Production of biogas from waste to increase soil fertility [Uzbekistan]

- Creation:

- Update:

- Compiler: Rustam Ibragimov

- Editor: –

- Reviewers: Elizaveta Soloveyva, Olga Andreeva, Alexandra Gavilano

Production of biogas from waste to increase soil fertility

technologies_3645 - Uzbekistan

- Full summary as PDF

- Full summary as PDF for print

- Full summary in the browser

- Full summary (unformatted)

- Использование отходов производства биогаза для повышения плодородия почв: Nov. 7, 2018 (inactive)

- Использование отходов производства биогаза для повышения плодородия почв: March 18, 2019 (inactive)

- Использование отходов производства биогаза для повышения плодородия почв: Aug. 22, 2019 (inactive)

- Production of biogas from waste to increase soil fertility: Jan. 27, 2020 (public)

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

SLM specialist:

Tashkuziev Maruf

State Research Institute of Soil Science and Agrochemistry

Uzbekistan

land user:

Yuldashev Ravshan

breeding farm "Milk agro"

Uzbekistan

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Decision Support for Mainstreaming and Scaling out Sustainable Land Management (GEF-FAO / DS-SLM)1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

The technology is based on production of biogas from waste as a highly effective environmentally friendly organic fertilizer

2.2 Detailed description of the Technology

Description:

Currently, the needs of livestock farms in fuel and energy resources are growing. Therefore, their stable energy supply is very important, and it is achieved through the introduction of energy production technologies from renewable sources. In 2015, the government of the Republic of Uzbekistan adopted a resolution to stimulate the construction of biogas plants. According to experts, Uzbekistan has the potential to produce about 9 billion m3 / year of biogas, which is about 10% of the country's annual energy needs (UNDP "Road map for the development of biogas technologies market in Uzbekistan", 2012). Easily degradable organic substances-manure, poultry manure, straw, cotton stems, tree leaves and other organic residues can serve as raw materials for the biogas production. UNDP projects and GEF small grants Programs on the biogas plants use for autonomous energy supply of farms have been successfully implemented in Uzbekistan. The technology of obtaining energy resources and highly effective organic fertilizers was implemented in Milk-agro farm and G. Abdullayev’s farm in Zangiata district in the framework of the UNDP Project "Assisting biogas technologies in Uzbekistan" (2006). The most successful example of biogas production and the use of waste as an organic fertilizer was shown by the farm "Nadezhda" in the Khavast district of the Syrdarya region. The biogas plant, launched as part of the GEF SGP pilot project (2010), provides electricity to the livestock complex and valuable organic fertilizer to forage crops fields. Biogas production technology is especially important for medium-sized farms due to their own energy supply and soil enrichment with humus. The decline in soil organic matter in recent decades has led to a decrease in the quantity and quality of soil biota, which has become one of the reasons for the decline in soil fertility. Concentrated organic fertilizer is obtained during the process of biogas production, without weed seeds and pathogenic microflora. It contains 2-4 times more basic nutrients than in conventional organic fertilizers, as well as humic acids, plant growth stimulants, vitamins and amino acids.

Costs of inputs needed for establishment:

Animal waste products are collected daily in special containers and then sent to the reactors. Organic fertilizers are stored for 7-10 days at a temperature of 38-40 C, so all bacteria and seeds of various herbs die. Therefore, the use of biofertilizers can further reduce the cost of weed control. Liquid waste diluted with water in a ratio of 1: 20 is used as a top dressing for plants. The rate of application is 1 t / ha per season.

The cost of an average individual Biogas plant (30 m3) ranges from 15,000 to 180,000 USD. The payback period is about 3-7 years. The larger the Biogas plant, the higher its profitability and shorter payback period. Savings due to the use of biofertilizer is 84 USD / ha. The use and sale of biofertilizer is the main source of income from the Biogas plant in the farm "Nadezda". Increasing farmland productivity will provide fodder for personal livestock, and will allow the sale of surplus silage, alfalfa, corn and feed wheat for an average of 1,600 USD per year.

2.3 Photos of the Technology

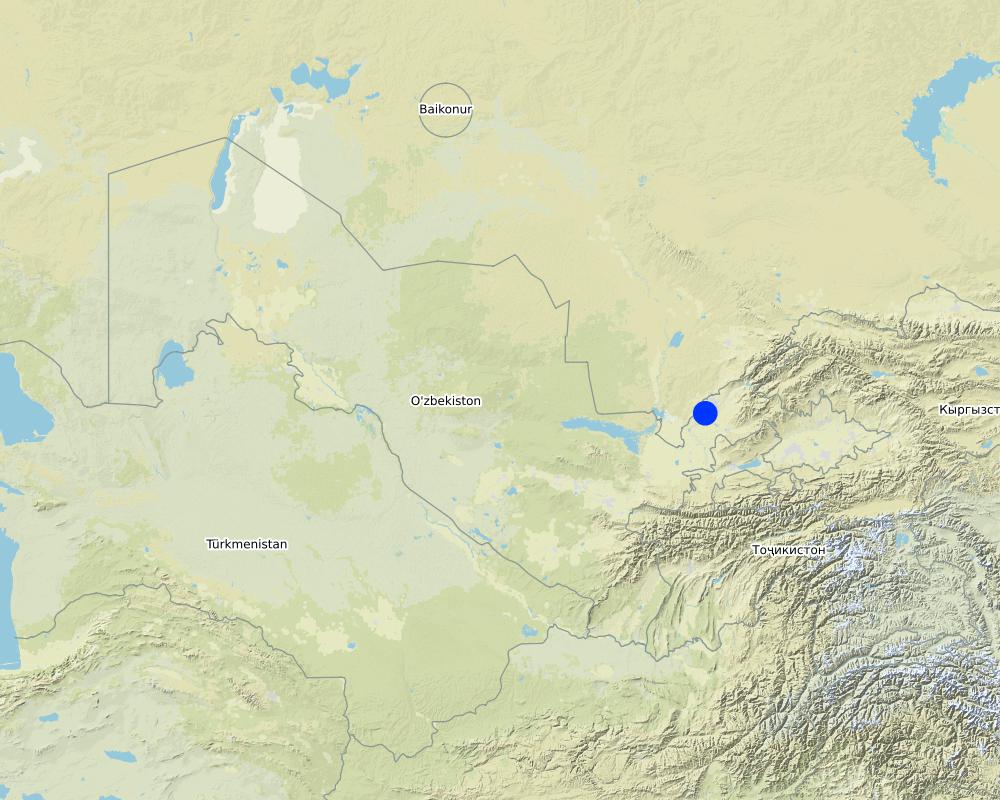

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Uzbekistan

Region/ State/ Province:

Zangiotinskiy district, Tashkent region

Further specification of location:

G. Abdullayev farm, farm Milk-agro

Specify the spread of the Technology:

- evenly spread over an area

If precise area is not known, indicate approximate area covered:

- < 0.1 km2 (10 ha)

Comments:

in the studied farms Milk-Agro and "Nadezhda" technology is used on an area of 10 hectares and 13 hectares, accordingly

Map

×2.6 Date of implementation

Indicate year of implementation:

2002

If precise year is not known, indicate approximate date:

- 10-50 years ago

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

Comments (type of project, etc.):

Technology is being implemented through the projects of the GEF SGP, UNDP

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- reduce, prevent, restore land degradation

- preserve/ improve biodiversity

- mitigate climate change and its impacts

- create beneficial economic impact

- Main tasks-production of biogas and biofertilizer

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

- Cotton and wheat, forage crops for livestock

Number of growing seasons per year:

- 2

Specify:

2 crops per year - 1 cotton crop, winter wheat and second crops (mung bean, beans, etc.) sown after wheat harvesting, 5-6 alfalfa mowing periods

3.3 Has land use changed due to the implementation of the Technology?

Has land use changed due to the implementation of the Technology?

- Yes (Please fill out the questions below with regard to the land use before implementation of the Technology)

3.4 Water supply

Water supply for the land on which the Technology is applied:

- full irrigation

Comments:

no change

3.5 SLM group to which the Technology belongs

- improved ground/ vegetation cover

- integrated soil fertility management

- waste management/ waste water management

3.6 SLM measures comprising the Technology

agronomic measures

- A1: Vegetation/ soil cover

- A2: Organic matter/ soil fertility

3.7 Main types of land degradation addressed by the Technology

chemical soil deterioration

- Cn: fertility decline and reduced organic matter content (not caused by erosion)

physical soil deterioration

biological degradation

- Bl: loss of soil life

Comments:

Low rates of organic fertilizers and harvesting of plant residues from the fields contributed to the reduction of humus content and soil biota. The content of humus affects the intensity of biochemical processes that cause the accumulation of nutrients needed by plants.

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- reduce land degradation

Comments:

The use of biogas production waste contributes to the increase of organic matter, improvement of soil biota, forms the soil structure.

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

The diagram illustrates a biogas complex for the production of biogas and biofertilizers

1st line from left to right: Farm - Buildings - Greenhouses - Local heating

2nd line from left to right: Slurry - Tank for heating maintaining - Heating - Block Heat And Power Plant - General power network

3rd linefrom left to right: Temporary storage facility - Fermenter - Fermented manure

4th line from left to right: Joint fermentation of renewable raw materials - Tank mixer - Subsequent processing of fermentation residues - Agricultural needs

Author:

https://econet.ru/articles/146539-kak-poluchit-biogaz-iz-navoza-tehnologiya-i-ustroystvo-ustanovki-po-proizvodstvu

4.2 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology area

Indicate size and area unit:

1 ha

Specify currency used for cost calculations:

- USD

If relevant, indicate exchange rate from USD to local currency (e.g. 1 USD = 79.9 Brazilian Real): 1 USD =:

3500.0

Indicate average wage cost of hired labour per day:

about 4 USD

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Purchase and installation of biogas plant | During warm season |

| 2. | Crop care (cultivation with fertilization, watering) | July-October |

| 3. | Harvest | November |

| 4. | Plant residues stocking | November |

| 5. | Harrowing, leveling and sowing of green manure | November |

| 6. | Siderat stocking | April |

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Equipment | Purchase and installation of biogas plant | unit | 1.0 | 18000.0 | 18000.0 | 30.0 |

| Total costs for establishment of the Technology | 18000.0 | |||||

| Total costs for establishment of the Technology in USD | 5.14 | |||||

If land user bore less than 100% of costs, indicate who covered the remaining costs:

paid for by the project

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | fertilizer delivery and application | 2-3 times during the growing season to feed plants |

Comments:

The delivery of biofertilizer to the field is the main task for Technology maintaining.

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | fertilizer delivery and application | USD/ha | 100.0 |

If land user bore less than 100% of costs, indicate who covered the remaining costs:

Costs relate only to fertilizer delivery to the field

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

The highest costs relate to the acquisition and installation of a biogas plant

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specify average annual rainfall (if known), in mm:

418.00

Specifications/ comments on rainfall:

96% of precipitation falls during October-May

Indicate the name of the reference meteorological station considered:

Tashkent

Agro-climatic zone

- semi-arid

The growing season is 160 days

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Comments and further specifications on topography:

450 m above sea level (Milc-Agro) and 273 m above sea level (Hawast)

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Soil texture (> 20 cm below surface):

- medium (loamy, silty)

Topsoil organic matter:

- low (<1%)

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

Meadow-gray soils, salted, on loamy-sandy loam alluvium and proluvium (Calcisol, sulphatic). The humus content in the arable layer is less than 1%.

5.4 Water availability and quality

Ground water table:

< 5 m

Availability of surface water:

good

Water quality (untreated):

good drinking water

Is water salinity a problem?

No

Comments and further specifications on water quality and quantity:

Water in surface sources is polluted from drainage runoff discharges from irrigation fields

5.5 Biodiversity

Species diversity:

- medium

Habitat diversity:

- medium

Comments and further specifications on biodiversity:

The vegetation is represented by cultural plant species: cotton, wheat, vegetables, melons, perennial plantations fruit and ornamental trees and shrubs

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- mixed (subsistence/ commercial)

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- average

Individuals or groups:

- individual/ household

Level of mechanization:

- mechanized/ motorized

Gender:

- men

Age of land users:

- middle-aged

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- medium-scale

Comments:

The average size of farms is 35-75 hectares, dekhkan and household plots - up to 0.35 hectares

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- state

- individual, titled

Land use rights:

- leased

- through Water Users Associations and irrigation systems management

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

energy generation

Income and costs

expenses on agricultural inputs

farm income

workload

Ecological impacts

Biodiversity: vegetation, animals

Vegetation cover

Climate and disaster risk reduction

emission of carbon and greenhouse gases

6.2 Off-site impacts the Technology has shown

Specify assessment of off-site impacts (measurements):

The Technology does not have negative off-site impacts

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | well | |

| seasonal temperature | summer | increase | well |

| annual rainfall | decrease | well | |

| seasonal rainfall | spring | decrease | well |

| seasonal rainfall | summer | decrease | well |

Climate-related extremes (disasters)

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| heatwave | well |

| drought | well |

Comments:

Technology does not depend on climate change, but only on the livestock producing raw materials for biogas production

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

negative

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

negative

Long-term returns:

very positive

Comments:

Payback period is more than 3 years, the land user will incur losses in the short term without external support

6.5 Adoption of the Technology

- 11-50%

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 11-50%

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

No

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| Energy self-sufficiency |

| Double benefit-biogas and fertilizer |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| High cost | Lending |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

July-November 2016-2017, 2013

- interviews with land users

3 persons

- interviews with SLM specialists/ experts

3 persons

- compilation from reports and other existing documentation

7.3 Links to relevant online information

Title/ description:

S. Shoeva CHEAP AND QUALITATIVE ENERGY FROM LOCAL RAW MATERIALS. 2009 year

URL:

http://www.cawater-info.net/news/04-2009/03.htm

Title/ description:

I.V. Dergacheva, P.T. Salikhov. Biogas, electricity, heat. 11 steps to the goal Practical Guide Tashkent, 2011

URL:

https://mineconomy.uz/sites/default/files/pictures/biogaz1.pdf

Title/ description:

L.V. Zavyalova, P.T. Salikhov. UNDP ROAD MAP for the development of the biogas technology market in Uzbekistan

URL:

https://mineconomy.uz/sites/default/files/pictures/biogaz3.pdf

Title/ description:

L.V. Zavyalova, I.V. Dergacheva UNDP. Use of BIOGAS for autonomous energy supply of the farm. HISTORY OF SUCCESS

URL:

https://mineconomy.uz/sites/default/files/pictures/biogaz2.pdf

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules