Sugar Mill Wastewater Re-use for Irrigation [菲律宾]

- 创建:

- 更新:

- 编制者: Philippine Overview of Conservation Approaches and Technologies

- 编辑者: –

- 审查者: Ursula Gaemperli, Alexandra Gavilano

technologies_1914 - 菲律宾

查看章节

全部展开 全部收起1. 一般信息

1.2 参与该技术评估和文件编制的资源人员和机构的联系方式

关键资源人

土地使用者:

Perater, Jr. Feliciano

BUSCO Sugar Milling Co., Inc.

菲律宾

SLM专业人员:

Betonio Gloria

Department of Agriculture-Regional Field Office 10

菲律宾

Raquid Jemar

Bureau of Soils and Water Management

菲律宾

Adel Dianne Michelle

Bureau of Soils and Water Management

菲律宾

Benavidez Ryan

Bureau of Soils and Water Management

菲律宾

有助于对技术进行记录/评估的项目名称(如相关)

Decision Support for Mainstreaming and Scaling out Sustainable Land Management (GEF-FAO / DS-SLM)有助于对技术进行记录/评估的机构名称(如相关)

Bureau of Soils and Water Management (Bureau of Soils and Water Management) - 菲律宾1.3 关于使用通过WOCAT记录的数据的条件

编制者和关键资源人员接受有关使用通过WOCAT记录数据的条件。:

是

1.4 所述技术的可持续性声明

这里所描述的技术在土地退化方面是否存在问题,导致无法被认为是一种可持续的土地管理技术?:

否

2. SLM技术的说明

2.1 技术简介

技术定义:

Re-using of wastewater to support agricultural crop production, as well as, to help in environmental protection

2.2 技术的详细说明

说明:

With increasing water demand and with the changing climate, water availability or water security is critical for the agriculture sector as this resource is a fundamental prerequisite in crop production. Various solutions are tapped and one of it is harnessing the potential of wastewater to be used for irrigation.

In the Philippines, one of the companies that utilize their treated wastewater is the BUSCO SUGAR MILLING CO., INC. located in Brgy. Butong, Quezon, Bukidnon. This treated wastewater is currently being re-used as irrigation water for the BUSCO Cane Farms areas, adjacent to the Mill Site covering 493 hectares and also to their leased adjacent 323-ha agricultural land.

Primarily, water as an industrial by-product is evident in both raw and refined sugar milling process. Volume of wastewater can be generated in the following sources or stations of sugar production: mill and cane handling station, process and/or boiling house, refinery house, and boiler house. In BUSCO, this wastewater all goes to their common wastewater treatment plant with a capacity of 100,000 volumetric meter and uses primary and secondary treatment.

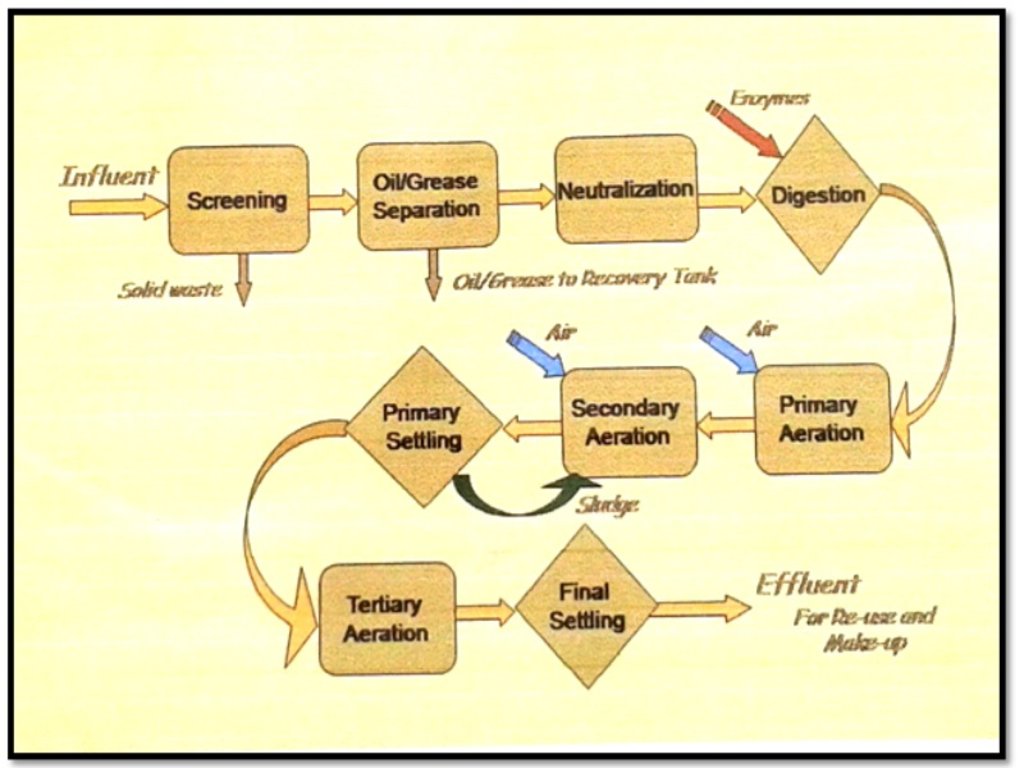

The treatment started with the screening of influent (waste water) which passes through a motor driven conveyor type system to separate the solid waste such as bagasse, bagacillo, silt/mud, sand, and trash canes. After the screening, it now proceeds to the oil/grease separation at the separator tank. Oil and grease that usually floats were removed via manual skimming. The next treatment process is called neutralization wherein the acidic influent (phof 4.0–5.0) will be added with chemicals (i.e. Lime and/or caustic soda) to neutralize and maintain the pH at 6.0–8.0. The neutralized wastewater is then impounded in a digester tank to undergo the process of digestion. Enzymes or bacteria are being introduced to enhanced biodegradation. Aeration is also applied to minimize suspended solids and scum formation. After this, wastewater is transferred to the lagoon for primary aeration process. Lagoons are belted with air diffuser membrane to produced fine bubbles and efficiently dissolved oxygen. Waste water was aerated and polluting substance decomposed. Further, the wastewater and the activated sludge are again mixed and aerated in the secondary and tertiary aeration where the polluting substances are further decomposed by oxidation and are absorbed. Finally, it will store in the final settling pond which will then be utilized for irrigation. The treated wastewater in BUSCO has a Biological Oxygen Demand (BOD) value of 50mg/L which is within the prescribed standard BOD parameters of wastewater quality to be used for crop irrigation (< 150mg/L).

Irrigation is done through the hand move spray irrigation system. It uses aluminum pipes backed by centrifugal pumps and spray nozzles. Aside from supporting the sugarcane water requirement particularly during dry months, the treated wastewater/effluent contains nutrients (Nitrogen- 2.5mg/L; Phosphorus- 3.8 mg/L; Potassium- 3.8 mg/L) which reduce fertilizer requirements of the sugarcane farm.

2.3 技术照片

2.5 已应用该技术的、本评估所涵盖的国家/地区/地点

国家:

菲律宾

区域/州/省:

Bukidnon

有关地点的进一步说明:

Butong, Quezon

具体说明该技术的分布:

- 均匀地分布在一个区域

如果不知道精确的区域,请注明大致覆盖的区域:

- 1-10 平方千米

Map

×2.6 实施日期

如果不知道确切的年份,请说明大概的日期:

- 10-50年前

2.7 技术介绍

详细说明该技术是如何引入的:

- 通过土地使用者的创新

3. SLM技术的分类

3.1 该技术的主要目的

- 减少、预防、恢复土地退化

- 保护生态系统

- 结合其他技术保护流域/下游区域

3.2 应用该技术的当前土地利用类型

农田

- 一年一作

- 多年一作(非木材)

多年生(非木质)作物 - 指定作物:

- 甘蔗

每年的生长季节数:

- 2

3.4 供水

该技术所应用土地的供水:

- 混合雨水灌溉

3.5 该技术所属的SLM组

- 废物管理/废水管理

3.6 包含该技术的可持续土地管理措施

结构措施

- S8:卫生/废水结构物

管理措施

- M6:废物管理(回收、再利用或减少)

3.7 该技术强调的主要土地退化类型

水质恶化

- Hp:地表水水质下降

3.8 防止、减少或恢复土地退化

具体数量名该技术与土地退化有关的目标:

- 减少土地退化

4. 技术规范、实施活动、投入和成本

4.1 该技术的技术图纸

技术规范(与技术图纸相关):

Wastewater treatment flow diagram of BUSCO. The treatment started with the screening of influent (waste water) which passes through a motor driven conveyor type system to separate the solid waste such as bagasse, bagacillo, silt/mud, sand, and trash canes. After the screening, it now proceeds to the oil/grease separation at the separator tank. Oil and grease that usually floats were removed via manual skimming. The next treatment process is called neutralization wherein the acidic influent (phof 4.0–5.0) will be added with chemicals (i.e. Lime and/or caustic soda) to neutralize and maintain the pH at 6.0–8.0. The neutralized wastewater is then impounded in a digester tank to undergo the process of digestion. Enzymes or bacteria are being introduced to enhanced biodegradation. Aeration is also applied to minimize suspended solids and scum formation. After this, wastewater is transferred to the lagoon for primary aeration process. Lagoons are belted with air diffuser membrane to produced fine bubbles and efficiently dissolved oxygen. Waste water was aerated and polluting substance decomposed. Further, the wastewater and the activated sludge are again mixed and aerated in the secondary and tertiary aeration where the polluting substances are further decomposed by oxidation and are absorbed. Finally, it will store in the final settling pond which will then be utilized for irrigation. The treated wastewater in BUSCO has a Biological Oxygen Demand (BOD) value of 50mg/L which is within the prescribed standard BOD parameters of wastewater quality to be used for crop irrigation (< 150mg/L).

作者:

BUSCO Sugar Milling Co.

4.2 有关投入和成本计算的一般信息

具体说明成本和投入是如何计算的:

- 每个技术单元

4.3 技术建立活动

| 活动 | 时间(季度) | |

|---|---|---|

| 1. | Establishment of Waste Water Treatment Facilities |

注释:

information not available.

4.4 技术建立所需要的费用和投入

注释:

information not available. The Company bore 100% of the cost.

4.5 维护/经常性活动

注释:

information not available. The Company bore 100% of the cost.

4.6 维护/经常性活动所需要的费用和投入(每年)

注释:

information not available. The Company bore 100% of the cost.

5. 自然和人文环境

5.1 气候

年降雨量

- < 250毫米

- 251-500毫米

- 501-750毫米

- 751-1,000毫米

- 1,001-1,500毫米

- 1,501-2,000毫米

- 2,001-3,000毫米

- 3,001-4,000毫米

- > 4,000毫米

农业气候带

- 潮湿的

5.2 地形

平均坡度:

- 水平(0-2%)

- 缓降(3-5%)

- 平缓(6-10%)

- 滚坡(11-15%)

- 崎岖(16-30%)

- 陡峭(31-60%)

- 非常陡峭(>60%)

地形:

- 高原/平原

- 山脊

- 山坡

- 山地斜坡

- 麓坡

- 谷底

垂直分布带:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

说明该技术是否专门应用于:

- 不相关

5.3 土壤

如有可能,附上完整的土壤描述或具体说明可用的信息,例如土壤类型、土壤酸碱度、阳离子交换能力、氮、盐度等。:

Soils are not relevant for this Technology.

5.4 水资源可用性和质量

地表水的可用性:

好

水质(未处理):

良好饮用水

水的盐度有问题吗?:

否

该区域正在发生洪水吗?:

否

5.5 生物多样性

物种多样性:

- 高

栖息地多样性:

- 高

5.6 应用该技术的土地使用者的特征

定栖或游牧:

- 定栖的

生产系统的市场定位:

- 商业/市场

个人或集体:

- 团体/社区

- 员工(公司、政府)

机械化水平:

- 机械化/电动

性别:

- 女人

- 男人

土地使用者的年龄:

- 中年人

- 老年人

5.7 应用该技术的土地使用者使用的平均土地面积

- < 0.5 公顷

- 0.5-1 公顷

- 1-2 公顷

- 2-5公顷

- 5-15公顷

- 15-50公顷

- 50-100公顷

- 100-500公顷

- 500-1,000公顷

- 1,000-10,000公顷

- > 10,000公顷

5.8 土地所有权、土地使用权和水使用权

土地所有权:

- 公司

- 个人,有命名

土地使用权:

- 租赁

- 个人

用水权:

- 自由进入(无组织)

5.9 进入服务和基础设施的通道

健康:

- 贫瘠

- 适度的

- 好

教育:

- 贫瘠

- 适度的

- 好

技术援助:

- 贫瘠

- 适度的

- 好

就业(例如非农):

- 贫瘠

- 适度的

- 好

市场:

- 贫瘠

- 适度的

- 好

能源:

- 贫瘠

- 适度的

- 好

道路和交通:

- 贫瘠

- 适度的

- 好

饮用水和卫生设施:

- 贫瘠

- 适度的

- 好

金融服务:

- 贫瘠

- 适度的

- 好

6. 影响和结论性说明

6.1 该技术的现场影响

社会经济效应

生产

作物生产

水资源可用性和质量

灌溉用水的可用性

收入和成本

农业投入费用

生态影响

水循环/径流

水量

土壤

养分循环/补给

减少气候和灾害风险

干旱影响

6.2 该技术的场外影响已经显现

地下水/河流污染

6.5 技术采用

- 单例/实验

在所有采用这项技术的人当中,有多少人是自发的,即未获得任何物质奖励/付款?:

- 91-100%

注释:

The BUSCO Sugar Milling did it spontaneously without receiving payments. Reduction in the wastewater discharge fee since the BOD level of the treated wastewater is within the allowable range.

6.6 适应

最近是否对该技术进行了修改以适应不断变化的条件?:

否

6.7 该技术的优点/长处/机会

| 土地使用者眼中的长处/优势/机会 |

|---|

|

•Source of irrigation during water shortage on dry months •Additional source of nutrients thus decreasing the dependency on chemical fertilizers •Eliminate/Reduce wastewater discharge on water bodies thus reduction of water pollution •Complying to the environmental standards •Savings on wastewater discharge fee of the industrial company |

| 编制者或其他关键资源人员认为的长处/优势/机会 |

|---|

|

Contribute in the elimination or reduction of water pollution in the near-by water bodies. Complying to the environmental standards. Water availability particularly during dry months. |

6.8 技术的弱点/缺点/风险及其克服方法

| 土地使用者认为的弱点/缺点/风险 | 如何克服它们? |

|---|---|

| none |

| 编制者或其他关键资源人员认为的弱点/缺点/风险 | 如何克服它们? |

|---|---|

| Investment cost. |

Optimizing the operation of the treatment facility; possible utilization of other wastes like sludge, mill ash, and mudpress into soil conditioner or fertilizer |

7. 参考和链接

7.1 信息的方法/来源

- 实地考察、实地调查

- 与土地使用者的访谈

(现场)数据是什么时候汇编的?:

05/10/2016

7.3 链接到网络上的相关信息

标题/说明:

not available

链接和模块

全部展开 全部收起链接

无链接

模块

无模块