Indigenous Micro Organism (IMO) use in Natural Pig Farming [Uganda]

- Creation:

- Update:

- Compiler: JOSELINE KASHAGAMA

- Editor: Kamugisha Rick Nelson

- Reviewers: Nicole Harari, Udo Höggel, Donia Mühlematter

Epunu

technologies_3366 - Uganda

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

land user:

Mujuruzi Benjamin

+256 775 392532 / +256 702 560904

Kegra Green Africa Farm (Kegra Farm)

P.O BOX 186 Keirere Village Bushenyi District - Uganda

Uganda

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Scaling-up SLM practices by smallholder farmers (IFAD)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

National Agricultural Research Organisation (NARO) - Uganda1.3 Conditions regarding the use of data documented through WOCAT

When were the data compiled (in the field)?

24/01/2018

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Indigenous Micro Organisms (IMO) are homemade microbe mixtures which foster rapid anaerobic digestion of waste to create and maintain a healthy deep bed litter flooring leaving behind a fertilizer rich material whilst ensure no smells or flies. The microbe mixtures are produced by fermenting natural plants with sugar.

2.2 Detailed description of the Technology

Description:

Natural pig farming is a non-polluting system of raising healthy pigs that uses the Indigenous Micro Organisms (IMO) in the sty’s deep bed litter floor to rapidly decompose pig waste.

Indigenous Micro Organisms (IMO) is a homemade microbe mixture that fosters rapid anaerobic digestion of waste. It is produced by fermenting plant materials like sweet potatoes or rice with sugar.

Piggery is a profitable enterprise but there is a belief that pigs are dirty animals. But if they are well looked after, they are clean farm animals. The use of Indigenous Micro - Organisms (IMO) in piggery creates and maintains an aesthetic and sanitized deep bed litter floor. The micro-organisms in the IMO mixture help in breaking down and convert the fecal matter rapidly into an unharmful product leaving the farmer with a rich fertilizer material whilst ensuring an odorless environment that attracts no flies. Many pig keepers are now adopting the use of IMO to improve piggery.

The IMO is applied to wood dust and the micro-organisms digest the cellulose in wood dust. The bedding including the IMO is frequently turned to mix it with the pig excrete. The IMO solution is sprayed to the bedding once a week which ensures a high level of micro-organism activity thus keeping the bedding healthy and free from smell.

The following are the materials needed to make IMO:

-sweet potatoes

-sugar

-water

-mineral lick (crude salt)

-saucepan

-a 100-litre container

The IMO production process requires boiling 20kg of sweet potatoes with crude salt (200g) until the potatoes are well cooked. The cooked potatoes are mashed into a paste, placed into a polythene bag and buried in the ground, about two 5cm deep, in a shaded area, preferably under trees to protect it from direct sunlight. The mixture is buried for 1 week. After this period, the mixture is unearthed and for every 2kg of it 500g of sugar are added and mixed. The mixture is kept in a plastic bucket and left to stand for another full week. After this time, the mixture would have changed color to black without a smell. To multiply the mixture, add 1kg of IMO to 200 ltrs of water and keep for two days. You may add some brown sugar to make the multiplication process quick. After 2 days the solution is ready for use.

The advantages of the IMO are that the pigs’ excrements become odorless, clean and dry that you literally don’t even have to clean it out. The micro-organisms in the wood dust help in breaking down fecal matter rapidly, leading to the elimination of odor. The inputs are made from natural materials, which are not only safe for the environment, but actually invigorate and rehabilitate the ecology. In terms of disease control the conditions inside the sty do not favor survival of disease causing pathogens due to the presence of IMOs which literally feed on the pathogens. The system is non-labour intensive as sties don’t require daily, weekly or even monthly mucking out. Production of high quality organic fertilizer as the decomposed litter will be removed from the sty after 9 months and used as manure. This manure is rich in IMO and is useful in improving the soil health than chemical fertilizers.

The disadvantages of the technology are that the sweetness of the IMO solution attracts the pigs to lick the wood dust which can led to the ingestion of the bedding material including endoparasite eggs. It is therefore, recommended that the farmer controls such potential infections through regular deworming of the animals.

2.3 Photos of the Technology

2.4 Videos of the Technology

Date:

24/1/2018

Location:

Bushenyi District, South Western Uganda

Name of videographer:

Joseline Kashagama

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Uganda

Region/ State/ Province:

Western Uganda

Further specification of location:

Keirere Village, Bushenyi Town Council ,Nyakabirizi Sub county

Comments:

Geo Coordinates (00.53345, 030.19235)

Map

×2.6 Date of implementation

Indicate year of implementation:

2016

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

Comments (type of project, etc.):

The land user was introduced to the technology through a study tour to the United States of America

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- create beneficial economic impact

- Control disease out break, source of organic manure

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

- Tree and shrub cropping

Main crops (cash and food crops):

Cabbages, Passion fruits, Coffee

Grazing land

Extensive grazing land:

- Ranching

Intensive grazing/ fodder production:

- Cut-and-carry/ zero grazing

Main animal species and products:

Pigs (Large white and Hampshire breeds)

3.3 Further information about land use

Water supply for the land on which the Technology is applied:

- mixed rainfed-irrigated

Comments:

The farmland has a swamp which is the main source of water

Number of growing seasons per year:

- 2

Specify:

Two rainy seasons

Livestock density (if relevant):

200 pigs per 0.5 acre

3.4 SLM group to which the Technology belongs

- integrated crop-livestock management

- integrated soil fertility management

- waste management/ waste water management

3.5 Spread of the Technology

Specify the spread of the Technology:

- applied at specific points/ concentrated on a small area

Comments:

The pigs are confined in the stalls and the other land is used for cropping.

3.6 SLM measures comprising the Technology

agronomic measures

- A2: Organic matter/ soil fertility

structural measures

- S8: Sanitation/ waste water structures

- S9: Shelters for plants and animals

management measures

- M2: Change of management/ intensity level

- M6: Waste management (recycling, re-use or reduce)

3.7 Main types of land degradation addressed by the Technology

chemical soil deterioration

- Cn: fertility decline and reduced organic matter content (not caused by erosion)

biological degradation

- Bl: loss of soil life

- Bp: increase of pests/ diseases, loss of predators

Comments:

Bp: micro-organisms help break down fecal matter rapidly leaving a fertilizer rich material whilst ensure no smells or flies. They produce various materials such as anti-biotic substances, enzymes and lactic acids which suppress various diseases and promote chemical reaction in the soil.

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

Comments:

The decomposed litter is used as manure (Organic fertilizer). The manure is rich in Indigenous Micro Organisms and is useful in improving the soil health.

4. Technical specifications, implementation activities, inputs, and costs

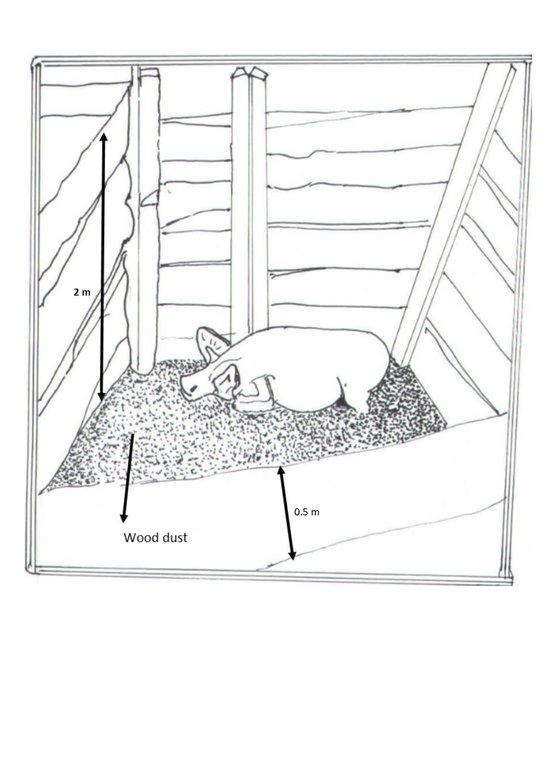

4.1 Technical drawing of the Technology

4.2 Technical specifications/ explanations of technical drawing

The sty is 50 m by 40 m and 1.5 m deep below the ground. Materials needed to construct included bricks to build the wall up to 1.2 meters high, wooden poles, roofing sheets (some transparent), welded wire mesh for the upper potion to allow proper ventilation. The floor is covered with wood dust to a depth of about 0.5 m, mixed with IMO solution while tapped water provided.

4.3 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology unit

Specify unit:

Piggery Unit

Specify currency used for cost calculations:

- US Dollars

Indicate exchange rate from USD to local currency (if relevant): 1 USD =:

3600.0

Indicate average wage cost of hired labour per day:

1.389

4.4 Establishment activities

| Activity | Type of measure | Timing | |

|---|---|---|---|

| 1. | Plan and make the budget | Management | Monthly |

| 2. | Purchase of the IMO ingredients | Management | Monthly |

| 3. | Prepare the mixture | Management | Monthly |

| 4. | Storage of the mixture | Management | Monthly |

4.5 Costs and inputs needed for establishment

If possible, break down the costs of establishment according to the following table, specifying inputs and costs per input. If you are unable to break down the costs, give an estimation of the total costs of establishing the Technology:

159.12

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour | Wage | 1.0 | 111.1 | 111.1 | 100.0 |

| Equipment | Potatoes | Kg | 20.0 | 0.417 | 8.34 | 100.0 |

| Equipment | Water | Litres | 400.0 | 0.028 | 11.2 | 100.0 |

| Equipment | Sauce pan | piece | 1.0 | 8.33 | 8.33 | 100.0 |

| Equipment | Sugar | kg | 5.0 | 0.972 | 4.86 | 100.0 |

| Equipment | Salt | kg | 2.5 | 0.56 | 1.4 | 100.0 |

| Equipment | 100 Litre Contianer / drum | piece | 1.0 | 13.89 | 13.89 | 100.0 |

| Total costs for establishment of the Technology | 159.12 | |||||

Comments:

The land user bore all the costs. Some of the costs are bore only at the initial establishment of the technology thus the costs vary with time

4.6 Maintenance/ recurrent activities

| Activity | Type of measure | Timing/ frequency | |

|---|---|---|---|

| 1. | Changing of wood shavings / dust | Management | After 9 months |

| 2. | Turning of wood shavings / dust | Management | Everyday |

| 3. | Provision of feeds | Management | Everyday |

4.7 Costs and inputs needed for maintenance/ recurrent activities (per year)

If possible, break down the costs of maintenance according to the following table, specifying inputs and costs per input. If you are unable to break down the costs, give an estimation of the total costs of maintaining the Technology:

1509.66

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour | Month | 12.0 | 111.1 | 1333.2 | 100.0 |

| Equipment | Wood shavings / dust | Bags | 200.0 | 0.139 | 27.8 | 100.0 |

| Equipment | Sweet potatoes | kg | 12.0 | 0.417 | 5.0 | 100.0 |

| Fertilizers and biocides | Mineral licks | Kg | 100.0 | 0.278 | 27.8 | 100.0 |

| Fertilizers and biocides | Feeds | Kg | 100.0 | 0.19 | 19.0 | 100.0 |

| Fertilizers and biocides | Sugar | kg | 30.0 | 0.97 | 29.1 | 100.0 |

| Fertilizers and biocides | Salt | kg | 10.0 | 0.056 | 0.56 | 100.0 |

| Fertilizers and biocides | Water | Litres | 2400.0 | 0.028 | 67.2 | 100.0 |

| Total costs for maintenance of the Technology | 1509.66 | |||||

Comments:

The maintenance costs have been calculated on the annual basis. The price of water has been estimated since the land user uses free water piped from the swamp.

4.8 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Initial pig sty establishment costs and regular deworming costs.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specify average annual rainfall (if known), in mm:

1233.00

Specifications/ comments on rainfall:

The driest month is July with 35 mm of rain. The greatest amount of precipitation occurs in November with an average of 154 mm.

Indicate the name of the reference meteorological station considered:

Bushenyi District Local Government Report 2018. (https://www.bushenyi.go.ug/lg/population-culture)

Agro-climatic zone

- humid

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- not relevant

Comments and further specifications on topography:

Bushenyi district is a low lying plateau with undulating hills.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Soil texture (> 20 cm below surface):

- medium (loamy, silty)

Topsoil organic matter:

- medium (1-3%)

5.4 Water availability and quality

Ground water table:

on surface

Availability of surface water:

good

Water quality (untreated):

for agricultural use only (irrigation)

Is water salinity a problem?

No

Is flooding of the area occurring?

No

Comments and further specifications on water quality and quantity:

Water quality is sometimes affected by the run off water that collects in the swamp.

5.5 Biodiversity

Species diversity:

- low

Habitat diversity:

- low

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- commercial/ market

Off-farm income:

- > 50% of all income

Relative level of wealth:

- average

Individuals or groups:

- individual/ household

Level of mechanization:

- manual work

Gender:

- men

Age of land users:

- middle-aged

5.7 Average area of land owned or leased by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, titled

Land use rights:

- individual

Water use rights:

- individual

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

Comments/ specify:

Micro-organisms help break down fecal matter rapidly leaving a fertilizer rich material which improves crop production.

crop quality

fodder production

fodder quality

animal production

Quantity before SLM:

Less weight

Quantity after SLM:

More weight gain

Comments/ specify:

The micro organisms in the IMO solution rapidly break down the fecal matter into environmental friendly matter rather than wet slurry which promotes bad smell and flies hence controlled pests and disease attacks

risk of production failure

Comments/ specify:

Indigenous Micro Organisms are a source of organic manure that improves the soil health.

land management

Water availability and quality

water availability for livestock

Comments/ specify:

Rain water is harvested from the animal shed and stored in the reservoir.

Income and costs

expenses on agricultural inputs

Comments/ specify:

Reduced feed costs and labour since there's no regular cleaning of the sty and only one permanent worker is employed at the farm to feed the pigs.

farm income

Comments/ specify:

Reduced maintenance costs and high piggery productivity.

diversity of income sources

Comments/ specify:

Incomes from sale of the organic manure and crops.

economic disparities

Comments/ specify:

Increased incomes.

workload

Quantity before SLM:

3 full time labourers

Quantity after SLM:

1 full time labourer

Comments/ specify:

Less since there's no regular cleaning of the sty and only one permanent worker is employed at the farm to feed the pigs.

Socio-cultural impacts

food security/ self-sufficiency

Comments/ specify:

Increased pigs and crop production.

land use/ water rights

Comments/ specify:

Improved land use since more land has been put into use for piggery and crop production (Coffee, seedling bed and Cabbages).

recreational opportunities

Comments/ specify:

The farm is being used for agricultural related study tours.

community institutions

Comments/ specify:

Community Institutions come for study tours regarding piggery and IMO use.

national institutions

Comments/ specify:

Local Government institutions bring farmers for study tours at the Farm.

SLM/ land degradation knowledge

Comments/ specify:

Land use and environmental study tours

Ecological impacts

Soil

soil accumulation

Comments/ specify:

Use of organic manure

nutrient cycling/ recharge

Comments/ specify:

Use of organic manure

6.2 Off-site impacts the Technology has shown

groundwater/ river pollution

Comments/ specify:

Non-polluting litter disposal.

damage on neighbours' fields

Comments/ specify:

The pigs are paddocked.

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

negative

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

positive

Long-term returns:

very positive

Comments:

The establishment costs are very high compared to the benefits gained in the short run but the benefits increase over time.

6.5 Adoption of the Technology

- 1-10%

If available, quantify (no. of households and/ or area covered):

10 households in the village.

Of all those who have adopted the Technology, how many have did so spontaneously, i.e. without receiving any material incentives/ payments?

- 90-100%

Comments:

Private initiatives.

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

No

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| It's a clean system of piggery using IMOs which create a healthy environment since it eliminates bad smell. |

| The wood dust can cheaply be obtained locally. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| The technology is environmentally friendly as it does not produce bad smell which is common in normal piggery enterprises. |

| The technology is not labour demanding since only one full time labourer is employed. |

| The saw dust once removed from the sty is used as manure which improves the soil health hence increases crop production. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| The technology is relatively expensive to establish |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| High initial costs to start the technology | Once established, it can be used for a very long time |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

3

- interviews with land users

3

- compilation from reports and other existing documentation

4

7.3 Links to relevant information which is available online

URL:

https://www.scribd.com/doc/54536534/Organic-Piggery-in-Uganda-IMO

Title/ description:

Natural Pig farming

URL:

https://www.naturalpigfarming.com/microorganismuse.htm

URL:

https://insteading.com/blog/indigenous-microorganisms-imo/

Title/ description:

Bushenyi District Local Government

URL:

https://www.bushenyi.go.ug/lg/population-culture

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules