Recycling rice husks in Sri Lanka as a biochar-based slow-release urea fertilizer [Sri Lanka]

- Creation:

- Update:

- Compiler: Head Soil Science

- Editor: –

- Reviewers: William Critchley, Rima Mekdaschi Studer

“anguru kata” pohora

technologies_6184 - Sri Lanka

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

SLM specialist:

Dissanayaka Lakmini

Coconut Research Institute

Sri Lanka

land user:

Senarathna Renuka

Sri Lanka

land user:

Nandasena Lekam Ralalage

Sri Lanka

land user:

Kirihamige Vimalawathi

Sri Lanka

co-compiler:

Dharmakeerthi Saman

University of Peradeniya

Sri Lanka

co-compiler:

Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Faculty of Agriculture, University of Peradeniya, Sri Lanka (AGRI.PDN) - Sri Lanka1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

Comments:

Urea is the type of nitrogen fertilizer available in Sri Lanka. Urea is readily soluble in water and hydrolyses to ammonia which in turn is converted to nitrate by microorganisms. Nitrate can be lost by leaching, volatilization, and denitrification in paddy fields. However, slow release fertilizer (SRF) releases the N in urea slowly to the soil and allows efficient uptake by the crop at the right time. Hence, it reduces the negative environmental impacts associated with N losses and also maintains adequate productivity in rice cultivation. In addition, this technology reduces CO2 emissions from rice husks to the atmosphere.

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

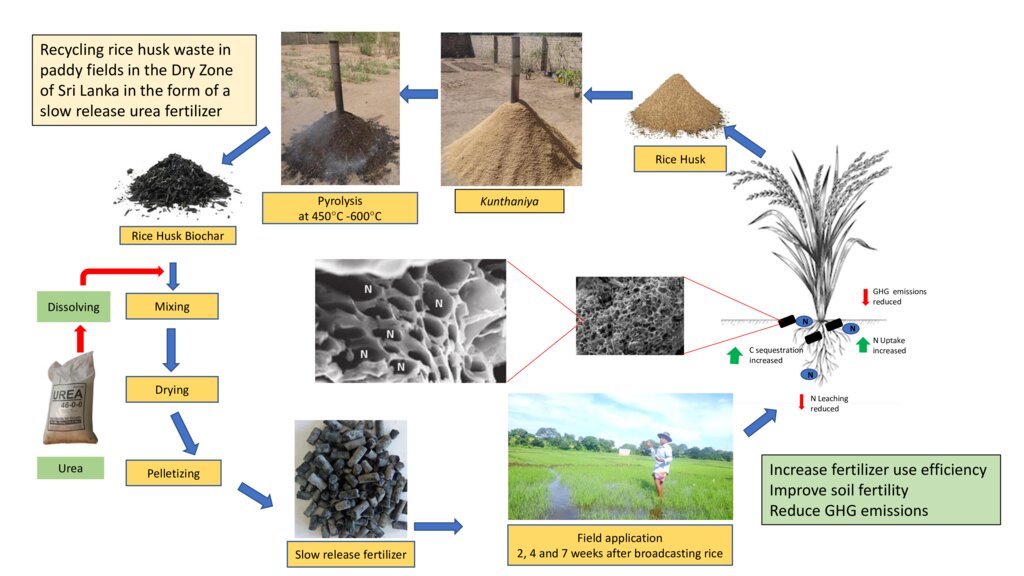

Rice husks, a waste product generated in rice mills, can release its carbon as a greenhouse gas (GHG) to the atmosphere through burning or decomposition. Converting it into biochar and intercalating (filled) with urea can produce a slow-release nitrogen (N) fertiliser that improves N-use efficiency while minimizing GHG emissions.

2.2 Detailed description of the Technology

Description:

Rice husks are often considered as a waste, and its carbon is released to the atmosphere as carbon dioxide (CO2) which is a greenhouse gas (GHG) through either decomposition or burning as a biofuel. However, rice husks can be converted into biochar – where its carbon is stable - with a large number of micro and sub-micron size pores in a honeycomb-like structure. Rice husk biochar was produced using an improved batch pyrolizer, “Kunthaniya”, at a temperature of between 450°C and 650°C. Pore spaces in rice husk biochar can be intercalated (filled) with urea and then, slow-release fertilizer (SRF) pellets can be produced through the use of a suitable biodegradable binder. This SRF has found to be more efficient in improving the N-use efficiency, hence the urea requirement of paddy fields in Sri Lanka can be reduced by about 25%, further contributing to environment sustainability. It has been well documented that biochar can improve soil physical, chemical and biological properties in a sustainable manner. This process is a contribution to creative recycling of agricultural waste.

The SRF technology was evaluated against current farmer practice in rice cultivated area in Mahakanumulla village, Anuradhapura district, Sri Lanka. The area belongs to the Dry Zone of Sri Lanka (mean annual rainfall <1750mm). Rice is cultivated during two seasons, yala (May-September) and maha (December – February): the yala season is generally drier. Farmers rely on irrigation water supplied from a small village tank. The SRF was transported to farmers’ fields and applied at 2 weeks (@ 100 kg/ha), at 4 weeks (@ 170 kg/ha) and 7 weeks (@ 145 kg/ha) after direct seeding.

Farmers indicated that the granule size was large and light, hence they had some concerns about even distribution of fertilizer. They perceive that plants receive N slowly compared to granular urea - suggesting the slow releasing nature of the new technology. They did not observe any yield difference. Obtaining rice husks in large quantities from rice mills to produce biochar can sometimes be difficult in some areas of the country due to competition for use in the poultry industry. Some farmers may be discouraged to implement this technology due to lack of knowledge: this can be overcome through extension officers operating at field level.

This new technology qualifies as a sustainable land management practice in number of ways. First it increases N-use efficiency in paddy fields, second it reduces the urea requirement by 25% while sustaining productivity, third it recycles agricultural wastes in paddy fields, fourth, repeated application of SRF improves soil fertility through rice husk biochar, and finally it reduces GHG emissions.

2.3 Photos of the Technology

General remarks regarding photos:

The photos show the application of SRF on farmers fields and the physical nature of the SRF.

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Sri Lanka

Region/ State/ Province:

North Central Province

Further specification of location:

Mahakanumulla village, Thirappane

Specify the spread of the Technology:

- applied at specific points/ concentrated on a small area

Is/are the technology site(s) located in a permanently protected area?

No

Map

×2.6 Date of implementation

Indicate year of implementation:

2021

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- during experiments/ research

- through projects/ external interventions

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- reduce, prevent, restore land degradation

- mitigate climate change and its impacts

- create beneficial economic impact

- create beneficial social impact

3.2 Current land use type(s) where the Technology is applied

Land use mixed within the same land unit:

No

Cropland

- Annual cropping

Annual cropping - Specify crops:

- cereals - rice (wetland)

Annual cropping system:

Continuous wetland rice

Number of growing seasons per year:

- 2

Specify:

yala and maha seasons

Is intercropping practiced?

No

Is crop rotation practiced?

No

3.3 Has land use changed due to the implementation of the Technology?

Has land use changed due to the implementation of the Technology?

- No (Continue with question 3.4)

3.4 Water supply

Water supply for the land on which the Technology is applied:

- mixed rainfed-irrigated

Comments:

Rice farmers in Mahakanumulla mainly depend on irrigation water supplied from a small tank located above the rice fields. However, farmers do not irrigate rice fields if they receive adequate rainfall. But, increasingly, farmers depend on irrigation water due to decreasing rainfall during the growing season.

3.5 SLM group to which the Technology belongs

- integrated soil fertility management

- waste management/ waste water management

3.6 SLM measures comprising the Technology

agronomic measures

- A2: Organic matter/ soil fertility

- A3: Soil surface treatment

- A6: Residue management

A3: Differentiate tillage systems:

A 3.3: Full tillage (< 30% soil cover)

A6: Specify residue management:

A 6.4: retained

Comments:

Application of SRF to the crop at the required growth stages to improve the soil fertility and, thus, crop productivity.

3.7 Main types of land degradation addressed by the Technology

chemical soil deterioration

- Cn: fertility decline and reduced organic matter content (not caused by erosion)

- Cp: soil pollution

water degradation

- Hp: decline of surface water quality

- Hq: decline of groundwater quality

Comments:

The SRF technology improves soil fertility by reducing nitrogen (N) loss from the soil due to leaching. And it also reduces accumulation of excess N in surface and ground water bodies, preventing water pollution.

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- reduce land degradation

Comments:

The use of conventional N fertilizers to cultivate rice for a long period of time causes higher N losses from the soil and results a potential risk of environment pollution. Application as an SRF reduces the losses of N from the soil, increases crop nutrient uptake and increases crop productivity. The reduced losses mitigate soil fertility degradation and deterioration of water quality.

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

Production of SRF: Rice husks were pyrolyzed using a locally modified “Kunthaniya” (a batch pyrolyser) to produce rice husk biochar. The temperature of the pyrolyser was around 450°C to 600°C with a heating rate of less than 20°C per hour. Pore structures were saturated using a urea solution through capillary action. The urea-intercalated rice husk biochar is then mixed with a biodegradable organic substance and pelletized using a medium scale pelletizer and dried to increase its mechanical properties such as resistance to disintegration and shear forces.

Field Experiment : Five paddy farmers were randomly selected from the command area of a small tank in the Mahakanumulla Village Tank Cascade System in the Dry Zone of Sri Lanka. The produced SRF was applied at a rate of 75% of recommended N in three split applications. Yields in SRF applied areas were compared against the current farmer practice. Experimental evidence showed that there is no yield reduction despite the reduction of nitrogen input into their fields.

Author:

H.P.G.T.N. Kulasinghe

4.2 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology area

Indicate size and area unit:

1ha

other/ national currency (specify):

LKR

If relevant, indicate exchange rate from USD to local currency (e.g. 1 USD = 79.9 Brazilian Real): 1 USD =:

275.0

Indicate average wage cost of hired labour per day:

1500

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Collection of paddy husk from rice milling stations | 2 months before cultivation |

| 2. | Pyrolyzing of paddy husk using a pyrolizer or a kunthani | 6 weeks before cultivation |

| 3. | Mixing with urea, ERP and other ingredients and pelletizing | 4 weeks before cultivation |

| 4. | Drying the pellets (SRF) | 2 weeks before cultivation |

| 5. | Packing and transporting SRF to the rice fields | 1 week before cultivation |

Comments:

One of the major raw materials to produce SRF is rice husks and it can be supplied from rice milling stations, generally available year-round. However, there is competition for rice husks in the market because of demand from the poultry industry. Hence, finding rice husks is sometimes difficult in some areas of the country.

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Manufacturing SRF | Labour days | 2.5 | 1500.0 | 3750.0 | |

| Fertilizers and biocides | Urea | kg | 200.0 | 270.0 | 54000.0 | |

| Construction material | Binding materials 1 | kg | 10.0 | 25.0 | 250.0 | |

| Construction material | Binding materials 2 | kg | 10.0 | 250.0 | 2500.0 | |

| Construction material | Rice husk biochar | kg | 200.0 | 50.0 | 10000.0 | |

| Total costs for establishment of the Technology | 70500.0 | |||||

| Total costs for establishment of the Technology in USD | 256.36 | |||||

If land user bore less than 100% of costs, indicate who covered the remaining costs:

Project funded by the National Research Council of Sri Lanka (Grant No. : NRC TO-16/07)

Comments:

SRF was given to the farmer, free, for application. The cost of SRF was borne by the project funded by the National Research Council of Sri Lanka (Grant No. : NRC TO-16/07)

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Application of first dose of SRF | 2 weeks after direct seeding of rice |

| 2. | Application of second dose of SRF | 4 weeks after direct seeding of rice |

| 3. | Application of third dose of SRF | 7 weeks after direct seeding of rice |

Comments:

Application of correct amount of SRF at the correct growth stage of the rice crop is important for efficient uptake of N to the crop and reduce losses.

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour for SRF application | Labour days | 3.0 | 1500.0 | 4500.0 | 100.0 |

| Total costs for maintenance of the Technology | 4500.0 | |||||

| Total costs for maintenance of the Technology in USD | 16.36 | |||||

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Labour availability and finding raw materials are the major factors that affect the cost.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specify average annual rainfall (if known), in mm:

1400.00

Specifications/ comments on rainfall:

The Mahakanumulla area receives monsoon rainfall during two distinct seasons, namely yala (May – September) and maha (December – February), hence a bimodal rainfall pattern can be observed. The highest amount of rainfall is received during the maha season, in which most of the rainfall comes from the North-eastern monsoonal rains. Lesser rainfall is received from the South-west monsoonal rains, during the yala season. Hence prolonged dry periods are observed during the yala season. Other than that, this area receives rainfall from two inter-monsoonal rains (March-April and October-November).

Indicate the name of the reference meteorological station considered:

Mahailuppallama, Anuradhapura

Agro-climatic zone

- semi-arid

Recorded minimum and maximum temperatures in the area are 20.8°C and 29.5°C respectively

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- not relevant

Comments and further specifications on topography:

The altitude of the area is 112m. An undulating pattern of topography is a distinct feature of this landscape. The rice is cultivated mainly in the valley area of the catena and other upland crops are cultivated in the crest area of the catena.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- coarse/ light (sandy)

Soil texture (> 20 cm below surface):

- medium (loamy, silty)

Topsoil organic matter:

- medium (1-3%)

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

Rice growing soils of the Mahakanumulla area are classified as Alfisols (Typic endoaquaalf). The soil is poorly drained. The pH of the soil is in the neutral range (6.05-7.23). Soil EC (55.5-143.0 µs/cm, 1:2.5 soil:water) values did not show any occurrence of soil salinity. Av. P content of the soil (Olsen P) was low for rice growth (<5 mg/kg) and ranged from 2.9-3.5 mg/kg. Av. K content of the soils was medium to high for rice growth and ranged from 61.3-99 mg/kg.

5.4 Water availability and quality

Ground water table:

< 5 m

Availability of surface water:

good

Water quality (untreated):

for agricultural use only (irrigation)

Water quality refers to:

both ground and surface water

Is water salinity a problem?

No

Is flooding of the area occurring?

No

Comments and further specifications on water quality and quantity:

The amount of water supplied through the irrigation is limited during the dry season (yala). The water quality is affected by soil macro-nutrients (N, P, K) added as fertilizers to the soil. Due to the undulating topography of the landscape, those soil nutrients can wash-off from higher positions to lower positions due to surface runoff and leaching into the ground water and accumulating in the water bodies in the lower positions of the catena.

5.5 Biodiversity

Species diversity:

- medium

Habitat diversity:

- medium

Comments and further specifications on biodiversity:

Number of different tree species, wild animals, birds, insects and aquatic life can be observed around Mahakanumulla village. Forest patches can be identified mostly around the small tank, and those areas are habitats for multiple wild animals and birds.

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- mixed (subsistence/ commercial)

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- poor

Individuals or groups:

- individual/ household

Level of mechanization:

- manual work

- mechanized/ motorized

Gender:

- women

- men

Age of land users:

- middle-aged

Indicate other relevant characteristics of the land users:

Most of the land users are dependent on full time rice farming. But some land users use rice farming as a secondary source of income and do other jobs in the city. Most of the younger generation in the village are migrating for jobs in the cities.

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

Comments:

Rice is cultivated over a large area. However, single farmer manage relatively small fields (0.5-1 ha or 2-5 ha). The fields managed by farmers are located adjacent to each other.

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, titled

Land use rights:

- individual

Water use rights:

- communal (organized)

Are land use rights based on a traditional legal system?

No

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

Comments:

The villagers of Mahaknumulla have access for most of the resources like infrastructure and energy/electricity/fuel. But most of the villagers/landusers complain about technical assistant/support for agricultural practices, finding markets for their produce and availability of good quality drinking water. The villagers go to nearby shops to buy day-to-day needs, but they have to go to the town, which is 8-10km away, for other services such as health and financial services.

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

Quantity before SLM:

6.5 t/ha (two seasons)

Quantity after SLM:

6.9 t/ha (two seasons)

Comments/ specify:

Although farmers could not observe a yield increase , experimental evidence suggests upto10% yield increase compared to farmer fertilizer management. A decrease in yield however not observed by farmers despite 25% reduction in N input. The above figures are for average of five farmers over two seasons.

crop quality

risk of production failure

product diversity

production area

land management

Water availability and quality

drinking water availability

drinking water quality

water availability for livestock

water quality for livestock

irrigation water availability

irrigation water quality

demand for irrigation water

Income and costs

expenses on agricultural inputs

Quantity before SLM:

LKR 60,750.00/ha for urea

Quantity after SLM:

LKR 70,500/ha for SRF

Comments/ specify:

LKR 270/kg urea and LKR 167/kg of SRF. Expenses were calculated assuming all other costs are constants under two situations

farm income

Quantity before SLM:

LKR 520,000/ha

Quantity after SLM:

LKR 552,000/ha

Comments/ specify:

LKR 80/kg of paddy. Average yields mentioned above was used to calculate the farm income. Therefore, farm income is expected to be increased more than the expenses in SRF applied fields.

diversity of income sources

economic disparities

workload

Comments/ specify:

Although a longer time is required for SRF application because of higher bulk volume (175kg more), this application cost is negligible

Socio-cultural impacts

food security/ self-sufficiency

Comments/ specify:

Expected improvements in productivity due to SRF application could strengthen the food security

health situation

land use/ water rights

cultural opportunities

recreational opportunities

community institutions

national institutions

SLM/ land degradation knowledge

Comments/ specify:

Farmers gain awareness through extension programmes when implementing the SRF technology

conflict mitigation

situation of socially and economically disadvantaged groups

Ecological impacts

Water cycle/ runoff

water quantity

water quality

Comments/ specify:

N accumulation in water bodies is reducing due to lower N losses of SRF

harvesting/ collection of water

surface runoff

excess water drainage

groundwater table/ aquifer

evaporation

Soil

soil moisture

Comments/ specify:

It is expected to have a better moisture content as a result of accumulation of biochar with repeated application of SRF

soil cover

Comments/ specify:

Experimental evidence suggests that soil cover is more with rice plants that grow better and tiller more due to better N utilization for crop growth

soil loss

soil accumulation

soil crusting/ sealing

soil compaction

nutrient cycling/ recharge

Quantity before SLM:

N uptake: 167 kg of N/ha

Quantity after SLM:

N uptake: 219 kg of N/ha

Comments/ specify:

Higher uptake of N by rice plants due to SRF application, nutrient recycling is expected to be improved. The above values were obtained from 5 farmer fields in the year 2021.

salinity

Quantity before SLM:

Electrical Conductivity : 0.11 dS/m

Quantity after SLM:

Electrical Conductivity : 0.09 dS/m

Comments/ specify:

The above values were obtained from 5 farmer fields in the year 2021.

soil organic matter/ below ground C

Comments/ specify:

SRF contains biochar which is a good source to improve the soil C.

acidity

Quantity before SLM:

pH : 7.42

Quantity after SLM:

pH : 7.38

Comments/ specify:

The above values were obtained from 5 farmer fields in the year 2021.

Biodiversity: vegetation, animals

Vegetation cover

Comments/ specify:

Efficient uptake of N cause to improve the crop growth, thereby vegetation cover

biomass/ above ground C

Quantity before SLM:

5.2 t/ha (straw) + 8.1 (grain)

Quantity after SLM:

6.0 t/ha (straw) + 8.7 t/ha (grain)

Comments/ specify:

Higher crop growth results higher biomass production. The above values were obtained from 5 farmer fields in the year 2021.

plant diversity

invasive alien species

animal diversity

beneficial species

habitat diversity

pest/ disease control

Climate and disaster risk reduction

flood impacts

landslides/ debris flows

drought impacts

impacts of cyclones, rain storms

emission of carbon and greenhouse gases

fire risk

wind velocity

micro-climate

Comments/ specify:

Because of the better growth of the rice plants micro climate in the paddy fields is expected to be improved.

Specify assessment of on-site impacts (measurements):

Plant growth parameters and yield

6.2 Off-site impacts the Technology has shown

water availability

reliable and stable stream flows in dry season

downstream flooding

downstream siltation

groundwater/ river pollution

Comments/ specify:

N accumulation in water bodies is expected to be reduced due to lower N losses from SRF

buffering/ filtering capacity

wind transported sediments

damage on neighbours' fields

damage on public/ private infrastructure

impact of greenhouse gases

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | not known | |

| annual rainfall | decrease | not known |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

neutral/ balanced

Long-term returns:

slightly positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

positive

Long-term returns:

slightly positive

6.5 Adoption of the Technology

- single cases/ experimental

If available, quantify (no. of households and/ or area covered):

5 farmers/households

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

No

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| This technology uses less chemical fertilizer and therefore it is good for their health and environment |

| This technology gives better crop growth and slightly higher yield |

| Biochar could improve the fertility of the soil |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| SRF reduces the N losses from the soil and allows the rice crop to uptake N effectively from soil at required growth stages. Efficient N uptake promotes the crop growth and increase the productivity. |

| Reduced N losses of SRF directly influence the water quality by reducing the losses of N through surface runoff and leaching and avoid accumulation in water bodies at the lower positions of the landscape. |

| Rice husks, which is are good source of C, are utilized for SRF production; hence it promotes C sequestration as it is added back to the soil as biochar. It improves the soil organic carbon pool and promotes carbon sequestration in soil. |

| Utilizing rice husks by returning back to the rice fields is an effective solution for rice waste management. |

| If the SRF production technology can be transferred to farmers, their societies can produce the SRF by themselves from the wastes generated in small scale rice mills. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| Additional cost despite reduced chemical fertilizer | increased crop yields can partially compensate this. They can produce their own SRF if the production technology is transferred to them |

| Uneven distribution of nitrogen in the field | Changing the water management practices that have been currently adopted by farmers |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| The raw materials need to be formulated accurately to get the benefits of the technology. Hence, technical knowledge and experience is required when preparing SRF. | Proper guidance and technical support from the beginning to the end of the process is essential. This can be achieved through educating and training extension officers to teach and disseminate knowledge for farmers. |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

More than 10 field visits

- interviews with land users

Interviewed 5 farmers

When were the data compiled (in the field)?

08/05/2021

Comments:

Plant growth measurements were collected 7 weeks after broadcasting rice and yield data collected after 3 ½ months after broadcasting.

7.2 References to available publications

Title, author, year, ISBN:

Preparation of Biochar as a Soil Amendment from Rice Husk and Corn Cob by Slow Pyrolysis Process, S.T. Munasinghe, R.S. Dharmakeerthi, P. Weerasinghe and L.G.S. Madusanka, ISSN 0041-3224

Available from where? Costs?

Tropical Agriculturist Journal

Title, author, year, ISBN:

Changes in Structural and Chemical Properties of Rice Husk Biochar Co-pyrolysed with Eppawala Rock Phosphate under Different Temperatures, D.K.R.P.L. Dissanayake, R.S. Dharmakeerthi, A.K. Karunarathna and W.S. Dandeniya, ISSN: 2706-0233

Available from where? Costs?

Tropical Agricultural Research Journal

Title, author, year, ISBN:

Biochar Based Slow-Release Urea Fertilizer: Production and Assessing the Effects on Growth of Lowland Rice and Nitrogen Dynamics in an Alfisol, M.K.N.W. Jayarathna, R.S. Dharmakeerthi and W.M.U.K. Rathnayaka, ISSN: 2706-0233

Available from where? Costs?

Tropical Agricultural Research Journal

7.3 Links to relevant online information

Title/ description:

Changes in Structural and Chemical Properties of Rice Husk Biochar Co-pyrolysed with Eppawala Rock Phosphate under Different Temperatures

URL:

http://192.248.43.153/bitstream/1/3160/2/PGIATAR_30_1_19.pdf

Title/ description:

Biochar Based Slow-Release Urea Fertilizer: Production and Assessing the Effects on Growth of Lowland Rice and Nitrogen Dynamics in an Alfisol

URL:

https://tar.sljol.info/articles/abstract/10.4038/tar.v32i2.8464/

7.4 General comments

The WOCAT questionnaire on SLM technologies covers all the aspects that can affect on the sustainability of natural and human environment.

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules