Lining irrigation canals [Mali]

- Creation:

- Update:

- Compiler: Dieter Nill

- Editor: –

- Reviewers: Deborah Niggli, Alexandra Gavilano

Revêtement des canaux d’irrigation (French)

technologies_1651 - Mali

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

SLM specialist:

Traore Minamba

IICEM

Mali

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Manual of Good Practices in Small Scale Irrigation in the Sahel (GIZ )Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH (GIZ) - Germany1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Lining canals is a powerful way to save irrigation water by minimising seepage losses, and to reduce pumping time and costs.

2.2 Detailed description of the Technology

Description:

The irrigation area’s main earthen canals have their inverts lined in concrete and their sides lined with solid cement blocks. Concrete support posts are set at intervals and capped in concrete. Each lined main canal should be no longer than two kilometres. The main canal’s turnouts into the secondary canals are built in cement and are equipped with gates that can be opened and closed as required.

Each turnout’s outflow area is protected by a rockfill structure that is built right up to the top of the canal wall to prevent the canal banks at the head of the secondary canals from becoming degraded.

Lining is mainly used to improve the efficiency of existing irrigation systems. Once the canal has been lined, yields increase by between 35% and 80%. This is because crops receive the water they need to ripen as and when it is required. Often, lining also makes it possible to extend the irrigated area. Pumping hours per hectare are considerably reduced (by 25% in the rainy season) because the canals ensure the correct distribution of irrigation water. Consequently, irrigation costs per tonne of produce drop due to the reduction in pumping hours and the costs of periodical maintenance and increases in yields.

Together with the growers, a memorandum of understanding was drawn up with IICEM and then signed by the mayor. The memorandum describes all the activities that form part of the collaboration between IICEM and the various beneficiaries. The works were carried out either in-company or constituted part of the highly labour-intensive work (HLIW).

a) Work delivered in-company (turnkey basis): Works are carried out in several stages: 1) Identifying the sites requiring lining. This involves locating the sites to develop and making contact with the NGOs that represent the project in the region, as well as regional directorates of rural engineering and economic operators working with the farming organisations in question. 2) The delimited sites chosen for development must undergo technical studies, which are entrusted to engineering consultancies recruited through an open tender process in accordance with the terms of reference for the studies to be conducted. 3) The technical feasibility studies comprise topographical, geotechnical, soil and environmental studies, as well as the creation of a development plan and quantification of materials required for the construction work. 4) Drawing up the invitation to tender (ITT) documents and communicating the tender process to businesses. In lieu of a ToR, an ITT is created by the project according to the requirements of the site. It is then published so that interested consultancies can put forward their bids. 5) Works are carried out under the control and supervision of the oversight office to ensure they adhere to professional standards.

b) Highly labour-intensive work: 1) The same as above. 2) Topographical surveys are carried out by IICEM specialists to calculate the calibration of the canals to ensure they are able to submerge plots over a large area. 3) After calibrating the schemes (energy dissipation basin and division box, main canal and secondary canal turnout, channel), a work plan is drawn up. This uses the measurements calculated to quantify construction material and equipment requirements. 4) Teams of (preferably local) builders are recruited to line the canals. The teams comprise master builders, reinforcing ironworkers, bricklayers and surveyors. 5) The materials and equipment required for each site are provided by an appropriate supplier recruited through a tendering process. 6) Provision of labour and farmer participation. Only the building contractors are paid for working on the project. Labour is supplied by the local community who are provided with lunch to maintain motivation and to prevent lost time caused by workers going off-site. 7) In villages where schemes are proposed, teams of shift workers from the local community are set up and trained in proper conduct for working on a canal lining project and in the keeping of a construction project log book.

Once the canal lining works are complete, IICEM provides a pump unit and subsidises the required fuel and consumables for one growing season. Training in how to run and maintain pump units is provided for the local beneficiaries tasked with their upkeep. Furthermore, training in the management and maintenance of irrigation schemes is delivered to the farming organisations’ steering committee.

The lifespan of a canal lining ranges from 10 to 20 years if small repairs are regularly undertaken. Ensuring linings are impermeable is of the utmost importance because water penetrating through micro-cracks as it flows through the network can lead to rapid and major water loss. It is therefore essential that producers can maintain installations and repair cracks.

The Sahel is a region where the population has always faced a high degree of climate variability, manifested both in terms of time (unexpected dry spells can occur during the rainy season) and in terms of space (rainfall can vary greatly from one area to another). The population is mainly composed of small farmers and livestock keepers.

Over the last two decades, the effects of climate change have exacerbated the already difficult conditions. Accord¬ing to projections made by climatologists, the Sahel will experience a rise in temperatures combined with highly variable rainfall and an increase in extreme weather events.

The Soil and Water conservation and rehabilitation techniques have helped people in the Sahel to manage their ecosystems more effectively and improve their productive land. As a result, communities are better prepared to cope with environmental changes (changes in the climate, land degradation, etc.) and the im¬pact of shocks, particularly droughts

2.3 Photos of the Technology

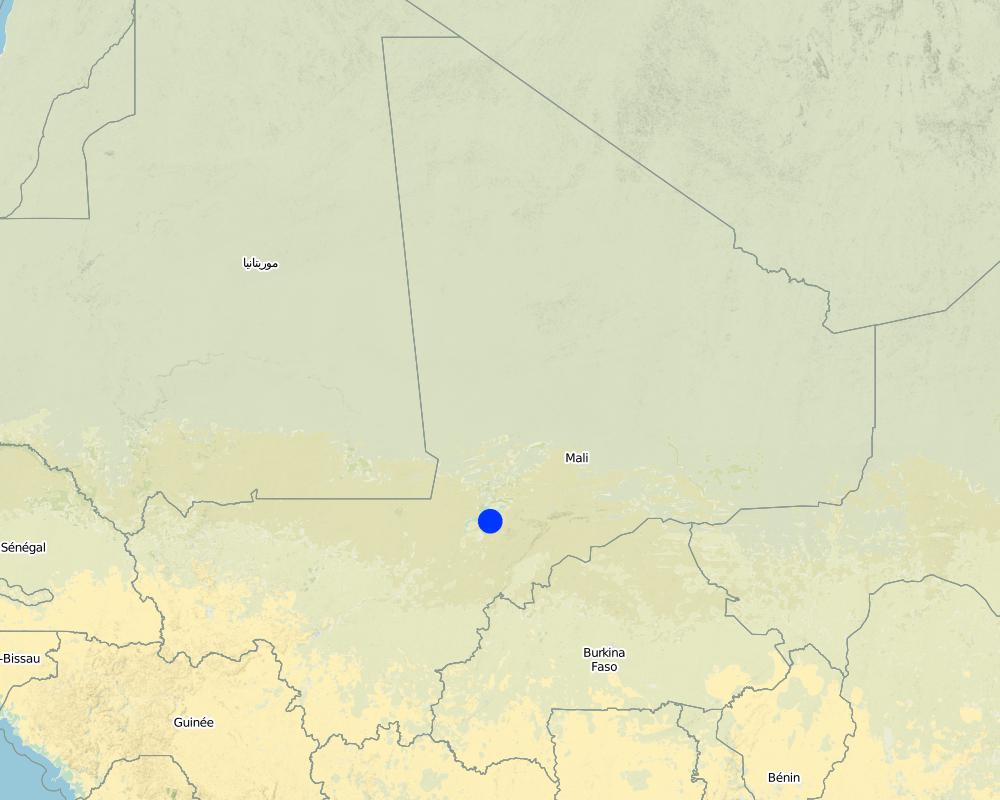

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Mali

Region/ State/ Province:

Mali

Further specification of location:

Mopti, Timbuktu, Gao, Sikasso

Specify the spread of the Technology:

- evenly spread over an area

If the Technology is evenly spread over an area, specify area covered (in km2):

12.0

Comments:

Total area covered by the SLM Technology is 12 km2.

Around 50 sites covering approximately 1200 hectares have had their canals lined

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

Comments (type of project, etc.):

This kind of practice has been carried out by IICEM since 2009.

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- conserve ecosystem

3.2 Current land use type(s) where the Technology is applied

Land use mixed within the same land unit:

Yes

Specify mixed land use (crops/ grazing/ trees):

- Agro-pastoralism (incl. integrated crop-livestock)

Cropland

- Annual cropping

Number of growing seasons per year:

- 1

Specify:

Longest growing period in days: 120Longest growing period from month to month: August-November

Grazing land

Waterways, waterbodies, wetlands

- Drainage lines, waterways

Comments:

Major land use problems (compiler’s opinion): unequal distribution of irrigation water, ineffective irrigation systems (water loss)

Livestock density: 1-10 LU /km2

3.4 Water supply

Water supply for the land on which the Technology is applied:

- mixed rainfed-irrigated

3.5 SLM group to which the Technology belongs

- pastoralism and grazing land management

- irrigation management (incl. water supply, drainage)

- water diversion and drainage

3.6 SLM measures comprising the Technology

structural measures

- S3: Graded ditches, channels, waterways

3.7 Main types of land degradation addressed by the Technology

soil erosion by water

- Wr: riverbank erosion

chemical soil deterioration

- Cn: fertility decline and reduced organic matter content (not caused by erosion)

biological degradation

- Bc: reduction of vegetation cover

water degradation

- Ha: aridification

Comments:

Main causes of degradation: soil management (Unadapted landuse methods, reduced or abandoned fallow periods), crop management (annual, perennial, tree/shrub) (Neglect of fallow periods and crop rotation), over abstraction / excessive withdrawal of water (for irrigation, industry, etc.), droughts (due to heat waves), population pressure (rapidly growing population increasing pressure on land), land tenure (insecure access to land and collectively managed communal land), poverty / wealth (very poor population)

Secondary causes of degradation: deforestation / removal of natural vegetation (incl. forest fires) (deforestation through overgrazing and fire wood collection), over-exploitation of vegetation for domestic use (firewood collection), overgrazing (cattle, sheep and goats), change in temperature (Climate change: heat waves), change of seasonal rainfall (more variable onset of rain), Heavy / extreme rainfall (intensity/amounts) (more variable and intensive rains), wind storms / dust storms (frequent storms), floods (due to intensive rain storms), labour availability (some migration of men to nearby cities), education, access to knowledge and support services (high level of illiteracy)

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

- reduce land degradation

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

The irrigation area’s main earthen canals have their inverts lined in concrete and their sides lined with solid cement blocks. Concrete support posts are set at intervals and capped in concrete. Each lined main canal should be no longer than two kilometres. The main canal’s turnouts into the secondary canals are built in cement and are equipped with gates that can be opened and closed as required. Each turnout’s outflow area is protected by a rockfill structure that is built right up to the top of the canal wall to prevent the canal banks at the head of the secondary canals from becoming degraded.

Technical knowledge required for field staff / advisors: high

Technical knowledge required for land users: low

Main technical functions: water harvesting / increase water supply, water spreading

Author:

Minamba Traore, IICEM

4.2 General information regarding the calculation of inputs and costs

other/ national currency (specify):

CFA Franc

If relevant, indicate exchange rate from USD to local currency (e.g. 1 USD = 79.9 Brazilian Real): 1 USD =:

512.0

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Identifying the sites requiring lining | |

| 2. | Launching the invitation to tender for the technical studies / Undertaking topographical surveys to calibrate schemes | |

| 3. | Performing the technical studies / Quantifying building material requirements | |

| 4. | Drawing up the invitation to tender (ITT) documents and communicating the tender process to businesses / Recruitment of masons, bricklayers and reinforcing ironworkers | |

| 5. | Delivery of works under the supervision of the oversight office / Invitation to tender for the provision of materials and equipment | |

| 6. | Provision of labour and farmer participation | |

| 7. | Training workers from the local community in building site conduct |

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | small repairs are regularly undertaken |

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Around 50 sites covering approximately 1,200 hectares have had their canals lined. Total costs: 1,587,865.50 US Dollar

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Agro-climatic zone

- semi-arid

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

- fine/ heavy (clay)

Topsoil organic matter:

- medium (1-3%)

- low (<1%)

5.4 Water availability and quality

Ground water table:

5-50 m

Availability of surface water:

medium

Water quality (untreated):

for agricultural use only (irrigation)

5.5 Biodiversity

Species diversity:

- medium

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- mixed (subsistence/ commercial)

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- poor

- average

Level of mechanization:

- manual work

Gender:

- men

Indicate other relevant characteristics of the land users:

Population density: < 10 persons/km2

Annual population growth: 2% - 3%

10% of the land users are rich.

50% of the land users are average wealthy.

30% of the land users are poor.

10% of the land users are poor.

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

5.8 Land ownership, land use rights, and water use rights

Comments:

The irrigated land is allocated by the chief

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

risk of production failure

production area

Income and costs

workload

Socio-cultural impacts

food security/ self-sufficiency

conflict mitigation

Ecological impacts

Water cycle/ runoff

water quantity

harvesting/ collection of water

6.2 Off-site impacts the Technology has shown

reliable and stable stream flows in dry season

groundwater/ river pollution

wind transported sediments

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | well |

Climate-related extremes (disasters)

Meteorological disasters

| How does the Technology cope with it? | |

|---|---|

| local rainstorm | not well |

| local windstorm | well |

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | well |

Hydrological disasters

| How does the Technology cope with it? | |

|---|---|

| general (river) flood | not well |

Other climate-related consequences

Other climate-related consequences

| How does the Technology cope with it? | |

|---|---|

| reduced growing period | not known |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

slightly negative

Long-term returns:

slightly positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

slightly positive

Long-term returns:

very positive

6.5 Adoption of the Technology

Comments:

Comments on spontaneous adoption: Lining of canals is an investment which is generally only feasible with external assistance.

There is no trend towards spontaneous adoption of the Technology

Comments on adoption trend: Irrigation system canals in Mopti, Timbuktu, Gao and Sikasso have been lined.

Around 50 sites covering approximately 1,200 hectares have had their canals lined. This kind of practice has been carried out by IICEM since 2009.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Lining canals is a powerful way to save irrigation water by minimising seepage losses. |

| Pumping time and costs are also greatly reduced through the speedy distribution of irrigation water supplies, and reducing the use of motorised pumps lowers maintenance costs. |

| Yields increase by between 35% and 80%. Often, lining also makes it possible to extend the irrigated area. |

| Training in how to run and maintain pump units is provided for the local beneficiaries tasked with their upkeep. Furthermore, training in the management and maintenance of irrigation schemes is delivered to the farming organisations’ steering committee |

| The lifespan of a canal lining ranges from 10 to 20 years |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

- interviews with land users

When were the data compiled (in the field)?

01/07/2012

7.2 References to available publications

Title, author, year, ISBN:

Manual of Good Practices in Small Scale Irrigation in the Sahel. Experiences from Mali. Published by GIZ in 2014.

Available from where? Costs?

http://star-www.giz.de/starweb/giz/pub/servlet.starweb

Title, author, year, ISBN:

www.iicem.net

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules