in one pit, the technology assists in harvesting rain water, conserving the moisture, managing of soil fertility and controlling of weed development. Use of this technique in Mbeere South District have produced higher grain yields, particularly on highly degraded sandy soils. They offers a good potential to both increase the livelihood of the rural population and at the same time, combat desertification.

Establishment / maintenance activities and inputs: The process is started in dry season of the year. Holes of 2ft by 2ft and 2ft deep are dug out. Remove the top soil and put it on the uphill side. Remove the subsoil and place it down hill to form a continuous bund from end to end of each row. The top soil is returned into the pit and mixed with animal manure at the rate of 1 debe per hole. Plant 9 maize seeds on the pit at a spacing of 1foot. The compost can be made from rotted cow/sheep dung, leaves, and ashes from wood-fueled stoves.

Natural / human environment: These maize pits are usually constructed on abandoned or unused ground. Thus, crop yields resulting from this practice bring a benefit of 100%.

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Kenya

Region/ State/ Province:

Eastern Province

Further specification of location:

Mbere South District

Specify the spread of the Technology:

- evenly spread over an area

If precise area is not known, indicate approximate area covered:

- < 0.1 km2 (10 ha)

Comments:

Practiced by many farmers with the assistance of an Agriculture extension officer from the ministry of Agriculture.

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- 10-50 years ago

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through land users' innovation

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- reduce, prevent, restore land degradation

- adapt to climate change/ extremes and its impacts

- create beneficial economic impact

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

Annual cropping - Specify crops:

- cereals - maize

- legumes and pulses - beans

Number of growing seasons per year:

- 1

Specify:

Longest growing period in days: 90, Longest growing period from month to month: March to May

Comments:

Major crop: Green grams / Maize

Major land use problems (compiler’s opinion): Crop water deficiency due to low soil moisture content

Major land use problems (land users’ perception): Inadequate water for the crop

Future (final) land use (after implementation of SLM Technology): Cropland: Ca: Annual cropping

3.3 Has land use changed due to the implementation of the Technology?

Has land use changed due to the implementation of the Technology?

- Yes (Please fill out the questions below with regard to the land use before implementation of the Technology)

Cropland

- Tree and shrub cropping

3.4 Water supply

Water supply for the land on which the Technology is applied:

- rainfed

Comments:

Water supply: Also post-flooding

3.5 SLM group to which the Technology belongs

- minimal soil disturbance

- integrated soil fertility management

- water harvesting

3.6 SLM measures comprising the Technology

structural measures

- S2: Bunds, banks

3.7 Main types of land degradation addressed by the Technology

water degradation

- Ha: aridification

Comments:

Main causes of degradation: soil management, Heavy / extreme rainfall (intensity/amounts), poverty / wealth, labour availability

Secondary causes of degradation: deforestation / removal of natural vegetation (incl. forest fires)

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

- restore/ rehabilitate severely degraded land

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

The technical drawing on the right side shows a representation of how the nine maize pits are prepared. The top soil is put aside and mixed with FYM or other organic matter. The area in between the pits is left undisturbed.

Location: Mbeere South District. Eastern

Date: 19/09/2012

Main technical functions: control of raindrop splash, water spreading, sediment retention / trapping, sediment harvesting

Secondary technical functions: control of dispersed runoff: retain / trap, control of concentrated runoff: retain / trap

Retention/infiltration ditch/pit, sediment/sand trap

Vertical interval between structures (m): 0.2

Spacing between structures (m): 0.3

Depth of ditches/pits/dams (m): 0.2

Width of ditches/pits/dams (m): 0.3

Length of ditches/pits/dams (m): 0.3

Author:

Paul Kahiga, 62000-00200 Nairobi

4.2 General information regarding the calculation of inputs and costs

other/ national currency (specify):

KSh

If relevant, indicate exchange rate from USD to local currency (e.g. 1 USD = 79.9 Brazilian Real): 1 USD =:

100.0

Indicate average wage cost of hired labour per day:

4.00

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Land clearing | Before onset of rainfall |

| 2. | Digging of pits | Before onste of rainfall |

| 3. | Buying of seed maize | before onset of rains |

| 4. | Planting of seed maize | just before onset of rain |

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour | ha | 1.0 | 24.0 | 24.0 | 100.0 |

| Equipment | Tools | ha | 1.0 | 15.0 | 15.0 | 100.0 |

| Plant material | Seeds | ha | 1.0 | 12.0 | 12.0 | 100.0 |

| Fertilizers and biocides | Manure (FYM) | ha | 1.0 | 50.0 | 50.0 | 100.0 |

| Total costs for establishment of the Technology | 101.0 | |||||

| Total costs for establishment of the Technology in USD | 1.01 | |||||

Comments:

Duration of establishment phase: 1 month(s)

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Weeding | after 2 months |

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour (weeding) | ha | 1.0 | 24.0 | 24.0 | 100.0 |

| Equipment | Tools | ha | 1.0 | 15.0 | 15.0 | 100.0 |

| Total costs for maintenance of the Technology | 39.0 | |||||

| Total costs for maintenance of the Technology in USD | 0.39 | |||||

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

It requires high intensity labour due to manual construction.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Agro-climatic zone

- semi-arid

Thermal climate class: tropics

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Topsoil organic matter:

- medium (1-3%)

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

Soil fertility: High

Soil drainage/infiltration: Good

Soil water storage capacity: High

5.4 Water availability and quality

Ground water table:

5-50 m

Availability of surface water:

medium

Water quality (untreated):

poor drinking water (treatment required)

5.5 Biodiversity

Species diversity:

- medium

5.6 Characteristics of land users applying the Technology

Market orientation of production system:

- mixed (subsistence/ commercial)

Relative level of wealth:

- average

Individuals or groups:

- individual/ household

Level of mechanization:

- manual work

Gender:

- women

Indicate other relevant characteristics of the land users:

Land users applying the Technology are mainly common / average land users

Population density: 10-50 persons/km2

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, not titled

Land use rights:

- individual

Water use rights:

- individual

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

markets:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

risk of production failure

land management

Comments/ specify:

Machinery

Income and costs

farm income

workload

Comments/ specify:

High manpower to dig the pits

Socio-cultural impacts

food security/ self-sufficiency

SLM/ land degradation knowledge

Food security and a source of income generation at household level

Ecological impacts

Water cycle/ runoff

harvesting/ collection of water

evaporation

Soil

soil moisture

6.2 Off-site impacts the Technology has shown

damage on neighbours' fields

damage on public/ private infrastructure

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | well |

Climate-related extremes (disasters)

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | well |

Comments:

Increase the depth of the pit for high water retention to enable drought tolerance

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

positive

Long-term returns:

positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

positive

Long-term returns:

positive

6.5 Adoption of the Technology

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 91-100%

Comments:

100% of land user families have adopted the Technology without any external material support

There is a moderate trend towards spontaneous adoption of the Technology

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| Prevention of soil erosion. |

| It is a water harvesting technology. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Food security. |

| Prevention of excessive evaporation. |

| Income generation at household level. |

| Improves ground water recharge. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| Encourages pests to stay in the pits |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| Labour intensive (construction & maintenance) | |

| In wet seasons, they can be prone to water logging | |

| Prevents machinery movement in the farms |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

- interviews with land users

When were the data compiled (in the field)?

19/09/2012

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules