African market gardens [Senegal]

- Creation:

- Update:

- Compiler: Julie Zähringer

- Editor: –

- Reviewers: Alexandra Gavilano, Fabian Ottiger

technologies_944 - Senegal

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

SLM specialist:

Dov Pasternak

International Crops Research Institute for the Semi-Arid Tropics (ICRISAT)

Niger

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Book project: SLM in Practice - Guidelines and Best Practices for Sub-Saharan Africa (SLM in Practice)Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

ICRISAT (ICRISAT) - Niger1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

The African Market Garden (AMG) is a horticultural production system based on low-pressure drip irrigation.

2.2 Detailed description of the Technology

Description:

According to the level of experience, market orientation or social structure of the land users, four different AMG models have been developed. This case study focuses on the “Cluster System” which is suitable for an organized group of independent vegetable producers sharing a common water delivery system. From a central source, water is distributed through a pipe network to a cluster of plots. Each farmer operates a 1,000 m2 unit, and each is equipped with an elevated 200 litre barrel and a standard irrigation kit, including a tap, filter and thick-tube drip laterals. Minimal size of an AMG unit should be 500 m2. Affordable high-quality material is used and the design and operation is simple. The barrel also serves as a fertilizer tank. A float ensures a constant pressure head. Water supply is calculated by the time needed for delivery of the daily water dosage, or through the use of water dosing valves. Producers have individual control of water use. Since the AMG requires only 1 meter pressure for operation, it can draw on low-capacity renewable energy sources such as elevated dams, solar pumps or reservoirs. To supply an area of 50,000 m2 with 8 mm/day in the hot season a 400 m3-reservoir is required. The crops are planted on elevated beds. Water mixed with urea as fertilizer is applied daily. Drip irrigation improves growing conditions for crops while at the same time saving labor, water and other inputs. AMG is promoted as a holistic management package, integrating all aspects of production, post-harvest and marketing in one system. This includes the use of improved vegetable varieties, improved crop husbandry, integrated pest management, as well as improved storage, processing and marketing of products, and improved access to inputs.

Establishment / maintenance activities and inputs: The following establishment activities are connected to this technology: 1. Build concrete reservoir. 2. Drill borehole (110 mm diameter; 12 m deep, hand drilled). 3. Install motor pump and tubes to connect well with reservoir. 4. Install drip kit with tap, filter and drip laterals (8-16 mm in diameter). 5. Establish a fence to protect the garden.

For maintenance the following activities are required: 1. Prepare elevated beds with a basic dressing of 4 kg/m2 manure and 0.1 kg/m2 NPK fertilizer biannually. 2.Add urea to irrigation water (concentration: 50-100 ppm N). 3. Operate water supply system.

Natural / human environment: AMG is spreading fast in Senegal and Burkina Faso. Up-scaling of AMG in dry West Africa will depend on access to technology, inputs, knowledge and organization, and a conducive institutional environment.

2.3 Photos of the Technology

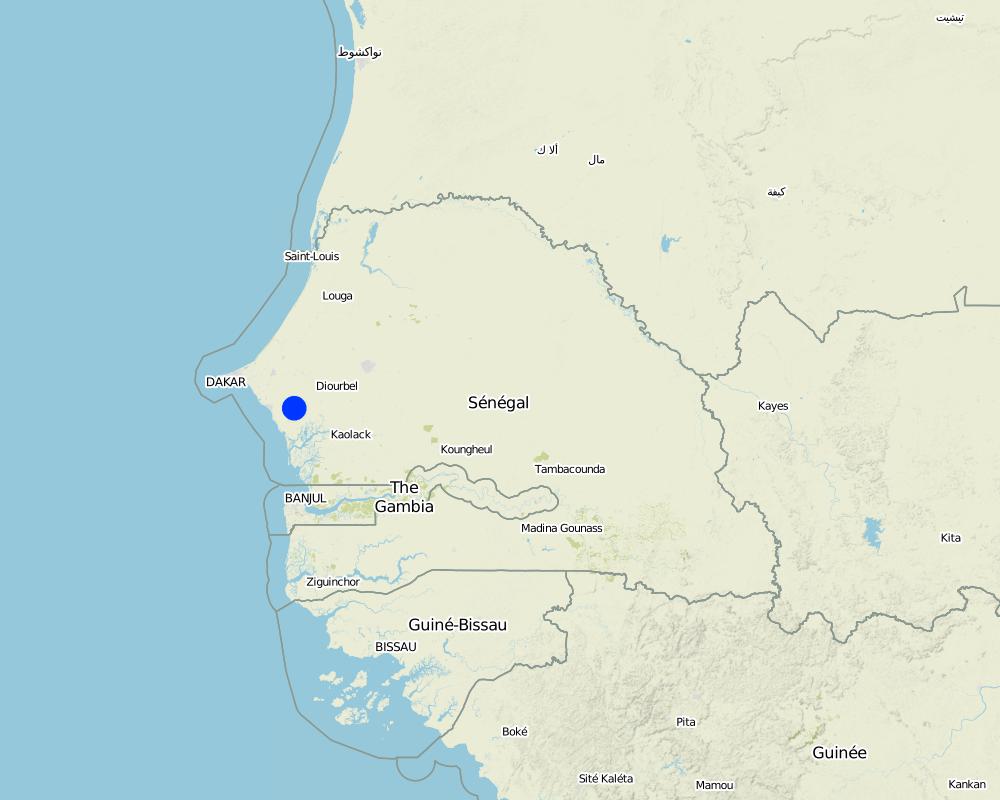

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Senegal

Further specification of location:

Ngoyé Ndioffogor and Mbassis Tadadem

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- during experiments/ research

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- reduce, prevent, restore land degradation

- create beneficial economic impact

3.2 Current land use type(s) where the Technology is applied

Cropland

- Annual cropping

Comments:

Type of cropping system and major crops comments: AMG is suitable for urban/peri¬urban areas where producers have access to credit, markets, technical support

Strong organisation in groups is important for the maintenance of the system and for access to training/backstopping

3.4 Water supply

Water supply for the land on which the Technology is applied:

- rainfed

3.5 SLM group to which the Technology belongs

- irrigation management (incl. water supply, drainage)

- post-harvest measures

3.6 SLM measures comprising the Technology

agronomic measures

- A7: Others

management measures

- M2: Change of management/ intensity level

3.7 Main types of land degradation addressed by the Technology

water degradation

- Ha: aridification

- Hg: change in groundwater/aquifer level

Comments:

Main type of degradation addressed: Ha: aridification, Hg: change in groundwater / aquifer level

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

4. Technical specifications, implementation activities, inputs, and costs

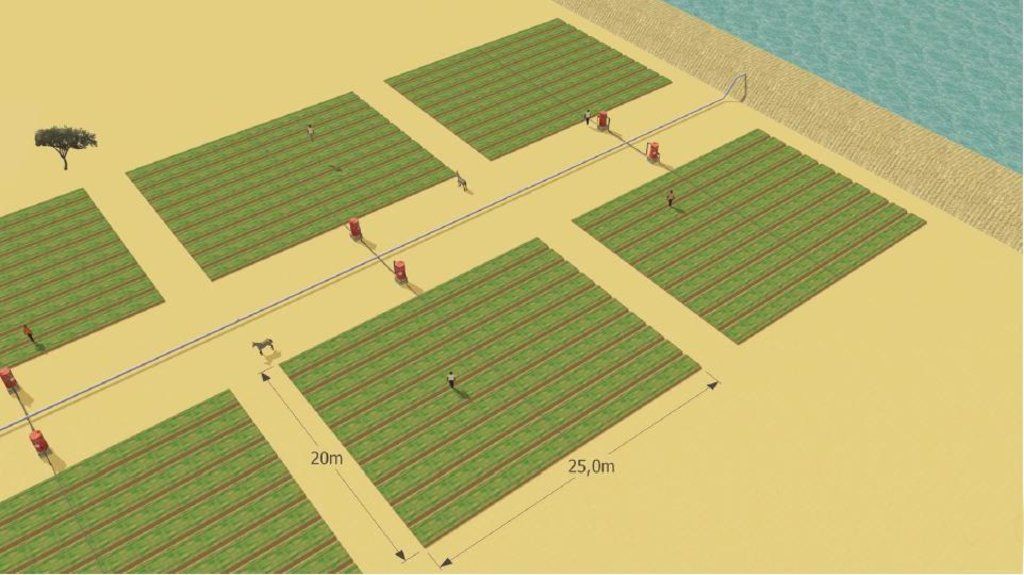

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

Cluster system with several AMG plots connected to a central water source - in this case a small elevated dam

Technical knowledge required for field staff / advisors: high

Technical knowledge required for land users: high

Main technical functions: increase of groundwater level / recharge of groundwater, water spreading

Agronomic measure: drip irrigation

Author:

ICRISAT, Niamey, Niger

4.2 General information regarding the calculation of inputs and costs

Indicate average wage cost of hired labour per day:

2.00

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Get inputs |

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Equipment | Tools | Unit | 1.0 | 65.0 | 65.0 | |

| Equipment | Drip system | Unit | 1.0 | 300.0 | 300.0 | |

| Equipment | Oil drum | Unit | 1.0 | 56.0 | 56.0 | |

| Equipment | Well/borehole | Unit | 1.0 | 16.0 | 16.0 | |

| Equipment | Motor pump | Unit | 1.0 | 34.0 | 34.0 | |

| Construction material | Fence | Unit | 1.0 | 25.0 | 25.0 | |

| Construction material | PVC connections | Unit | 1.0 | 79.0 | 79.0 | |

| Total costs for establishment of the Technology | 575.0 | |||||

| Total costs for establishment of the Technology in USD | 575.0 | |||||

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Prepare elevated beds with a basic dressing of 4 kg/m2 manure and 0.1 kg/m2 NPK fertilizer biannually | biannually |

| 2. | Add urea to irrigation water (concentration: 50-100 ppm N) | |

| 3. | Operate water supply system |

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour | Unit | 1.0 | 510.0 | 510.0 | |

| Total costs for maintenance of the Technology | 510.0 | |||||

| Total costs for maintenance of the Technology in USD | 510.0 | |||||

Comments:

A unit corresponds to the area irrigated by one producer (=500 m2). Establishment costs include labour inputs (2 US$ per person-day). Annual maintenance costs include labour, fuel and agricultural inputs (e.g. fertilizer, seeds; based on ICRISAT recommended rates). For a 1000m2-unit prices are doubled (except for tools and fence)

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Agro-climatic zone

- semi-arid

Thermal climate class: tropics

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- coarse/ light (sandy)

Topsoil organic matter:

- low (<1%)

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

Soil fertility: Low

Soil drainage/infiltration: Good

Soil water storage capacity: Low

5.6 Characteristics of land users applying the Technology

Market orientation of production system:

- commercial/ market

Individuals or groups:

- groups/ community

Level of mechanization:

- manual work

- mechanized/ motorized

Indicate other relevant characteristics of the land users:

Land users applying the Technology are mainly common / average land users

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, titled

Land use rights:

- individual

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

land management

Comments/ specify:

Effective application of fertilizer with the water

Income and costs

farm income

Comments/ specify:

Due to doubled profits from vegetable production (compared to traditional irrigation methods)

workload

Comments/ specify:

Reduced workload: total workload for AMG is 11.5 man-days compared to 30 man-days in traditional irrigation system (allows people to engage in other activities or education)

Other socio-economic impacts

Production cost

Comments/ specify:

Costs for drip irrigated gardens are 50% lower than for traditional irrigated gardens due to savings in labour, water and consequently in fuel

Socio-cultural impacts

food security/ self-sufficiency

community institutions

Comments/ specify:

Improved organisation (farmer associations, user groups)

SLM/ land degradation knowledge

Comments/ specify:

Improved knowledge on irrigation techniques /horticulture

Ecological impacts

Water cycle/ runoff

water quantity

Comments/ specify:

Water availability / reduced pressure on water resources

evaporation

Comments/ specify:

Effective use of water due to accurate and equal distribution of water at optimal rates

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | well |

Climate-related extremes (disasters)

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | not well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

slightly negative

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

very positive

Long-term returns:

very positive

Comments:

Payback period is only 6 months. Net income per farmer after all deduction is about US$ 1,000 per year. The profitability of the AMG is around double that of vegetable gardens irrigated with traditional methods

6.5 Adoption of the Technology

Comments:

There is a strong trend towards spontaneous adoption of the Technology

Comments on adoption trend: AMG is spreading fast in Senegal and Burkina Faso. Cost reduction (e.g. alternative energy sources), collective action and intensive training / back¬stopping are very important provisions for successful adoption. Adoption trend: Up-scaling of AMG in dry West Africa will depend on access to technology, inputs, knowledge and organization, and a conducive institutional environment.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| AMG is a holistic management package, integrating all aspects of production, post-harvest and marketing in one system |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| Irrigated vegetable production is a capital intensive undertaking | sharing infrastructure, land and water through producer groups can cut investment costs by 60% per unit area. Set-up and operation costs further decrease if producer groups can use communally owned infrastructure and/or alternative energy sources (e.g. elevated dams, solar pumps, artesian well). |

| The AMG system is not suitable for farmers with limited access to knowledge, marketing and services | improve access to markets and training programs (for extensionists and farmers); guarantee technical assistance during 2-3 years; target the system to educated producers who make a living out of vegetable production. Set up AMG service and demonstration centres offering credit, farm inputs, marketing support, training and technical advice. |

7. References and links

7.1 Methods/ sources of information

7.2 References to available publications

Title, author, year, ISBN:

Woltering L., D. Pasternak and J. Ndjeunga. 2009. The African Market Garden: Development of an Integrated Horticultural Production System for Smallholder Producers in West Africa – Draft Submitted to Irrigation and Drainage 21-10-2009

Title, author, year, ISBN:

ICRISAT. 2009. The African Market Garden - Advanced Horticulture for the Poor (Flyer)

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules