Lining the bottom of the channel with polyethylene film [Uzbekistan]

- Creation:

- Update:

- Compiler: Rustam Ibragimov

- Editor: –

- Reviewers: Elizaveta Soloveyva, Olga Andreeva, Alexandra Gavilano

Waterproofing of the channel with polyethylene film /lining the bottom of the channel with polyethylene film

technologies_4010 - Uzbekistan

- Full summary as PDF

- Full summary as PDF for print

- Full summary in the browser

- Full summary (unformatted)

- Экранирование дна канала полиэтиленовой пленкой: Aug. 30, 2018 (inactive)

- Экранирование дна канала полиэтиленовой пленкой: March 18, 2019 (inactive)

- Экранирование дна канала полиэтиленовой пленкой: Aug. 22, 2019 (inactive)

- Lining the bottom of the channel with polyethylene film: Feb. 4, 2020 (public)

View sections

Expand all Collapse all1. General information

1.2 Contact details of resource persons and institutions involved in the assessment and documentation of the Technology

Key resource person(s)

SLM specialist:

Eshchanov Ruzimboy

Urgench State University

Uzbekistan

SLM specialist:

Volkov Alexey

Small grant programs in Uzbekistan

Uzbekistan

Rudenko Inna Yurievna

Urgench State University; Khorezm Agro-Consultative Center "KRASS"

Uzbekistan

Name of project which facilitated the documentation/ evaluation of the Technology (if relevant)

Decision Support for Mainstreaming and Scaling out Sustainable Land Management (GEF-FAO / DS-SLM)1.3 Conditions regarding the use of data documented through WOCAT

The compiler and key resource person(s) accept the conditions regarding the use of data documented through WOCAT:

Yes

1.4 Declaration on sustainability of the described Technology

Is the Technology described here problematic with regard to land degradation, so that it cannot be declared a sustainable land management technology?

No

2. Description of the SLM Technology

2.1 Short description of the Technology

Definition of the Technology:

Covering the bottom of the channel and slopes with polyethylene film reduces water infiltration losses during transportation from the source to the field and increases the water use efficiency from 0.50 to 0.89 points

2.2 Detailed description of the Technology

Description:

There are about 4.3 million hectares of irrigated lands that are served by irrigation canals with a length of over 180 thousand km in Uzbekistan.

Large trunk and inter-farm channels have concrete insulation, intra-farm canals are mostly laid in an earthen bed. Water losses due to infiltration reach 50-60% in the ground channels, which is a huge amount, given the scale of irrigation systems. Channel infiltration losses are the main source of groundwater supply and the reason for their high level. As a result of evaporation, salts from groundwater rise to the surface and accumulate in the topsoil. Fields located in the rear of the channels receive insufficient water volume due to high losses. Consequently crop yields are reduced, wind erosion processes are intensifying. The fact that half of the water taken from rivers is lost from canals requires decisive and urgent action. Sheathing/ lining the channels with concrete is a very expensive solution. In the 80s of the last century, various measures to reduce infiltration were used: compaction, gleying, colmatation with chemicals, colmatization with clay particles and bentonite, bitumen, etc. Lining the bottom of the channel with plastic film could be an alternative. The only opponent of polyethylene is ultraviolet rays, and this requires constant monitoring and sprinkling of film on the sides of the channel. Otherwise, the duration of such waterproofing is almost unlimited. The Technology was tested by representatives of Urgench State University with the support of the GEF SGP on the Navruz-Yap channel in the Yangyaryk district of the Khorezm region (2009-2012). The 2.6 km long channel provided 400 hectares of irrigated land with water and provided water to more than 2500 local people. Before taking measuresа to reduce water infiltration losses, the channel efficiency changed seasonally from 0.43 to 0.52 (0.49 on average). With a channel capacity of 1.5-2 m3 / s, a lack of irrigation water was constantly observed due to infiltration. In the Khorezm region, channels without infiltration coverage, such as Navruz-Yap, occupy more than 98% of the territory.

The Technology includes:

1.Сleaning works with the use of an excavator

2.Construction of small hydraulic structures to ensure gravity flow of water in the channel

3.Manual preparation of slopes and the bottom of the channel to ensure gravity flow of water.

4.Creation of a 10-15 cm sand layer for laying a plastic film

5.Laying a plastic film 100 microns thick.

6. Filling the bottom and the edges of the channel over the film with a 10-15 cm sand layer to avoid film damage.

7.Backfilling the bottom of the channel with soil, 1 m thick, and the edges of the channel 0.5-0.6 m thick

The total cost of waterproofing 1 km of the channel is 15324 USD.

Savings were achieved through the delivery of material (9575 USD). Energy savings (no need for pumps) are 3207 USD (2013).

An additional cotton crop and, accordingly, additional income were obtained due to the extra irrigated area (water can reach the end of the canal) and due to an increase in productivity (decrease in the groundwater level in nearby fields). The total Technology benefit is 13,252 USD (calculations per 1 km of the channel, 2013). Estimated payback is 1-2 years. However, not every farmer can invest 15324 USD per 1 km of canal. Nevertheless, there are already farmers who intend to apply this technology. They hope that this will provide sufficient watering, especially in conditions of low water, which has become more frequent in recent years.

2.3 Photos of the Technology

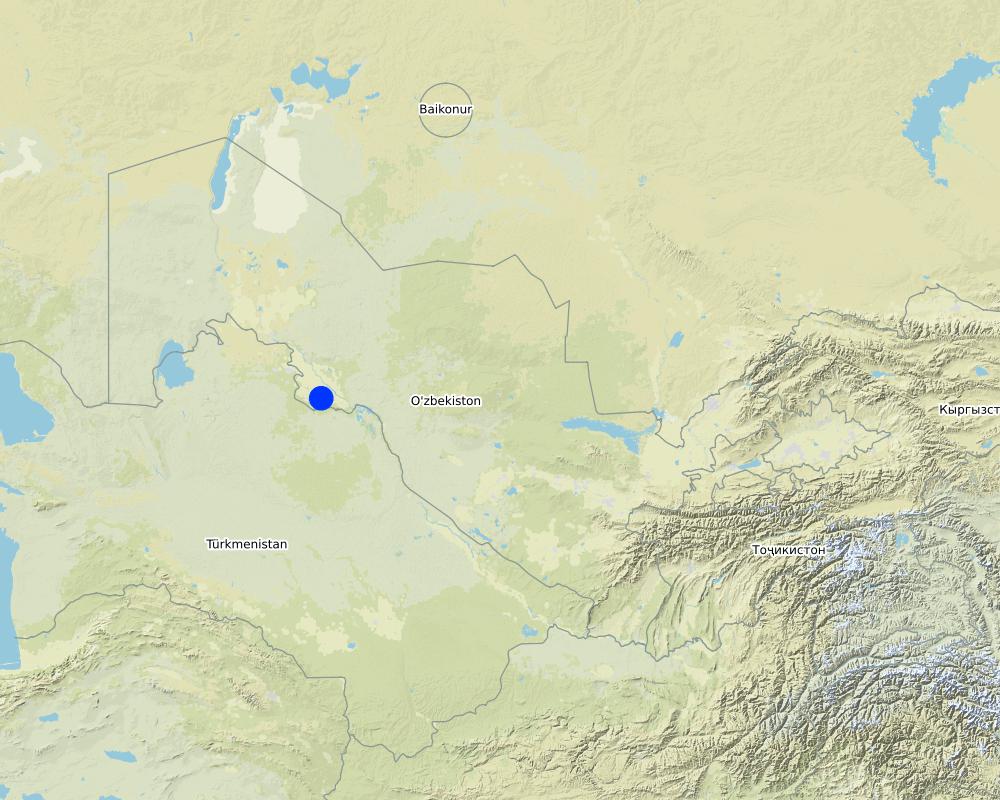

2.5 Country/ region/ locations where the Technology has been applied and which are covered by this assessment

Country:

Uzbekistan

Region/ State/ Province:

Yangiarik district / Khorezm region

Specify the spread of the Technology:

- evenly spread over an area

If precise area is not known, indicate approximate area covered:

- 10-100 km2

Comments:

The materials were obtained from the publications of the GEF SGP project, consultations with representatives of the Urgench State University and Agro-Consultative Center "KRASS"

Map

×2.6 Date of implementation

Indicate year of implementation:

2009

If precise year is not known, indicate approximate date:

- less than 10 years ago (recently)

2.7 Introduction of the Technology

Specify how the Technology was introduced:

- during experiments/ research

- through projects/ external interventions

Comments (type of project, etc.):

The technology is implemented through projects aimed at improving the efficiency of irrigation water use.

3. Classification of the SLM Technology

3.1 Main purpose(s) of the Technology

- improve production

- reduce risk of disasters

- adapt to climate change/ extremes and its impacts

- reduction of unproductive water losses from channels

3.2 Current land use type(s) where the Technology is applied

Waterways, waterbodies, wetlands

- irrigation channel

Main products/ services:

Reduced water filtration in the channel

Comments:

Improving the efficiency of the channel through the waterproofing of the bottom and slopes with a plastic film

3.3 Has land use changed due to the implementation of the Technology?

Comments:

does not changed

3.4 Water supply

Water supply for the land on which the Technology is applied:

- full irrigation

Comments:

Number of growing seasons per year: 2

Specify:

The natural and climatic conditions of the Khorezm region allow to get 2 crops per year of short growing season crops (vegetables, potatoes), or when they are cultivated after harvesting winter wheat. Major crops - cotton and wheat produce 1 crop / year

3.5 SLM group to which the Technology belongs

- irrigation management (incl. water supply, drainage)

- energy efficiency technologies

3.6 SLM measures comprising the Technology

structural measures

- S7: Water harvesting/ supply/ irrigation equipment

3.7 Main types of land degradation addressed by the Technology

chemical soil deterioration

- Cs: salinization/ alkalinization

physical soil deterioration

- Pw: waterlogging

biological degradation

- Bl: loss of soil life

Comments:

The deterioration of the soil chemical properties due to the secondary salinization is caused by natural conditions (arid climate, difficult groundwater outflow conditions) and irrational management and use of water resources (low efficiency of irrigation systems, large filtration losses of water from canals). Filtration from canals is one of the main reasons leading to the deterioration of the land reclamation state (waterlogging and secondary salinization).

As the habitat of soil organisms is deteriorating due to salinization and waterlogging, the biological degradation of the soils is observed.

3.8 Prevention, reduction, or restoration of land degradation

Specify the goal of the Technology with regard to land degradation:

- reduce land degradation

Comments:

The Technology helps to reduce filtration losses in the channel, which are a source of groundwater supply, thereby reducing the processes of waterlogging and secondary salinization of irrigated lands.

4. Technical specifications, implementation activities, inputs, and costs

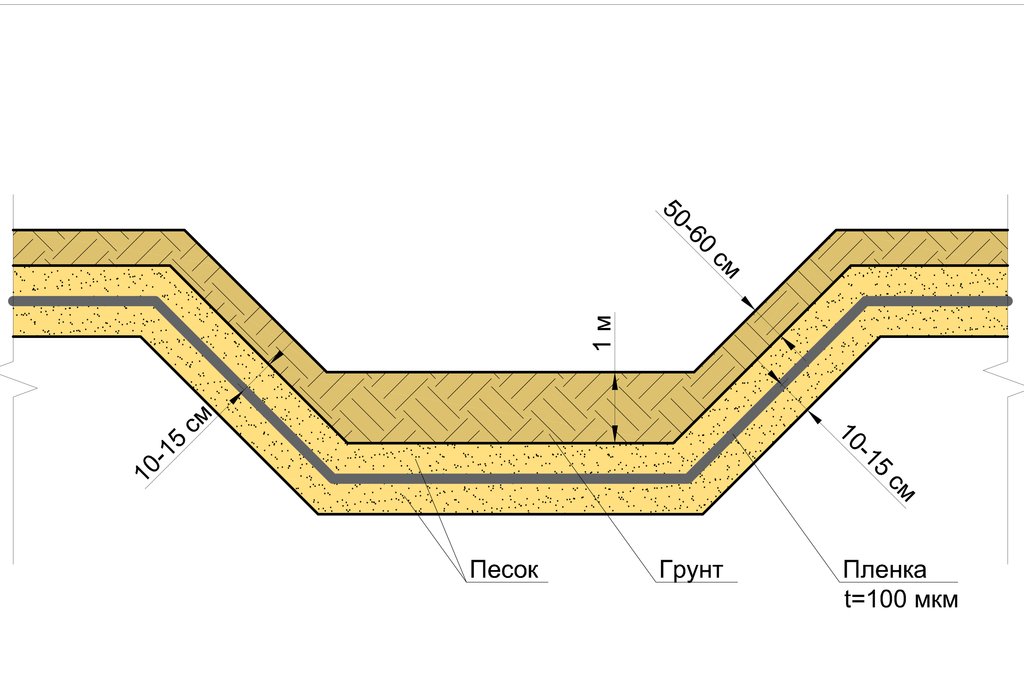

4.1 Technical drawing of the Technology

Technical specifications (related to technical drawing):

To ensure the water gravity movement to irrigated fields, the following measures are taken: cleaning the channel, filling the soil to create a channel slope angle.

After that, the bottom and slopes are filled with 10-15 cm sand layer, on which a polyethylene film with a thickness of 100 microns is laid. The next step is filling the film, first 10-15-cm layer of sand to avoid damage to the film, and then the filling of the channel bottom with soil, a layer of 1 m, and the channel slopes with a layer of 0.5-0.6 m.

Technical drawing from left to right: 10-15 cm - Sand - Ground - Polyethylene film (100 microns) - 10-15 cm - 50-60 cm

Author:

R. Ibrahimov

Date:

27/08/2018

4.2 General information regarding the calculation of inputs and costs

Specify how costs and inputs were calculated:

- per Technology area

Indicate size and area unit:

1 km

Specify currency used for cost calculations:

- USD

If relevant, indicate exchange rate from USD to local currency (e.g. 1 USD = 79.9 Brazilian Real): 1 USD =:

2100.0

Indicate average wage cost of hired labour per day:

about 10 USD

4.3 Establishment activities

| Activity | Timing (season) | |

|---|---|---|

| 1. | Сleaning works with the use of an excavator | During Autumn-Winter period |

| 2. | Manual preparation of slopes and channel bottom | During Autumn-Winter period |

| 3. | Irrigation (counter irrigation) | During Autumn-Winter period |

| 4. | Creating a 10-15 cm sand layer for laying the film | During Autumn-Winter period |

| 5. | Laying of polyethylene film | During Autumn-Winter period |

| 6. | Filling the bottom and the edges of the channel over the film with a layer of sand and soil | During Autumn-Winter period |

Comments:

The work is carried out in the autumn-winter period when no water is supplied through the channel

4.4 Costs and inputs needed for establishment

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | The cost of manual labor and mechanization | USD/km2 | 1.0 | 14279.0 | 14279.0 | |

| Construction material | Polyethylene film for channel insulation | USD/km2 | 1.0 | 1045.0 | 1045.0 | |

| Total costs for establishment of the Technology | 15324.0 | |||||

| Total costs for establishment of the Technology in USD | 7.3 | |||||

If land user bore less than 100% of costs, indicate who covered the remaining costs:

paid by project

Comments:

The Technology implementation requires significant costs and special equipment (excavators).

In this case, the cost of fuels and the salary of the excavator are included in the cost of mechanization

4.5 Maintenance/ recurrent activities

| Activity | Timing/ frequency | |

|---|---|---|

| 1. | Control and sprinkling the film with the soil on the sides of the channel | permanently |

| 2. | Cleaning the channel from silting | In the early spring before the start of the irrigation period |

Comments:

Activities to maintain the technology include ongoing monitoring of sprinkling of the film with earth on the sides of the channel. There are no special costs for maintaining the technology. The only threat is siltation of the bottom of the canal. According to the Project recommendations, mini excavators are used to clean the bottom, which remove the sludge layer of not more than 30 cm.

4.6 Costs and inputs needed for maintenance/ recurrent activities (per year)

| Specify input | Unit | Quantity | Costs per Unit | Total costs per input | % of costs borne by land users | |

|---|---|---|---|---|---|---|

| Labour | sprinkling the film with the soil on the sides of the channel | 1.0 | 100.0 | 100.0 | ||

| Equipment | Cleaning the channel from silting | |||||

| Total costs for maintenance of the Technology | 100.0 | |||||

| Total costs for maintenance of the Technology in USD | 0.05 | |||||

4.7 Most important factors affecting the costs

Describe the most determinate factors affecting the costs:

There are no special costs for maintaining the technology.

5. Natural and human environment

5.1 Climate

Annual rainfall

- < 250 mm

- 251-500 mm

- 501-750 mm

- 751-1,000 mm

- 1,001-1,500 mm

- 1,501-2,000 mm

- 2,001-3,000 mm

- 3,001-4,000 mm

- > 4,000 mm

Specifications/ comments on rainfall:

90% of the precipitation falls between October and May

Indicate the name of the reference meteorological station considered:

Urgench

Agro-climatic zone

- arid

The duration of the growing season is 70 days

5.2 Topography

Slopes on average:

- flat (0-2%)

- gentle (3-5%)

- moderate (6-10%)

- rolling (11-15%)

- hilly (16-30%)

- steep (31-60%)

- very steep (>60%)

Landforms:

- plateau/plains

- ridges

- mountain slopes

- hill slopes

- footslopes

- valley floors

Altitudinal zone:

- 0-100 m a.s.l.

- 101-500 m a.s.l.

- 501-1,000 m a.s.l.

- 1,001-1,500 m a.s.l.

- 1,501-2,000 m a.s.l.

- 2,001-2,500 m a.s.l.

- 2,501-3,000 m a.s.l.

- 3,001-4,000 m a.s.l.

- > 4,000 m a.s.l.

5.3 Soils

Soil depth on average:

- very shallow (0-20 cm)

- shallow (21-50 cm)

- moderately deep (51-80 cm)

- deep (81-120 cm)

- very deep (> 120 cm)

Soil texture (topsoil):

- medium (loamy, silty)

Soil texture (> 20 cm below surface):

- medium (loamy, silty)

Topsoil organic matter:

- low (<1%)

If available, attach full soil description or specify the available information, e.g. soil type, soil PH/ acidity, Cation Exchange Capacity, nitrogen, salinity etc.

Meadow soils, humus content in the arable layer is less than 1%, maximum field moisture capacity (% , by weight) - 20.3-21.9% (Khorezm region)

5.4 Water availability and quality

Ground water table:

< 5 m

Availability of surface water:

good

Water quality (untreated):

good drinking water

Is water salinity a problem?

Yes

Specify:

the water is suitable for irrigation and drinking

Is flooding of the area occurring?

No

Comments and further specifications on water quality and quantity:

Surface sources water is polluted from drainage runoff discharges from irrigation fields

5.5 Biodiversity

Species diversity:

- medium

Habitat diversity:

- medium

Comments and further specifications on biodiversity:

The vegetation in the irrigated area is represented by cultural species of plants - cotton, wheat, vegetables, melons, perennial plantations, fruit and ornamental trees and shrubs

5.6 Characteristics of land users applying the Technology

Sedentary or nomadic:

- Sedentary

Market orientation of production system:

- mixed (subsistence/ commercial)

Off-farm income:

- > 50% of all income

Relative level of wealth:

- average

Individuals or groups:

- individual/ household

Level of mechanization:

- mechanized/ motorized

Gender:

- men

Age of land users:

- middle-aged

5.7 Average area of land used by land users applying the Technology

- < 0.5 ha

- 0.5-1 ha

- 1-2 ha

- 2-5 ha

- 5-15 ha

- 15-50 ha

- 50-100 ha

- 100-500 ha

- 500-1,000 ha

- 1,000-10,000 ha

- > 10,000 ha

Is this considered small-, medium- or large-scale (referring to local context)?

- medium-scale

Comments:

The average size of the farm area is 35-75 hectares, dehkan and household farms are up to 0.35 hectares

5.8 Land ownership, land use rights, and water use rights

Land ownership:

- state

Land use rights:

- leased

- through Water Users Associations and irrigation systems management

5.9 Access to services and infrastructure

health:

- poor

- moderate

- good

education:

- poor

- moderate

- good

technical assistance:

- poor

- moderate

- good

employment (e.g. off-farm):

- poor

- moderate

- good

markets:

- poor

- moderate

- good

energy:

- poor

- moderate

- good

roads and transport:

- poor

- moderate

- good

drinking water and sanitation:

- poor

- moderate

- good

financial services:

- poor

- moderate

- good

6. Impacts and concluding statements

6.1 On-site impacts the Technology has shown

Socio-economic impacts

Water availability and quality

irrigation water availability

demand for irrigation water

Income and costs

farm income

Ecological impacts

Water cycle/ runoff

groundwater table/ aquifer

Climate and disaster risk reduction

drought impacts

emission of carbon and greenhouse gases

6.2 Off-site impacts the Technology has shown

impact of greenhouse gases

Specify assessment of off-site impacts (measurements):

The Technology does not have negative off-site impacts

6.3 Exposure and sensitivity of the Technology to gradual climate change and climate-related extremes/ disasters (as perceived by land users)

Gradual climate change

Gradual climate change

| Season | increase or decrease | How does the Technology cope with it? | |

|---|---|---|---|

| seasonal rainfall | spring | decrease | well |

| seasonal rainfall | summer | decrease | well |

Climate-related extremes (disasters)

Climatological disasters

| How does the Technology cope with it? | |

|---|---|

| drought | well |

6.4 Cost-benefit analysis

How do the benefits compare with the establishment costs (from land users’ perspective)?

Short-term returns:

slightly negative

Long-term returns:

very positive

How do the benefits compare with the maintenance/ recurrent costs (from land users' perspective)?

Short-term returns:

negative

Long-term returns:

very positive

Comments:

Technology pays off economically. Water conservation, energy savings, income from additional yields provide total benefits of 13,252 USD per 1 km of the channel. The estimated payback is 1-2 years.

6.5 Adoption of the Technology

- single cases/ experimental

Of all those who have adopted the Technology, how many did so spontaneously, i.e. without receiving any material incentives/ payments?

- 0-10%

6.6 Adaptation

Has the Technology been modified recently to adapt to changing conditions?

No

6.7 Strengths/ advantages/ opportunities of the Technology

| Strengths/ advantages/ opportunities in the land user’s view |

|---|

| Water loss from the channel is reduced, and crop productivity is increased |

| Groundwater level decreases and waterlogging is reduced |

| Strengths/ advantages/ opportunities in the compiler’s or other key resource person’s view |

|---|

| Unproductive losses are reduced, the risk of waterlogging and secondary salinization is reduced |

| The water availability and crop yields are Increased |

6.8 Weaknesses/ disadvantages/ risks of the Technology and ways of overcoming them

| Weaknesses/ disadvantages/ risks in the land user’s view | How can they be overcome? |

|---|---|

| High cost | Government subsidy |

| Weaknesses/ disadvantages/ risks in the compiler’s or other key resource person’s view | How can they be overcome? |

|---|---|

| High initial costs of inputs on Technology implementation | Lending, Association of water users |

7. References and links

7.1 Methods/ sources of information

- interviews with land users

5 persons

- interviews with SLM specialists/ experts

When were the data compiled (in the field)?

2018

7.3 Links to relevant online information

Title/ description:

Channel bottom isolation technology for water and energy conservation. SGP GEF

URL:

sgp.uz/news/622; uz.denemetr.com/docs/676/index-33405-1.htme

Links and modules

Expand all Collapse allLinks

No links

Modules

No modules