Irrigation of uplands through Hydraulic Flange Pump [Afghanistan]

- Création :

- Mise à jour :

- Compilateur : Aqila Haidery

- Rédacteur : –

- Examinateurs : Alexandra Gavilano, David Streiff

Aabyari zamin hai boland Aaba thawasut Pump_e_Aabi_Charkhdar

technologies_1731 - Afghanistan

Voir les sections

Développer tout Réduire tout1. Informations générales

1.2 Coordonnées des personnes-ressources et des institutions impliquées dans l'évaluation et la documentation de la Technologie

Spécialiste GDT:

Spécialiste GDT:

Spécialiste GDT:

Nom du ou des institutions qui ont facilité la documentation/ l'évaluation de la Technologie (si pertinent)

HELVETAS (Swiss Intercooperation)Nom du ou des institutions qui ont facilité la documentation/ l'évaluation de la Technologie (si pertinent)

People in Need (PIN) (People in Need (PIN)) - Afghanistan1.3 Conditions relatives à l'utilisation par WOCAT des données documentées

Quand les données ont-elles été compilées (sur le terrain)?

18/05/2016

Le compilateur et la(les) personne(s) ressource(s) acceptent les conditions relatives à l'utilisation par WOCAT des données documentées:

Oui

2. Description de la Technologie de GDT

2.1 Courte description de la Technologie

Définition de la Technologie:

Technology for lifting water to uplands: hydraulic flange pump, reservoir and pipe scheme.

2.2 Description détaillée de la Technologie

Description:

This technology is documented by the Sustainable Land Management Project, implemented by HELVETAS Swiss Intercooperation and funded by the Swiss Agency for Development and Cooperation (SDC), with close support and cooperation of People in Need.

Samangan, Khuram wa Sarbagh district, Klor-e-Bala village is situated in a mountainous region where the greatest limiting factor to agricultural production is water. Arable lands are located far away from water sources. Lack of technology to exploit these lands prohibits villagers to cultivate their land to make a livelihood. Therefore, families are compelled to leave their village during summer.

Purpose of the Technology: To address this problem, People in Need (PIN), with financial support from GIZ and the Czech Embassy (CzDA) introduced irrigation through hydraulic flange pump. The hydraulic flange pump provides water to 30 orchards of Klor-e-Bala village, drinking water to the 43 village households, the mosque and the school of 500 students.

Establishment / maintenance activities and inputs: The main water source which starts and runs the hydraulic flange pump is the Khuwaja Hayat spring. The spring water arrives to the hydraulic flange pump from 1.8 meter height on a 12 percent slope in 200 meters distance from the water source. The water flow passes through the intake and moves towards the water wheel which starts/runs the hydraulic flange pump. The water is then pumped through three pipes of one inch to the reservoir. The hydraulic flange pump has the capacity of lifting water up to 250 meters.

The reservoir’s storage capacity is 25,600 liters of water with the dimensions as follows: 4.9 meter length; 2.9 m width; and 1.8 m height. It has two outlets: a spill way fitted with three pipes of one inch at the top of the reservoir and two outlets fitted with two pipes of three inches at the bottom. The lower outlet leads water to the orchards by diverting water after 40 meters into two pipes which are 1,000 meters long. Each orchard is connected to one of these two pipes by a T-connector and the water flows into a tin water tank with the capacity of 1,000 liters for each orchard. The two pipes are extended as far as the school which is located near the orchards and has been equipped with a 2000 liters tin water tank.

The hydraulic flange pump is made locally in Taloqan city, Takhar province of Afghanistan in the Baradaran-e- Kargar workshop. The pump costs 140,000 Afghani/ 2,200 US$, including installment. The estimated cost of the construction of the reservoir and the pump’s room including the hydraulic flange pump is 19,000 US$. The pipe scheme of the project was installed by the Community Development Council (CDC) with technical support from PIN’s engineering team. Community members contributed 10 percent of the costs as labor. As Klor-e-Bala village is situated in flood prone area and flooding is a common occurrence, PIN, with funding from the GIZ, constructed in 2015 two protection walls, 45 m and 55 m in length, on both sides of the river, to minimize erosion and protect the pump’s intake from floods. The protection walls were built through cash for work programme, but community members provided 10 percent contribution through labor and by providing stones for construction. The total estimated cost of the hydraulic flange pump, reservoir and pipe scheme technology amounted to 37,000 US$.

Furthermore, in order to maintain the technology, a caretaker, who lives close to the pump’s room has been appointed. The caretaker was trained by the technician who installed the hydraulic flange pump and has voluntarily taken the responsibility of maintenance activities; changing the oil and cleaning of the hydraulic flange pump's room and changing of the pipes in case of need. The owners of the orchards have to cover for all maintenance costs and the chairman of the Community Development Council (CDC) has the responsibility of managing the money for maintenance and other recurrent activities.

The flange pump technology contributed to the economic growth of the community members by increasing the orchards’ yields. Currently, the hydraulic flange pump irrigates 12 jireb/2.4 ha (30*800m2) orchards of apple, apricot, almond, pear and cherry trees. In addition to the orchards, alfalfa, potato, vegetables and other crops are as well cultivated on these lands. Furthermore, the pump supports the community members to settle year-round in their villages and prevents from their seasonal displacement. Moreover, the flange pump enables the provision of drinking water to the whole community and the school.

Natural / human environment: Samangan is one of the northern provinces of Afghanistan. Wheat, melons, pistachio,

almonds, potatoes, onions and caraway are important crops and Karakul sheep

and goats the main livestock for meat, dairy, and wool production. Rugs are the

main handicraft of this area. Khuram-wa-Sarbagh district in Samangan has two growing

seasons, the longest of which is 150 days from February to June and the second is 90

days from June to September. The average rainfall is below 500mm and the climate semi-arid.

The community members have limited access to off farm employment, market, energy,

financial services, roads and transportation and moderate access to health and education.

2.3 Photos de la Technologie

2.5 Pays/ région/ lieux où la Technologie a été appliquée et qui sont couverts par cette évaluation

Pays:

Afghanistan

Région/ Etat/ Province:

Samangan

Autres spécifications du lieu:

Khuram-wa-Sarbagh district, Klor_e_Bala village

2.6 Date de mise en œuvre de la Technologie

Si l'année précise est inconnue, indiquez la date approximative: :

- il y a moins de 10 ans (récemment)

2.7 Introduction de la Technologie

Spécifiez comment la Technologie a été introduite: :

- par le biais de projets/ d'interventions extérieures

3. Classification de la Technologie de GDT

3.1 Principal(aux) objectif(s) de la Technologie

- améliorer la production

- access to water

3.2 Type(s) actuel(s) d'utilisation des terres, là où la Technologie est appliquée

Terres cultivées

- Cultures annuelles

- Plantations d’arbres ou de buissons

Pâturages

Commentaires:

Major land use problems (compiler’s opinion): Lack of safe drinking and irrigation water which makes agricultural activities difficult.

Major land use problems (land users’ perception): Lack of cultivation due to the scarcity of water. High workloads and small incomes.

Future (final) land use (after implementation of SLM Technology): Mixed: Mf: Agroforestry

Si l'utilisation des terres a changé en raison de la mise en œuvre de la Technologie, indiquez l'utilisation des terres avant la mise en œuvre de la Technologie:

Other: Ow: Waterways, drainage lines, ponds, dams

3.3 Informations complémentaires sur l'utilisation des terres

Approvisionnement en eau des terres sur lesquelles est appliquée la Technologie:

- pluvial

Nombre de période de croissance par an: :

- 2

Précisez:

Longest growing period in days: 150; Longest growing period from month to month: February - June; Second longest growing period in days: 90; Second longest growing period from month to month: June - September

3.4 Groupe de GDT auquel appartient la Technologie

- gestion des forêts naturelles et semi-naturelles

- agroforesterie

- gestion de l'irrigation (incl. l'approvisionnement en eau, le drainage)

3.5 Diffusion de la Technologie

Spécifiez la diffusion de la Technologie:

- répartie uniformément sur une zone

Si la Technologie est uniformément répartie sur une zone, indiquez la superficie couverte approximative:

- 1-10 km2

Commentaires:

The technology area which is considered here is the distance from the water area where the machine exists to the reservoir and reservoir to the orchard and crop land.

3.6 Mesures de GDT constituant la Technologie

structures physiques

- S5: Barrages/retenues, micro-bassins, étangs

3.7 Principaux types de dégradation des terres traités par la Technologie

dégradation biologique

- Bc: réduction de la couverture végétale

- Bq: baisse de la quantité/ biomasse

Commentaires:

Secondary types of degradation addressed: Bq: quantity / biomass decline

Main causes of degradation: disturbance of water cycle (infiltration / runoff), droughts, education, access to knowledge and support services

3.8 Prévention, réduction de la dégradation ou réhabilitation des terres dégradées

Spécifiez l'objectif de la Technologie au regard de la dégradation des terres:

- restaurer/ réhabiliter des terres sévèrement dégradées

4. Spécifications techniques, activités, intrants et coûts de mise en œuvre

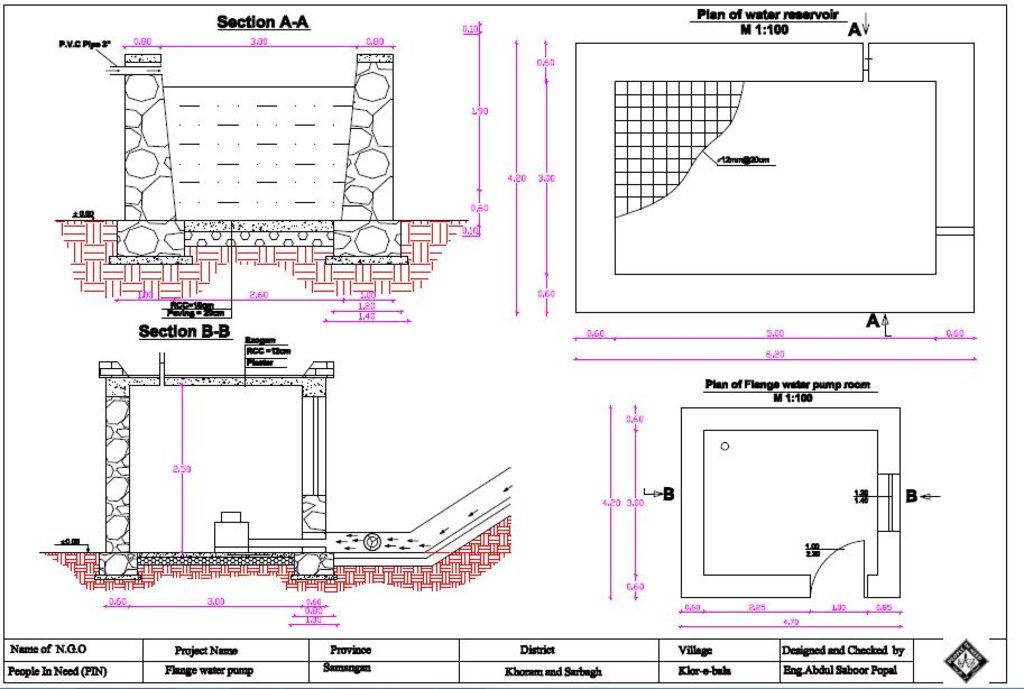

4.1 Dessin technique de la Technologie

4.2 Spécification/ explications techniques du dessin technique

A detailed technical drawing of the hydraulic flange pump and the reservoir, Klor-e-Bala village, Khuram-wa-Sarbagh district, Samangan province.

Technical knowledge required for field staff / advisors: high

Technical knowledge required for land users: moderate

Main technical functions: improvement of ground cover, improvement of surface structure (crusting, sealing), improvement of topsoil structure (compaction), stabilisation of soil (eg by tree roots against land slides), water harvesting / increase water supply, water spreading

4.3 Informations générales sur le calcul des intrants et des coûts

Indiquez la monnaie utilisée pour le calcul des coûts:

- dollars US

Indiquez le coût salarial moyen de la main d'œuvre par jour:

7.00

4.4 Activités de mise en place/ d'établissement

| Activité | Type de mesures | Calendrier | |

|---|---|---|---|

| 1. | Excavation of the foundation | Structurel | |

| 2. | Construction activities,Stone masonry foundation and wall: | Structurel | |

| 3. | a:P.C.C concrete foundationb:R.C.C concretec:Iron shattering for walls, roof and floord:External and internal pointing | Structurel | |

| 4. | a:Plasteringb:Steel barsc:Door and window | Structurel | |

| 5. | Pipe scheme:a:Pipesb:Water tanksc:other equipmentd:Skilled and unskilled labor | Structurel | |

| 6. | Procurement of the Hydraulic flange pump | Structurel |

4.5 Coûts et intrants nécessaires à la mise en place

| Spécifiez les intrants | Unité | Quantité | Coûts par unité | Coût total par intrant | % des coût supporté par les exploitants des terres | |

|---|---|---|---|---|---|---|

| Main d'œuvre | Excavation of the foundation | square meters | 50,0 | 2,88 | 144,0 | 10,0 |

| Main d'œuvre | Excavation of the foundation | cubic meters | 161,0 | 2,4037 | 387,0 | 10,0 |

| Main d'œuvre | Skilled and unskilled labor | persons/day | 343,0 | 9,47521 | 3250,0 | 10,0 |

| Equipements | Water tanks | pieces | 39,0 | 98,615384 | 3846,0 | 10,0 |

| Equipements | Pipes | meter | 2900,0 | 2,9241379 | 8480,0 | 10,0 |

| Equipements | Other equipment | all | 1,0 | 2424,0 | 2424,0 | 10,0 |

| Equipements | Procurement of the Hydraulic flange pump | pieces | 1,0 | 2200,0 | 2200,0 | 10,0 |

| Matériaux de construction | Concrete foundation | cubic meters | 12,23 | 96,64758 | 1182,0 | 10,0 |

| Matériaux de construction | Concrete | cubic meters | 8,4 | 114,0476 | 958,0 | 10,0 |

| Matériaux de construction | Iron shattering for walls, roof and floor | cubic meters | 110,0 | 4,86363 | 535,0 | 10,0 |

| Matériaux de construction | External and internal pointing | square meters | 226,0 | 2,85398 | 645,0 | 10,0 |

| Matériaux de construction | Plastering | square meters | 32,0 | 5,9375 | 190,0 | 10,0 |

| Matériaux de construction | Steel bars | square meters | 364,4 | 1,21844 | 444,0 | 10,0 |

| Matériaux de construction | Door and window | square meters | 3,98 | 28,8944 | 115,0 | 10,0 |

| Matériaux de construction | Stones | square meters | 244,0 | 50,0 | 12200,0 | 10,0 |

| Coût total de mise en place de la Technologie | 37000,0 | |||||

Commentaires:

Duration of establishment phase: 7 month(s)

4.6 Activités d'entretien/ récurrentes

| Activité | Type de mesures | Calendrier/ fréquence | |

|---|---|---|---|

| 1. | Changing of the pipes | Structurel | Once a year |

| 2. | Cleaning of the flange pump room | Structurel | Six times a year |

| 3. | Changing of the hydraulic flange pump oil | Structurel |

4.7 Coûts et intrants nécessaires aux activités d'entretien/ récurrentes (par an)

| Spécifiez les intrants | Unité | Quantité | Coûts par unité | Coût total par intrant | % des coût supporté par les exploitants des terres | |

|---|---|---|---|---|---|---|

| Main d'œuvre | Changing of the pipes | persons/day | 1,0 | 7,0 | 7,0 | 100,0 |

| Main d'œuvre | Cleaning of the flange pump room | persons/day | 1,0 | 7,0 | 7,0 | 100,0 |

| Main d'œuvre | Changing of the hydraulic flange pump oil | persons/day | 1,0 | 7,0 | 7,0 | 100,0 |

| Equipements | Pipes | meter | 20,0 | 0,65 | 13,0 | 100,0 |

| Equipements | Oil | times/year | 4,0 | 4,5 | 18,0 | 100,0 |

| Coût total d'entretien de la Technologie | 52,0 | |||||

4.8 Facteurs les plus importants affectant les coûts

Décrivez les facteurs les plus importants affectant les coûts :

Labor, stone and equipment are the main fundamental factors which need high initial investments.

After a couple of years pipes may need to be changed.

5. Environnement naturel et humain

5.1 Climat

Précipitations annuelles

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1000 mm

- 1001-1500 mm

- 1501-2000 mm

- 2001-3000 mm

- 3001-4000 mm

- > 4000 mm

Zone agro-climatique

- semi-aride

Thermal climate class: temperate

5.2 Topographie

Pentes moyennes:

- plat (0-2 %)

- faible (3-5%)

- modéré (6-10%)

- onduleux (11-15%)

- vallonné (16-30%)

- raide (31-60%)

- très raide (>60%)

Reliefs:

- plateaux/ plaines

- crêtes

- flancs/ pentes de montagne

- flancs/ pentes de colline

- piémonts/ glacis (bas de pente)

- fonds de vallée/bas-fonds

Zones altitudinales:

- 0-100 m

- 101-500 m

- 501-1000 m

- 1001-1500 m

- 1501-2000 m

- 2001-2500 m

- 2501-3000 m

- 3001-4000 m

- > 4000 m

5.3 Sols

Profondeur moyenne du sol:

- très superficiel (0-20 cm)

- superficiel (21-50 cm)

- modérément profond (51-80 cm)

- profond (81-120 cm)

- très profond (>120 cm)

Texture du sol (de la couche arable):

- grossier/ léger (sablonneux)

Matière organique de la couche arable:

- faible (<1%)

Si disponible, joignez une description complète du sol ou précisez les informations disponibles, par ex., type de sol, pH/ acidité du sol, capacité d'échange cationique, azote, salinité, etc.

Soil fertility is medium

Soil drainage / infiltration is medium

Soil water storage capacity is low

5.4 Disponibilité et qualité de l'eau

Profondeur estimée de l’eau dans le sol:

5-50 m

Disponibilité de l’eau de surface:

moyenne

Qualité de l’eau (non traitée):

eau potable

5.5 Biodiversité

Diversité des espèces:

- moyenne

Diversité des habitats:

- moyenne

5.6 Caractéristiques des exploitants des terres appliquant la Technologie

Sédentaire ou nomade:

- Nomade

Revenus hors exploitation:

- 10-50% de tous les revenus

Niveau relatif de richesse:

- pauvre

Individus ou groupes:

- groupe/ communauté

Genre:

- hommes

Indiquez toute autre caractéristique pertinente des exploitants des terres:

Land users applying the Technology are mainly disadvantaged land users

Difference in the involvement of women and men: Constructional activities which are done outside of the houses and compounds are mainly applied by men in Afghanistan.

Population density: 10-50 persons/km2

Annual population growth: 2% - 3%

100% of the land users are poor.

5.7 Superficie moyenne des terres détenues ou louées par les exploitants appliquant la Technologie

- < 0,5 ha

- 0,5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1 000 ha

- 1 000-10 000 ha

- > 10 000 ha

Cette superficie est-elle considérée comme de petite, moyenne ou grande dimension (en se référant au contexte local)?

- petite dimension

5.8 Propriété foncière, droits d’utilisation des terres et de l'eau

Propriété foncière:

- communauté/ village

Droits d’utilisation des terres:

- communautaire (organisé)

Droits d’utilisation de l’eau:

- communautaire (organisé)

5.9 Accès aux services et aux infrastructures

santé:

- pauvre

- modéré

- bonne

éducation:

- pauvre

- modéré

- bonne

assistance technique:

- pauvre

- modéré

- bonne

emploi (par ex. hors exploitation):

- pauvre

- modéré

- bonne

marchés:

- pauvre

- modéré

- bonne

énergie:

- pauvre

- modéré

- bonne

routes et transports:

- pauvre

- modéré

- bonne

eau potable et assainissement:

- pauvre

- modéré

- bonne

services financiers:

- pauvre

- modéré

- bonne

6. Impacts et conclusions

6.1 Impacts sur site que la Technologie a montrés

Impacts socio-économiques

Production

production agricole

production fourragère

qualité des fourrages

diversité des produits

surface de production

gestion des terres

Disponibilité et qualité de l'eau

disponibilité de l'eau potable

disponibilité de l'eau pour l'élevage

qualité de l'eau pour l'élevage

disponibilité de l'eau d'irrigation

qualité de l'eau d'irrigation

Revenus et coûts

dépenses pour les intrants agricoles

revenus agricoles

diversité des sources de revenus

charge de travail

Impacts socioculturels

sécurité alimentaire/ autosuffisance

situation sanitaire

connaissances sur la GDT/ dégradation des terres

apaisement des conflits

Commentaires/ spécifiez:

In case the owner of the first orchard do not obey the water use right

livelihood and human well-being

Commentaires/ spécifiez:

The pump improved households’ economy through increasing agricultural yieIds and by decreasing the need for a generator pump. It has as well reduced the workload of the community members

Impacts écologiques

Cycle de l'eau/ ruissellement

récolte/ collecte de l'eau

évaporation

Sols

humidité du sol

couverture du sol

encroûtement/ battance du sol

compaction du sol

salinité

Biodiversité: végétale, animale

diversité végétale

diversité animale

Réduction des risques de catastrophe et des risques climatiques

impacts des inondations

6.2 Impacts hors site que la Technologie a montrés

disponibilité de l'eau

Commentaires/ spécifiez:

It has decreased the water flow only in the place where the hydraulic flange pump is installed.

flux des cours d'eau fiables et stables en saison sèche

pollution des rivières/ nappes phréatiques

capacité tampon/de filtration

dommages sur les champs voisins

dommages sur les infrastructures publiques/ privées

6.3 Exposition et sensibilité de la Technologie aux changements progressifs et aux évènements extrêmes/catastrophes liés au climat (telles que perçues par les exploitants des terres)

Changements climatiques progressifs

Changements climatiques progressifs

| Saison | Type de changements/ extrêmes climatiques | Comment la Technologie fait-elle face à cela? | |

|---|---|---|---|

| températures annuelles | augmente | bien | |

| précipitations annuelles | augmente | bien |

Extrêmes climatiques (catastrophes)

Catastrophes météorologiques

| Comment la Technologie fait-elle face à cela? | |

|---|---|

| pluie torrentielle locale | pas connu |

| tempête de vent locale | pas bien |

Catastrophes climatiques

| Comment la Technologie fait-elle face à cela? | |

|---|---|

| sécheresse | bien |

Catastrophes hydrologiques

| Comment la Technologie fait-elle face à cela? | |

|---|---|

| crue éclair | pas bien |

Autres extrêmes climatiques (catastrophes)

| autre (précisez) | Comment la Technologie fait-elle face à cela? |

|---|---|

| length of growing period | bien |

6.4 Analyse coûts-bénéfices

Quels sont les bénéfices comparativement aux coûts de mise en place (du point de vue des exploitants des terres)?

Rentabilité à court terme:

très négative

Rentabilité à long terme:

légèrement positive

Quels sont les bénéfices comparativement aux coûts d'entretien récurrents (du point de vue des exploitants des terres)?

Rentabilité à court terme:

neutre / équilibrée

Rentabilité à long terme:

positive

6.5 Adoption de la Technologie

- 10-50%

Si disponible, quantifiez (nombre de ménages et/ou superficie couverte):

98 households covering 50 percent of the stated area

Parmi tous ceux qui ont adopté la Technologie, combien d'entre eux l'ont fait spontanément, à savoir sans recevoir aucune incitation matérielle ou aucun paiement?

- 0-10%

Commentaires:

98 land user families have adopted the Technology with external material support

Comments on spontaneous adoption: Due to high expenses of the implementation of the technology, it has not been applied without any external support.

There is a little trend towards spontaneous adoption of the Technology

Comments on adoption trend: The technology is of a high cost and needs external support to be established.

6.7 Points forts/ avantages/ possibilités de la Technologie

| Points forts/ avantages/ possibilités du point de vue de l'exploitant des terres |

|---|

|

Application of the technology has reduced the workload for the families. How can they be sustained / enhanced? Greater awareness on water management can be created by training/workshop for the water users. |

| Points forts/ avantages/ possibilités du point de vue du compilateur ou d'une autre personne ressource clé |

|---|

|

The technology has supported the community members economically by increasing agricultural yields. Moreover, it contributes to reduce the costs of water during the summer season. How can they be sustained / enhanced? The land users should try to plant local and native trees and cultivate the crops which are adapted to the land.Community members should actively participate in maintenance activities. |

|

Provides safe drinking water to the 43 households and the school at low cost. How can they be sustained / enhanced? Pipe scheme and cover of the reservoir, should be cleaned regularly. If any leakages occurs in the pipes or reservoir, they should be sealed. Water taps and water tanks should be properly maintained. |

|

This technology has been applied in a low slope/latitude where the water flows with a very low speed and the application of other technologies was difficult. How can they be sustained / enhanced? Protect from sedimentation. |

|

The hydraulic flange pump is produced locally. Procurement and installment of the pump contributes therefore to local economic growth and private sector development. How can they be sustained / enhanced? Link the company to the other potential buyers. |

6.8 Faiblesses/ inconvénients/ risques de la Technologie et moyens de les surmonter

| Faiblesses/ inconvénients/ risques du point de vue de l’exploitant des terres | Comment peuvent-ils être surmontés? |

|---|---|

| Social conflicts can occur during the distribution of water | The water in keeper/maintainer can be introduced by CDCs for the distribution of water. |

| Electricity cannot be produced by applying this technology. The slope and latitude of the location where the flange pump is installed is too small. |

| Faiblesses/ inconvénients/ risques du point de vue du compilateur ou d'une autre personne ressource clé | Comment peuvent-ils être surmontés? |

|---|---|

|

It is difficult to apply the technology without any external and financial support. |

Locally available materials should be used to reduce costs. |

| High level of technical knowledge is required for the establishment of the technology. | The technical knowledge should be transferred to the extension workers or local people to provide technical support in the future. |

|

This technology needs regular maintenance and the reservoir has to be properly cleaned after heavy rainfalls. |

The CDC should monitor maintenance activities by the caretaker as well as manage funds for maintenance costs. |

Liens et modules

Développer tout Réduire toutLiens

Aucun lien

Modules

Aucun module trouvé