Sugar Mill Wastewater Re-use for Irrigation [Philippines]

- Creation:

- Update:

- Compiler: Philippine Overview of Conservation Approaches and Technologies

- Editor: –

- Reviewers: Ursula Gaemperli, Alexandra Gavilano

technologies_1914 - Philippines

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

land user:

Perater, Jr. Feliciano

BUSCO Sugar Milling Co., Inc.

Philippines

SLM specialist:

Betonio Gloria

Department of Agriculture-Regional Field Office 10

Philippines

Raquid Jemar

Bureau of Soils and Water Management

Philippines

Adel Dianne Michelle

Bureau of Soils and Water Management

Philippines

Benavidez Ryan

Bureau of Soils and Water Management

Philippines

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Decision Support for Mainstreaming and Scaling out Sustainable Land Management (GEF-FAO / DS-SLM)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Bureau of Soils and Water Management (Bureau of Soils and Water Management) - Philippines1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Re-using of wastewater to support agricultural crop production, as well as, to help in environmental protection

2.2 Detailed description of the Technology

Description:

With increasing water demand and with the changing climate, water availability or water security is critical for the agriculture sector as this resource is a fundamental prerequisite in crop production. Various solutions are tapped and one of it is harnessing the potential of wastewater to be used for irrigation.

In the Philippines, one of the companies that utilize their treated wastewater is the BUSCO SUGAR MILLING CO., INC. located in Brgy. Butong, Quezon, Bukidnon. This treated wastewater is currently being re-used as irrigation water for the BUSCO Cane Farms areas, adjacent to the Mill Site covering 493 hectares and also to their leased adjacent 323-ha agricultural land.

Primarily, water as an industrial by-product is evident in both raw and refined sugar milling process. Volume of wastewater can be generated in the following sources or stations of sugar production: mill and cane handling station, process and/or boiling house, refinery house, and boiler house. In BUSCO, this wastewater all goes to their common wastewater treatment plant with a capacity of 100,000 volumetric meter and uses primary and secondary treatment.

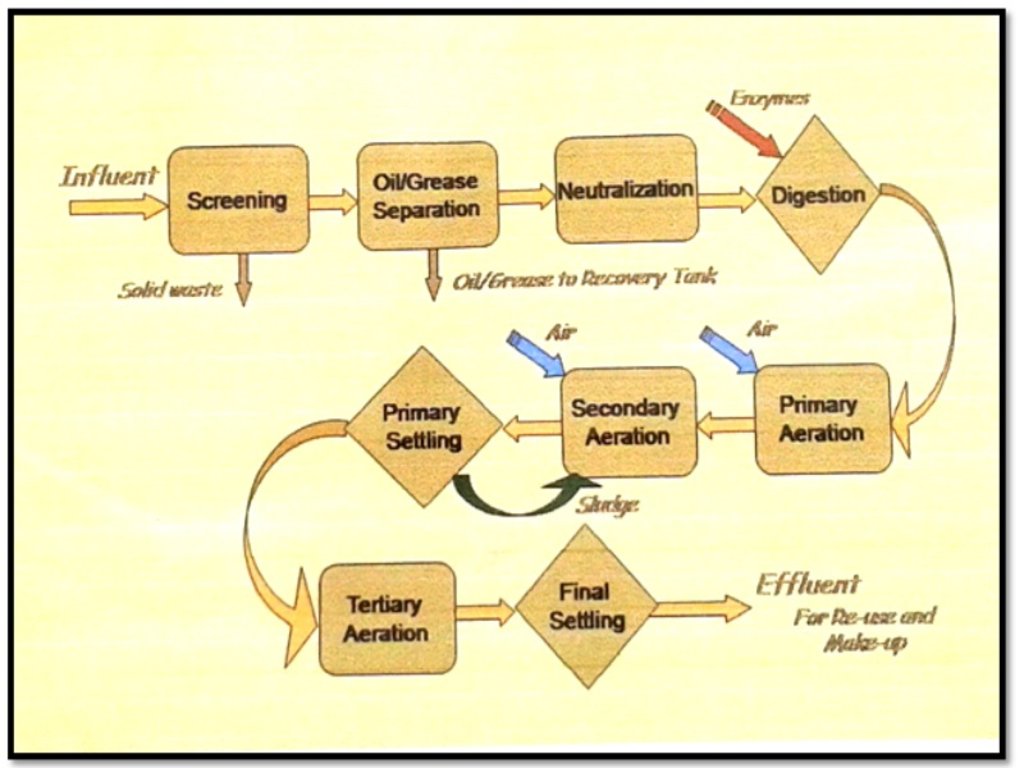

The treatment started with the screening of influent (waste water) which passes through a motor driven conveyor type system to separate the solid waste such as bagasse, bagacillo, silt/mud, sand, and trash canes. After the screening, it now proceeds to the oil/grease separation at the separator tank. Oil and grease that usually floats were removed via manual skimming. The next treatment process is called neutralization wherein the acidic influent (phof 4.0–5.0) will be added with chemicals (i.e. Lime and/or caustic soda) to neutralize and maintain the pH at 6.0–8.0. The neutralized wastewater is then impounded in a digester tank to undergo the process of digestion. Enzymes or bacteria are being introduced to enhanced biodegradation. Aeration is also applied to minimize suspended solids and scum formation. After this, wastewater is transferred to the lagoon for primary aeration process. Lagoons are belted with air diffuser membrane to produced fine bubbles and efficiently dissolved oxygen. Waste water was aerated and polluting substance decomposed. Further, the wastewater and the activated sludge are again mixed and aerated in the secondary and tertiary aeration where the polluting substances are further decomposed by oxidation and are absorbed. Finally, it will store in the final settling pond which will then be utilized for irrigation. The treated wastewater in BUSCO has a Biological Oxygen Demand (BOD) value of 50mg/L which is within the prescribed standard BOD parameters of wastewater quality to be used for crop irrigation (< 150mg/L).

Irrigation is done through the hand move spray irrigation system. It uses aluminum pipes backed by centrifugal pumps and spray nozzles. Aside from supporting the sugarcane water requirement particularly during dry months, the treated wastewater/effluent contains nutrients (Nitrogen- 2.5mg/L; Phosphorus- 3.8 mg/L; Potassium- 3.8 mg/L) which reduce fertilizer requirements of the sugarcane farm.

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Philippines

Region/ State/ Province:

Bukidnon

Further specification of location:

Butong, Quezon

Specify the spread of the Technology:

- evenly spread over an area

If precise area is not known, indicate approximate area covered:

- 1-10 km2

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- 10-50 years ago

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through land users' innovation

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- reduce, prevent, restore land degradation

- conserve ecosystem

- protect a watershed/ downstream areas – in combination with other Technologies

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

- Perennial (non-woody) cropping

Perennial (non-woody) cropping - Specify crops:

- sugar cane

Number of growing seasons per year:

- 2

3.4 Water supply

Water supply for the land on which the Technology is applied:

- mixed rainfed-irrigated

3.5 SLM group to which the Technology belongs

- waste management/ waste water management

3.6 SLM measures comprising the Technology

structural measures

- S8: Sanitation/ waste water structures

management measures

- M6: Waste management (recycling, re-use or reduce)

3.7 Main types of land degradation addressed by the Technology

water degradation

- Hp: decline of surface water quality

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- reduce land degradation

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

Wastewater treatment flow diagram of BUSCO. The treatment started with the screening of influent (waste water) which passes through a motor driven conveyor type system to separate the solid waste such as bagasse, bagacillo, silt/mud, sand, and trash canes. After the screening, it now proceeds to the oil/grease separation at the separator tank. Oil and grease that usually floats were removed via manual skimming. The next treatment process is called neutralization wherein the acidic influent (phof 4.0–5.0) will be added with chemicals (i.e. Lime and/or caustic soda) to neutralize and maintain the pH at 6.0–8.0. The neutralized wastewater is then impounded in a digester tank to undergo the process of digestion. Enzymes or bacteria are being introduced to enhanced biodegradation. Aeration is also applied to minimize suspended solids and scum formation. After this, wastewater is transferred to the lagoon for primary aeration process. Lagoons are belted with air diffuser membrane to produced fine bubbles and efficiently dissolved oxygen. Waste water was aerated and polluting substance decomposed. Further, the wastewater and the activated sludge are again mixed and aerated in the secondary and tertiary aeration where the polluting substances are further decomposed by oxidation and are absorbed. Finally, it will store in the final settling pond which will then be utilized for irrigation. The treated wastewater in BUSCO has a Biological Oxygen Demand (BOD) value of 50mg/L which is within the prescribed standard BOD parameters of wastewater quality to be used for crop irrigation (< 150mg/L).

Author:

BUSCO Sugar Milling Co.

4.2 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology unit

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Establishment of Waste Water Treatment Facilities |

Comments:

information not available.

4.4 Costs and inputs needed for establishment

Comments:

information not available. The Company bore 100% of the cost.

4.5 Maintenance/ recurrent activities

Comments:

information not available. The Company bore 100% of the cost.

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

Comments:

information not available. The Company bore 100% of the cost.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Agro-climatic zone

- humid

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- not relevant

5.3 Soils

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

Soils are not relevant for this Technology.

5.4 Water availability and quality

Availability of surface water:

good

Water quality (untreated):

good drinking water

Is water salinity a problem?

No

Is flooding of the area occurring?

No

5.5 Biodiversity

Species diversity:

- high

Habitat diversity:

- high

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- commercial/ market

Individuals or groups:

- groups/ community

- employee (company, government)

Level of mechanization:

- mechanized/ motorized

Gender:

- women

- men

Age of land users:

- middle-aged

- elderly

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- company

- individual, titled

Land use rights:

- leased

- individual

Water use rights:

- open access (unorganized)

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

Water availability and quality

irrigation water availability

Income and costs

expenses on agricultural inputs

Ecological impacts

Water cycle/ runoff

water quantity

Soil

nutrient cycling/ recharge

Climate and disaster risk reduction

drought impacts

6.2 Off-site impacts the Technology has shown

groundwater/ river pollution

6.5 Adoption of the Technology

- single cases/ experimental

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 91-100%

Comments:

The BUSCO Sugar Milling did it spontaneously without receiving payments. Reduction in the wastewater discharge fee since the BOD level of the treated wastewater is within the allowable range.

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

No

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

|

•Source of irrigation during water shortage on dry months •Additional source of nutrients thus decreasing the dependency on chemical fertilizers •Eliminate/Reduce wastewater discharge on water bodies thus reduction of water pollution •Complying to the environmental standards •Savings on wastewater discharge fee of the industrial company |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

|

Contribute in the elimination or reduction of water pollution in the near-by water bodies. Complying to the environmental standards. Water availability particularly during dry months. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| none |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| Investment cost. |

Optimizing the operation of the treatment facility; possible utilization of other wastes like sludge, mill ash, and mudpress into soil conditioner or fertilizer |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

- interviews with land users

When were the data compiled (in the field)?

05/10/2016

7.3 Links to relevant online information

Title/ description:

not available

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules