Planting pits for soil fertilisation and moisture improvement [Uganda]

- Creation:

- Update:

- Compiler: Wilson Bamwerinde

- Editor: –

- Reviewer: Fabian Ottiger

EBISANIYA (Runyankore language)

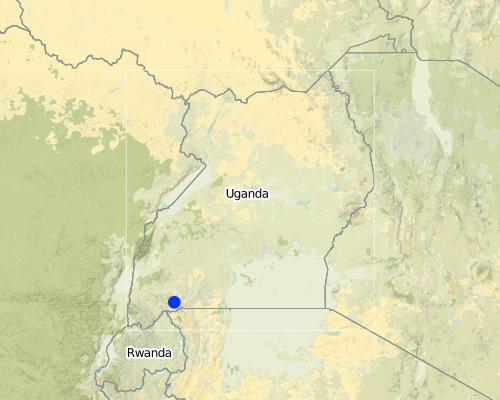

technologies_1587 - Uganda

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

SLM specialist:

SLM specialist:

SLM specialist:

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

The Transboundary Agro-ecosystem Management Project for the Kagera River Basin (GEF-FAO / Kagera TAMP )Name of the institution(s) which facilitated the documentation/ evaluation of the Technology (if relevant)

Food and Agriculture Organization of the United Nations (FAO) - Italy1.3 Conditions regarding the use of data documented through WOCAT

When were the data compiled (in the field)?

16/11/2013

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

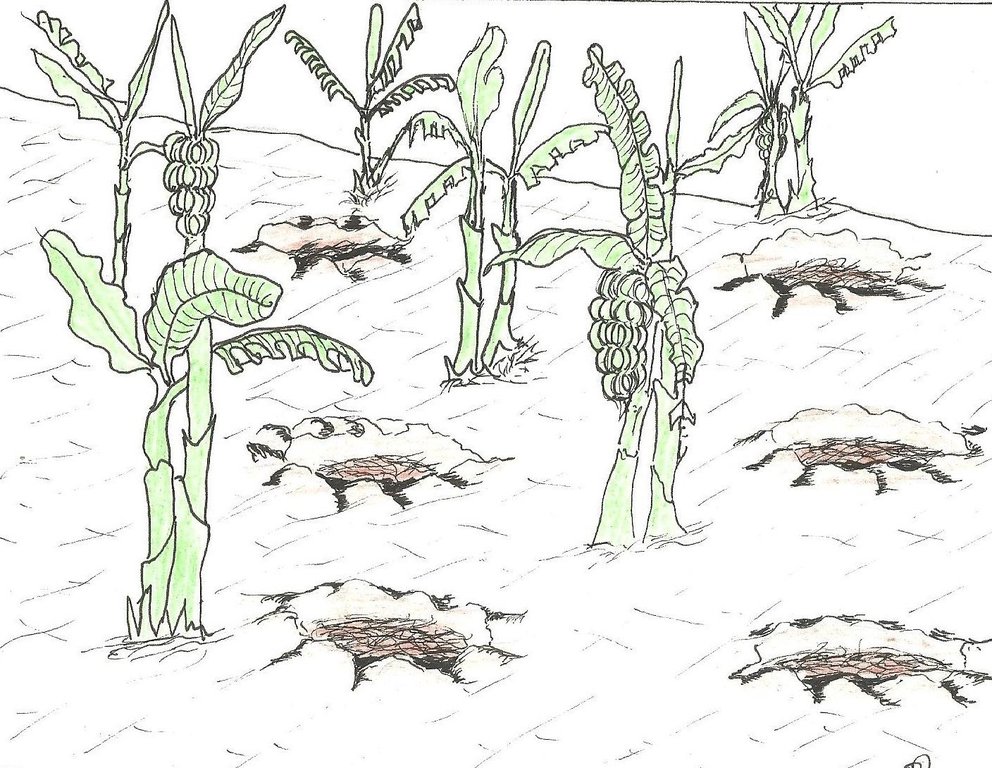

Planting pits in banana plantation filled with a mixture of manure, organic material and soil, to improve soil moisture and fertility and to enhance crop production and famer's income.

2.2 Detailed description of the Technology

Description:

The planting pits are established between banana stems and filled with organic vegetative material mixed with decomposing manure to form a reservoir of nutrients for a long run. On gentle slopes covered with extensive banana plantations, the planting pits are dug at the center of banana stands. Before estbalishment of this technology, only the composting process was available for the conversion of organic domestic waste into manure. However, compost manure takes slightly longer to produce and is more bulky than conservation troughs making the latter easier to adopt. The technology can be applied to annual cropland as well. Application of the technology improves banana bunch size and plantation yield by over 300%.

Purpose of the Technology: The main objective is to improve soil fertility. The planting pits also check runoff thereby reducing soil erosion, improving moisture infiltration and retention, and enabling the plantation to withstand the dry months. Cabbages, beans and other high value vegetables can be grown directly on top of the trough.

Establishment / maintenance activities and inputs: The planting pits are established using simple tools such as the hand hoe, spade, panga and wheelbarrow. The hoe is used to dig up the soil and soften it. The soil is then scooped out using a spade, to create a bowl-shaped trough. The panga is used to chop the remains of harvested bananas (stems and leaves) which are then, carried to the troughs using a wheel barrow. The planting pit is 0.45 m to 0.60 m deep depending on the amount of manure available and 0.6 m wide. Each trough is about 0.60 m from the nearest banana stand. It is filled with chopped banana stems, followed by a layer of manure and then covered with mulch to prevent excessive evaporation of moisture. The planting pit is then covered with soil. After 3 to 4 months, the vigor of the banana stems improves. If the trough is opened by digging, roots are observed to have grown through the walls of the planting pit from all directions.

During the rainy season, the trough slowly fills with sediment from surface erosion. Weeding at the trough is done by uprooting the weeds using hands or a hand hoe.

Natural / human environment: Over time, the banana stands grow towards the trough. To maintain the distance between the stands, the suckers nearest to the trough are pruned.

2.3 Photos of the Technology

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Uganda

Region/ State/ Province:

Uganda

Further specification of location:

Mbarara

Comments:

Boundary points of the Technology area: -0.86269 30.62587; -0.86275 30.62622; -0.86279 30.62631; -0.86405 30.62522; -0.86393 30.62539, -0.86387 30.62503

Map

×2.6 Date of implementation

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- through land users' innovation

Comments (type of project, etc.):

In 2012, Kagera TAMP introduced the Farmer Field School methodology. The members of these schools have been experimenting on several SLM technologies since then and the troughs are one of the successful innovations

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- reduce, prevent, restore land degradation

- create beneficial economic impact

3.2 Current land use type(s) where the Technology is applied

Cropland

- Perennial (non-woody) cropping

Main crops (cash and food crops):

Major cash crop: Banana

Major food crop: Banana

Major other crops: Maize, beans, peas, Irish potatoes

Comments:

Major land use problems (compiler’s opinion): The light, sandy loam soil on a hilly slope has very little capacity to hold water. The soils are dry a few days after it rains. The banana plantation therefore suffers two problems: inadequate soil water for plant growth and low nutrient retention. The problem of soil erosion is critical in the area but is addressed more adequately by fanya ju retention trenches stabilized with Napier grass strips.

Major land use problems (land users’ perception): Low productivity of the land compared to past seasons.

3.3 Further information about land use

Water supply for the land on which the Technology is applied:

- rainfed

Number of growing seasons per year:

- 2

Specify:

Longest growing period in days: 120 Longest growing period from month to month: February to May Second longest growing period in days: 90 Second longest growing period from month to month: September to November

3.4 SLM group to which the Technology belongs

- integrated soil fertility management

3.5 Spread of the Technology

Comments:

Total area covered by the SLM Technology is 0.04 km2.

3.6 SLM measures comprising the Technology

agronomic measures

- A6: Others

structural measures

- S4: Level ditches, pits

Comments:

Main measures: structural measures

Specification of other agronomic measures: Manure application (supp.

3.7 Main types of land degradation addressed by the Technology

chemical soil deterioration

- Cn: fertility decline and reduced organic matter content (not caused by erosion)

Comments:

Main type of degradation addressed: Cn: fertility decline and reduced organic matter content

Main causes of degradation: soil management (No manure was being applied to replenish nutrients inspite of continuous banana harvesting)

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- prevent land degradation

- reduce land degradation

Comments:

Main goals: mitigation / reduction of land degradation

Secondary goals: prevention of land degradation

4. Technical specifications, implementation activities, inputs, and costs

4.1 Technical drawing of the Technology

4.2 Technical specifications/ explanations of technical drawing

Conservation troughs (0.4-0.6 m deep) are partially filled with a mixture of manure, undecomposed banana stems and other organic matter to add organic matter into the soil. They also capture rainfall runoff and help to maintain suitable soil moisture. The conservation trough should be dug about 0.6 m from banana plant so that the heat produced during decay does not affect the plant.

Location: Rubagano, Mwizi, Mbarara district. Uganda

Date: 29-Nov-2013

Technical knowledge required for field staff / advisors: low (Self explanatory)

Technical knowledge required for land users: moderate (Basic training required on the construction methodology e.g. location selection, recommended dimentions of the trough (depth))

Main technical functions: increase in organic matter, increase in nutrient availability (supply, recycling,…), increase of infiltration, increase / maintain water stored in soil, water harvesting / increase water supply

Secondary technical functions: improvement of topsoil structure (compaction), improvement of subsoil structure (hardpan)

Retention/infiltration ditch/pit, sediment/sand trap

Vertical interval between structures (m): n/a

Spacing between structures (m): 3

Depth of ditches/pits/dams (m): 0.6

Width of ditches/pits/dams (m): 2

Length of ditches/pits/dams (m): 2

Height of bunds/banks/others (m): n/a

Width of bunds/banks/others (m): n/a

Length of bunds/banks/others (m): n/a

Reshaping surface

Vertical interval between structures (m): n/a

Spacing between structures (m): n/a

Depth of ditches/pits/dams (m): 3

Width of ditches/pits/dams (m): 0.6

Length of ditches/pits/dams (m): 2

Height of bunds/banks/others (m): 2

Width of bunds/banks/others (m): n/a

Length of bunds/banks/others (m): n/a

Construction material (earth): Troughs are developed by excavating soil; soil mixed with manure is used to fill the pit partially.

Construction material (stone): n/a

Construction material (wood): n/a

Construction material (concrete): n/a

Construction material (other): n/a

Slope (which determines the spacing indicated above): n/a%

If the original slope has changed as a result of the Technology, the slope today is: n/a%

Lateral gradient along the structure: n/a%

Specification of dams/ pans/ ponds: Capacity n/am3

Catchment area: n/am2

Beneficial area: n/am2

Slope of dam wall inside: n/a%;

Slope of dam wall outside: n/a%

Dimensions of spillways: n/am

Other specifications: n/a

For water harvesting: the ratio between the area where the harvested water is applied and the total area from which water is collected is: 1:n/a

4.3 General information regarding the calculation of inputs and costs

other/ national currency (specify):

UGX

Indicate exchange rate from USD to local currency (if relevant): 1 USD =:

2500.0

Indicate average wage cost of hired labour per day:

4.00

4.4 Establishment activities

| Activity | Type of measure | Timing | |

|---|---|---|---|

| 1. | Measuring and marking pit positions | Structural | Wet season |

| 2. | Excavating pits | Structural | Wet season |

| 3. | Mixing top soil with animal manure, filling mixture into pits, putting domestic and field organic residues into pits, covering pits | Structural | Wet season |

4.5 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour | ha | 1.0 | 44.0 | 44.0 | 100.0 |

| Equipment | Tools | ha | 1.0 | 7.0 | 7.0 | |

| Fertilizers and biocides | Compost/manure | ha | 1.0 | 40.0 | 40.0 | 100.0 |

| Total costs for establishment of the Technology | 91.0 | |||||

Comments:

Duration of establishment phase: 2 month(s)

4.6 Maintenance/ recurrent activities

| Activity | Type of measure | Timing/ frequency | |

|---|---|---|---|

| 1. | Weeding by hand | Structural | Wet season |

| 2. | Addition of manure and residues | Structural | Once a year |

4.7 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | Labour | ha | 1.0 | 10.0 | 10.0 | 100.0 |

| Equipment | Tools | ha | 1.0 | 4.0 | 4.0 | 100.0 |

| Fertilizers and biocides | Compost/manure | ha | 1.0 | 20.0 | 20.0 | 100.0 |

| Total costs for maintenance of the Technology | 34.0 | |||||

Comments:

Machinery/ tools: hand hoe, wheel barrow

The calculations were made for the rainy season of September to November, 2013.

4.8 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

Availability of labour and animal manure are the most important factors affecting cost of the establishment activities. To reduce cost of labour it is recommended to apply Farmer Field Schools approach. To reduce cost of manure farmers can produce their own farmyard manure, e.g. by implementing zero-grazing technology.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specifications/ comments on rainfall:

1400 mm spread over 2 seasons

Agro-climatic zone

- sub-humid

Thermal climate class: tropics. Located at the Equator. A good supply of rain much of the year, but plenty of sunshine too

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

Indicate if the Technology is specifically applied in:

- not relevant

Comments and further specifications on topography:

Altitudinal zone: 1501-2000 m a.s.l. (1715 to 1740 m a.s.l.)

Landforms: Hill slopes (ranked 1, concave) and ridges (ranked 2, convex)

Slopes on average: Hilly (Where the technology has been applied so far is on hilly slopes (< 30%) but the adjacent slopes where the technology is planned next is quite steep (> 45%))

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- coarse/ light (sandy)

Topsoil organic matter:

- medium (1-3%)

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

Soil depth on average: Shallow (The soils are generally shallow)

Soil fertility: Low

Topsoil organic matter: Medium (Mulching had already introduced topsoil organic matter)

Soil drainage/infiltration: Good

Soil water storage capacity: Medium

5.4 Water availability and quality

Ground water table:

> 50 m

Availability of surface water:

poor/ none

Water quality (untreated):

poor drinking water (treatment required)

Comments and further specifications on water quality and quantity:

Ground water table: >50 m (Boreholes have been sank before to great lengths but have invariably dried up)

Availability of surface water: Poor/none (Available only as trapped runoff behind rocky formations, but soon dries up)

Water quality (untreated): Poor drinking water (treatment required, runoff)

5.5 Biodiversity

Species diversity:

- medium

5.6 Characteristics of land users applying the Technology

Market orientation of production system:

- mixed (subsistence/ commercial

Off-farm income:

- less than 10% of all income

Relative level of wealth:

- average

Individuals or groups:

- individual/ household

Level of mechanization:

- manual work

Gender:

- women

- men

Indicate other relevant characteristics of the land users:

Land users applying the Technology are mainly common / average land users

Difference in the involvement of women and men: n/a

Population density: 100-200 persons/km2

Annual population growth: 3% - 4%

and own 20% of the land.

and own 30% of the land.

40% of the land users are average wealthy and own 40% of the land.

and own 10% of the land.

Off-farm income specification: There has been an improvement in yields which translate into money generated per hectare. However, the farmers applying the technology have not yet diversified into other enterprises.

Level of mechanization: Manual work (Hand hoe, spade, wheel barrow)

Market orientation: Mixed (Surplus has grown to such a level that the commercial component has become inevitable)

5.7 Average area of land owned or leased by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- small-scale

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- individual, not titled

Land use rights:

- individual

Water use rights:

- open access (unorganized)

- individual

Comments:

Individual access to water rights is relatively new with the introduction of water harvesting.

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Production

crop production

Quantity before SLM:

8 Kg

Quantity after SLM:

25 Kg

Comments/ specify:

Bunch of bananas is bigger and heavier at harvest

risk of production failure

Quantity before SLM:

20%

Quantity after SLM:

67%

Comments/ specify:

During the dry season or extended drought periods, only about 20% of the banana stands would have a fruiting stem; now well over two thirds of the stands do.

Income and costs

expenses on agricultural inputs

farm income

Quantity before SLM:

80 US$

Quantity after SLM:

200 US$

Comments/ specify:

Monthly harvests for sale have increased from 20 to over 50 bunches

workload

Socio-cultural impacts

food security/ self-sufficiency

Quantity before SLM:

50%

Quantity after SLM:

100%

Comments/ specify:

Whereas extended drought posed food insecurity, this is no longer the case

Improved livelihoods and human well-being

Comments/ specify:

The earning power has increased greatly. Children are going to school because tuition fees are no longer burdensome and health needs are easily met. The farmers practicing the technology report making some savings from their incomes unlike before.

Ecological impacts

Water cycle/ runoff

evaporation

Soil

soil moisture

nutrient cycling/ recharge

soil organic matter/ below ground C

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | Type of climatic change/ extreme | How does the Technology cope with it? | |

|---|---|---|---|

| annual temperature | increase | well |

Climate-related extremes (disasters)

Meteorological disasters

| How does the Technology cope with it? | |

|---|---|

| local rainstorm | well |

| local windstorm | well |

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | well |

Hydrological disasters

| How does the Technology cope with it? | |

|---|---|

| general (river) flood | not known |

Other climate-related consequences

Other climate-related consequences

| How does the Technology cope with it? | |

|---|---|

| reduced growing period | well |

Comments:

The advantages of the technology to cropland are to be found underground. Therefore the technology is protected against most natural adversities above ground.

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

positive

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

very positive

Long-term returns:

very positive

Comments:

Costs at establishment are the only ones involved. There are no maintenance costs involved though pits need to be re-established every 2-3 years

6.5 Adoption of the Technology

If available, quantify (no. of households and/ or area covered):

22

Of all those who have adopted the Technology, how many have did so spontaneously, i.e. without receiving any material incentives/ payments?

- 90-100%

Comments:

Comments on acceptance with external material support: It is a farmer initiative and no support has been received for the adoption of this technology.

100% of land user families have adopted the Technology without any external material support

22 land user families have adopted the Technology without any external material support

Comments on spontaneous adoption: This is a farmer field school initiative and the district facilitator for Kagera TAMP (and also an Agricultural officer of the local government) provided guidance on positioning the pits for maximum utility.

There is a strong trend towards spontaneous adoption of the Technology

Comments on adoption trend: Noticing the results in only 3 seasons, the other farmers (not members of farmer field school) are also adopting the technology.

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

|

The technology requires the use of only the simplest of farm tools such as a hand hoe, a spade and a wheel barrow. How can they be sustained / enhanced? Dissemination of the the technology through regular community meetings and a local language newsletter |

|

Demonstration of benefits is achieved quite quickly and therefore adoption by farmers is good. How can they be sustained / enhanced? Emphasize technology at farmer field school demonstration plots |

|

Technology bears similar benefits to composting but with a shorter list of activities How can they be sustained / enhanced? Encourage adoption through demonstration |

|

Since the technology utilizes stem cuttings, whole stems are harvested reducing the risk of pests and diseases especially banana bacteria, that would be harbored by exposed rotting stems How can they be sustained / enhanced? Knowledge dissemination through regular community meetings and local language newsletter |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| The technology is labor intensive | Farmer Field Schools bring farmers together in a community level effort |

| The technology requires livestock manure in a predominantly cultivator community | Introduce zero-grazing livestock for manure production |

7. References and links

7.2 References to available publications

Title, author, year, ISBN:

Kagera TAMP project website

Available from where? Costs?

http://www.fao.org/nr/kagera/en/

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules