Stonelines [Kenya]

- Creation:

- Update:

- Compiler: Paul Kahiga

- Editor: –

- Reviewers: David Streiff, Alexandra Gavilano

Miraini ya maviga

technologies_1581 - Kenya

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

SLM specialist:

Mwangi Gathenya

JKUAT

Kenya

SLM specialist:

Home Patrick

JKUAT

Kenya

SLM specialist:

Wamuongo Jane

KARI

Kenya

SLM specialist:

Namirembe Sara

ICRAF

Kenya

SLM specialist:

Chege Timothy

JKUAT

Kenya

SLM specialist:

Karanja Andrew

KARI

Kenya

Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

International Centre for Research in Agroforestry (ICRAF) - KenyaName of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

KARI Headquarters (KARI Headquarters) - KenyaName of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Jomo Kenyatta University (Jomo Kenyatta University) - Kenya1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Stonelines are constructed along the contours to slow down the speed of runoff, filter the soil and enhance water infiltration.

2.2 Detailed description of the Technology

Description:

In Kenya stone lines are mostly practiced in areas that receive 200-750 mm of annual rainfall with a spacing of 15-30 m between them. They are particularly common in areas where rocks are readily available, such as Mbeere, Laikipia, Baringo, Mwingi, Kitui and Tharaka. Since the stonelines are permeable they do not pond runoff water but instead, they slow down the speed, filter it and spread the water over the field, thus enhancing water infiltration and reducing soil erosion. They are built in series running along the slope. In addition, the stone barrier blocks and settles down the sediments transported from the upper slopes.

Purpose of the Technology: They are often used to rehabilitate eroded and abandoned land. The advantages of stonelines include; slowing down the runoff thereby increasing infiltration and soil moisture. They also induce a natural process of terracing, reducing erosion and rehabilitation of eroded lands by trapping silt. They are easy to design and construct and since the stone line structure is permeable there is no need for construction of spillways to drain the excess runoff water. When it rains, the soil builds up on the upslope side of the stonelines and over time a natural terrace is formed.

Establishment / maintenance activities and inputs: The stonelines are spaced 15-30 m apart, a shorter distance being used for the steeper slopes. Stonelines are normally suitable on gentle slopes. Slopes above 35% should be avoided. They are established in the following manner: first, the contour line are marked out with the help of a tube level or line levels. In this region here, it is done with the help of the frontline agricultural extension officers. Secondly, a shallow foundation trench is dug across the slope (5-10 cm to 30 cm deep) using basic farm equipments (jembes or hoes). As shown on the above photographs, the larger stones are put on the down slope side of the trench while the smaller stones are used to build the rest of the bund. The smallest stones are used to fill the gaps and increase the heights of the bunds up to the desired level. Farmers plant fruit trees (pawpaws) as show in the photograph above on the upper part. The trees utilises the moisture and rich sediments deposited on the upper part. The stonelines can be reinforced with earth, or crop residues to make them more stable. Maintenance of stonelines is done by repairing the already damaged /fallen stoneline that may have been knocked down or disarranged by livestock or by human beings. In this case animal access needs to be limited and/or the bund should be laid out in a way that allows the animals to pass through.

Natural / human environment: In the lower Mbeere South District where the stoneline technologies is largely practiced, unless there are stones in the individual farms, it might be difficult to import stones from other farms as the exercise can be labor intensive. In this catchment, the Ministry of Agriculture through the front line extension officers has taken a lead role in encouraging farmers to adopt the technology especially the farms which have many stones. Most of the farmers who have implemented this technology in the Lower Mbeere South District learn from the ones who are already practicing through field days or individual initiatives.

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Kenya

Region/ State/ Province:

Eastern Province

Further specification of location:

Mbeere South District

Specify the spread of the Technology:

- evenly spread over an area

If precise area is not known, indicate approximate area covered:

- < 0.1 km2 (10 ha)

Comments:

Not many farmers are practicing stonelines, the farmers who are practicing are copying from some successful farmers within their neighborhood. They also corroborate with the local agricultural extension officers from the Ministry of Agriculture (MoA) to show them how to construct the stonelines along the contours.

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- 10-50 years ago

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through land users' innovation

Comments (type of project, etc.):

The land had too many stones which inhibited operations. By removing the stones, the farmer placed them in line along the contour.

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- reduce, prevent, restore land degradation

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

- Perennial (non-woody) cropping

- Tree and shrub cropping

Annual cropping - Specify crops:

- cereals - maize

- cereals - millet

- cereals - sorghum

- legumes and pulses - peas

Tree and shrub cropping - Specify crops:

- mango, mangosteen, guava

- pome fruits (apples, pears, quinces, etc.)

Number of growing seasons per year:

- 2

Specify:

Longest growing period in days: 90 Longest growing period from month to month: March-May Second longest growing period in days: 90 Second longest growing period from month to month: October - December

Comments:

Major crop: Sorghum, maize, mangoes, pawpaws, miraa, millet, cowpeas

Major land use problems (compiler’s opinion): Limited cultivation land due to hindrances that are brought about by the scattered stones on the land's surface.

Major land use problems (land users’ perception): Soil erosion because of lack of soil and water conservation structures that leads to low land productivity.

Future (final) land use (after implementation of SLM Technology): Cropland: Ca: Annual cropping

3.3 Has land use changed due to the implementation of the Technology?

Has land use changed due to the implementation of the Technology?

- Yes (Please fill out the questions below with regard to the land use before implementation of the Technology)

Cropland

- Tree and shrub cropping

3.4 Water supply

Water supply for the land on which the Technology is applied:

- rainfed

3.5 SLM group to which the Technology belongs

- water diversion and drainage

3.6 SLM measures comprising the Technology

structural measures

- S2: Bunds, banks

3.7 Main types of land degradation addressed by the Technology

soil erosion by water

- Wt: loss of topsoil/ surface erosion

Comments:

Main type of degradation addressed: Wt: loss of topsoil / surface erosion

Main causes of degradation: soil management, Heavy / extreme rainfall (intensity/amounts), poverty / wealth, labour availability (Construction of the technology is labour intensive)

Secondary causes of degradation: deforestation / removal of natural vegetation (incl. forest fires)

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

- restore/ rehabilitate severely degraded land

Comments:

Secondary goals: mitigation / reduction of land degradation

4. Technical specifications, implementation activities, inputs, and costs

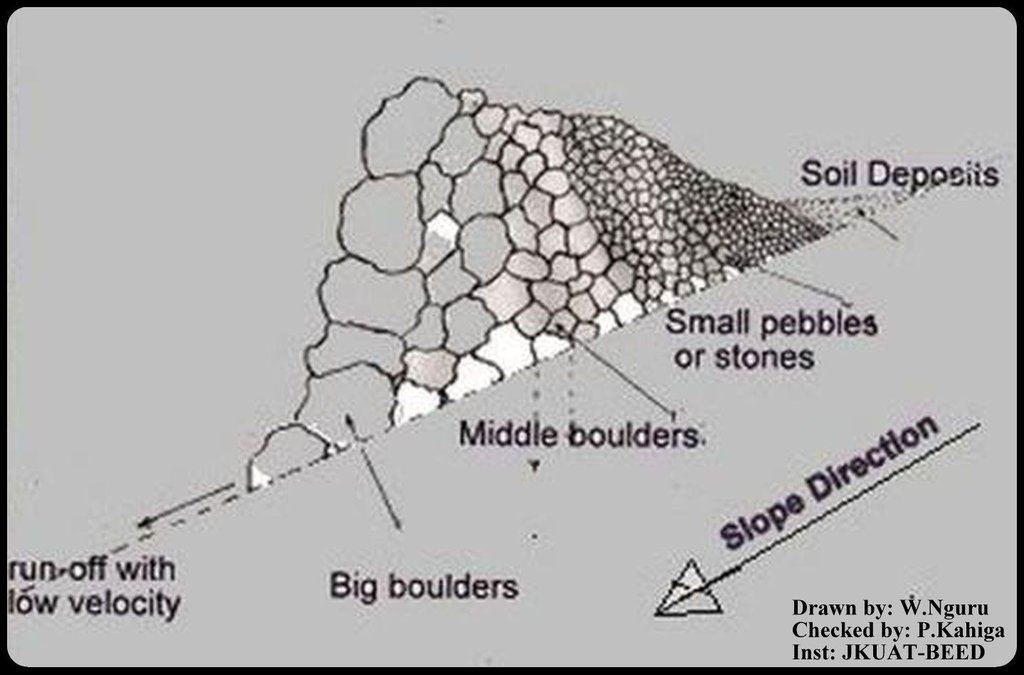

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

This is a technical drawing representing a cross-section view of how the stonelines are constructed by the emerging farmers in the lower Mbeere South District.

First, a small trench is dug along an established contour line, the farmer starts arranging the stones with reference to their sizes. The bigger ones are arranged on the lower side and the small ones on the upper side as shown on the technical drawing.

By so doing, the eroded soils are trapped on the upper side by the small pebbles, allowing the water to pass through at lower speed hence low erosive capacity.

Location: Ntharawe. Lower Mbeere South District

Date: 2011-08-02

Technical knowledge required for field staff / advisors: moderate (In order to implement this technology, the farmers contact the front line agricultural extension officer in order to assist in making the contours.)

Technical knowledge required for land users: high (Stone required placement of a certain order. Big stone on the lower side and small stones on the upper side-Vertically)

Main technical functions: water spreading, sediment retention / trapping, sediment harvesting

Secondary technical functions: reduction of slope angle

Bund/ bank: graded

Spacing between structures (m): 15

Height of bunds/banks/others (m): 0.8

Width of bunds/banks/others (m): 1.2

Length of bunds/banks/others (m): 27.6

Slope (which determines the spacing indicated above): 8%

Lateral gradient along the structure: 8%

Author:

W.Nguru, P.O.Box 12776-00100 Nairobi

4.2 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology unit

Specify unit:

Stonelines

other/ national currency (specify):

Kshs

If relevant, indicate exchange rate from USD to local currency (e.g. 1 USD = 79.9 Brazilian Real): 1 USD =:

80.0

Indicate average wage cost of hired labour per day:

2.50

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Establish a contour line and dig up a trench upon which the stones will be arranged | yearly |

| 2. | stones are collected and arranged along the established trench. The big boulders are reduced to the required sizes by the use of mattocks | once |

| 3. | The big stones are arranged on the lower side and the rest follows with respect to their sizes on the upper side | |

| 4. | This formation is done per meter length. Mostly is charged 150Kshs per meter. |

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Establish a contour line | Persons/day | 0.5 | 3.76 | 1.88 | 100.0 |

| Labour | Reduce stone size | Persons/day | 0.5 | 3.76 | 1.88 | 100.0 |

| Labour | Arranging stones | Persons/day | 0.5 | 3.76 | 1.88 | 100.0 |

| Equipment | Mattock | pieces | 1.0 | 18.75 | 18.75 | 100.0 |

| Equipment | Wheelbarrow | pieces | 1.0 | 20.0 | 20.0 | 100.0 |

| Construction material | Stone | no | 1.0 | 1.88 | 1.88 | 100.0 |

| Total costs for establishment of the Technology | 46.27 | |||||

| Total costs for establishment of the Technology in USD | 0.58 | |||||

Comments:

Duration of establishment phase: 1 month(s)

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Repair/Rearrange stone on stone line after a rainy seasons or when people and animals have destroyed the stone line. | yearly during dry season |

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Repair/Rearrange stone | mandays/acre | 14.0 | 2.5 | 35.0 | 100.0 |

| Total costs for maintenance of the Technology | 35.0 | |||||

| Total costs for maintenance of the Technology in USD | 0.44 | |||||

Comments:

Machinery/ tools: A wheel barrow (for carrying) and mattocks (for breaking) may be used

The cost applies for the year 2011 and was calculated per metre square, metre length, metre height and metre width.

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

The system is labour intensive and hence will affect the cost of constructing the stonelines. However, availability of farm equipments like wheelbarrows, mattocks or oxen will help reduce the total cost and time required for construction and maintaining the stonelines. On steep slopes, the spacing between the lines is small as compared to a relatively gentle slope.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specifications/ comments on rainfall:

Annual rainfall: Also < 250 mm

Agro-climatic zone

- semi-arid

Thermal climate class: tropics

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- coarse/ light (sandy)

Topsoil organic matter:

- low (<1%)

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

Soil texture: With a lot of stones

Soil fertility is medium

Soil drainage / infiltration is medium

Soil water storage capacity is medium

5.4 Water availability and quality

Ground water table:

> 50 m

Availability of surface water:

poor/ none

Water quality (untreated):

good drinking water

Comments and further specifications on water quality and quantity:

Availability of surface water: The rivers are seasonal, water availability is from river beds if not during the rainy seasons

5.5 Biodiversity

Species diversity:

- medium

5.6 Characteristics of land users applying the Technology

Market orientation of production system:

- mixed (subsistence/ commercial)

Off-farm income:

- less than 10% of all income

Relative level of wealth:

- poor

Individuals or groups:

- individual/ household

Level of mechanization:

- manual work

- animal traction

Gender:

- men

Indicate other relevant characteristics of the land users:

Land users applying the Technology are mainly common / average land users

Population density: 10-50 persons/km2

Annual population growth: < 0.5%

80% of the land users are poor.

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, titled

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

risk of production failure

production area

land management

Comments/ specify:

Such that it hinders mechanisation tractors cannot operate due to the stone line arragement

Income and costs

workload

Comments/ specify:

The operation is labour intensive

Other socio-economic impacts

Livelihood and human well-being

Comments/ specify:

Increased food security (the yield near the stoneline is better as compared to the situation that it was before implementation).

Socio-cultural impacts

SLM/ land degradation knowledge

situation of socially and economically disadvantaged groups

Ecological impacts

Soil

soil moisture

soil loss

Biodiversity: vegetation, animals

pest/ disease control

Comments/ specify:

Snakes and scorpions

Climate and disaster risk reduction

flood impacts

6.2 Off-site impacts the Technology has shown

downstream flooding

buffering/ filtering capacity

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | well |

Climate-related extremes (disasters)

Meteorological disasters

| How does the Technology cope with it? | |

|---|---|

| local rainstorm | not well |

| local windstorm | well |

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | well |

Hydrological disasters

| How does the Technology cope with it? | |

|---|---|

| general (river) flood | not well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

slightly positive

Long-term returns:

positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

positive

Long-term returns:

positive

6.5 Adoption of the Technology

Comments:

There is a moderate trend towards spontaneous adoption of the Technology

Comments on adoption trend: The technology is mainly practiced on the farms with stones even though the farmers admit that the task of construction is labour intensive. However, these not withstanding, the farmers do acknowledge that the technology is beneficial since they can see the results of yields from the ones who are already practicing.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

|

By concentrating the stones along a contour, the farmer is able to make use of the land which otherwise is not possible if the stones are scatered. How can they be sustained / enhanced? Farmers should be encouraged to learn from one another but they should also seek advice from extension officers in making the contours. |

| The cost of replacement of farm equipments (jembes, forks and pangas) is reduced since they aren't broken by stones during land preparation. |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

|

The stones for constructing the technology are readily available in most of the farms. How can they be sustained / enhanced? Encouraging farmers to use the available stones to put up the technology. |

|

Stoneline technology prevents soil loss due to erosion. How can they be sustained / enhanced? Modification of the technology to allow more infiltration. |

|

No high level technical knowledge is required for construction of stoneline technology. How can they be sustained / enhanced? More farmers should be encouraged to adopt the technology since they dont need a high level of technical knowledge. |

|

Stone lines technology can be modified to prevent soil and water from running off on the side of stone line ridge. How can they be sustained / enhanced? Construction of side ridges. |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| Contour profiling is challenging. | Assistance from the front line agricultural extension officers. |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| Labour intensive. | When constructing, always move the stones downslope by gravity instead of moving upwards i.e. start from the contours from the upper side |

| The technology only allows the soil to deposit on the upper side of the stoneline but water passes through. | Proper arrangement of the stones should be enhanced basing on their sizes. |

| Increased habitats for snakes and other dangerous creatures like scorpions that hide on the stonelines. | Where there creatures are prone, the farmers should be careful. |

7. References and links

7.1 Methods/ sources of information

7.2 References to available publications

Title, author, year, ISBN:

Thomas, D.B. (eds) 1997. Soil and Water Conservation Manual for Kenya. Soil and Water Conservation Branch. Ministry of Agriculture, Livestock Development and Marketing. 210 p.

Title, author, year, ISBN:

Critchley W and Seigert K (1991) Water Harvesting. FAO

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules