Wire Mesh Maize Storage Crib [Uganda]

- Creation:

- Update:

- Compiler: PRISCILLA VIVIAN KYOSABA

- Editors: Jalia Namakula, Kamugisha Rick Nelson

- Reviewer: Udo Höggel

Akaju k'obutimba akubarabikamu ebikyoli

technologies_3375 - Uganda

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

land user:

Musinguzi Garuga

Kamwenge District, South Western Uganda

Uganda

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Scaling-up SLM practices by smallholder farmers (IFAD)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

National Agricultural Research Organisation (NARO) - Uganda1.3 Conditions regarding the use of data documented through WOCAT

When were the data compiled (in the field)?

15/11/2017

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

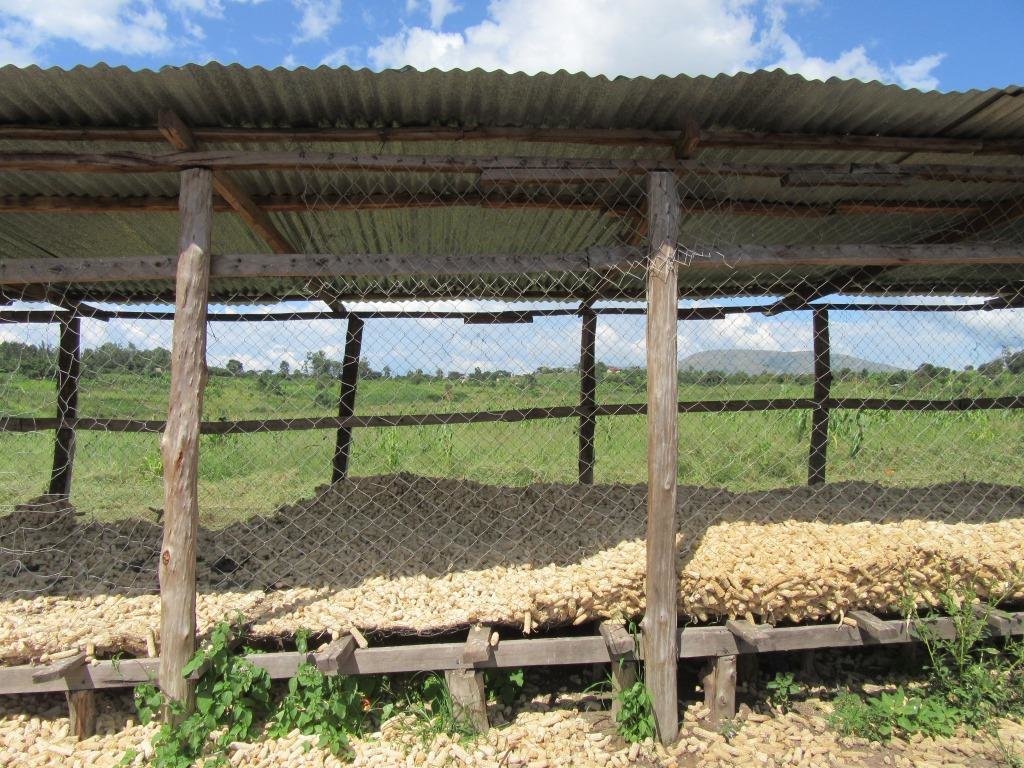

Wire mesh maize storage crib technology is a medium to large scale technology promoted by a farmer in Kamwenge District in South Western Uganda to prevent maize grains from being affected by rainfall. The technology allows for good air circulation which is essential for drying out the maize grains. In this way the grain quality is improved.

2.2 Detailed description of the Technology

Description:

The technology is suitable for farmers growing maize on medium to large scale for commercial purposes. It was adopted from Europe by a farmer in Kamwenge District to help in handling large quantities of maize harvests from a 50-acre farm, which is the largest piece of land under maize farming in the area. Most operations on the farm e.g. land preparation, planting, weeding, spraying and harvesting are semi mechanized. Maize harvest from the farm averages about 2,000 tons per season. This requires a reliable post- harvest handling system that can store the large volumes of maize grain safely with good quality for the market.

The storage cribs are constructed with a wire mesh which is bent to form a rectangular shape to allow more space for storage. The wire mesh structure is then placed on a wooden platform raised a 1 meter above the ground. The whole system is then protected from elements of weather by an iron sheet roof raised 3 meters away from the platform. In front of the structure is a floor space where the harvested maize is first spread on a tarpaulin for sun drying to reduce the moisture content that may be a source of mould leading to grain spoilage and reduces grain quality.

The crib is suitable for storage of maize cobs in both the humid and dry seasons in the Kamwenge area. The structure is well positioned with the longer side in a direction perpendicular to the prevailing wind direction thus facilitating natural ventilation. This allows the drying process to continue even during storage and minimises the possibility of post harvest losses through spoilage.

The storage life greatly depends on the prevailing ambient temperature and relative humidity, and other factors like the inherent moisture pests and diseases. The rectangular shape allows for more space for storage and the material used is durable to beyond 7 years if repairs are done in time. Yet, despite these advantages, the wide open wire mesh allows in birds which feed on the maize which brings about losses.

Establishment cost of the maize storage crib is mainly determined by the construction materials and size. The farmer reported using US$ 4,191.7 in total to establish the structural size of 30 m length, 12 m height and 3 m width . Maintenance activities included repairing the damaged patches on the crib plus also fumigating the units to prevent insects from damaging the poles and eating harvested maize which costs the farmer about US$ 54.8 per season.The costs involved in establishing the technology are slightly higher in the short run while in the long run the net benefits surpass the initial costs. This system is best suited for farmers practising commercial maize farming. However, small scale farmers may be able to construct small size storage cribs using cheaper materials like reeds, bamboo and wood.

2.3 Photos of the Technology

General remarks regarding photos:

Photo clearly shows the usefulness of the maize crib as a post handling technique

2.4 Videos of the Technology

Comments, short description:

A video for the Wire Mesh Maize Storage Crib

Date:

15/11/2017

Location:

Kamwenge District, South Western Uganda

Name of videographer:

Aine Amon

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

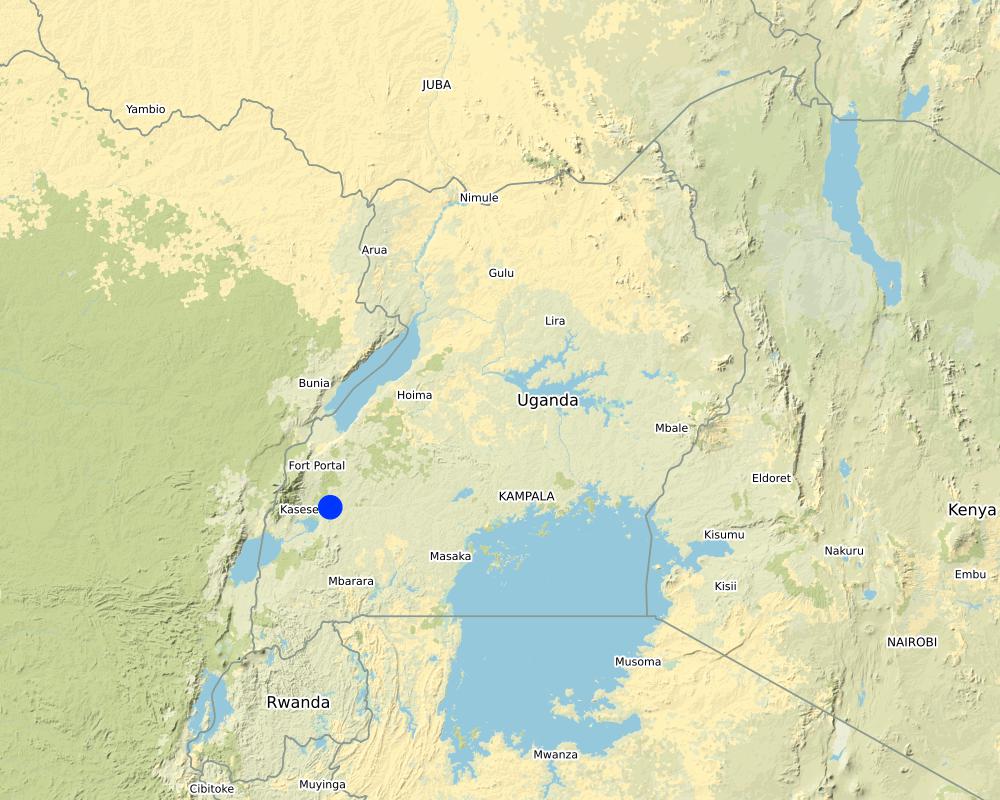

Country:

Uganda

Region/ State/ Province:

South Western Region

Further specification of location:

Kamwenge District, South Western Uganda

Map

×2.6 Date of implementation

Indicate year of implementation:

2007

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through projects/ external interventions

Comments (type of project, etc.):

Through exchange visit from established farmers from other locations

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- create beneficial economic impact

- Reduction of post harvest lossses

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

Main crops (cash and food crops):

Maize

3.3 Further information about land use

Water supply for the land on which the Technology is applied:

- rainfed

Number of growing seasons per year:

- 2

3.4 SLM group to which the Technology belongs

- post-harvest measures

3.5 Spread of the Technology

Specify the spread of the Technology:

- applied at specific points/ concentrated on a small area

Comments:

Cribs constructed in the middle of the maize field.

3.6 SLM measures comprising the Technology

other measures

Comments:

Maize storage construction

3.7 Main types of land degradation addressed by the Technology

other

Comments:

Reduction of post harvest losses which contributes to saving resources e.g soil

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

- not applicable

Comments:

Reduction of post harvest losses which contributes to saving resources e.g soil

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

Author:

Prossy Kaheru

Date:

15/11/2017

4.2 Technical specifications/ explanations of technical drawing

Crib structure dimension

-Length is 30 meters, height 4 meters and width is 3 meters

-Spacing between crib units is 2 meters

-Wire mesh size is measure depending on the size of structure in this case 30 by 4 meters

-Timber used is eucalyptus variety, pole size is 16 centimeters diameter, pole height 5.5 meters

-Gentle sloping

-Construction materials used are wire mesh, nails, timber, poles and iron sheets

4.3 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology area

Indicate size and area unit:

Crip: 30m*4m*3m

Specify currency used for cost calculations:

- US Dollars

Indicate exchange rate from USD to local currency (if relevant): 1 USD =:

3600.0

Indicate average wage cost of hired labour per day:

50,000 Uganda shillings

4.4 Establishment activities

| Activity | Type of measure | Timing | |

|---|---|---|---|

| 1. | Construction labor | Structural | Once |

| 2. | Wire Mesh | Structural | Once |

| 3. | Iron sheets | Structural | Once |

| 4. | Nails | Structural | Once |

| 5. | Timber | Structural | once |

| 6. | Poles | Structural | Once |

Comments:

Establishing activities as reported by farmer

4.5 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Construction labor | Days | 30.0 | 13.8 | 414.0 | 100.0 |

| Construction material | Wire Mesh | Meters | 150.0 | 7.9 | 1185.0 | 100.0 |

| Construction material | Poles | Pieces | 268.0 | 0.6 | 160.8 | 100.0 |

| Construction material | Nails | Kilograms | 105.0 | 1.2 | 126.0 | 100.0 |

| Construction material | Timber | Pieces | 420.0 | 1.0 | 420.0 | 100.0 |

| Other | Iron sheets | Pieces (2.5mX0.5m) | 120.0 | 6.2 | 744.0 | 100.0 |

| Total costs for establishment of the Technology | 3049.8 | |||||

Comments:

All the costs were met the farmers

4.6 Maintenance/ recurrent activities

| Activity | Type of measure | Timing/ frequency | |

|---|---|---|---|

| 1. | Repairing damaged patches of the crib | Structural | Once a year |

| 2. | Fumigating the crib units to prevent pests | Management | During harvesting periods |

4.7 Costs and inputs needed for maintenance/ recurrent activities (per year)

If possible, break down the costs of maintenance according to the following table, specifying inputs and costs per input. If you are unable to break down the costs, give an estimation of the total costs of maintaining the Technology:

166.0

Comments:

Maintenance cost calculated on a yearly basis

4.8 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Construction materials

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Agro-climatic zone

- humid

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- not relevant

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Soil texture (> 20 cm below surface):

- coarse/ light (sandy)

Topsoil organic matter:

- high (>3%)

5.4 Water availability and quality

Ground water table:

5-50 m

Availability of surface water:

medium

Water quality (untreated):

for agricultural use only (irrigation)

Is water salinity a problem?

No

Is flooding of the area occurring?

No

5.5 Biodiversity

Species diversity:

- high

Habitat diversity:

- medium

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- commercial/ market

Off-farm income:

- 10-50% of all income

Relative level of wealth:

- rich

Individuals or groups:

- individual/ household

Level of mechanization:

- mechanized/ motorized

Gender:

- men

Age of land users:

- elderly

Indicate other relevant characteristics of the land users:

Individual owning a company that runs all the farm activities

5.7 Average area of land owned or leased by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- large-scale

Comments:

It is a large scale because the size of the farm area is 50 acres with a production of 2000 tones of maize / year

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, titled

Land use rights:

- individual

Water use rights:

- individual

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

Comments/ specify:

Increased crop production since a farmer has a secure safe storage system hence he can produce more as it is stored

crop quality

Comments/ specify:

Being it the grains are kept properly and in a favorable environment for the grains

Income and costs

farm income

Comments/ specify:

The technology has promoted income increase simply because with the storage system a farmer can get to sell his produce

Socio-cultural impacts

food security/ self-sufficiency

Comments/ specify:

This has helped in solving a problem of food insecurity since the maize grains can be stored for a relatively long period. Hence, at any time grains can be processed into maize flour.

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

slightly negative

Long-term returns:

positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

slightly negative

Long-term returns:

very positive

6.5 Adoption of the Technology

- single cases/ experimental

Comments:

None has adopted the technology because of the high establishment cost and most farmers sell their farm produce immediately after harvesting.

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

No

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| Maintains the maize grains in good conditions |

| Allows drying process to continue even during storage time |

| The farmer generates more income since he sells when the market prices are favorable |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Quite a good innovation practice especially for those farmers growing maize on large scale for commercial purposes |

| Reliable post harvesting technique |

| Reliable storage system |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| Crib establishment is relatively costly | Farmers opt for cheap system like the traditional granaries |

| Best for farmers growing maize on a very large scale for commercial purposes | To be adopted by farmers growing maize on commercial scale |

| Fumigating the units during harvest period is relatively expensive |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| Only favors farmers who can handle the establishment cost | Farmer organisations and government should come in to help middle farmers by providing them with establishment materials at a relatively lower price, this will enable them adopt the system. |

7. References and links

7.1 Methods/ sources of information

- field visits, field surveys

one

- interviews with land users

One person in this case the farm manager

7.3 Links to relevant information which is available online

Title/ description:

Economic importance of different maize storage structures in Kenya

URL:

https://www.slideshare.net/pchenevixtrench/economic-importance-of-different-maize-storage-structures-in-kenya

Title/ description:

Does Improved Storage Technology modern input use and food security? Evidence of randomized trial in Uganda

URL:

https://www.sciencedirect.com/science/article/pii/S030438781830926X

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules