Improved farmyard manure through sunlight, rain and runoff protection [Nepal]

- Creation:

- Update:

- Compiler: Richard Allen

- Editor: –

- Reviewers: David Streiff, Alexandra Gavilano

Gham, bhalpani ra baleni bata bachai nirman gariyeko ramro gnastar ko gothemal (Nepali)

technologies_1756 - Nepal

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

SLM specialist:

Director

Soil Management Directorate, Department of Agriculture

Nepal

SLM specialist:

Team Leader

Sustainable Soil Management Programme

Nepal

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Sustainable Soil Management Programme, Nepal (SSMP)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Department of Agriculture, Soil Management Directorate, Hariharbhawan Lalitpur (doasoil) - NepalName of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

HELVETAS (Swiss Intercooperation)1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.5 Reference to Questionnaire(s) on SLM Approaches (documented using WOCAT)

Farmer field schools on integrated plant nutrient systems [Nepal]

Participatory and collaborative learning through the farmer field school approach

- Compiler: Richard Allen

Farmer-to-farmer diffusion [Nepal]

Wider diffusion of sustainable soil management technologies through a demand responsive farmer-to-farmer diffusion approach

- Compiler: Richard Allen

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Improving farmyard manure by protecting it from direct sunlight, rainfall, and runoff to reduce volatilisation and leaching

2.2 Detailed description of the Technology

Description:

Farmyard manure is the most common form of organic fertiliser applied to crops in the midhills of Nepal. Farmyard manure has a high proportion of organic material which nurtures soil organisms and is essential for maintaining an active soil life. Typically, only about half of the nutrient content of farmyard manure becomes available for crop growth during the first year after it is applied to the soil. The rest of the nutrients are channelled through soil biotic processes and are released in the following years. The high organic matter content and the more active soil life improve or maintain a friable soil structure, increase the cation exchange capacity, the water holding capacity, and the infiltration rate, and reducing the risk of soil pests.

Indigenous methods of preparing and using farmyard manure vary depending on the ecological zone, access to bedding material from crop or forest land and to crop residues and fodder, the availability of labour, and other factors. Traditionally, Nepali farmers take the manure out of their sheds to dry it for 2-3 days and then carry it to the field where it is left in small heaps for a number of days before being spread and incorporated into the soil.

Farmers rate the quality of manure according to which livestock species it comes from. These ratings have been confirmed by nutrient analysis as cattle manure (NPK%: 0.6, 0.13, 0.66) is considered to be better than buffalo manure (0.33, 0.25, 0.10), and horse manure; while pig (0.5, 0.18, 0.42), goat (0.6, 0.13, 0.99), and sheep manure (0.6, 0.13, 0.99) are considered better than cattle manure. Chicken manure (1.46, 0.51, 0.51) is considered the best of all.

It has however been shown that considerable nutrient losses occur if the manure is inappropriately handled or stored. Drying of the manure leads to loss of nutrients through volatilisation, and rainfall and runoff leads to leaching or washing out of nutrients. In addition, the common disposal of urine - the part of the excreta with the highest nutrient concentration - further reduces the level of nutrients in manure.

To reduce nutrient losses farmyard manure needs to be protected from direct sunlight; protected from rainfall or run-on; and protected from runoff. This can be achieved in a variety of ways using a variety of inputs. It is most important to protect the manure during storage and just before it is applied in the field to make the best use of this valuable local resource.

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Nepal

Further specification of location:

Midhills districts of Nepal

Specify the spread of the Technology:

- applied at specific points/ concentrated on a small area

Map

×3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- Improve manure

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

Comments:

Major land use problems (compiler’s opinion): Intensifying cultivation practices with either 1) inadequate application of fertilisers leading to a decline in soil fertility and the mining of soil nutrients or 2) application of too much fertiliser causing environmental problems through excessive leaching, and losses of fertiliser in surface runoff and consequent eutrophication or nitrification of streams, ponds or groundwater

3.5 SLM group to which the Technology belongs

- integrated soil fertility management

3.6 SLM measures comprising the Technology

management measures

- M2: Change of management/ intensity level

3.7 Main types of land degradation addressed by the Technology

chemical soil deterioration

- Cn: fertility decline and reduced organic matter content (not caused by erosion)

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- reduce land degradation

4. Technical specifications, implementation activities, inputs, and costs

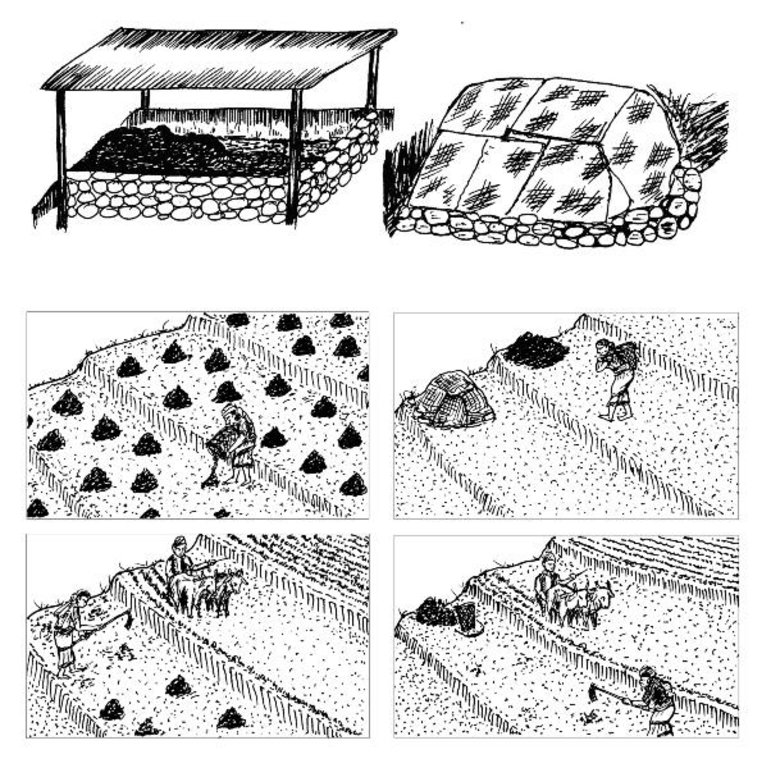

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

a) Covering the farmyard manure with a roof made of tin sheet or plastic sheets. Cheaper alternatives are:

- a thatched roof

- shading with creepers like cucurbits

- planting broadleaf mustard on the heap

- applying a covering of crop residues or forest material

b) Farmyard manure is traditionally carried to the fi elds in doko baskets and left there in unprotected heaps to be incorporated often weeks and sometimes several months later (top and bottom left). It is much better to incorporate it on the day of transport as the longer it is left out on the fi elds in heaps the greater are the nutrient losses from the heaps (bottom right). Alternatively it can be stored in a corner of the fi eld covered with plastic sheets, crop residues, or in some other way (top right).

Technical knowledge required for field staff / advisors: low

Technical knowledge required for land users: low

Main technical functions: increase in organic matter, increase in soil fertility, increase in soil productivity

Secondary technical functions: increased infiltration rate and water holding capacity, improved soil physical properties (friability,easier soil preparation)

Layout change according to natural and human environment: protect farmyard manure; change application

4.2 General information regarding the calculation of inputs and costs

Specify currency used for cost calculations:

- USD

Indicate average wage cost of hired labour per day:

2.00

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Cover the farmyard manure heap or pit with any available material (crop residues, forest material, plastic sheet, thatched roof, zinc sheet, etc.) |

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Building manure pit and shelter | Persons/day | 1.0 | 2.0 | 2.0 | 100.0 |

| Construction material | Material | unit | 1.0 | 25.0 | 25.0 | 100.0 |

| Total costs for establishment of the Technology | 27.0 | |||||

| Total costs for establishment of the Technology in USD | 27.0 | |||||

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Pour household wastewater onto the heap or pit to keep the farmyard |

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

Comments:

Cost as in January 2007

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specifications/ comments on rainfall:

Annual rainfall: Also 2000-3000 mm

Agro-climatic zone

- humid

Thermal climate class: subtropics

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Comments and further specifications on topography:

Slopes on average: Also moderate (6-10%), rolling (11-15%) and hilly (16-30%)

Landforms: Also footslopes

Altitudinal zone: Also 1000-1500 m a.s.l., 1500-2000 m a.s.l. and 2000-2500 m a.s.l.

5.6 Characteristics of land users applying the Technology

Market orientation of production system:

- subsistence (self-supply)

- mixed (subsistence/ commercial)

Individuals or groups:

- individual/ household

Indicate other relevant characteristics of the land users:

Off-farm income specification: In most farm households, off-farm income plays at least a minor and increasingly a major role. Occasional opportunities for off-farm income present themselves in the form of daily labour wages. Some households’ members receive regular salaries, whilst an increasing number of Nepalis are working in India, the Middle East, Malaysia, and elsewhere and sending remittance incomes home.

Market orientation of production system: Also commercial/ market

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, not titled

- individual, titled

Land use rights:

- leased

- individual

Comments:

Sharecropping between owner and tenant

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

Income and costs

expenses on agricultural inputs

Comments/ specify:

Reduced expenditure on mineral fertilisers

Ecological impacts

Other ecological impacts

Soil characteristics

6.2 Off-site impacts the Technology has shown

groundwater/ river pollution

Comments/ specify:

Reduction of nutrient influx into water bodies

Dependence on outside inputs

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

positive

Long-term returns:

positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

positive

Long-term returns:

positive

Comments:

Large short- and long-term benefits due to need to use less of the costly mineral fertilisers. The only extra ‘cost’ is the extra labor needed.

6.5 Adoption of the Technology

Comments:

Comments on acceptance with external material support: An independent assessment found that 95% of the farmers participating in SSMP’s farmyard improvement activities were accepted the technology.

Comments on adoption trend: About 70% of non-participant farmers who had come into contact with the technologies had also adopted them.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

|

The use of improved farmyard manure reduced the need for mineral fertiliser thereby reducing production costs and outside dependency How can they be sustained / enhanced? Further promotion of the technology will increase this impact |

| A simple technology affordable by poor farmers in remote areas far from a roadhead |

| The increased use of organic fertiliser improves the physical characteristics of soil making ploughing easier and increasing water holding capacity of the soil |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| Cost of a permanent roof for the manure heap may hinder adoption of the technology | Promote simple alternatives to high cost roofs such as straw cover, cover with broad leaf mustard, thatch, and waste plastic |

7. References and links

7.1 Methods/ sources of information

7.2 References to available publications

Title, author, year, ISBN:

STSS; SSMP (2001) Farmyard Manure and Compost Management (in Nepali) Kathmandu: Soil Testing Services Section, Department of Agriculture and Sustainable Soil Management Programme

Available from where? Costs?

SSMP

Links and modules

Expand all Collapse allLinks

Farmer field schools on integrated plant nutrient systems [Nepal]

Participatory and collaborative learning through the farmer field school approach

- Compiler: Richard Allen

Farmer-to-farmer diffusion [Nepal]

Wider diffusion of sustainable soil management technologies through a demand responsive farmer-to-farmer diffusion approach

- Compiler: Richard Allen

Modules

No modules